Patents

Literature

66results about How to "Improve environmental indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enterococcus faecalis HEW-A131 and application thereof

ActiveCN104293696ASignificant probioticInhibition of growth and reproductionBacteriaMicroorganism based processesMicroorganismEconomic benefits

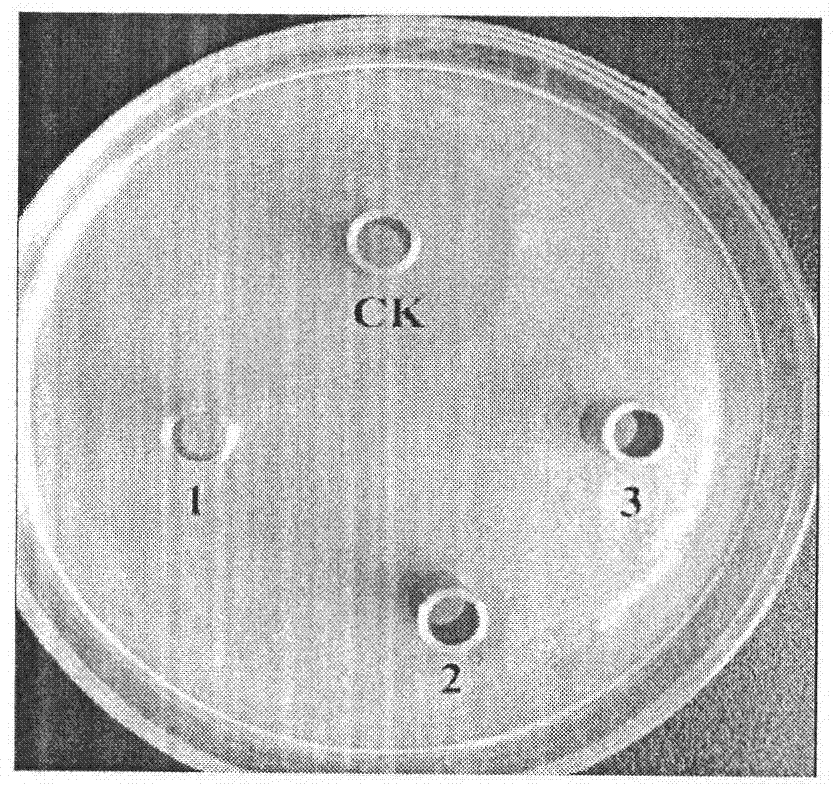

The invention discloses enterococcus faecalis HEW-A131 which is high in thermal resistance, wide in acid-alkali resistance range, high in stress resistance and relatively high in probiotic property. The strain is preserved in the China General Microbiological Culture Collection Center on June 17th, 2014, the preservation serial number is CGMCC NO.9353, and the classification name is enterococcus faecalis. The enterococcus faecalis HEW-A131 has excellent microorganism characteristics, remarkable probiotic property and stress resistance and super high fermentation property, not only is the utilization efficiency of feed of animals increased, but also the cost is reduced, moreover the stability of the environment inside the alimentary canals of animals is greatly improved, the adsorption and utilization of nutrition are promoted, the animal growth is promoted, the production performance, immunity and breeding property of the animals are remarkably improved, the production cost is lowered, and the economic benefits are increased.

Owner:江西好实沃生物技术有限公司

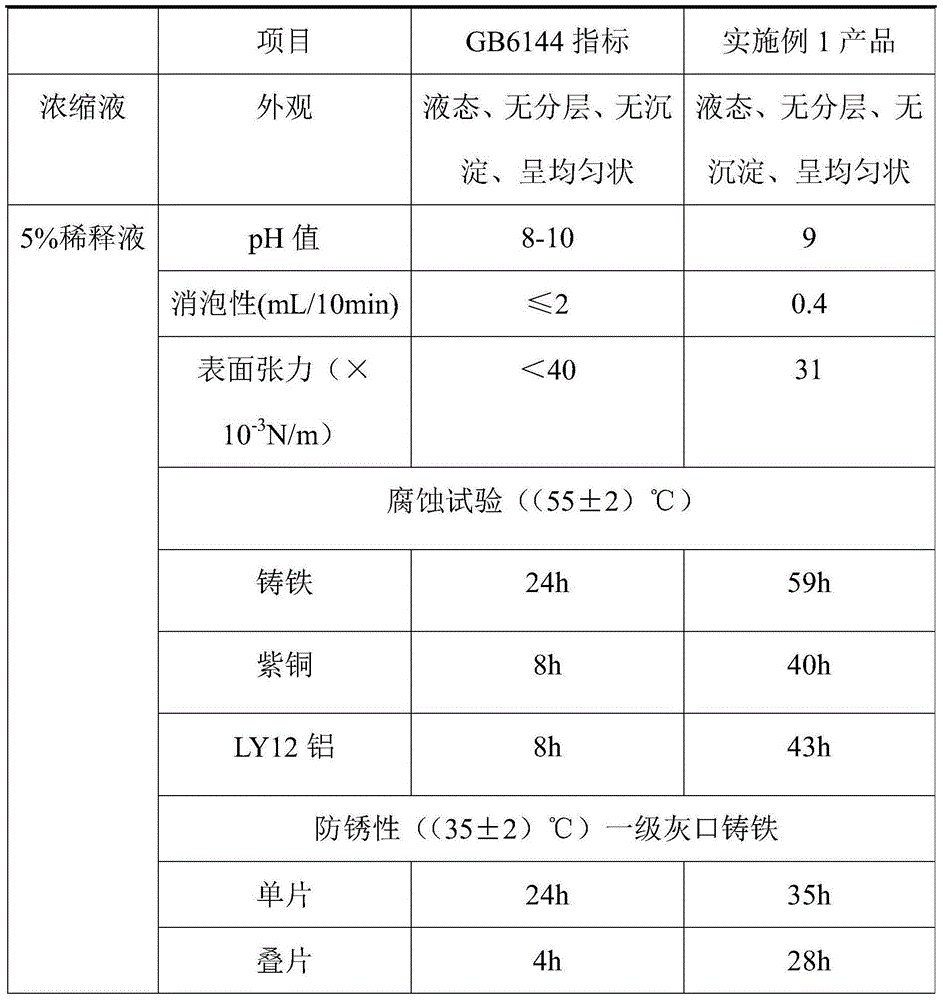

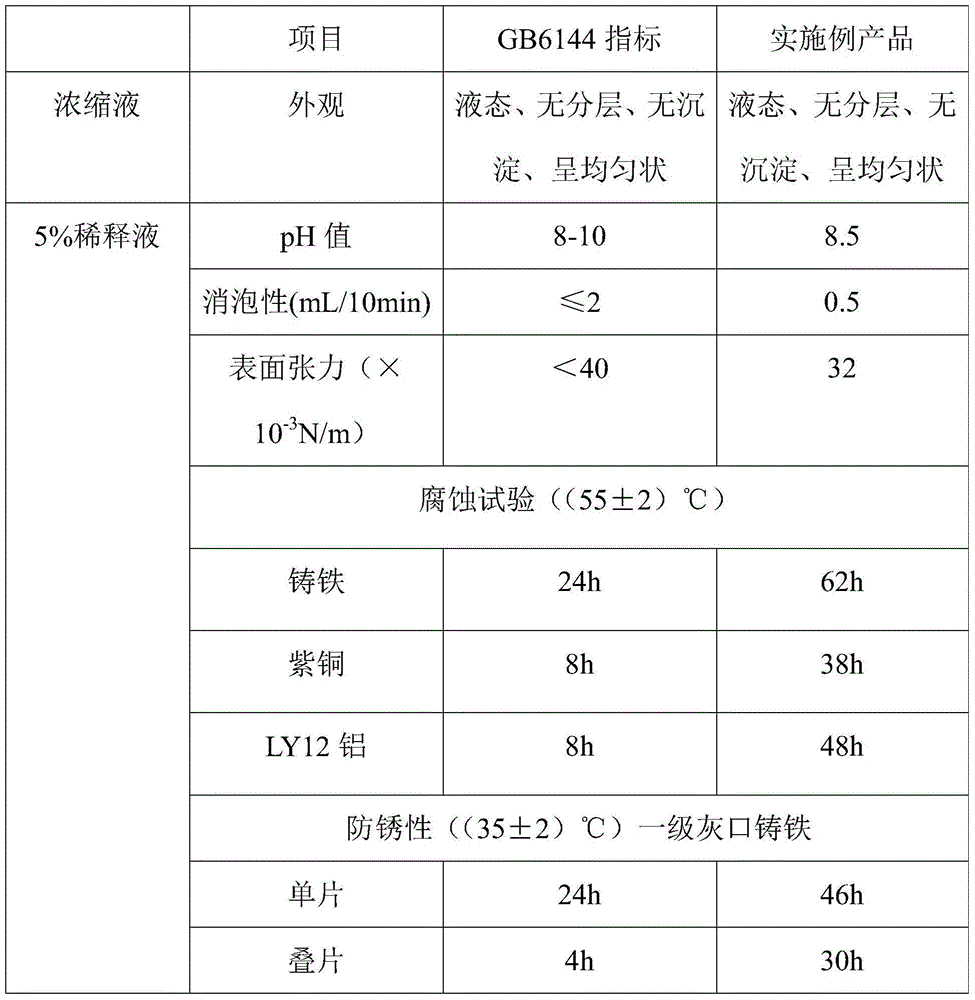

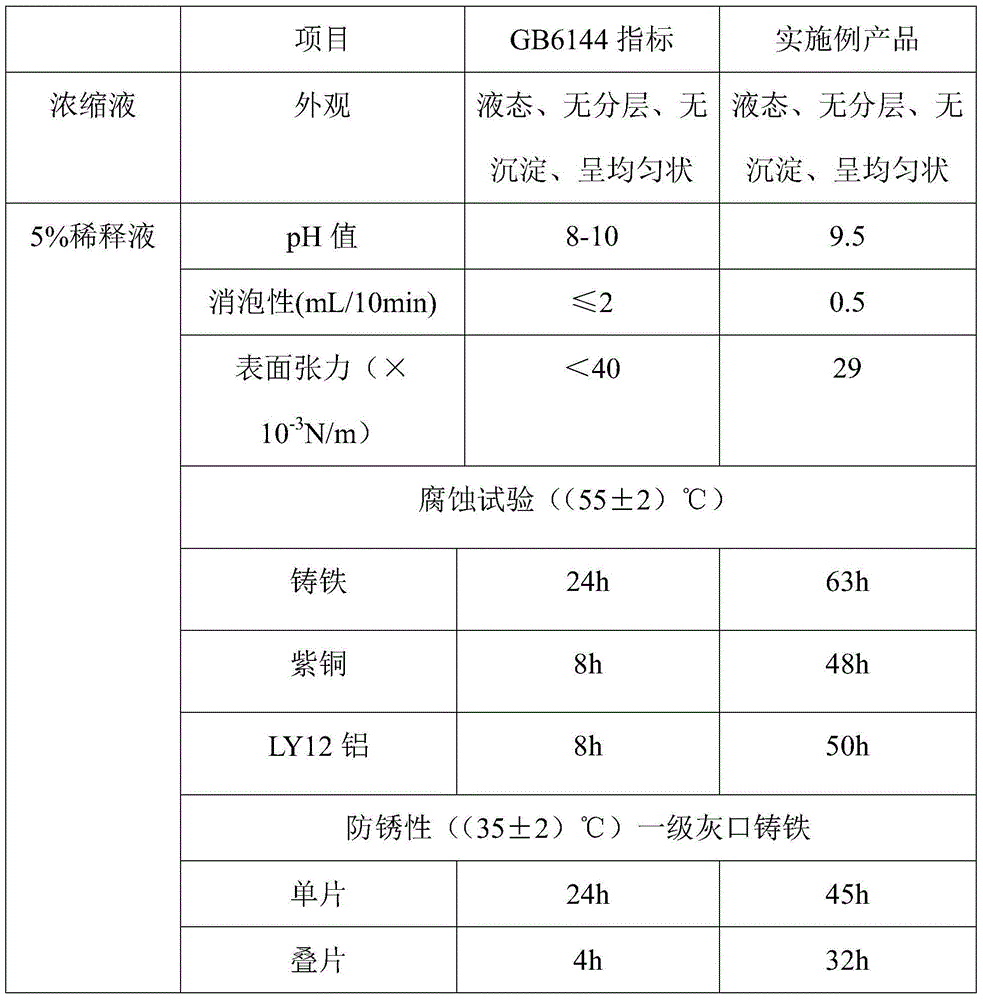

High-performance metal cutting fluid

InactiveCN104403772AEasy to cleanImprove anti-corrosion performanceLubricant compositionPhosphateChemistry

The invention discloses a high-performance metal cutting fluid including following raw materials, by weight: 3-15 parts of an oleamide-based nonionic surfactant, 5-12 parts of twain, 10-25 parts of dodecyl aminopropionic acid, 5-10 parts of a betaine-typed ampholytic surfactant, 10-20 parts of sodium alkyl benzene sulfonate, 1-10 parts of sophorolipid, 10-25 parts of a water-soluble lubricant, 5-18 parts of triethanolamine oleate, 5-15 parts of sodium borate, 1-5 parts of benzotriazole, 5-20 parts of cyclohexanehexol phosphate, 8-25 parts of an organic borate, 5-15 parts of a molybdate, 3-8 parts of copper citrate, 3-10 parts of a chelating agent, 3-10 parts of sodium citrate, 4-15 parts of citric acid and 80-150 parts of water. The high-performance metal cutting fluid is excellent in cleaning performance, corrosion-resistant performance, cooling performance, lubricating performance and anti-hard-water performance, is stable when being stored and is suitable for various materials.

Owner:CHAOHU GUANGFENG METAL PROD

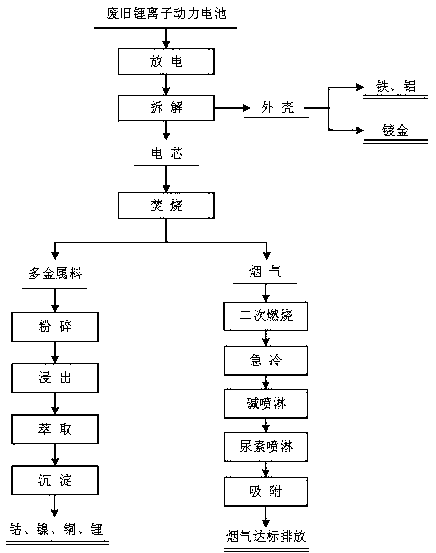

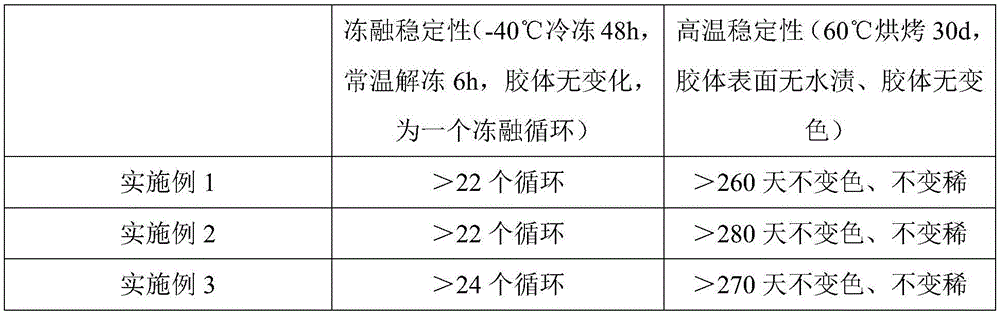

Resource recycling method for waste lithium ion power battery

ActiveCN107623152AImprove environmental indicatorsImprove recycling ratesWaste accumulators reclaimingRecovery methodElectrical battery

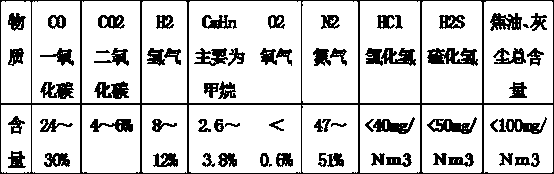

The invention discloses a resource recycling method for a waste lithium ion power battery. The method comprises the following process steps: carrying out electro discharge treatment, dismantling treatment, incineration treatment, polymetallic material crushing treatment, polymetallic material acid leaching treatment, extracting treatment, sedimentation treatment, flue gas secondary combustion treatment, flue gas rapid cooling treatment, flue gas alkali spraying treatment, flue gas urea spraying treatment, flue gas adsorption treatment and the like on the waste lithium ion power battery. The resource recycling method for the waste lithium ion power battery can fully recycle valuable metals from the waste lithium ion power battery, improve the recovery and utilization rate of metal to the maximum extent, and realize the recycling of metal resources; the flue gas can be directly discharged after being subjected to the process treatments such as the secondary combustion treatment, rapid cooling treatment, alkali spraying treatment, urea spraying treatment and adsorption treatment, the environmental protection index during the process of recycling and utilization of the waste lithium ion power battery is improved, no secondary pollution is generated, cleaner production is realized, and the economic benefits and environmental benefits are significant.

Owner:JIANGXI UNIV OF SCI & TECH

Efficient environment-friendly concrete preservative

The invention relates to an efficient environment-friendly concrete preservative, which comprises the following components in portion by weight: 10 to 18 portions of various benzoic acids and boric acids, 20 to 40 portions of silica fume, 20 to 35 portions of alkalis; 35 to 50 portions of ethanolamine, and 15 to 20 portions of active components. The preservative can be widely applied to various building materials, especially to concrete and cement, and is reliable in rust prevention and corrosion resistance and good in environmental indexes. The preservative has the advantages of containing no mineral oil, containing no nitrite, chromate and the like harmful to human body, adapting to compressive strength (50 MPa in general) of actual requirements, improving strength, durability and heat resistance and meeting the requirements for high-performance concrete, along with no toxicity, no stimulation, no pollution, good construction performance, high dimensional stability, less shrinkage and no cracking in the hardening process.

