Comprehensive utilization apparatus for flue gas exhaust heat

A flue gas waste heat and flue gas technology, which is applied to steam generation methods using heat carriers, lighting and heating equipment, steam boilers, etc., can solve the problems of large heat grade drop, low waste heat recovery rate, high entropy increase, etc., and achieve entropy reduction Added value and the effect of improving the heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

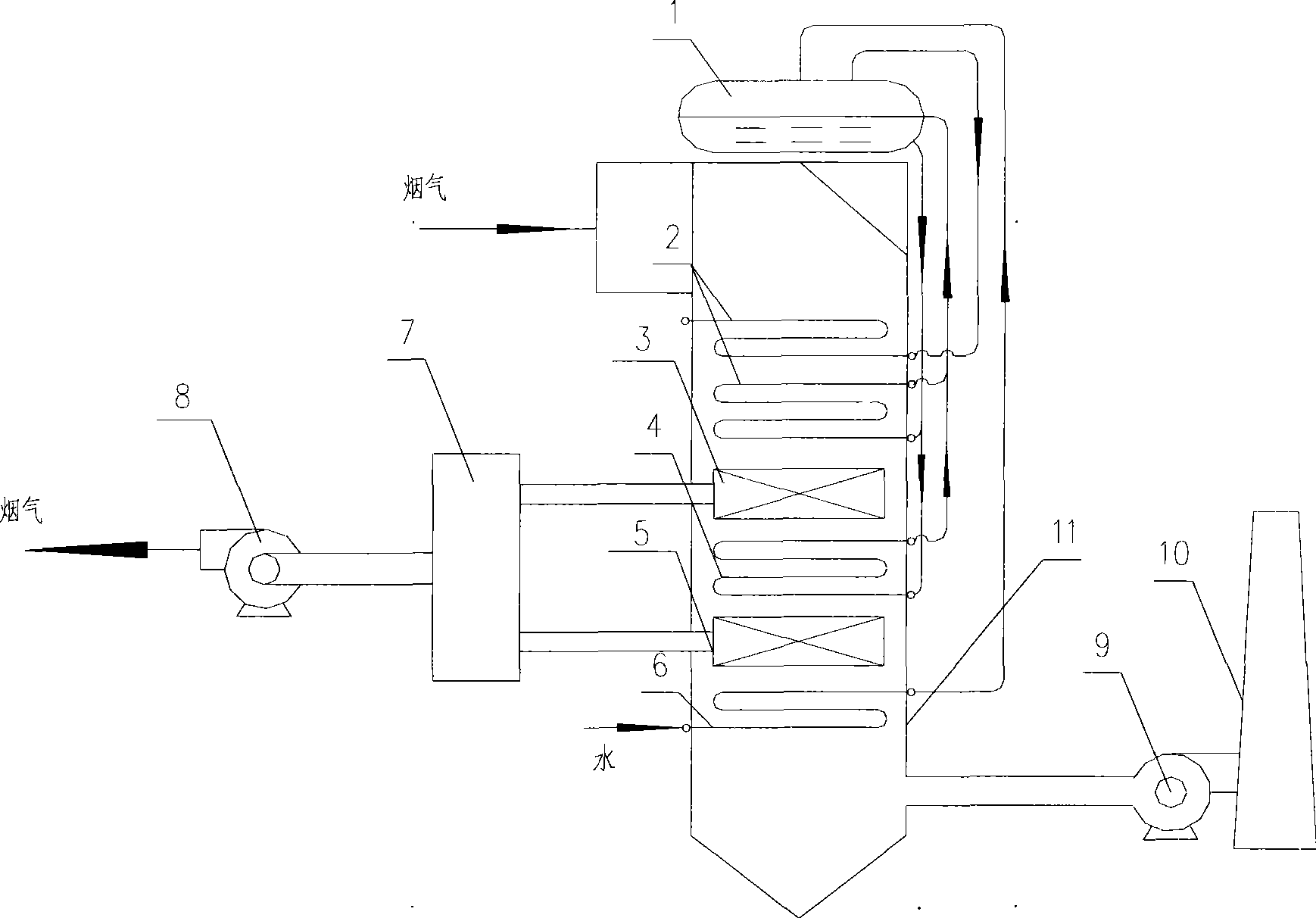

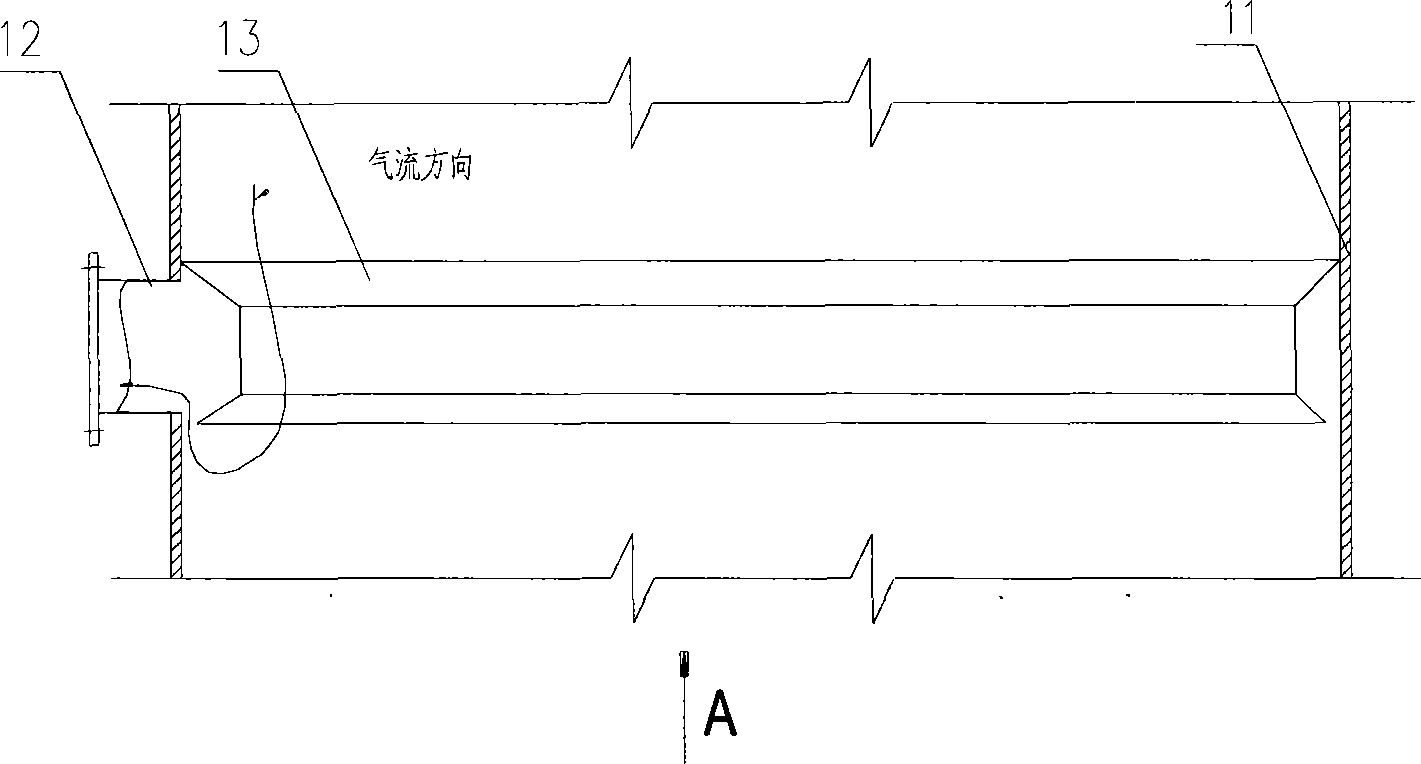

