Method and Device for Heating, In Particular Highly Viscous Products

a high viscosity, product technology, applied in the field of heating, can solve the problem that the low-temperature section is not recuperatively operated, and achieve the effect of low investment cost and high heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

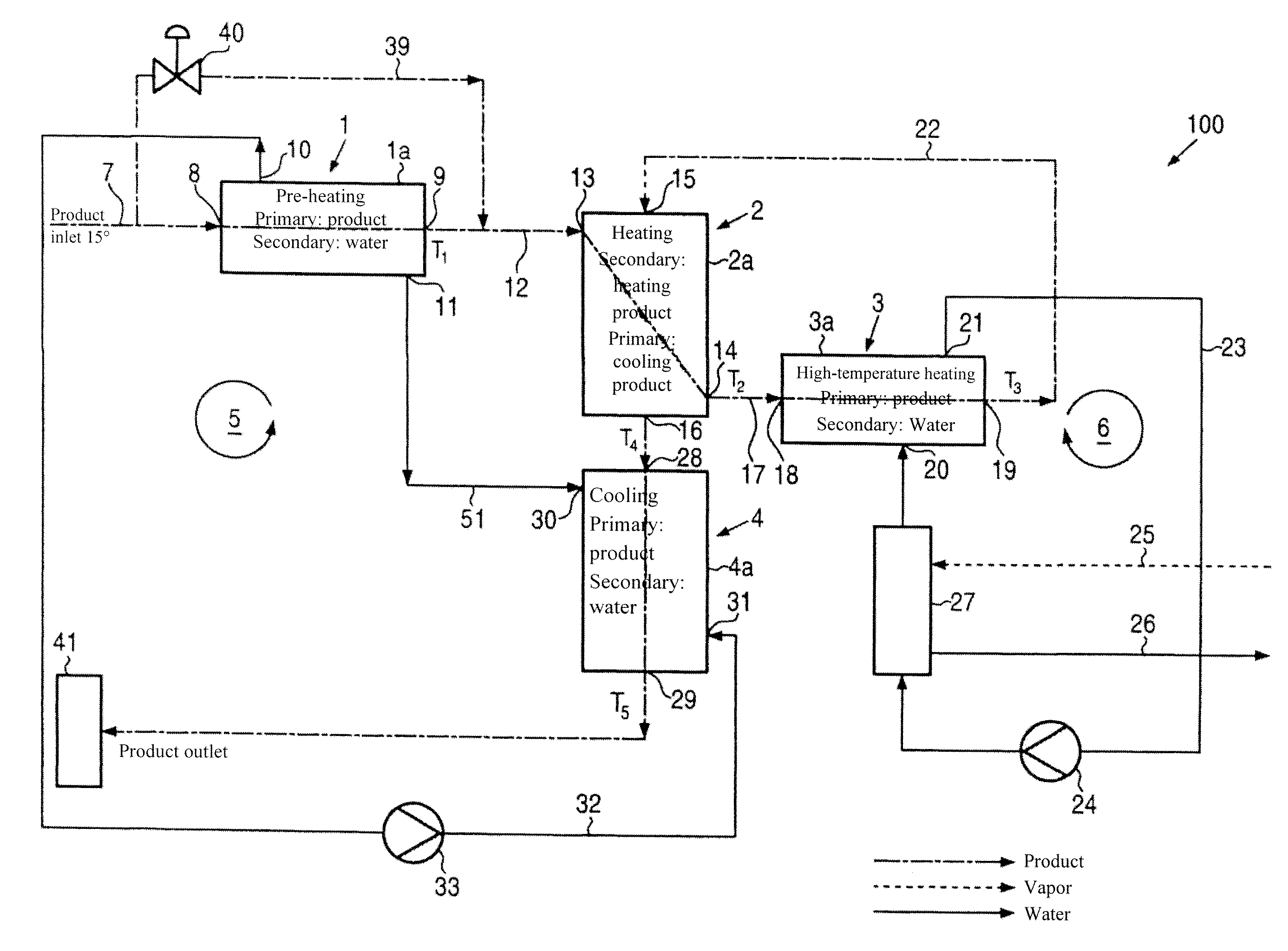