Owner:凌明明

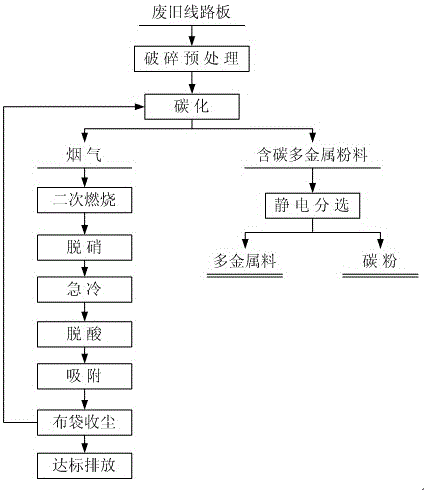

Resourceful treatment method for waste circuit board

ActiveCN105728434AImprove energy efficiencyEnables continuous processingSolid waste disposalTransportation and packagingHalogenCombustion

The invention discloses a resourceful treatment method for a waste circuit board. The resourceful treatment method comprises the process steps: carrying out crushing pretreatment of the waste circuit board, carbonization treatment of the waste circuit board, selective separation of carrying out flows including carbon-containing polymetallic materials, secondary combustion of flue gas, denitrification of the flue gas, rapid solidification treatment of the flue gas, deacidification treatment of the flue gas, adsorption treatment of the flue gas and collection and treatment of the flue gas; and finally respectively recovering a metal mixture and carbon powder, which are supplied for subsequent recycling. The resourceful treatment method has the following advantages that harms of dioxins and halogen substances can be fundamentally put an end, so that the environmental protection index is increased, and sanitary production of resource recycling the waste circuit board is realized; compared with other circuit board methods, the resourceful treatment method can fully utilize the heat energy of organic components in the waste circuit board, and the energy utilization ratio of the waste circuit board is increased; and metal and nonmetal in the waste circuit board are effectively separated from each other, regeneration recycling of resources is realized without secondary pollution, and the environmental, social and economic benefits are remarkable.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

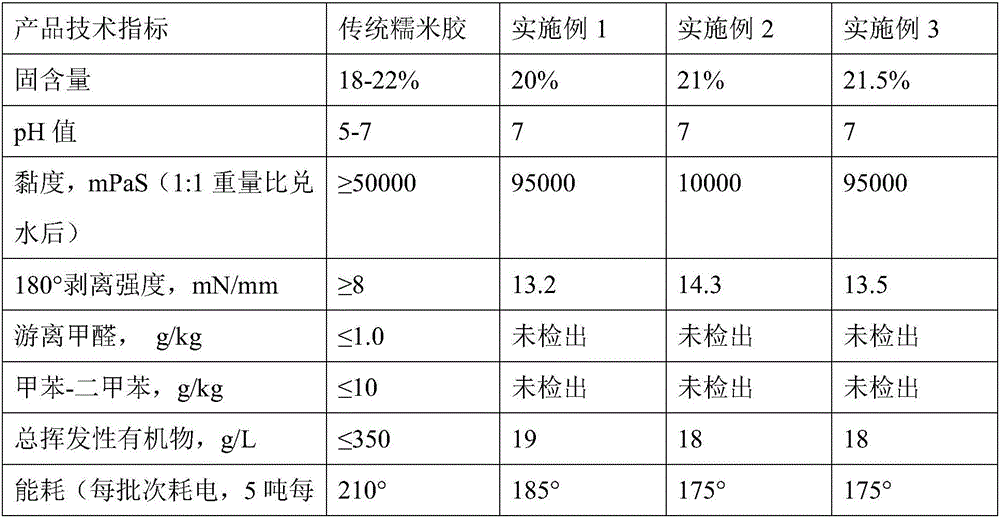

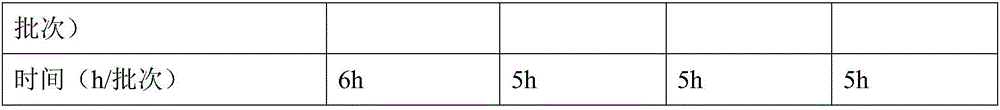

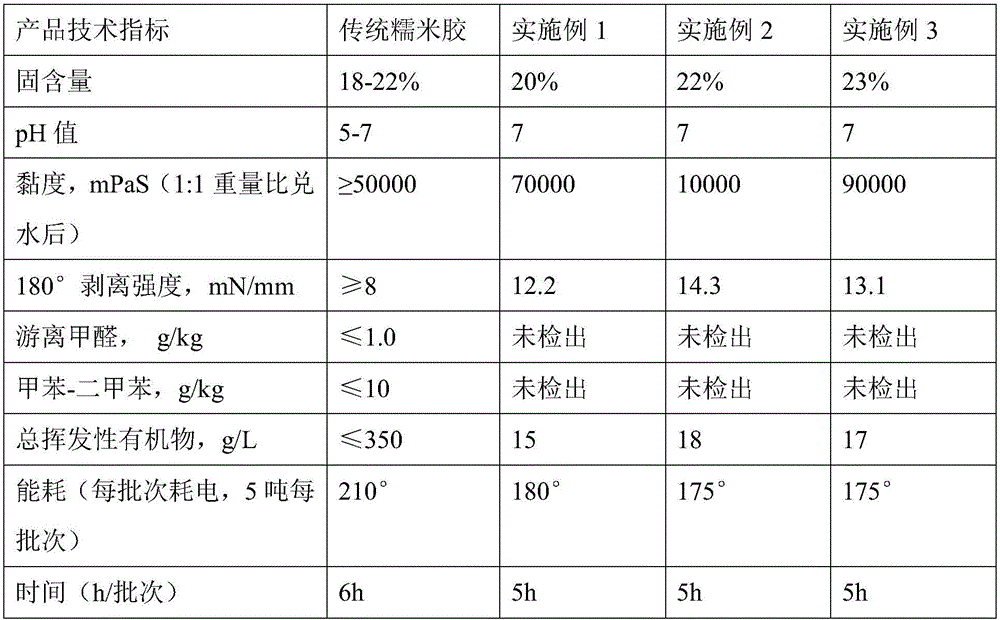

Edible environmentally-friendly glutinous rice glue composition used for pasting wallpapers, and production method thereof

InactiveCN106381089AAdd lessReduce breakage rateNon-macromolecular adhesive additivesStarch adhesivesViscosityCitric acid

The invention relates to the technical field of wallpaper auxiliary materials, and especially relates to an edible environmentally-friendly glutinous rice glue composition used for pasting wallpapers, and a production method thereof. The glutinous rice glue composition used for pasting wallpapers, which can be produced in a high temperature packing manner, is produced from, by mass, 5-8% of modified starch A, 3-8% of modified starch B, 4-10% of glutinous rice starch, 5-15% of waxy maize starch, 0.5-1% of a cross-linking agent, 0.6-3% of an antiseptic anti-mildew agent, 0.1-0.5% of monostearin, 1-3% of glucolactone, 0.2-1.5% of sorbitol, 2-6% of a thickener, 0.1-1.2% of citric acid, 0.01-0.15% of a stabilizer, and the balance of water. The glutinous rice glue composition obtained through compounding safe edible raw materials according to the above improved formula has the advantages of good stability, good safety and environmental protection, and has better viscosity than similar products.

Owner:GAREFU TECH CO LTD

Gasification system for recycling high-temperature sensible heat

InactiveCN108165311AHigh heat recovery rateReduce manufacturing costEnergy inputGasification processes detailsChemical industrySlag

The invention belongs to the field of energy and chemical industry and relates to a gasification system for recycling high-temperature sensible heat. The system includes the following process steps: 1. a pretreatment process; 2. a gasification process; 3. a sensible heat recovery and utilization process; 4. a waste heat convection recovery and ash separation process; 5. a dry ash removal process;6. a cooling washing process; 7. a slag treatment process; and 8. a black water treatment process. High-grade heat energy generated by gasification can be recovered while synthesis gas producing, by-product steam is used for power generation, the heat energy recovery rate of the gasification system is improved, the production cost of coal chemical products is effectively reduced, pollutant emission is reduced, and environmental indicators are superior.

Owner:宁夏神耀科技有限责任公司

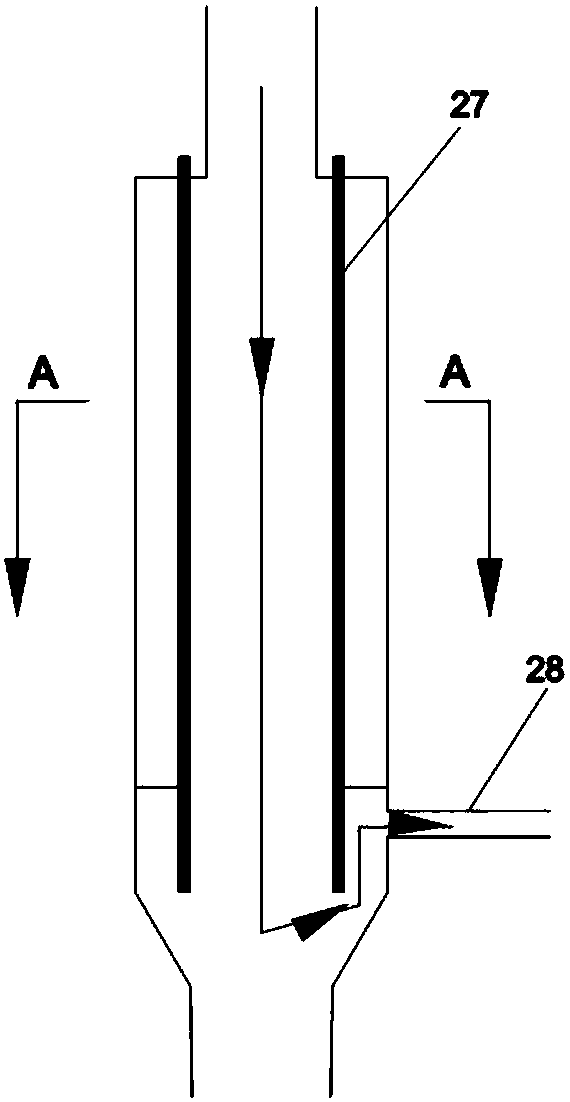

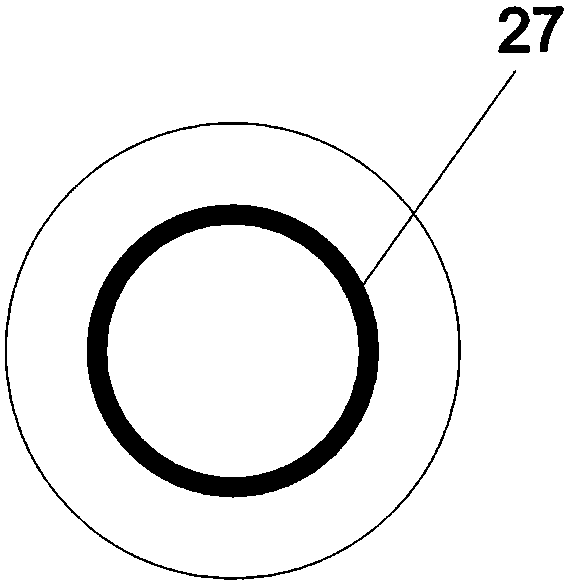

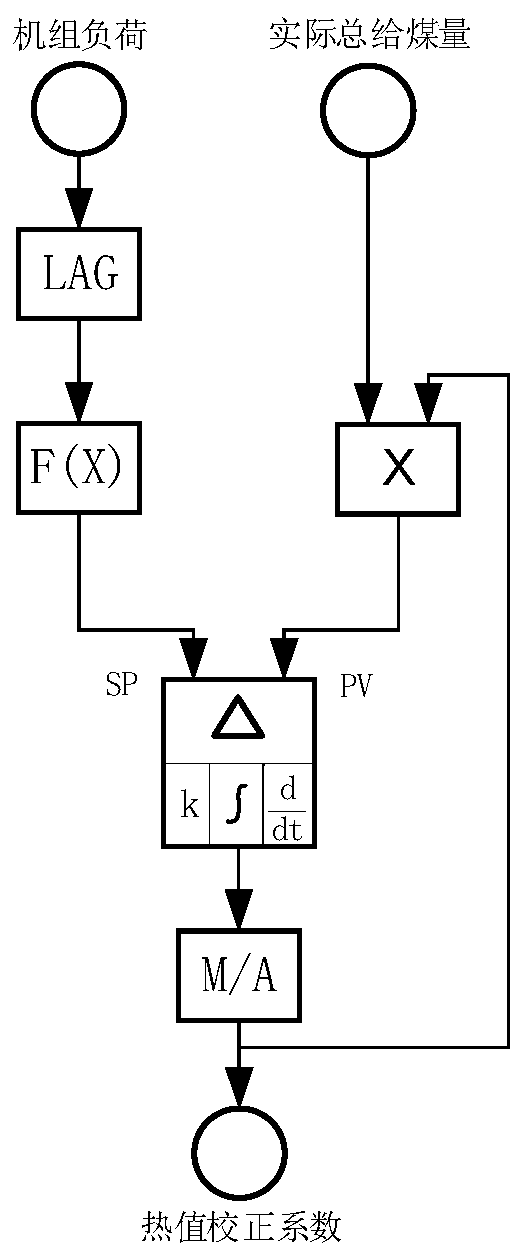

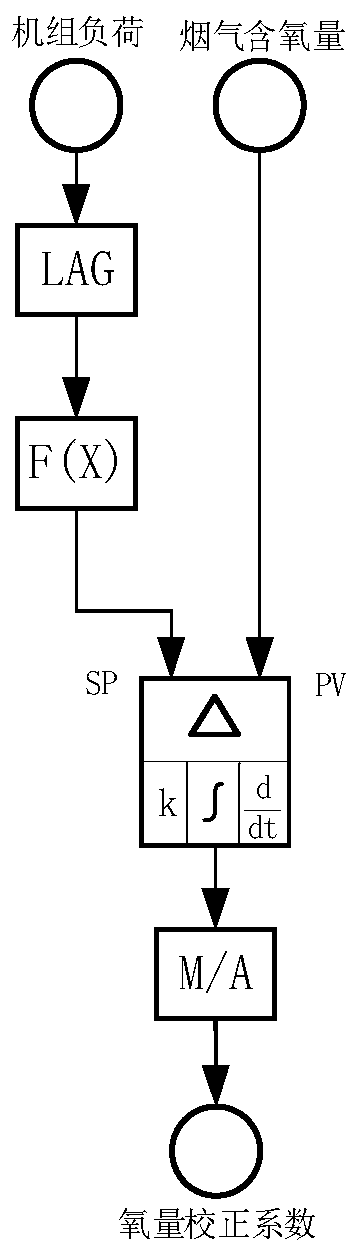

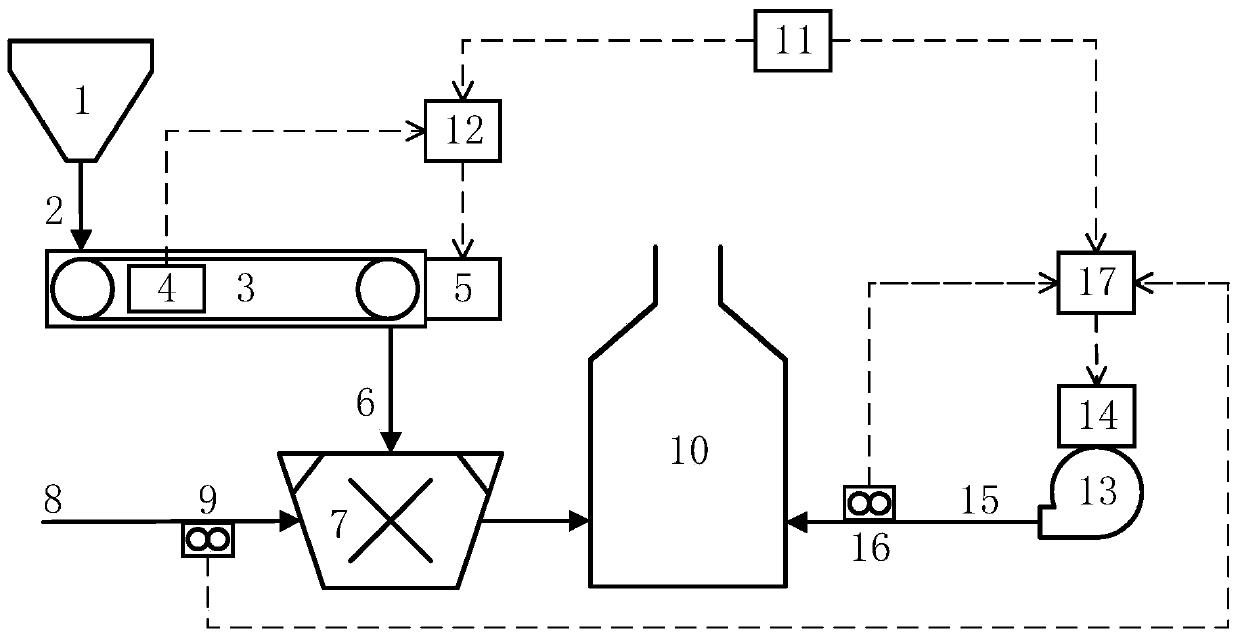

Unit plant control system and method based on real-time online analysis of coal quality

