Gasification system for recycling high-temperature sensible heat

A gasification system, high temperature technology, applied in the field of gasification system, can solve the problems of low energy utilization rate, high water consumption, high investment, etc., achieve the effect of superior environmental indicators, improve heat energy recovery rate, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be further described below in conjunction with specific embodiments.

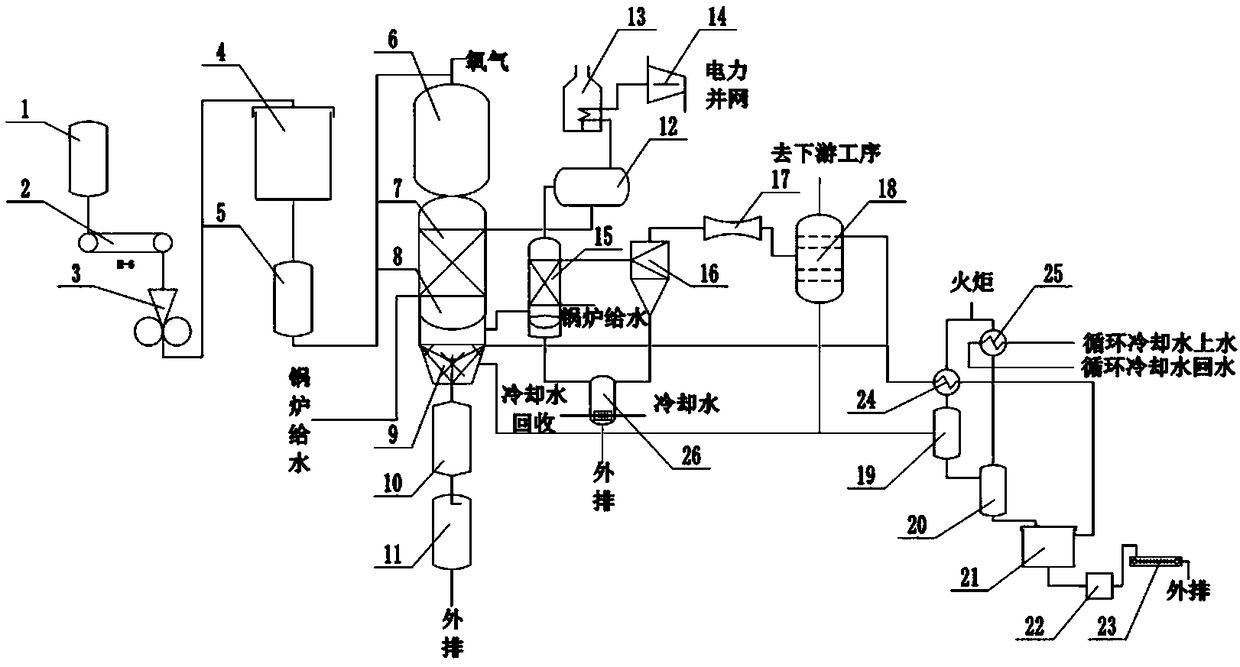

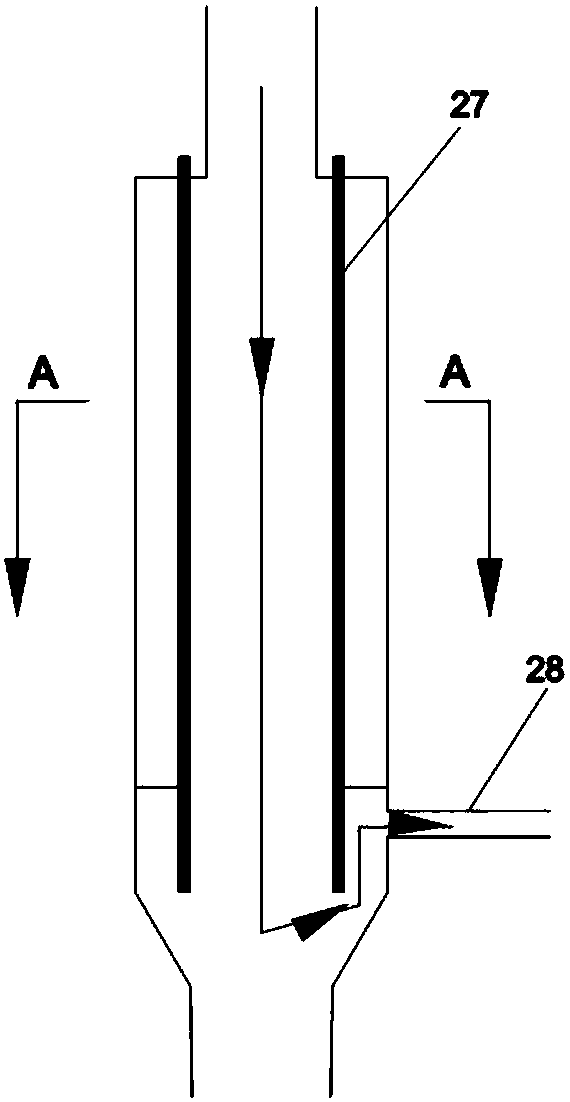

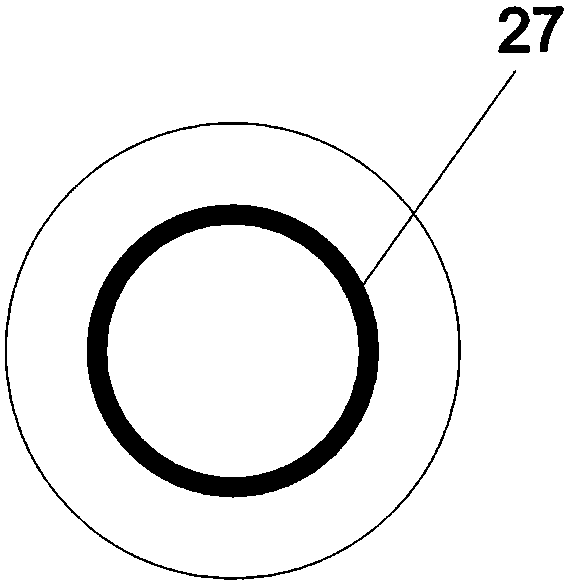

[0022] Such as figure 1 As shown, the process of the gasification system for recovering and utilizing high-temperature sensible heat is as follows: the gasification material from the raw coal bunker 1 is weighed by the weighing coal feeder 2, and then sent to the mill 3 for grinding and drying to make a gasification material that meets the requirements of the gasification system. The dry pulverized coal required to be converted into pulverized coal is transported to the pulverized coal bunker 4, and then sent to the gasifier 6 after passing through the pulverized coal pressurized delivery pump 5. In the gasifier 6, the pulverized coal is mixed with oxygen Incomplete combustion gasification, producing CO and H 2 The main crude synthesis gas, gasified slag and crude gas flow down and enter into the radiation waste boiler cooler 7, in the radiation waste boiler cooler 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com