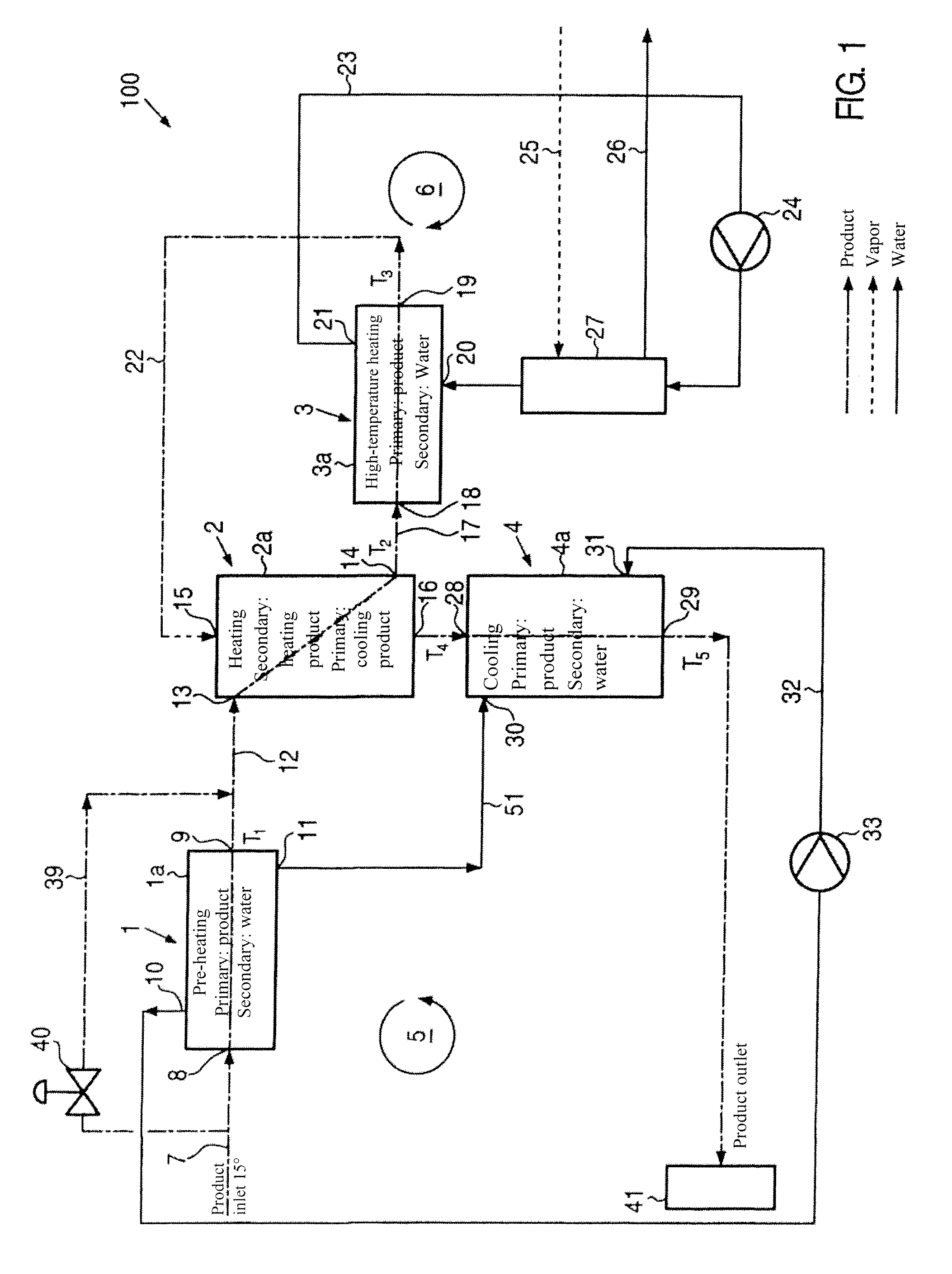

[0020]FIG. 1 shows a device for heating a product, in particular for thermally heating a product. Such a device is in particular employed in the beverage industry for sterilizing beverages or other liquid food. However, the device is also suited for all recuperative applications, in particular for heating highly viscous products.