PendingCN111396919AReal-time correctionReal-time correction of air distribution conditionsFuel supply regulationMeasurement devicesBoiler furnaceAir volume

The invention discloses a unit plant control system and method based on real-time online analysis of the coal quality. The system comprises a raw coal hopper, a raw coal hopper outlet pipeline, a coalfeeder belt, a weighing instrument, a coal feeder speed change motor, a coal feeder outlet pipeline, a coal mill, a coal mill inlet primary air pipeline, a primary air volume measuring element, a boiler hearth, a coal quality online monitoring module, a coal feeding controller, an air feeder, an air feeder variable-output element, an air supply pipeline, a secondary air volume measuring element and a secondary air controller. By means of the method, on the basis of acquirable coal-as-fired online data meeting the real-time operation control requirement, the precise fuel and air distribution of a thermal power generating unit is realized, and the practical value is remarkable.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

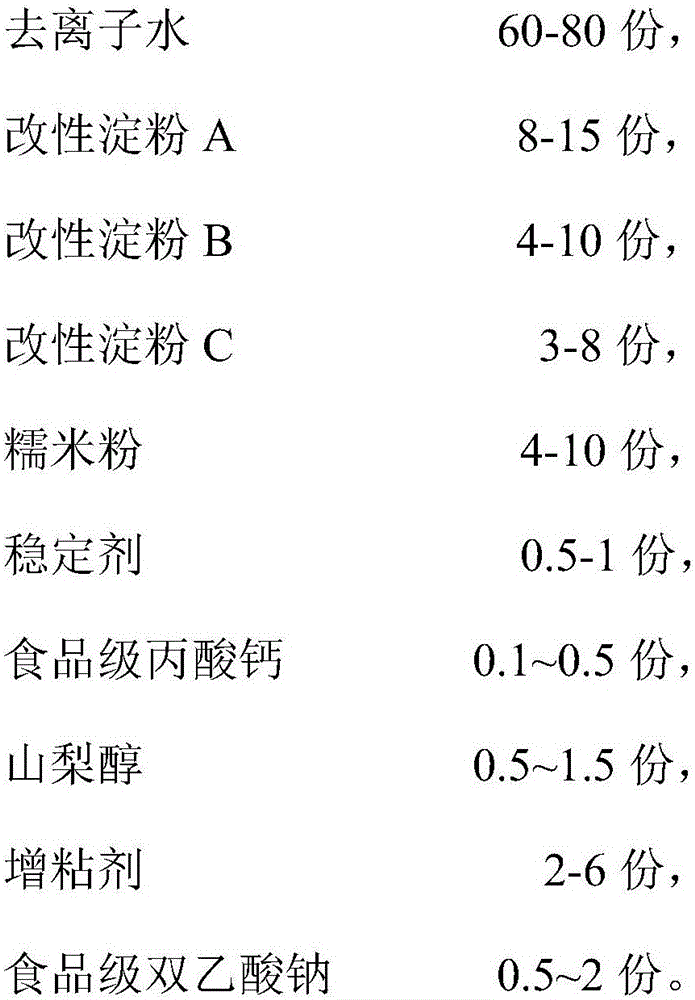

Glutinous rice adhesive subpackagable at high temperature and used for wallpaper, and preparation method thereof

ActiveCN105838283AIncrease viscosityExtended shelf lifeNon-macromolecular adhesive additivesStarch adhesivesAdhesiveSodium diacetate

The invention relates to the technical field of accessory materials for wallpaper, especially to a glutinous rice adhesive subpackagable at high temperature and used for wallpaper, and a preparation method thereof. The glutinous rice adhesive which can be subpackaged and produced at high temperature and is used for pasting of wallpaper is mainly prepared from the following components by mass: 60 to 80 parts of deionized water, 8 to 15 parts of modified starch A, 4 to 10 parts of modified starch B, 3 to 8 parts of modified starch C, 4 to 10 parts of glutinous rice flour, 0.5 to 1 part of a stabilizing agent, 0.1 to 0.5 part of food-grade calcium propionate, 0.5 to 1.5 parts of sorbitol, 2 to 6 parts of a tackifier and 0.5 to 2 parts of food-grade sodium diacetate. Compared with traditional processes, the glutinous rice adhesive provided by the invention can be directly packaged at high temperature, so the step of cooling is omitted, energy loss is substantially reduced, and the usage efficiency of a reaction vessel is improved.

Owner:GAREFU TECH CO LTD

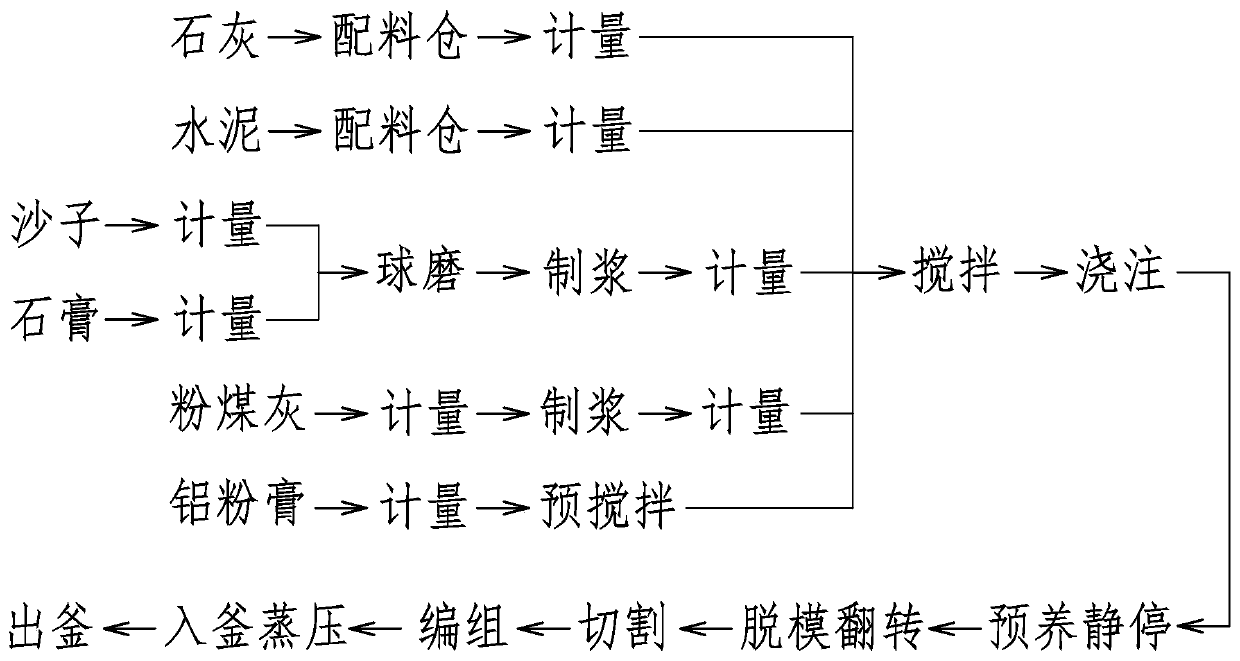

Autoclaved aerated concrete block and preparation process thereof

The invention discloses an autoclaved aerated concrete block and a preparation process thereof. The autoclaved aerated concrete block is prepared from, by weight, 100-130 parts of fly ash, 260-300 parts of sand, 8-12 parts of gypsum, 75-80 parts of lime, 80-85 parts of cement and 0.5-0.7 part of aluminum powder paste; according to the invention, the application range of the low-quality fly ash generated by the combustion of the boiler of the thermal power plant is expanded, so that the treatment ways of the fly ash generated by the coal-fired boiler are greatly increased, the technical difficulty of manufacturing the high-quality autoclaved aerated concrete block by using the low-quality fly ash is overcome, and the practical value is very high.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD

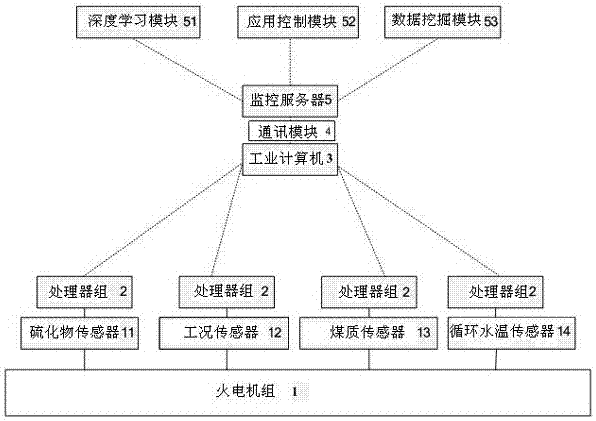

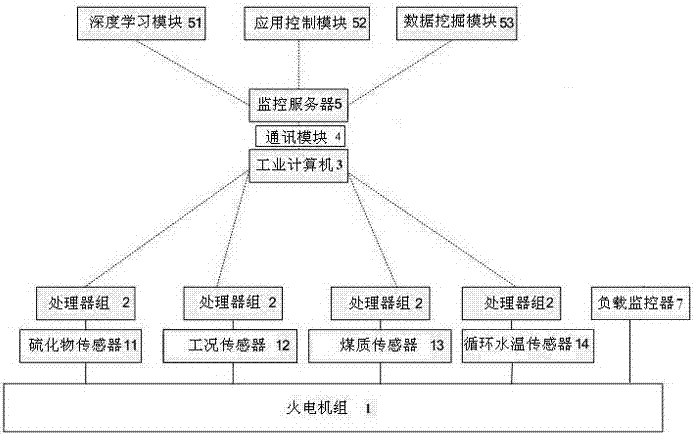

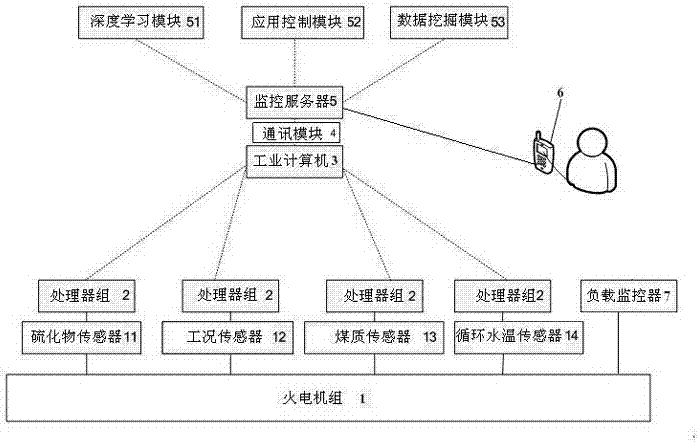

Environment-friendly thermal power unit system

InactiveCN106873518AImprove environmental indicatorsEmission reductionProgramme control in sequence/logic controllersEnvironmental resistanceEnvironmental index

The invention discloses an environment-friendly thermal power unit system comprising a thermal power unit. The system further comprises a sensor group used for collecting key data of the thermal power unit, a processor group used for collecting and analyzing the data, an industrial computer used for sorting and summarizing uploaded data, and a monitoring server used for optimally controlling the running state of the equipment of the thermal power unit. The output end of the sensor group is connected with the input end of the processor group. The processor group communicates with the monitoring server through the industrial computer. With the system applied, the sulfide emission of thermal power plants can be reduced greatly, and the environmental index of thermal power plants can be optimized.

Owner:SKILL TRAINING CENT STATE GRID JIBEI ELECTRONICS POWER COMPANY +1

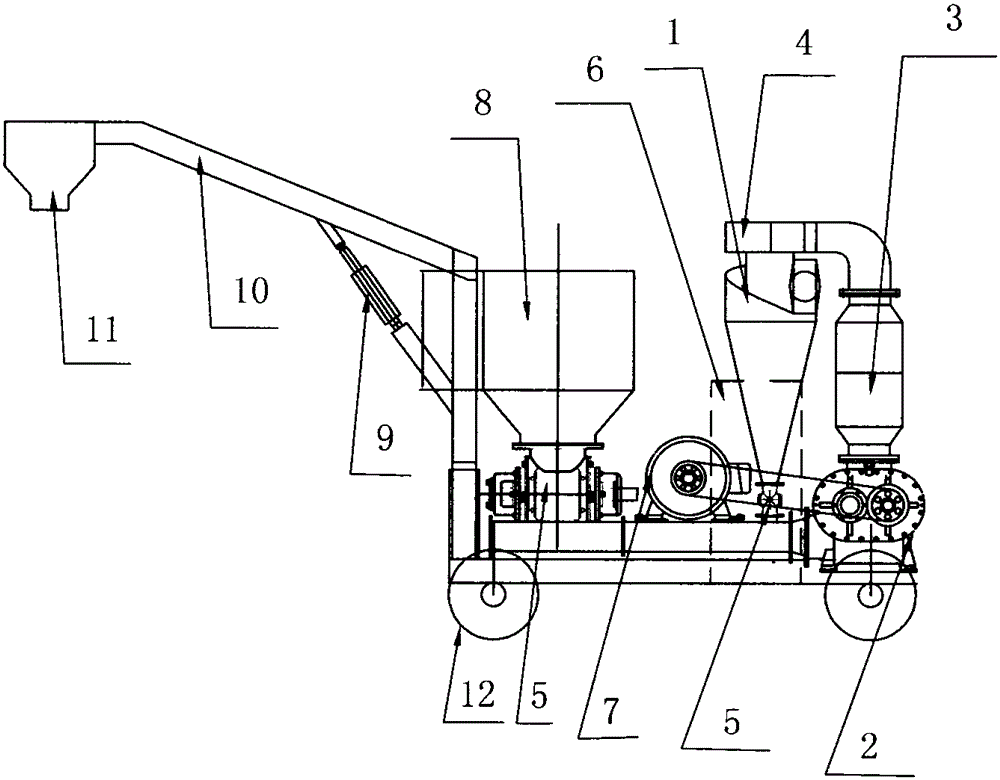

Large grain elevator

InactiveCN105151800AImprove work efficiencyImprove environmental indicatorsBulk conveyorsCycloneGrain elevator

The invention discloses a large grain elevator, and relates to the field of material transferring and transporting. The large grain elevator comprises a grain sucking device, a Roots blower, a silencer, a cyclone dust collector, an air seal device, an electric control cabinet, a motor, a buffering bin, an oil cylinder, an outlet pipeline, an outlet cyclone and walking wheels. The cyclone dust collector is arranged at the upper end of the grain sucking device and connected with the silencer through a pipeline. The Roots blower is arranged below the silencer. The air seal device is connected with the bottom of the grain sucking device. The electric control cabinet is arranged outside the air seal device. The Roots blower is connected with the motor through a crawler belt. The grain sucking device is communicated with the buffering bin through a bottom channel. The air seal device is connected between the buffering bin and the channel. The upper portion of the buffering bin is communicated with the outlet pipeline, and the other end of the outlet pipeline is connected with the outlet cyclone. The lower portion of the outlet pipeline is connected with the oil cylinder. The walking wheels are arranged at the bottom of the whole grain elevator. The large grain elevator has the beneficial effects of being high in working efficiency, large in yield, high in environment protection index and convenient, safe and reliable to operate.