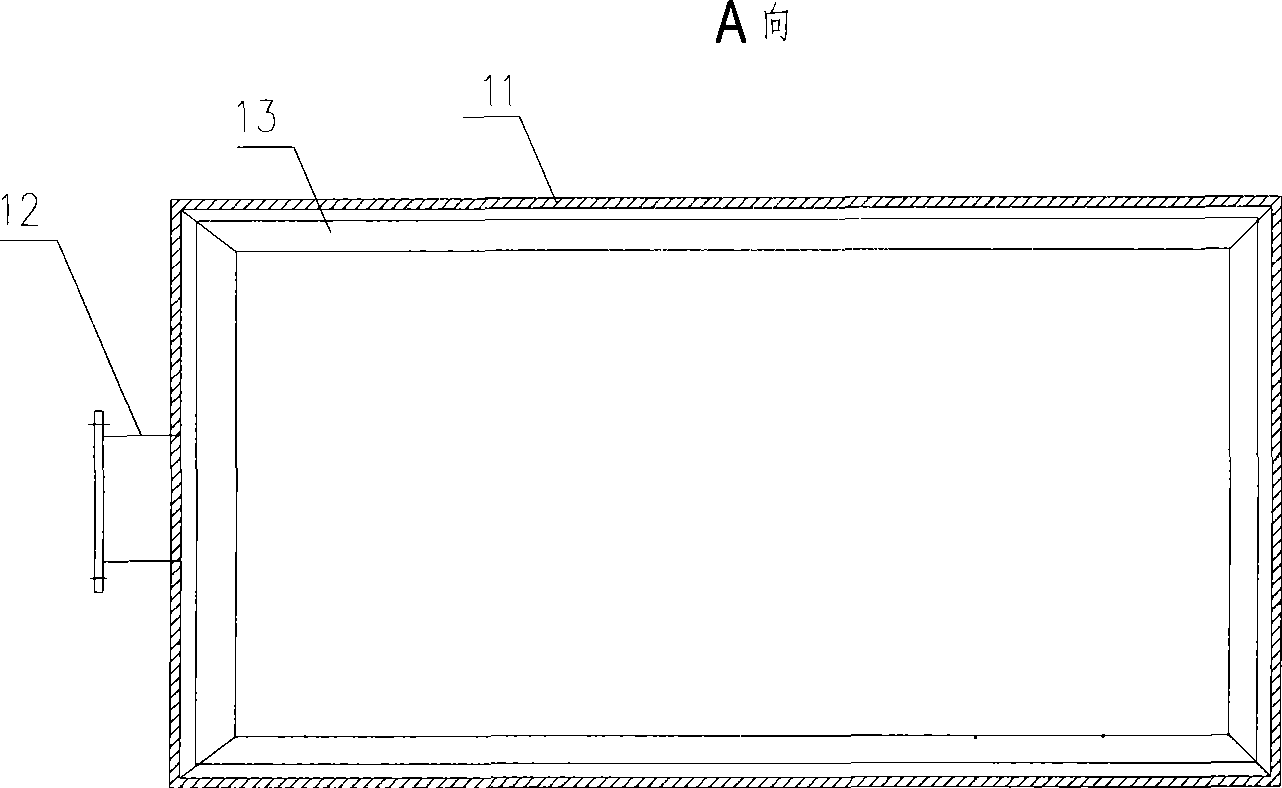

[0021] The structure of the embodiment of the present invention is as figure 1 shown. The flue gas waste heat comprehensive utilization device includes a steam drum 1, a water heating heating surface 6 and a water vaporization heating surface arranged in the flue type furnace 11, and steam is generated by heating the water vaporization heating surface and the water heating heating surface, wherein the water The vaporization heating surface is composed of a high-temperature vaporization heating surface 2 and a low-temperature vaporization heating surface 4. The steam drum is connected with the water heating heating surface and the water vaporization heating surface through input and output pipes, and is set between the high-temperature vaporization heating surface 2 and the low-temperature vaporization heating surface 4 The high-temperature flue gas extraction device 3 is provided with a low-temperature flue gas extraction device 5 between the low-temperature vaporization heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com