Oilfield produced fluid heat energy recovery device and method

A heat energy recovery and production fluid technology, which is applied in steam generation devices, preheating, and production fluids, etc., can solve the problems of low recovery efficiency of oilfield production fluid, inability to fully utilize heat energy, and inability to burn associated gas, etc., and achieve convenient scale Universal promotion and application, easy operation, full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

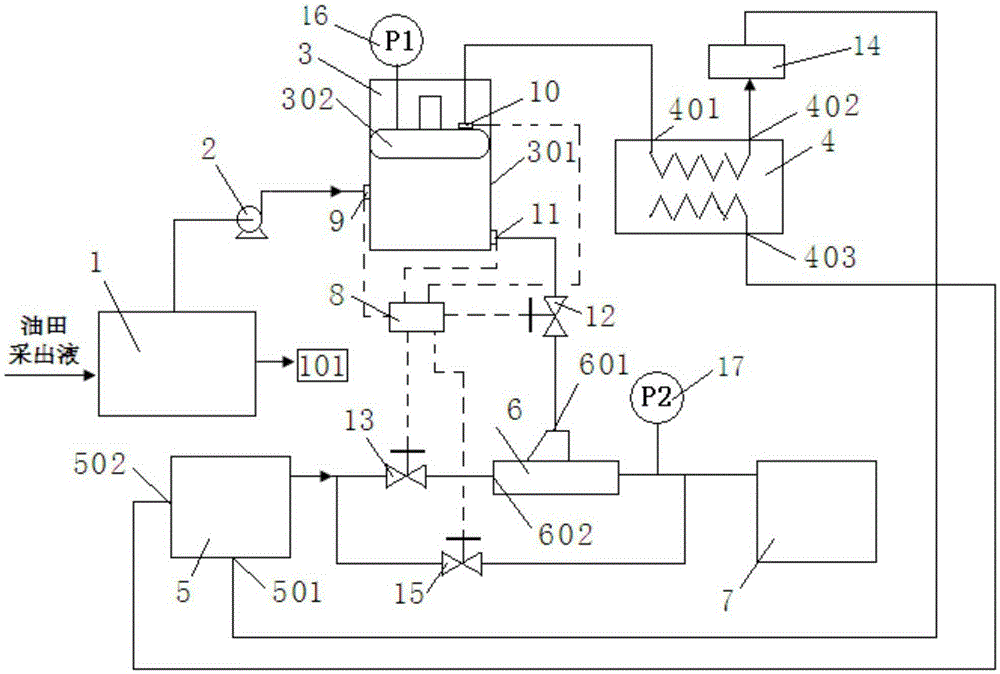

[0073] This embodiment provides a heat energy recovery device for oilfield produced liquid, including: steam separation tank 1, pressure booster pump 2, variable volume separation tank 3, heat exchanger 4, steam boiler 5, ejector 6, heavy oil heater 7. Piston pressure gauge 16, steam pressure gauge 17, associated gas storage tank 14, PLC controller 8, and a check valve 9 electrically connected to the PLC controller 8, the first control valve 10, the second control valve 11, the first Three control valves 12 , a fourth control valve 13 , and a fifth control valve 15 .

[0074] The variable volume separation tank 3 comprises: a tank body 301, a piston 302 arranged in the tank body 301 and a steam pressure gauge 17 arranged on the top of the piston 302, the piston 302 can move axially in the tank body 301, and the tank body 301 is divided into Two upper and lower chambers separated from each other and variable in volume can monitor the internal pressure of the lower chamber throu...

Embodiment 2

[0077] In this embodiment, the oilfield produced fluid heat energy recovery device provided in Example 1 is used to recover the heat energy of the oilfield produced fluid, including the following steps:

[0078] The oilfield production fluid is introduced into the steam separation tank 1 for separation to obtain a gas phase part and a liquid phase part. The liquid phase part is discharged through the sewage discharge port 101 on the steam separation tank 1, while the gas phase part is discharged through the booster pump 2 and the one-way valve 9 flows into the variable volume separation tank 3 for gas-liquid separation, when the value of the piston pressure gauge 16 reaches 3.2-3.5MPa, the water vapor in the variable volume separation tank 3 condenses into a liquid state, and associated gas and condensed water are obtained, making the piston pressure gauge Keep the value of 16 in the range of 3.2-3.5MPa for 10 minutes, then open the first control valve 10 and the second control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com