Owner:常州润雍机械厂

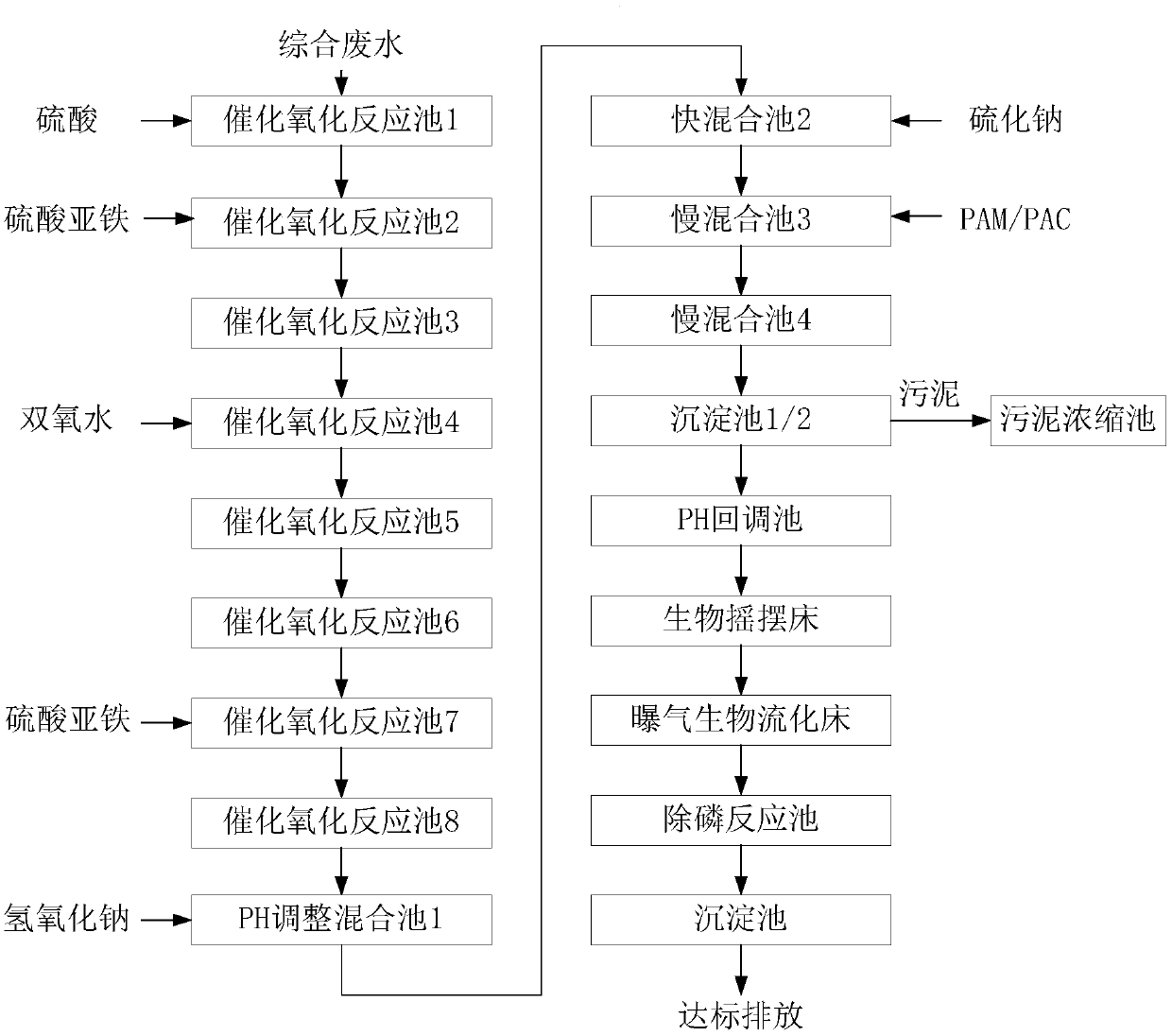

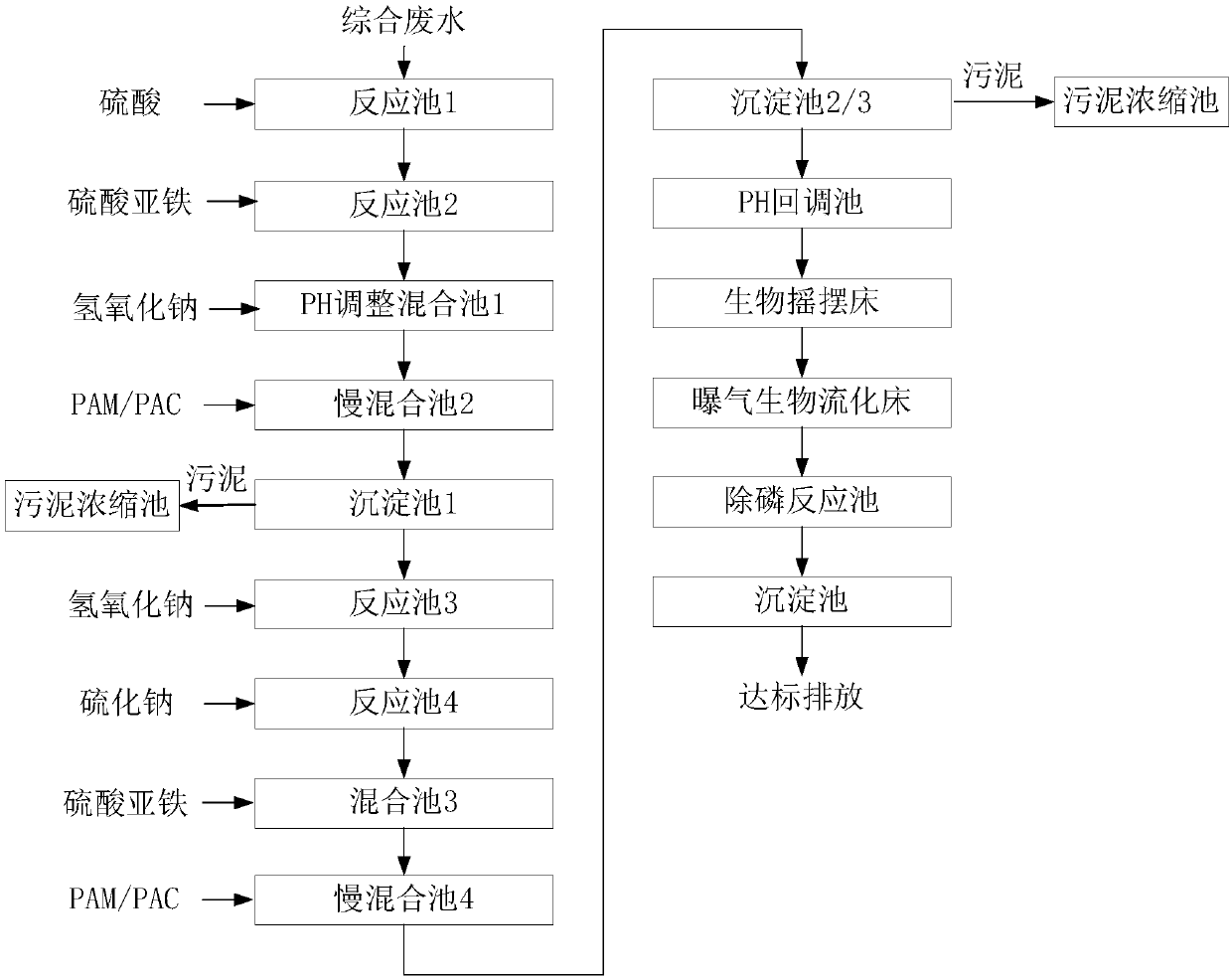

Treatment method for comprehensive wastewater in circuit board industry

InactiveCN109607856AReduce the concentration of copper ionsAvoid fungal poisoningWater contaminantsTreatment involving filtrationIonChemistry

The invention discloses a treatment method for comprehensive wastewater in a circuit board industry. The method comprises the following steps: step 1, adding sulfuric acid into the comprehensive wastewater, adjusting the pH to 2.5-3.5, adding ferrous sulfate, and performing a complex breaking reaction; step2, adding NaOH, adjusting the pH to 9.5-10.5 to remove copper ions, then adding a coagulant,performing stirring, performing primary filtration or sedimentation to obtain intermediate wastewater 1, and performing concentration collection on sludge; step 3, adding NaOH into the intermediate wastewater 1, adjusting the pH to 9.5-10.5, and adding sodium sulfide for a secondary copper removing reaction; step 4: adding ferrous sulfate to remove excess sulfur ions; and step 5, adding a coagulant, performing stirring, performing secondary filtration or sedimentation to obtain intermediate wastewater 2, and performing concentration collection on sludge. According to the method disclosed in the invention, copper removing reactions of a sodium hydroxide method and a sodium sulfide method are adopted for sewage treatment, so that a concentration of copper ions in preformed precipitate wateris reduced, metal ion poisoning of bacteria and fungi in subsequent processes is avoided, and the material costs are reduced; and the method has outstanding characteristics of a good environmentally-friendly index and low production costs..

Owner:DALIAN CHONGDA CIRCUIT

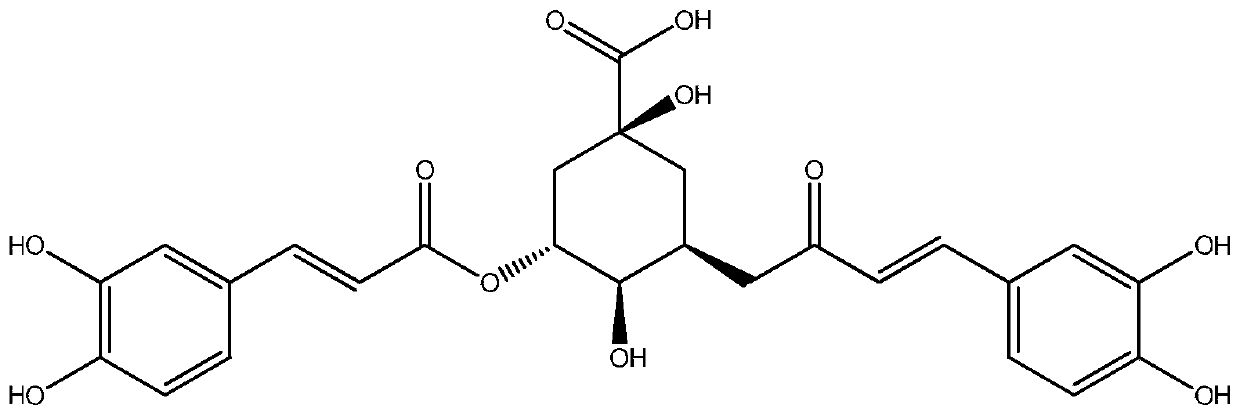

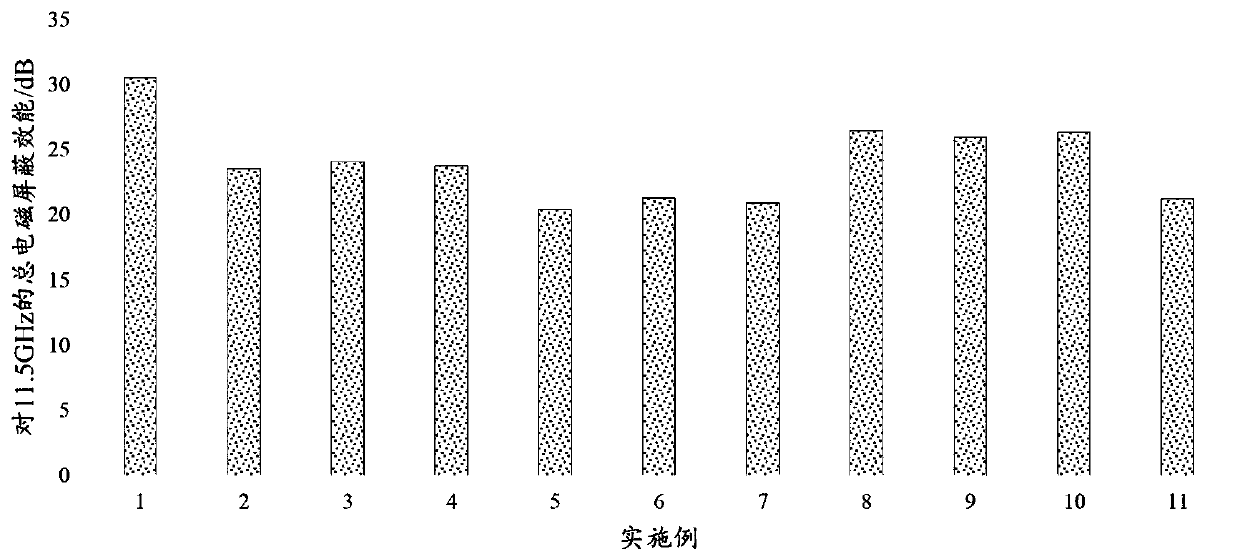

Antibacterial and mildew-proof wallpaper and preparation method thereof

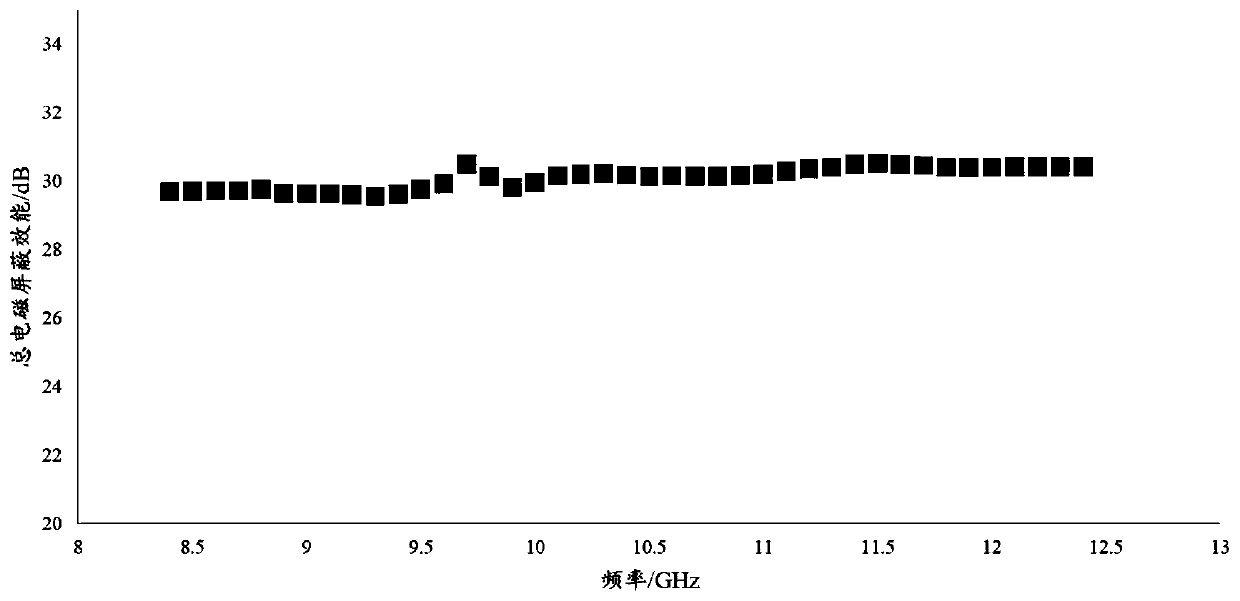

PendingCN111218847AHealthy and environmentally friendlyResistant to germsSpecial paperPaper/cardboardFiberPolymer science

The invention relates to wallpaper, and concretely relates to antibacterial and mildew-proof wallpaper and a preparation method thereof. The wallpaper comprises: a wallpaper base layer containing alginate fibers and all-wood pulp fibers; an antibacterial and mildew-proof agent sprayed on the surface of the wallpaper base layer; and a PVC paste applied to the surface of the wallpaper base layer ina coating manner. The alginate fibers and all-wood pulp are subjected to selection, mixing, pulping, papermaking and drying to obtain the wallpaper base layer; the antibacterial and mildew-proof agentis uniformly sprayed on the surface of the wallpaper base layer; the surface of the wallpaper base layer is coated with the PVC paste to obtain wallpaper base paper; and a pattern is printed on the wallpaper base paper in an extruded mode to obtain corresponding lines, and the wallpaper is obtained by cutting the wallpaper base paper into required specifications after drying and shaping. The antibacterial and mildew-proof wallpaper has excellent antibacterial and mildew-proof performance, has an antibacterial rate on common harmful germs of 99.5% or above, is harmless to human bodies and canadsorb indoor formaldehyde gas and purify room air, damage of ionizing radiation to the human bodies can be reduced due to the excellent electromagnetic shielding effect, and the use experience is good.

Owner:上海威泽装饰材料有限公司

Functional masterbatch of polyolefin plastic woven product and preparation and application thereof

InactiveCN106957481APhysical performance balanceUniform colorMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchPolyolefin

The invention discloses a functional masterbatch of a polyolefin plastic woven product and a preparation and application thereof. The functional masterbatch of the polyolefin plastic woven product is prepared from the following components in parts by weight: 60-80 parts of polyolefin, 12-28 parts of an assistant and 3-5 parts of stearate, wherein the assistant contains an antioxidant and a light stabilizer; the mass ratio of the antioxidant to the light stabilizer is 1:(3-6); the stearate contains calcium stearate and zinc stearate; and the polyolefin is polyethylene or polypropylene. The functional masterbatch of the polyolefin plastic woven product is convenient to operate when the woven product is prepared, dust pollution and manpower and material losses can be avoided, and the functional masterbatch of the polyolefin plastic woven product has good light aging resistance.