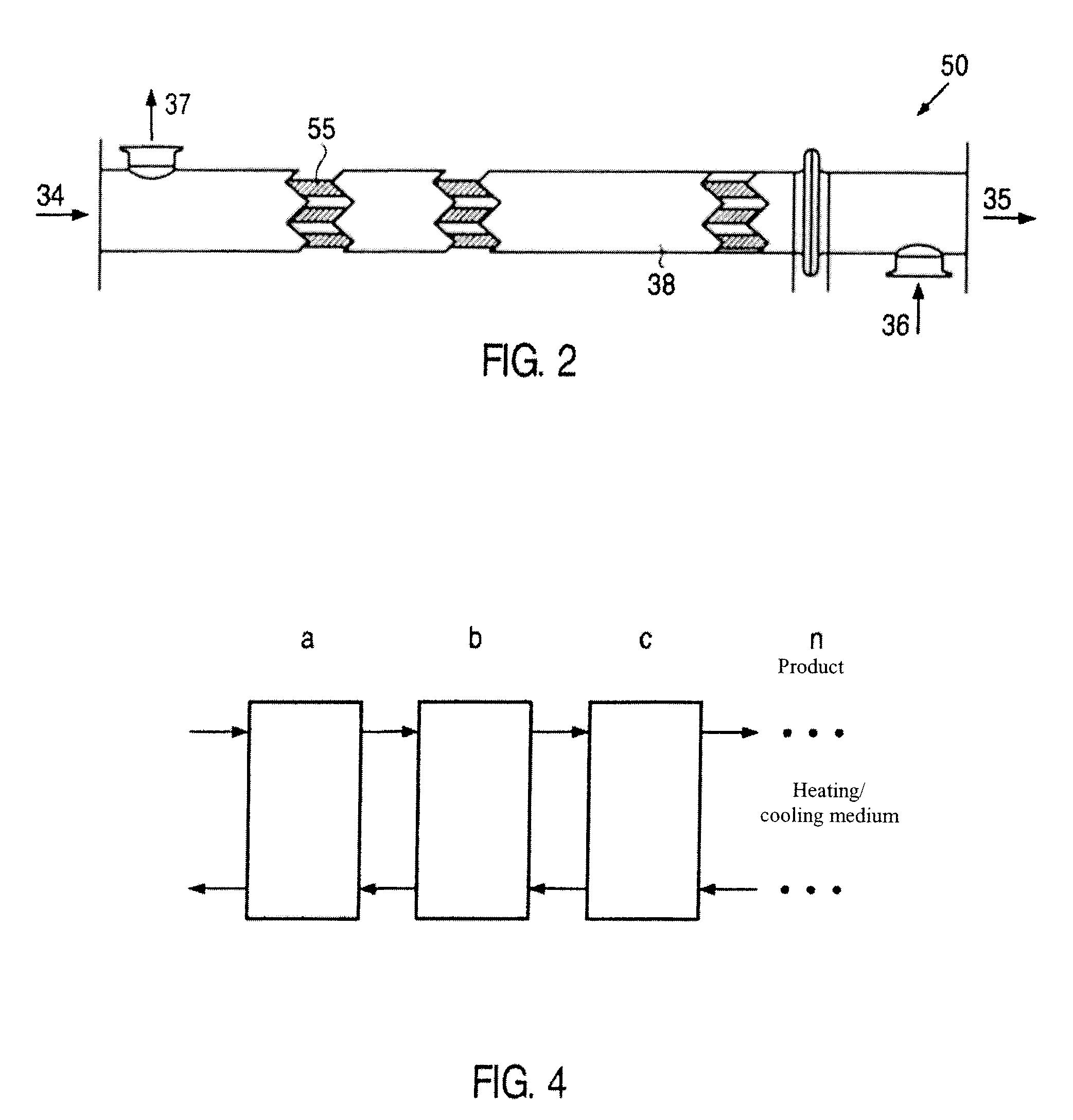

[0021]As can be taken from FIG. 1, the device comprises a product inlet 7 through which the product flows into the device. The course of the product to be heated is represented by the dot-dash line, the course of the water by the solid line, and the course of vapor by the dashed lines. The device comprises a first heating region 1 which comprises at least one product / water heat exchanger section 1a by which the product can be pre-heated to a pre-heating temperature T1 with water as the heating medium. In FIG. 1, only one heat exchanger section 1a is shown. However, several first product / heat exchanger sections 1a can also be connected in series. FIG. 4 shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com