Dacron-based label tape

A trademark tape and polyester technology is applied in the field of preparing polyester-based trademark tapes that can be coated with alcohol-based solvents. The effect of clear pattern and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

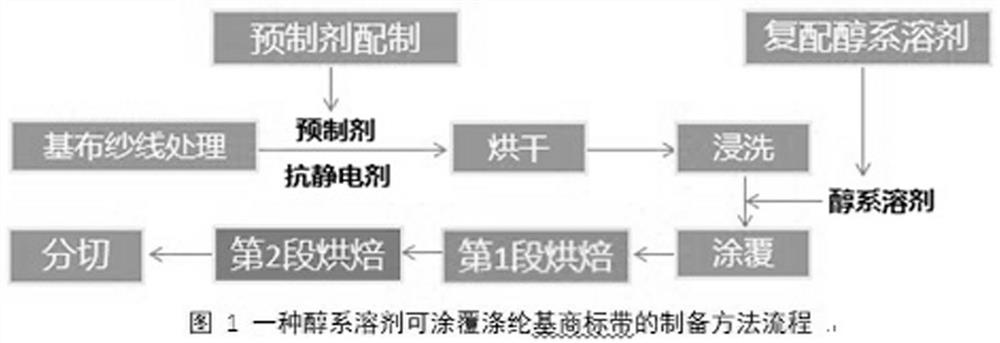

Method used

Image

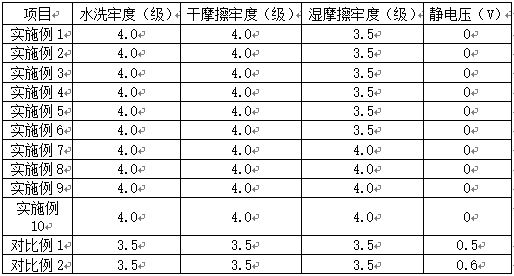

Examples

Embodiment 1

[0045]Use polyester base fabric yarn with a specification of 60D, with a warp density of 70 threads / cm and a weft thread density of 30 threads / cm, using ethanol, ethylene glycol, vinyl triethoxysilane, vinyl trimethoxysilane, hard Fatty acid, 2-3 kinds of deionized water, use the mixed slurry of 1 wt% pre-preparation and 0.2 wt% antistatic agent compounded at a ratio of 1:1:1 for spraying treatment, after drying at 105 ℃ for 1 min Carry out fabric setting; use 15 wt% weak alkali mixed solution (soda ash 5 g / L, caustic soda 0.5 g / L, deionized water: ethanol = 10:1) soak for 10 min, pure water rinse once, at 110 Dry at ℃ for 2 min to obtain the treated fabric after soaking and drying.

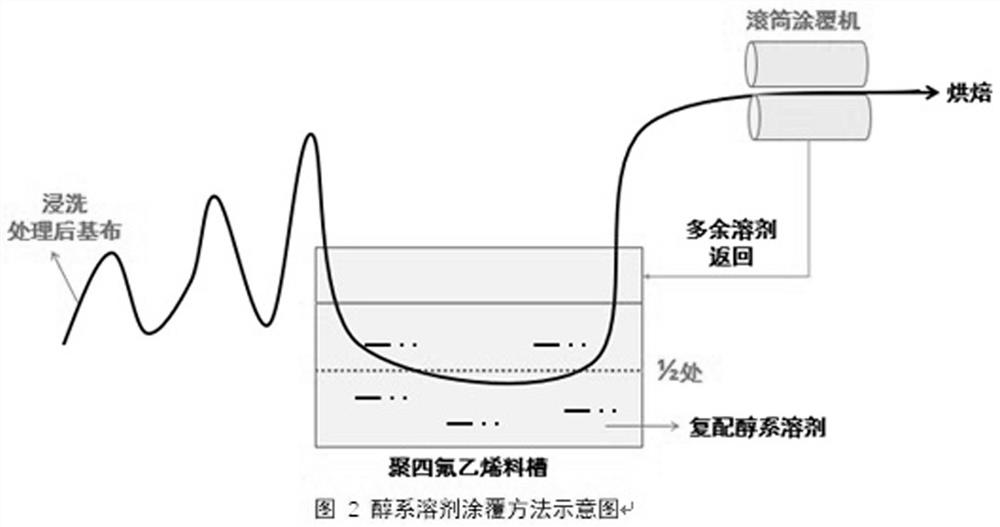

[0046] Soak the treated fabric in a polytetrafluoroethylene trough. The alcohol solvent is composed of methacrylic acid, ethyl acrylate, methanol, ethylene glycol and deionized water in a ratio of 1:1:1:1:1. The planetary agitator is mixed, and the residence time in the 10 wt% compound liquid tr...

Embodiment 2

[0048] Use polyester base cloth yarn with a specification of 70D, with a warp density of 80 threads / cm and a weft thread density of 40 threads / cm, using ethanol, ethylene glycol, vinyl triethoxysilane, vinyl trimethoxysilane, hard Fatty acid and 2-3 kinds of deionized water, using a 2:1:1 ratio of 8 wt% pre-preparation and 0.4 wt% antistatic agent mixed slurry for spraying treatment, after drying at 110 ℃ for 2 minutes Carry out fabric setting; use 15 wt% weak alkali mixed solution (soda ash 6 g / L, caustic soda 0.8 g / L, deionized water: ethanol = 10:1) soak for 10 min, rinse with pure water twice, at 120 Dry at ℃ for 10 minutes to obtain the treated cloth after soaking and drying.

[0049] Soak the treated fabric in a polytetrafluoroethylene trough. The alcohol solvent is composed of methanol, ethylene glycol, silicone, ethyl acetate, and hydrogen peroxide in a ratio of 1.2:1:1:1:1. Mix with a type agitator, configure the residence time of 10 wt% compound liquid in the trough...

Embodiment 3

[0051] Use the polyester base fabric yarn with a specification of 120D, the warp yarn density is 150 yarns / cm, and the weft yarn density is 60 yarns / cm, using ethylene glycol, vinyl triethoxysilane, vinyl trimethoxysilane, using 2: The mixed slurry of 20 wt% pre-preparation and 0.8 wt% antistatic agent compounded at a ratio of 1:1 was sprayed, dried at 110 °C for 2 min, and then the fabric was set; 15 wt% weak alkali mixture ( Soda ash 6 g / L, caustic soda 0.8 g / L, deionized water:ethanol=10:1) immersion for 10 minutes, pure water rinse twice, and drying at 150 ℃ for 8 minutes to obtain fabric.

[0052] Soak the treated cloth in a polytetrafluoroethylene trough. The alcohol solvent is mixed with ethyl acetate, hydrogen peroxide and deionized water in a ratio of 3:1:1, and mixed with a planetary mixer, and configured into 10 The residence time of wt% compound liquid in the trough is 10s, and a roller coating machine is connected to the right end of the trough to coat the alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com