Owner:BEIJING ADDITIVES INST

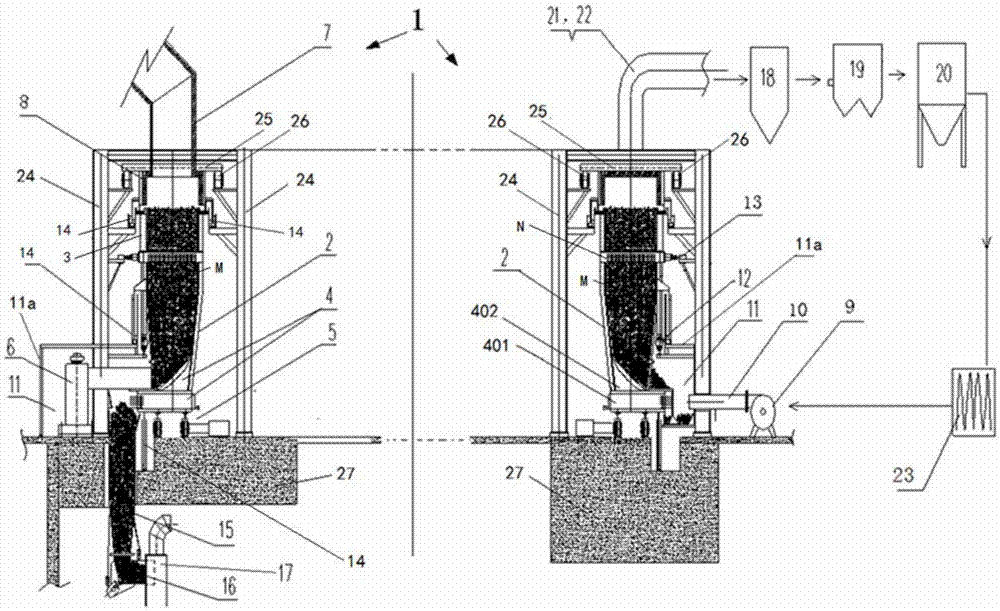

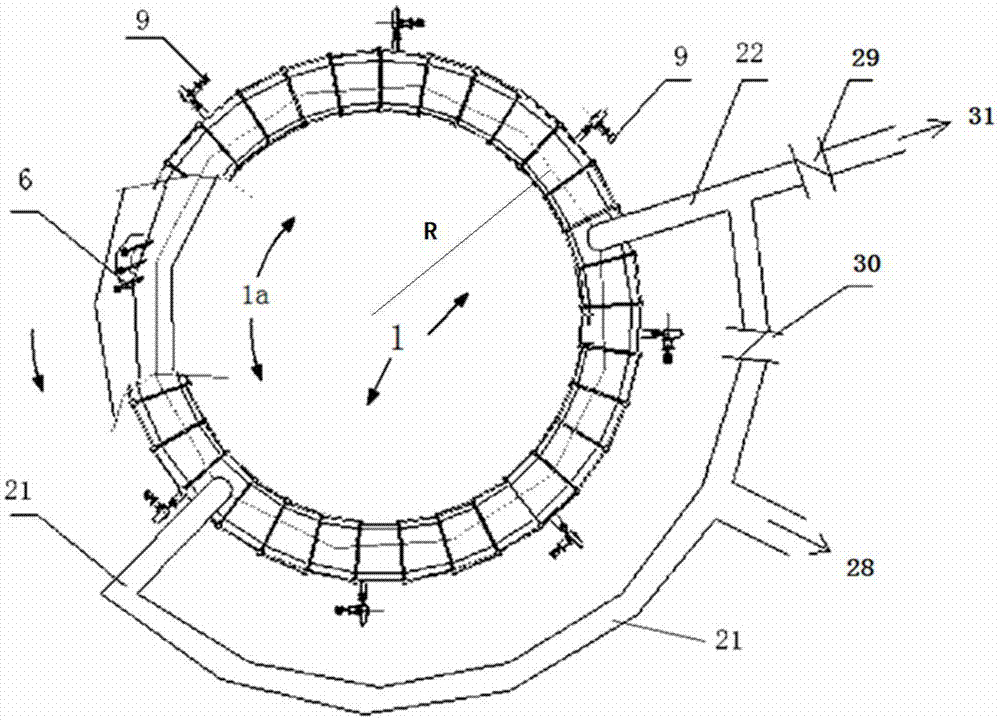

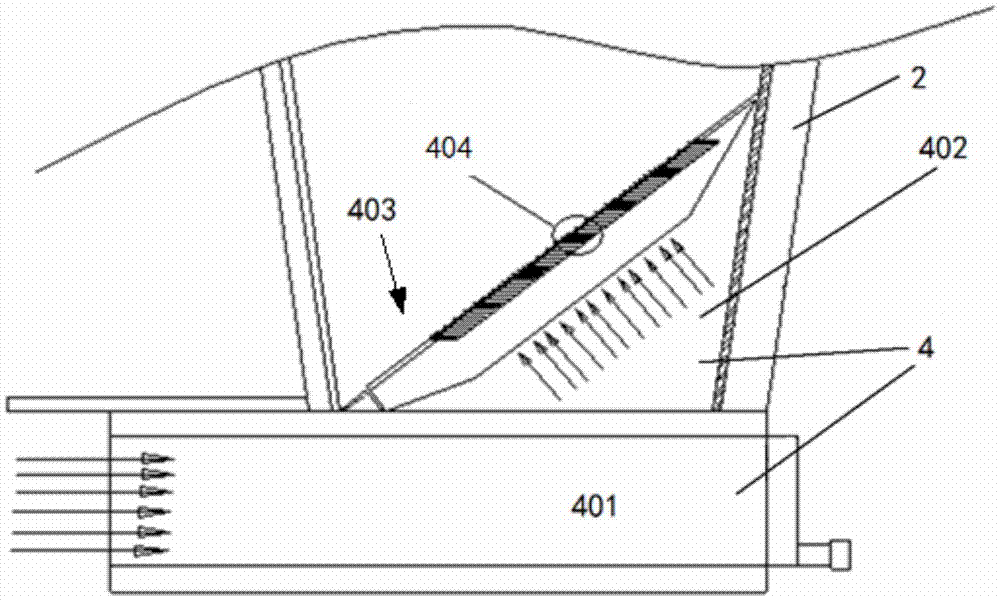

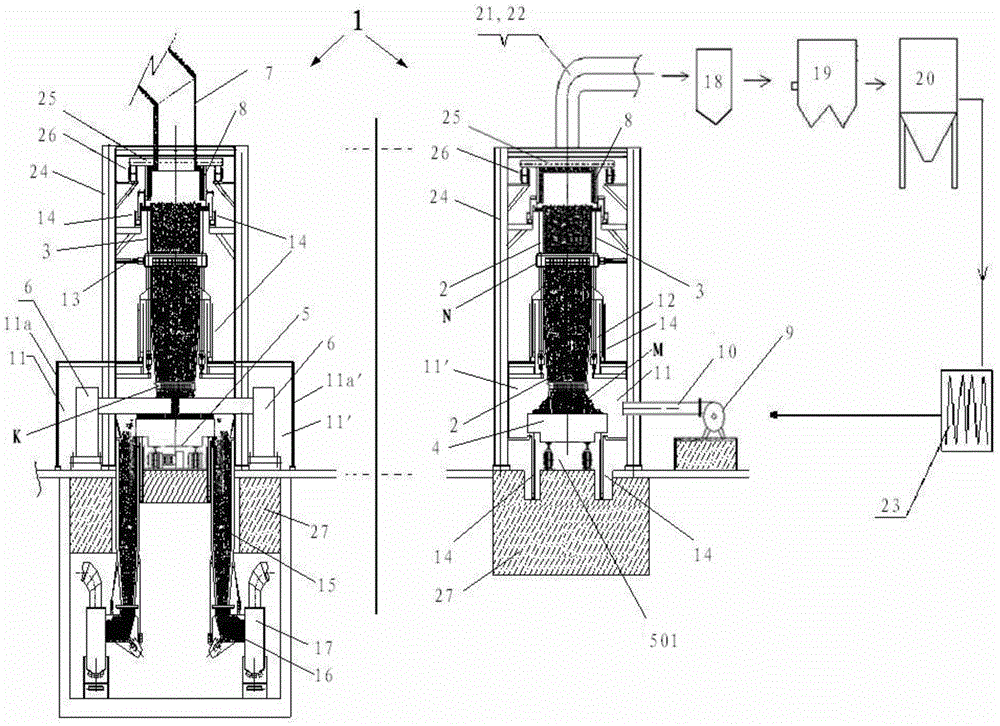

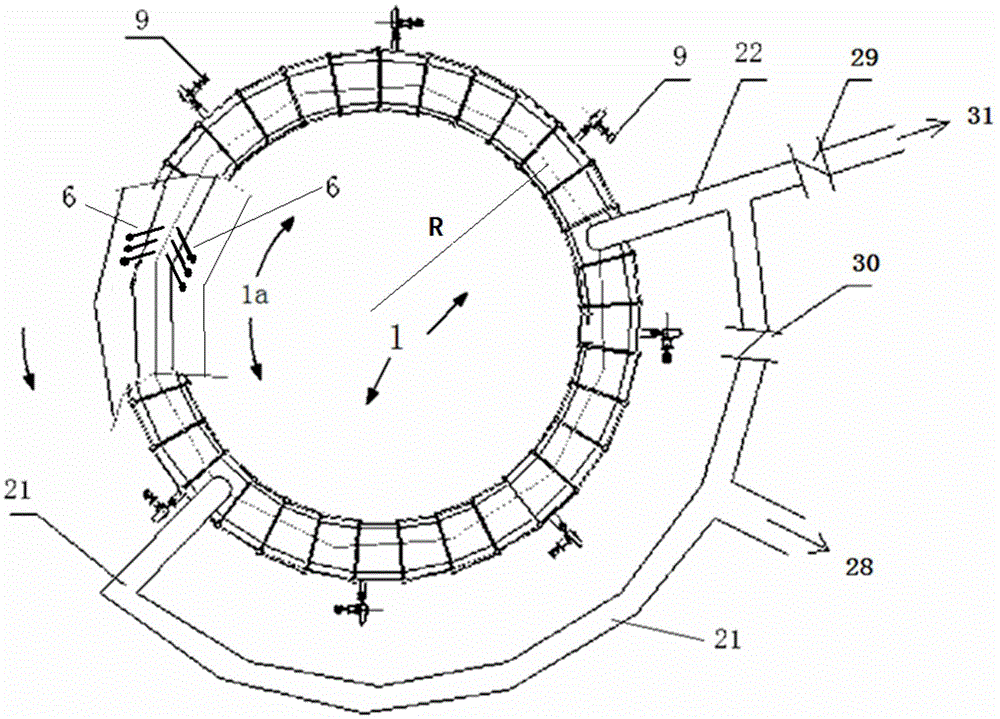

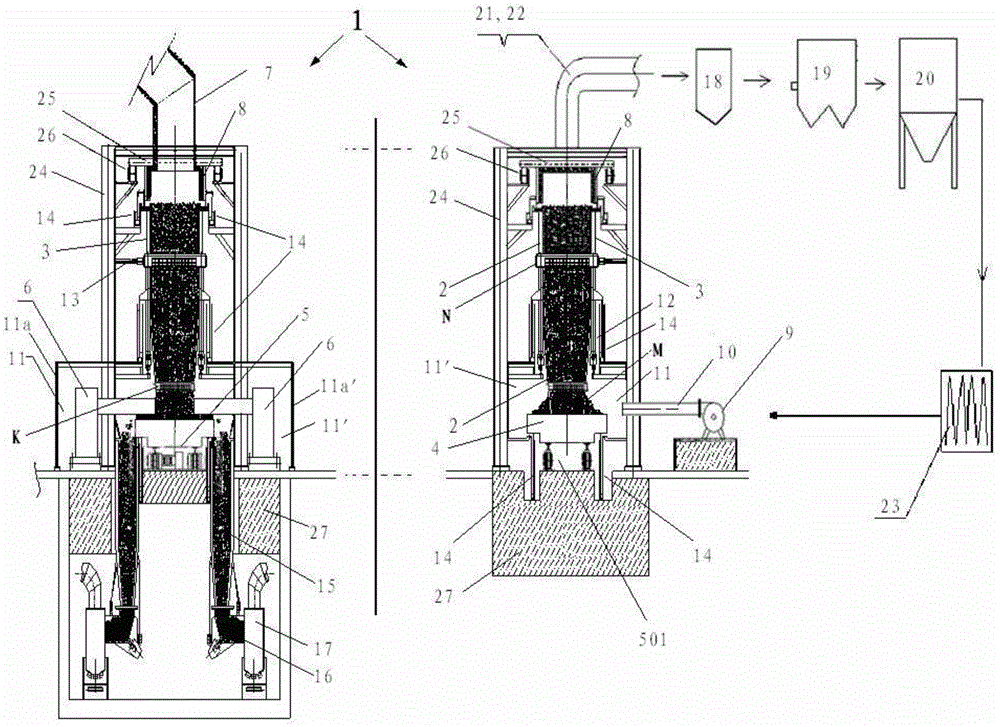

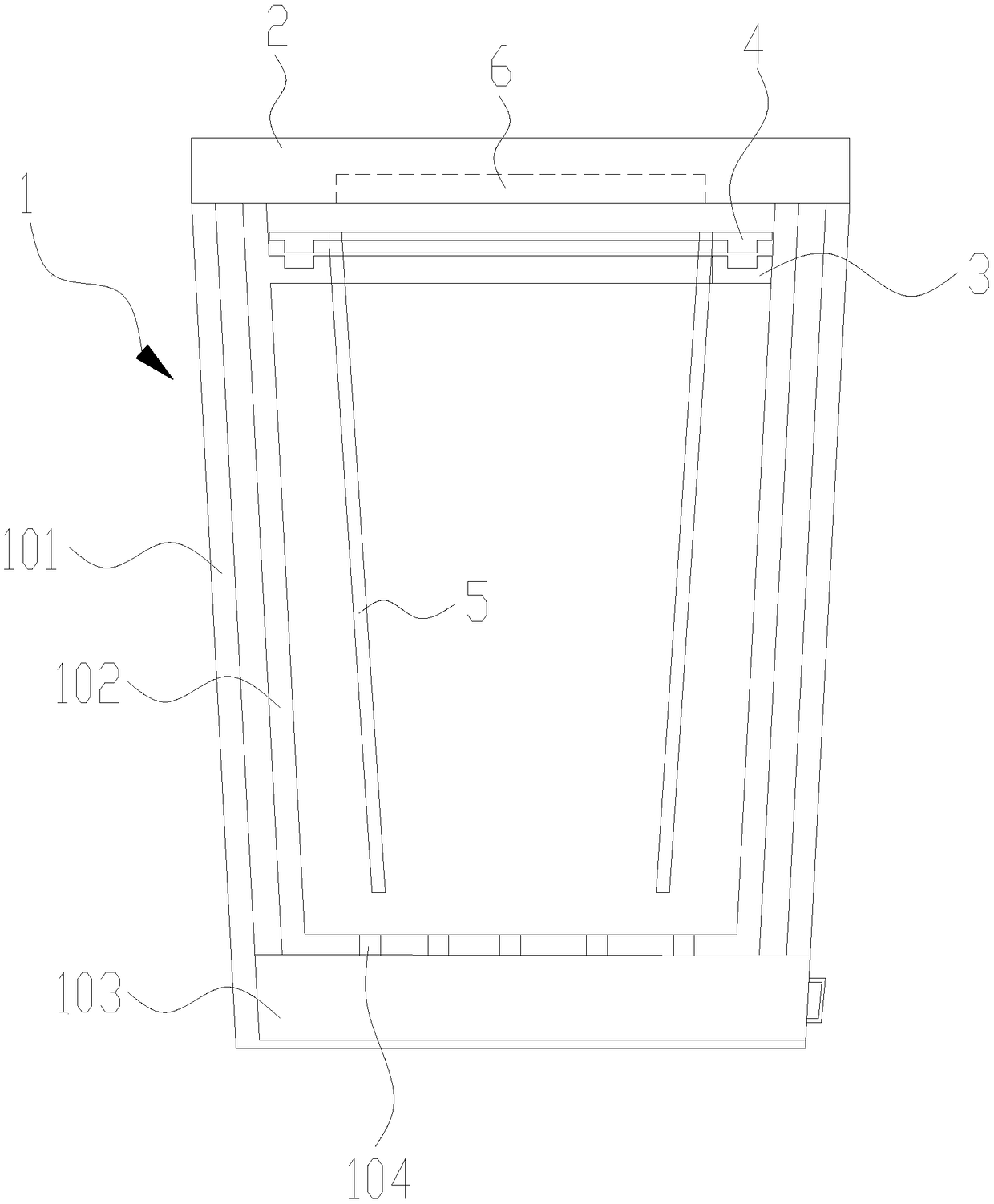

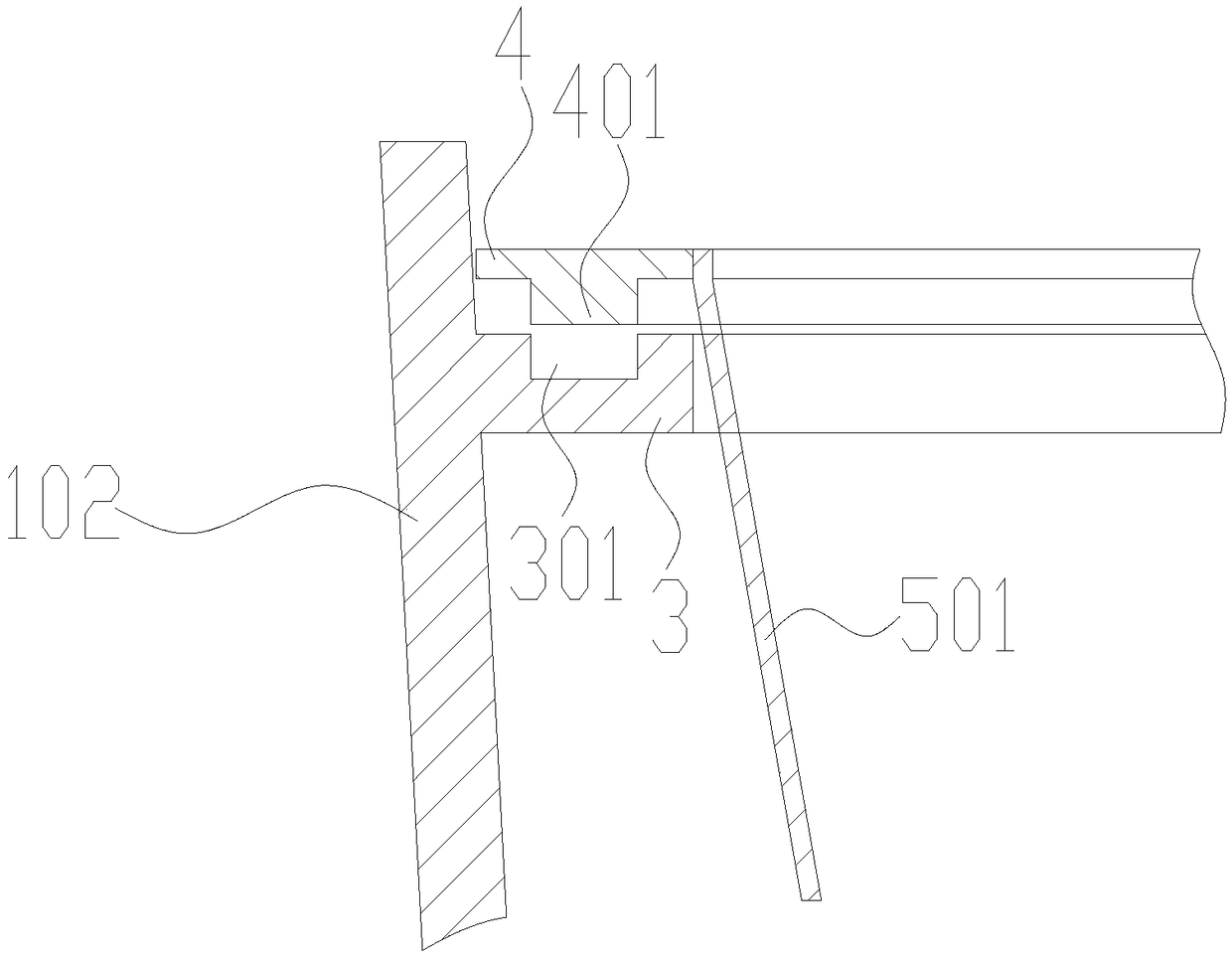

Groove type liquid-seal blast cooling device and method for sintered ores

ActiveCN107014216AImprove impact performanceWill not cause elevationHandling discharged materialAir blowerAir blast

The invention provides a groove type liquid-seal blast cooling device (1) for sintered ores. The device comprises <1> an annular groove-shaped accumulating tank body, <2> a wheel rail driving device (5) of the tank body, <3> an annular engine cover (8), <4> a first air outlet pipeline (21) and a second air outlet pipeline (22), <5> a closed annular air charging chamber (11), <6> a liquid sealing device (14), <7> a plurality of air blowers (9), and <8> one or more scraper devices (6), wherein the tank body comprises an inner annular wall (2), an outer annular wall (3) and a whole circle of annular tray (4) which is arranged at the bottom of the tank body; the annular engine cover (8) is arranged at the upper part of the tank body; the first air outlet pipeline (21) and the second air outlet pipeline (22) are connected with the top of the engine cover (8); a sealing effect is played between the liquid sealing device (14) and the inner annular tank body wall (2) and the outer annular tank body wall (3) of the rotating annular groove-shaped accumulating tank body; and each scraper device (6) is installed at the outer side of a discharging section (1a) of the cooling device (1). The cooling device (1) has outstanding advantages in aspects of manufacturing cost, reduction of environmental pollution and waste-heat utilization.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

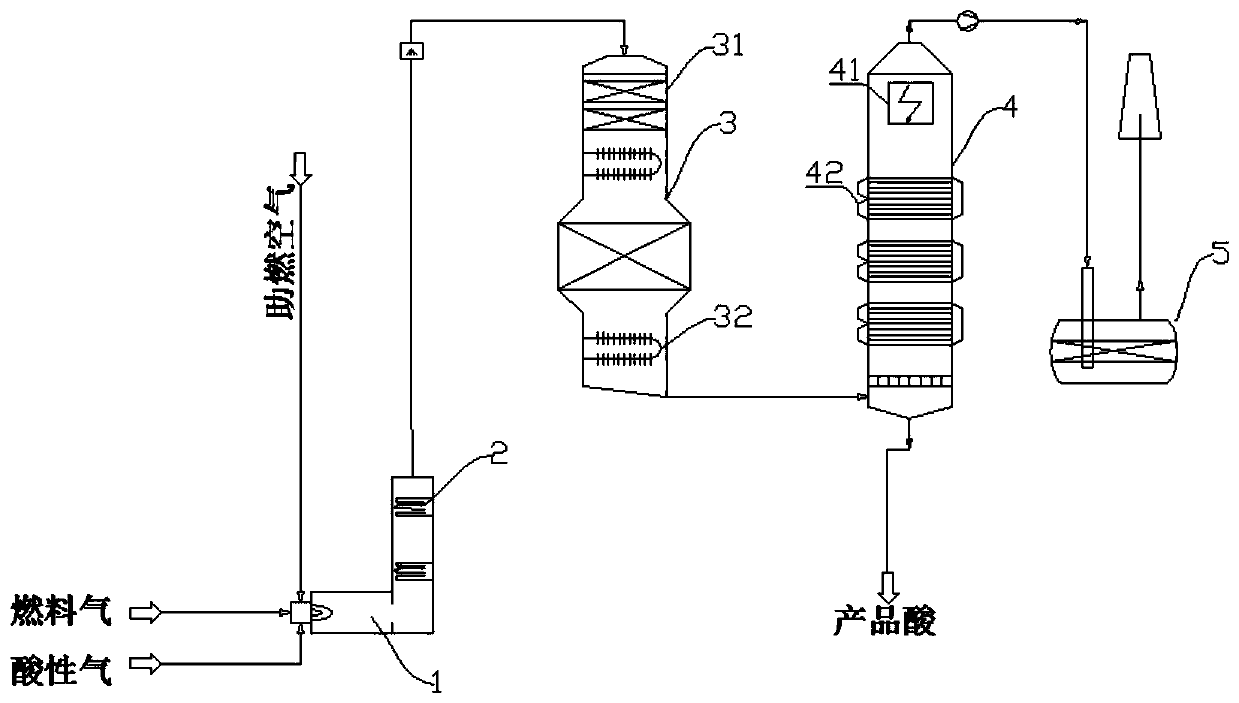

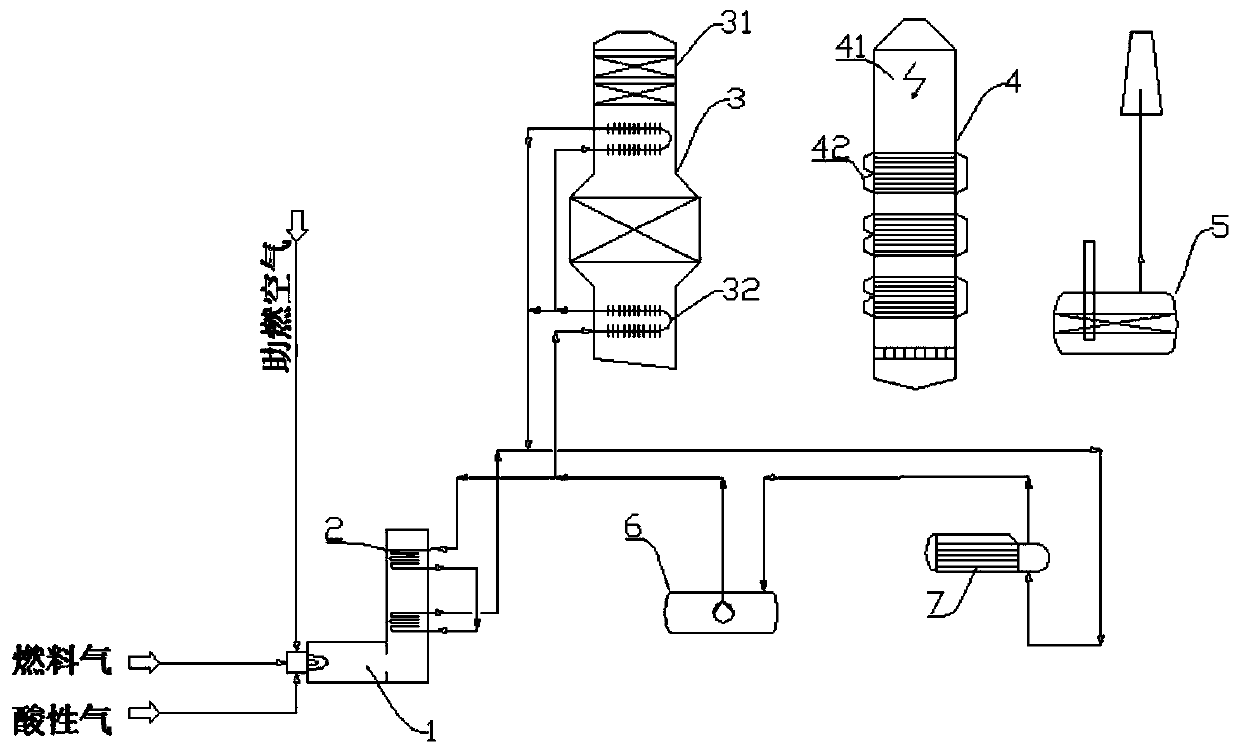

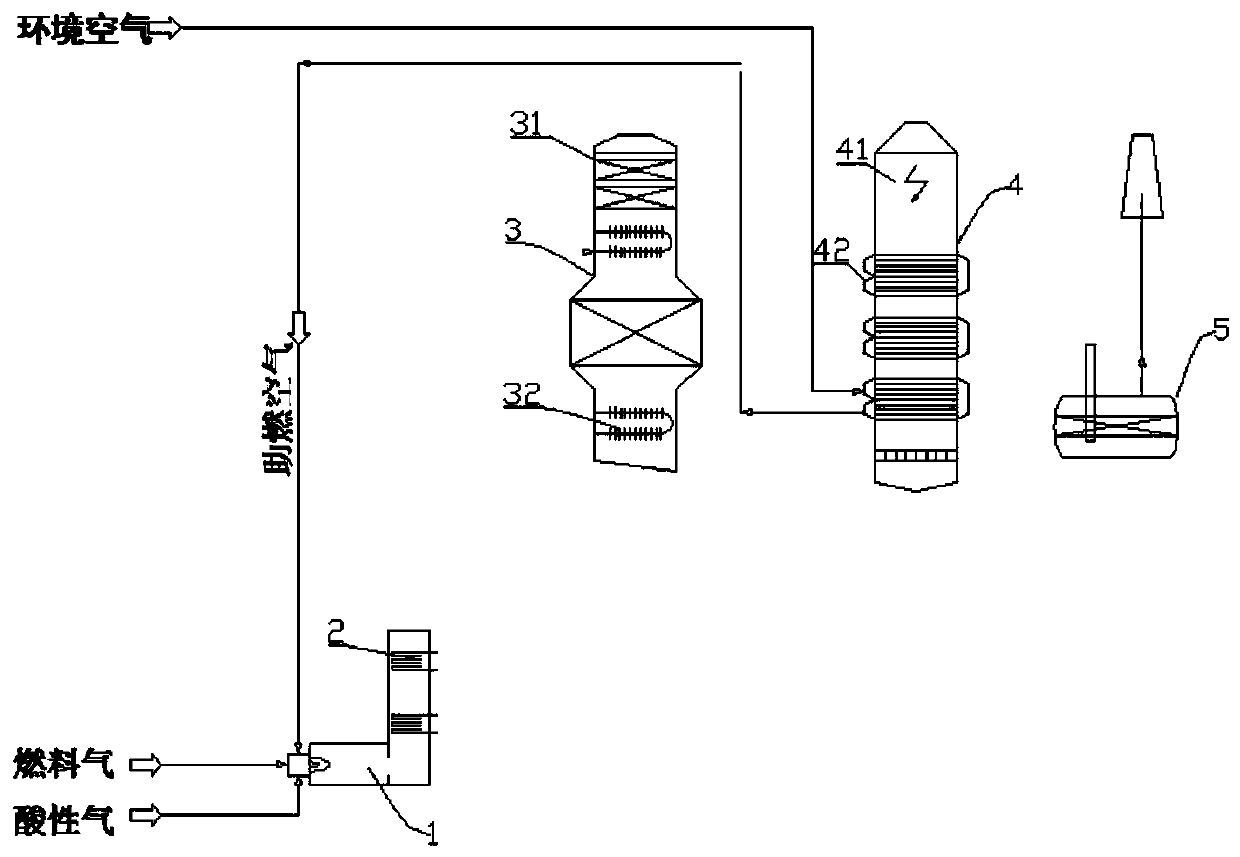

Device and process for producing sulfuric acid

ActiveCN109987587AImprove recycling efficiencyReduce operating energy consumptionSulfur compoundsEnergy inputEnvironmental resistanceCatalytic oxidation

The invention provides a device for producing sulfuric acid. The device for producing sulfuric acid comprises a combustion furnace, a reactor, a condenser and an activated carbon reaction bed which are sequentially connected through a pipeline, wherein the combustion furnace is used for burning a raw material, a heat exchanger is further arranged at the position, near a gas outlet, of the interiorof the combustion furnace, and the heat exchanger is used for cooling high-temperature gas obtained through combustion in the combustion furnace; the reactor is used for performing a catalytic oxidization reaction on the gas obtained after cooling is performed through the heat exchanger, the condenser is used for converting gas obtained after catalysis is performed by the reactor into sulfuric acid and performing condensation and concentration, and the activated carbon reactor is used for oxidizing residual SO2 gas; and exhaust gas is discharged through a chimney. Furthermore, the invention also provides a sulfuric acid preparation process which adopts the device for producing sulfuric acid. The device and process for producing sulfuric acid have high recovery efficiency of total sulfur,low energy consumption of long-cycle operation, a small device occupied area and a high index of environmental protection.

Owner:HARBIN BOAO ENVIRONMENTAL TECHNOLOGY CO LTD

Two-side unloading groove-type liquid seal air blast cooling device and method for sinter mine

ActiveCN107179002AImprove impact performanceWill not cause elevationHandling discharged materialEngineeringMechanical engineering

The invention discloses a two-side unloading groove-type liquid seal air blast cooling device (1) for a sinter mine. The device comprises 1) an annular-groove-shaped accumulation box body, 2) a wheel rail driving device (5) of the box body, 3) an annular machine cover (8) on the upper portion of the box body, 4) at least one air outlet pipelines (21, 22) connected with the top of the annular machine cover (8), 5) an airtight annular air inlet chamber (11), 6) a liquid seal device (14), 7) a plurality of blowers (9), 8) scraper devices (6) mounted on the inner side and the outer side of an unloading section (1a) of the cooling device (1) and 9) a plurality of lower air inlet devices (k) located in the lower space of the box body but on the upper portions of scrapers, wherein the box body comprises an inner annular wall (2), an outer annular wall (3) and a whole ring annular tray (4) at the bottom, and the liquid seal device (14) forms the seal effect with the inner annular box body wall (2) and the outer annular box body wall (3) of the rotatable annular-groove-shaped accumulation box body. The cooling device (1) has the outstanding advantages in the aspects of manufacturing cost, environmental pollution reducing and waste heat utilization.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Environmental protection type garbage can

The invention discloses an environmental protection type garbage can. The environmental protection type garbage can is novel in structure, capable of reducing smell emitted by rotten garbage and preventing an internal garbage bag from being damaged, and convenient and fast to operate. The environmental protection type garbage can comprises a can body, the can body comprises an inner can body and an outer can body, a garbage bag embedding ring is formed on the upper portion of the inner can body, a garbage bag embedding groove is formed on the upper surface of the garbage bag embedding ring, the garbage bag embedding ring is provided with a garbage bag pressing ring, the garbage bag pressing ring presses the upper portion of the garbage bag into the garbage bag embedding groove, a garbage bag rounding barrel extended downwards along the inner wall of the inner can body is formed on the inner circle of the garbage bag pressing ring, the lower end of the garbage rounding barrel is opened,and the garbage bag rounding barrel is sleeved with the garbage bag. The garbage can is further internally provided with an activated carbon adsorption assembly where activated carbon particles can be filled. By means of the garbage can, using structural stability of the garbage bag can be improved, the service life of the garbage bag can be prolonged, peculiar smell emitted from interior can beadsorbed through adsorbing agent, and environmental protection requirements are met.

Owner:刘依萍

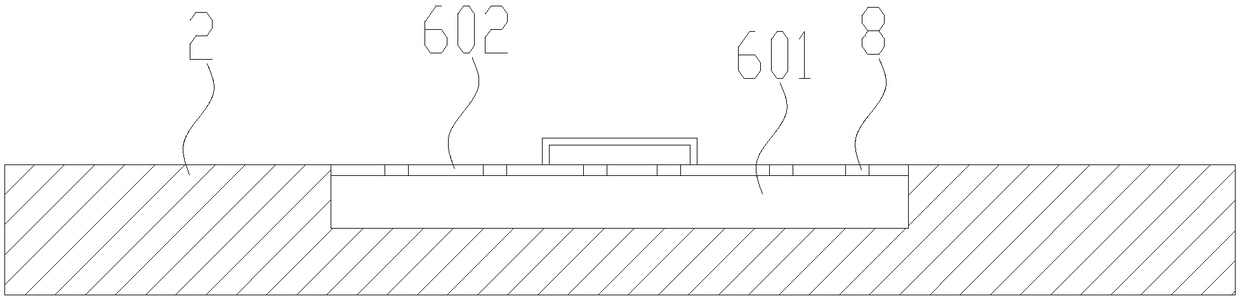

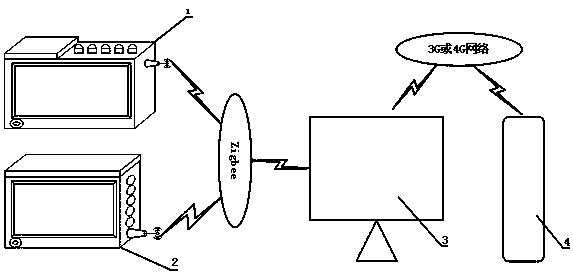

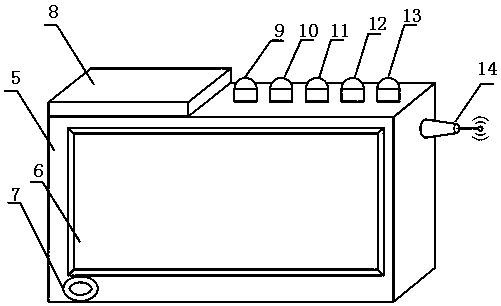

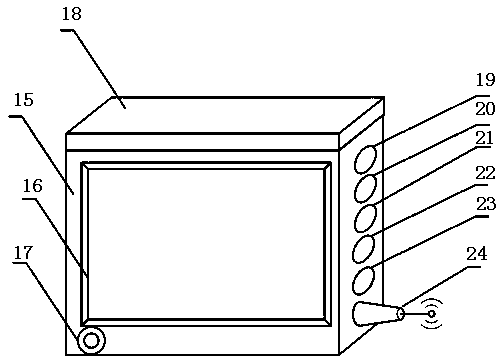

Intelligent control system for pigsty

InactiveCN108064702AMany nodesReliable transmissionTransmission systemsAnimal housingData acquisitionEngineering

The invention provides an intelligent control system for a pigsty and relates to an environmental control system. A liquid crystal display is arranged on the front of a host of a data acquisition device of the intelligent control system, an infrared receiver is arranged on the front lower left corner, a solar photovoltaic panel covers the left side of the upper portion of the host, and five sensors are disposed on the right side of the upper portion of the host and are sequentially a temperature sensor, a humidity sensor, a carbon dioxide concentration sensor, a light sensor and an ammonia concentration sensor from left to right, and a ZigBee antenna is disposed on the right side of the host. The temperature sensor, the humidity sensor, the carbon dioxide concentration sensor, the light sensor and the ammonia concentration sensor are connected to an MSP430FR2000 microprocessor in the host through series ports respectively. The front of the environmental control host is provided with the liquid crystal display, the front lower left corner of the host is provided with an infrared remote control receiver, and the upper portion of the host is covered with a solar cell panel. Accordingto the system, through the pigsty data acquisition device, the growth environment of pigs in the pigsty is adjusted so that the environment in the pigsty can meet the pig growth requirements.

Owner:SHENYANG UNIV

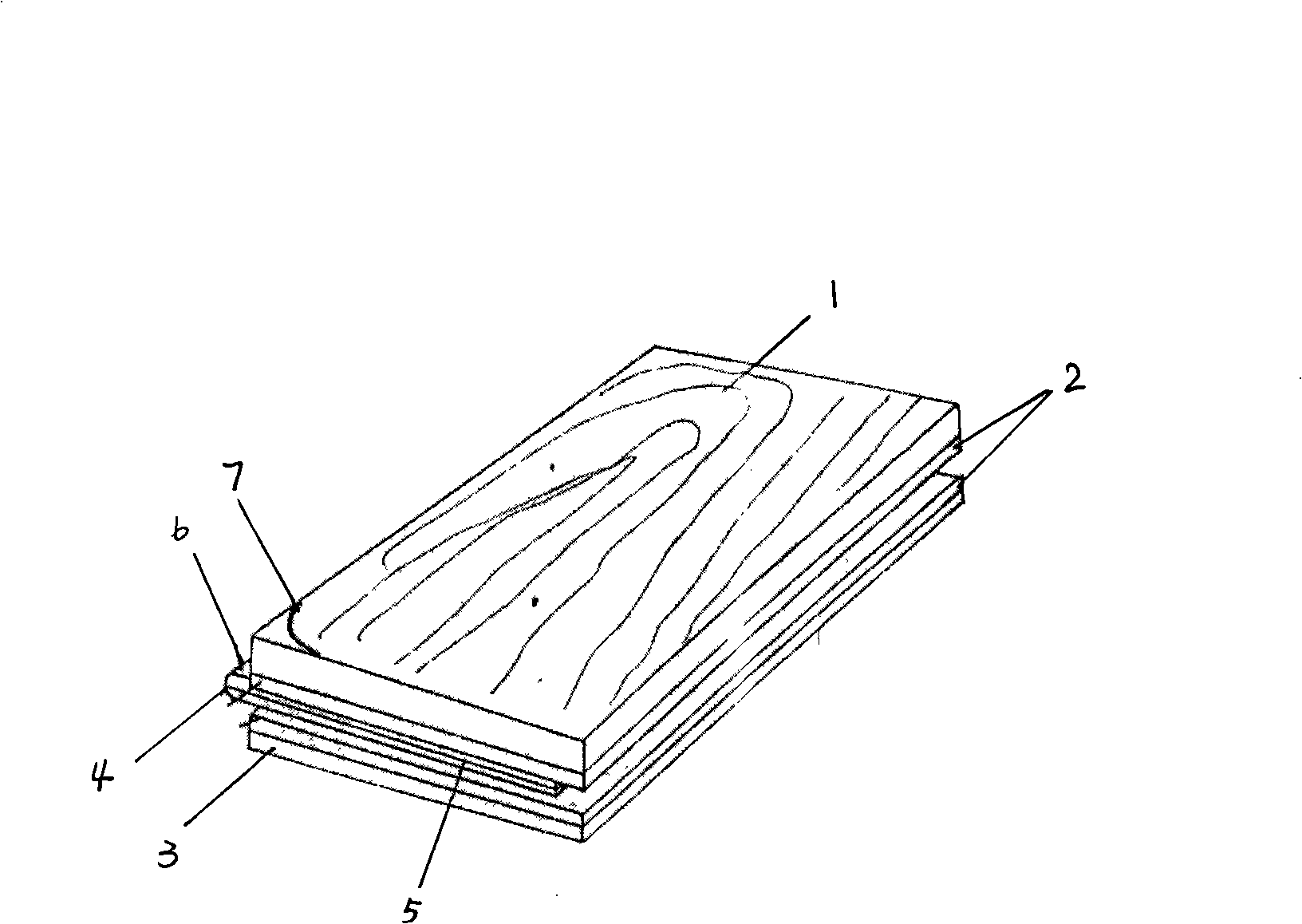

Method for manufacturing primary composite multi-layer wood floor

InactiveCN101318346ASimplify the balance layerImprove environmental indicatorsWood working apparatusAldehyde/ketone condensation polymer adhesivesSolid woodHeat press

The invention relates to a method for manufacturing a composite multi-layer solid wood floor at one time and the floor is veneered by heat pressing dash boards, core boards, central boards and back boards at a time. The method of the invention uses low-value and middle-and-low diameter class crude wood and reasonably processes the high and low quality single boards, thus simplifying the processing procedures of the floor, increasing the processing efficiency, and raising the product quality and stability.

Owner:JILIN FOREST IND GRP JINQIAO FLOORING GRP

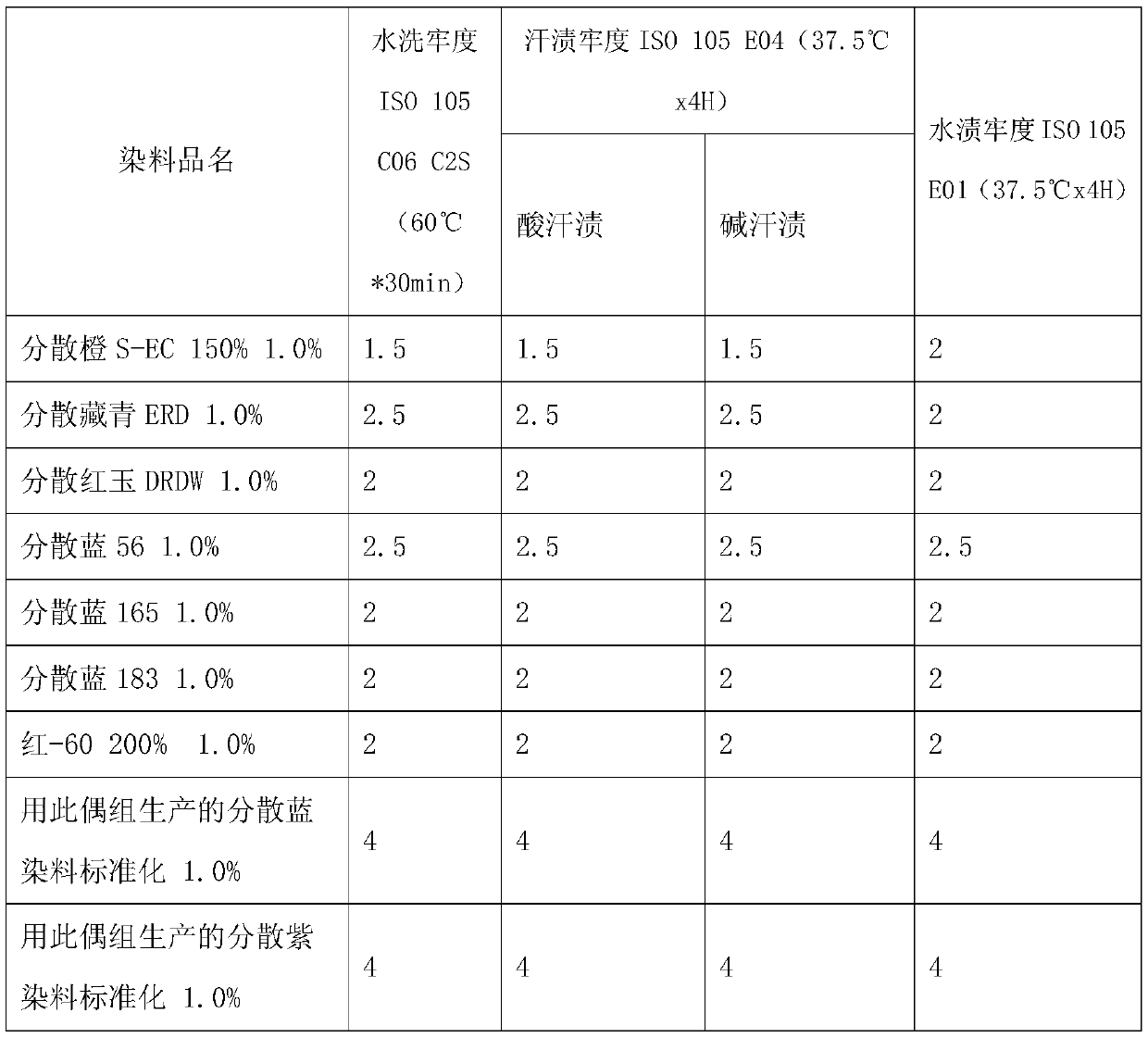

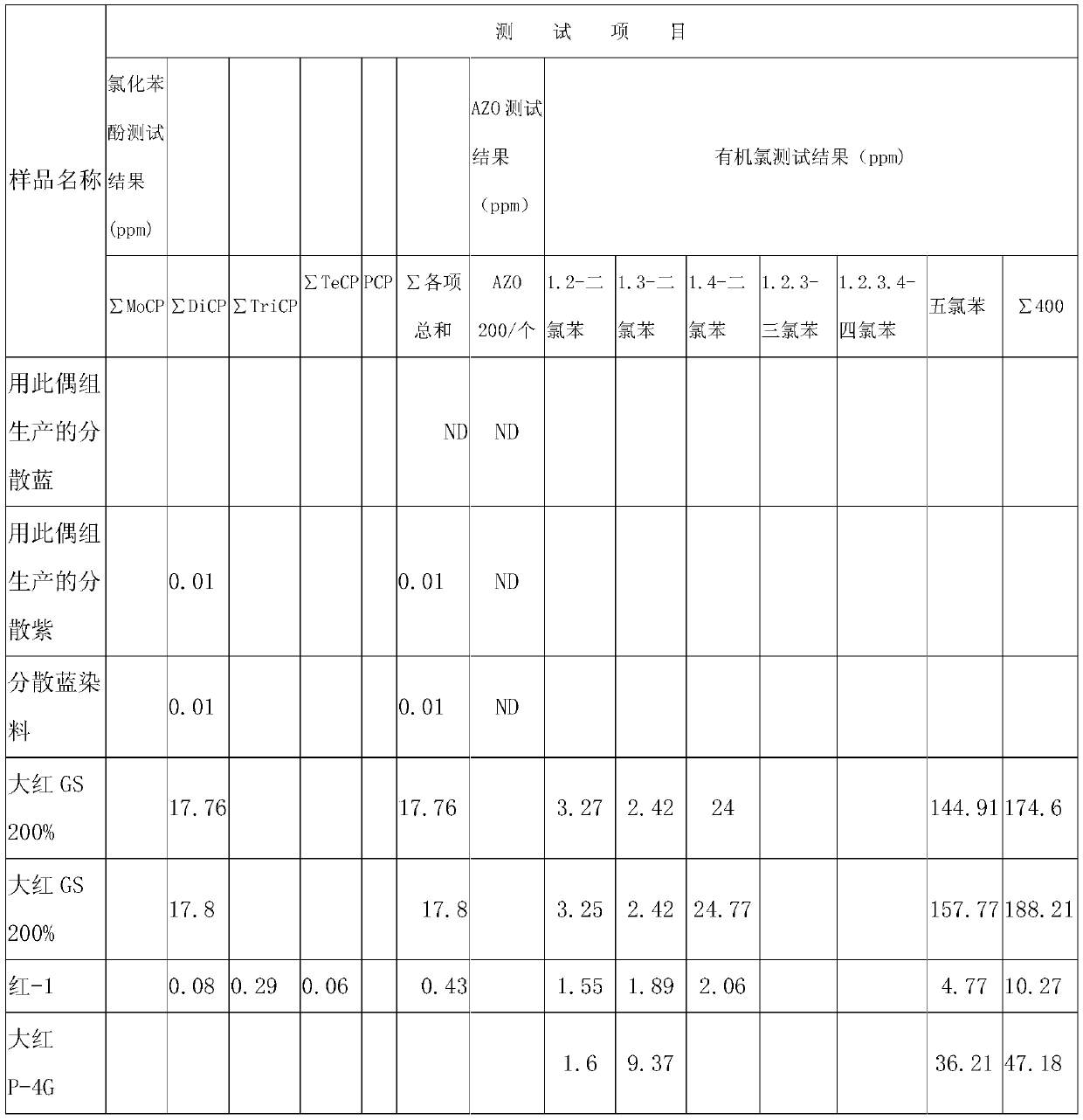

Disperse blue dye coupling component and preparation method thereof

The invention discloses a disperse blue dye coupling component, which is characterized by comprising the following components in parts by weight: 115-136 parts of methyl chloroacetate, 550-580 parts of sodium carbonate, 68-75 parts of a reduction product, 10-13 parts of sodium bromide, and 180-220 parts of acetic acid. The invention also discloses a preparation method of the disperse blue dye coupling component. The main innovation point of the invention is as follows: a blue disperse dye produced from the coupling component is low in cost, high in fastness and good in environmental protectionindex, and especially meets the fastness requirement of polyester and polyurethane fabrics.

Owner:DONGYING ANNUOQI TEXTILE MATERIALS +3

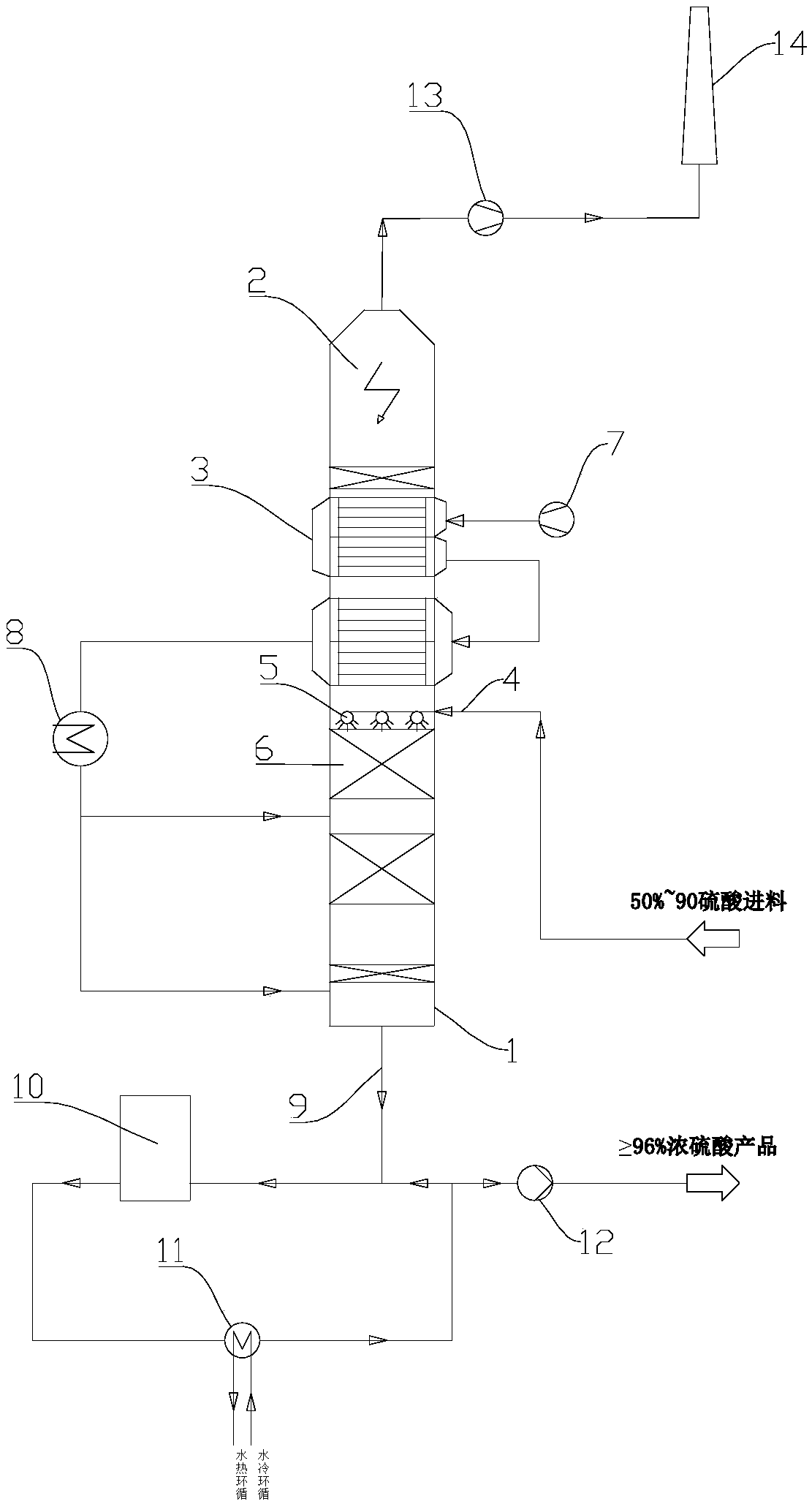

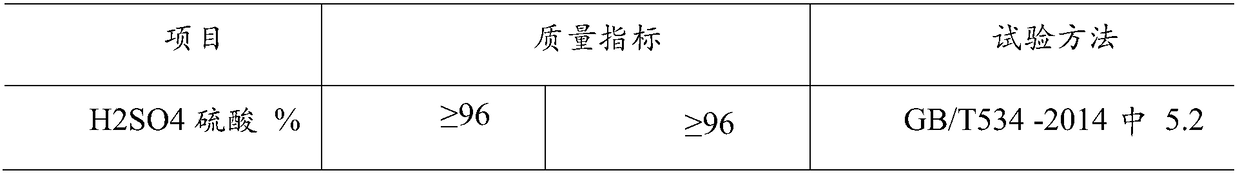

Sulfuric acid concentration equipment and process

The invention relates to sulfuric acid concentration equipment and a sulfuric acid concentration method. The sulfuric acid concentration equipment comprises a concentration tower, wherein the top of atower body of the concentration tower is provided with a gas phase outlet, the middle of the tower body is provided with a liquid phase inlet, the bottom of the tower body is provided with a liquid phase outlet, and the lower end of the tower body is provided with a plurality of gas phase inlets; the concentration tower comprises a stripping section positioned at the lower part and a rectification section positioned at the upper part; a plurality of glass tube heat exchangers are arranged at intervals from top to bottom in the rectification section; shell sides of the glass tube heat exchangers are connected in the rectification section; an external hot air gas source feeds hot air into the concentration tower from the gas phase inlets to carry out gas stripping on dilute sulfuric acid; and process gas in the stripping section forms full reflux in the shell sides of the plurality of glass tube heat exchangers in the rectification section. The apparatus provided by the invention has the advantages of small occupied area, high environmental protection index and good concentration effect.

Owner:HARBIN BOAO ENVIRONMENTAL TECHNOLOGY CO LTD

Degradable plastic granule

The invention discloses degradable plastic granules which are prepared from the following raw materials in parts by weight: 30-40 parts of a glass fiber, 30-50 parts of polylactic acid, 10-20 parts of hydroxybutyric acid, 10-20 parts of polyethylene terephthalate, 5-8 parts of graphene, 3-5 parts of a curing agent and 5-10 parts of an adhesive. The degradable plastic granules are good in stability and high in security and can be degraded within a short time, and the environment can be protected.

Owner:贵州通汇塑料科技有限公司

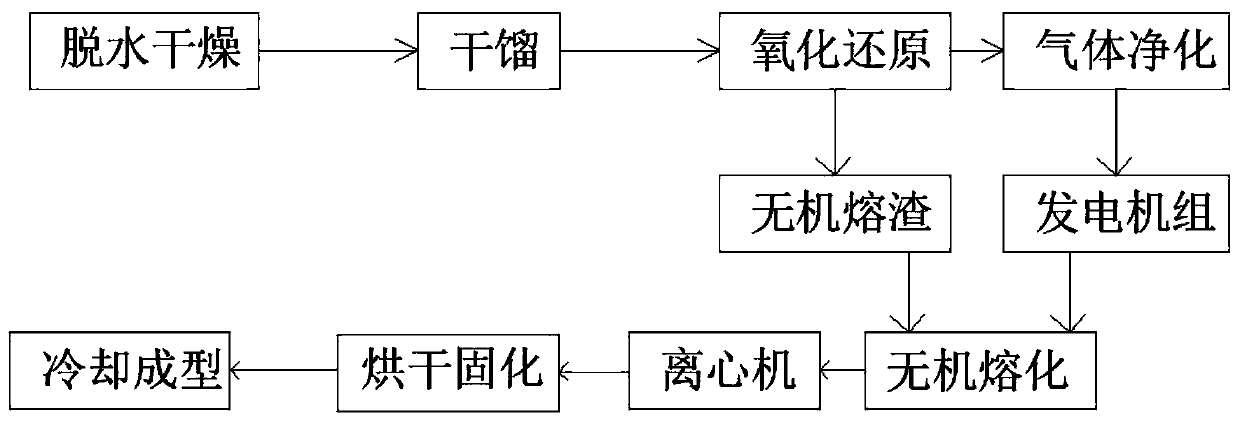

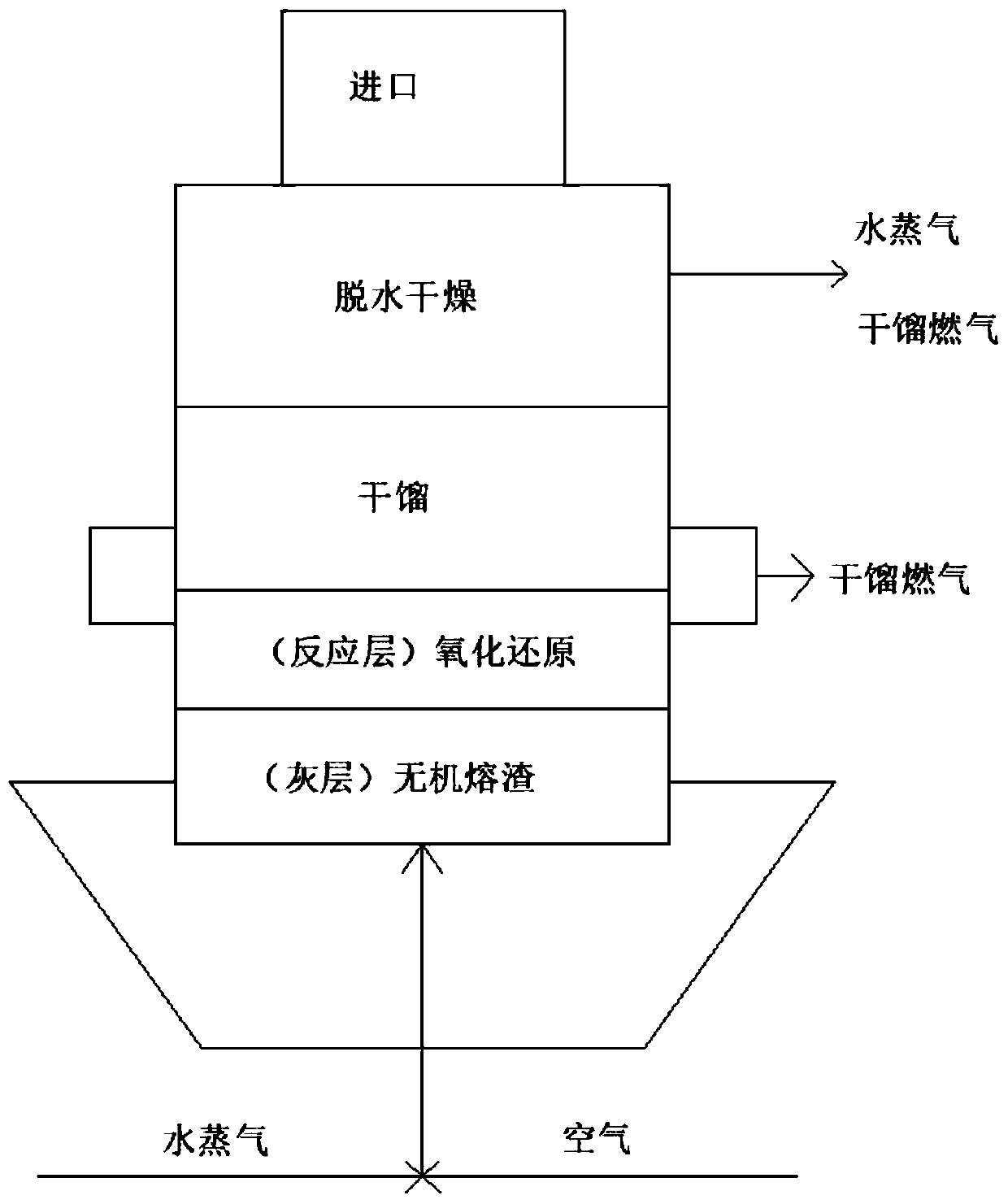

Method for preparing rock wool by gasifying and melting industrial activated sludge for power generation

InactiveCN111499129AOxygen exclusionAvoid contamination riskGlass making apparatusSludge treatment by de-watering/drying/thickeningActivated sludgeAlkane

The invention discloses a method for preparing rock wool by gasifying and melting industrial activated sludge for power generation. A whole set of system method is formed by relying on drying, granulation, gasification, power generation and rock wool preparation. On the premise of no odor and no pollution, reduction, harmlessness and recycling of large-scale industrial activated sludge are realized, organic matters are pyrolyzed into combustible gases such as carbon monoxide, hydrogen and alkanes, the combustible gases enter a fuel gas power generator set, generated electric power is used forrock wool production and can be more conveniently and cleanly utilized, and resource recycling economy is achieved; sludge is subjected to heat gasification melting high-temperature treatment, the size is greatly reduced, gasified organic matter generates power in a gas form, power generation is used for melting residual inorganic matter to prepare rock wool, the density of the inorganic matter ishigher, the mass is heavier, the strength is greatly improved, and the method can be used for rock wool production.

Owner:杨绪涛

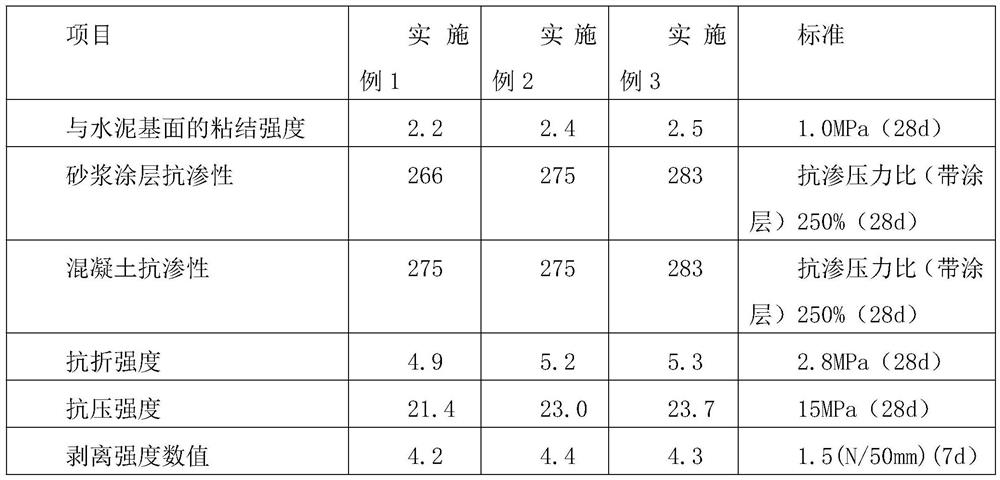

Capillary crystalline waterproof coating and waterproof coiled material composite waterproof system and construction method thereof

PendingCN113668714AAdhesive firmly and obedientlyGood waterproof effectBuild-up roofsProtective foundationPolyolefinHigh-density polyethylene

The invention relates to a capillary crystalline waterproof coating and waterproof coiled material composite waterproof system and a construction method thereof. The capillary crystalline waterproof coating and waterproof coiled material composite waterproof system comprises a capillary crystalline waterproof coating layer and a waterproof coiled material layer, wherein the capillary crystalline waterproof coating layer is blade-coated on a base surface, and the waterproof coiled material layer is immediately attached to the blade-coated capillary crystalline waterproof coating layer; the waterproof coiled material layer is a thermoplastic polyolefin waterproof coiled material or a high-density polyethylene self-adhesive film waterproof coiled material; a capillary crystalline waterproof coating is prepared from the following components in parts by mass: 50-500 parts of Portland cement, 400-800 parts of heavy aggregate of 70-140 meshes, 10-100 parts of capillary crystalline master batch, 5-20 parts of dispersible latex powder, 0.1-10 parts of water-retaining agent and 1-10 parts of water reducing agent. According to a construction method of the capillary crystalline waterproof coating and waterproof coiled material composite waterproof system, a substrate and the waterproof coiled material are firmly and tightly bonded, and the waterproof effect is good.

Owner:上海三棵树防水技术有限公司

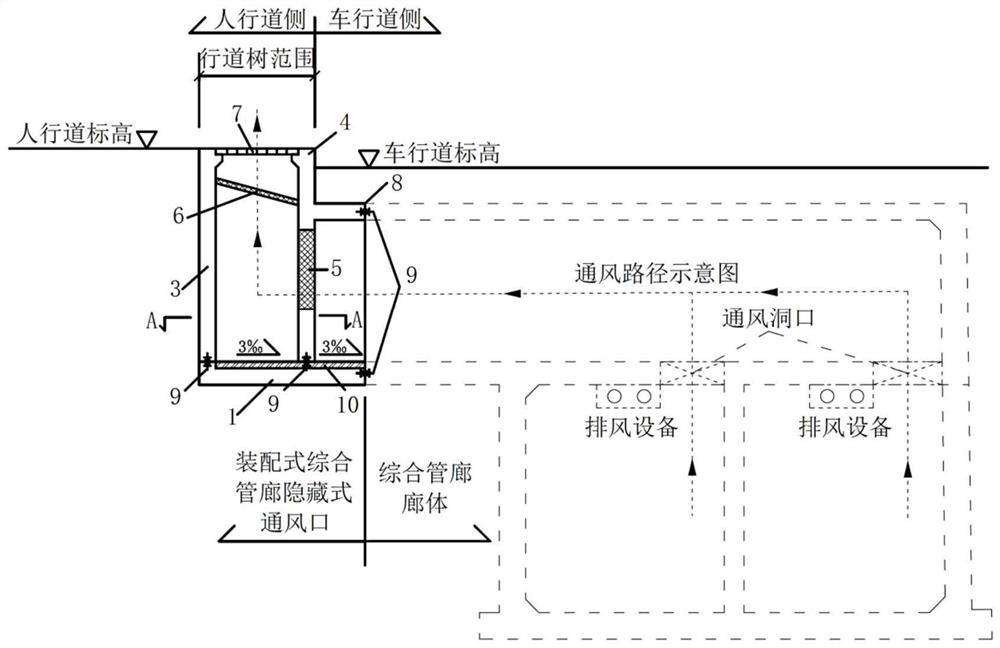

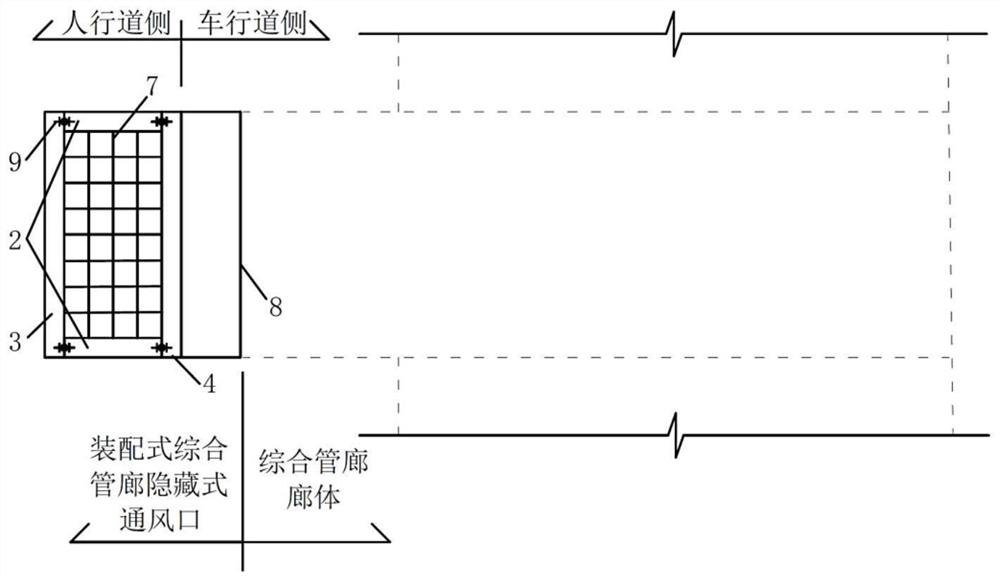

Assembly type comprehensive pipe gallery hidden ventilation opening structure

InactiveCN112814026AOvercome defects such as inability to coordinate and unifyShort construction periodArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention discloses an assembly type comprehensive pipe gallery hidden ventilation opening structure. The assembly type comprehensive pipe gallery hidden ventilation opening structure is composed of a bottom plate, side walls, an outer side wall, an inner side wall, a ventilation steel grating, a garbage-proof grating net, an anti-theft and anti-corrosion grating cover plate, a connector, a rubber steel plate water stop belt, a prestressed anchor bolt and other prefabricated reinforced concrete components or standardized structures. Assembly type comprehensive pipe gallery hidden ventilation openings are formed between sidewalk tree pools every 200 meters in the longitudinal direction of a comprehensive pipe gallery, and a complete ventilation system is formed by the assembly type comprehensive pipe gallery hidden ventilation openings, a comprehensive pipe gallery body and mechanical ventilation equipment. The assembly type comprehensive pipe gallery hidden ventilation opening structure is simple in structure and easy and convenient to construct, can be applied to a newly-built comprehensive pipe gallery ventilation structure arranged between the sidewalk tree pools and can also be applied to upgrading and reconstruction of a built comprehensive pipe gallery ventilation structure protruding out of the ground by a certain height, and therefore coordination and unification with urban landscape are achieved, and high generalizability is achieved.

Owner:南京大地建设科技有限责任公司

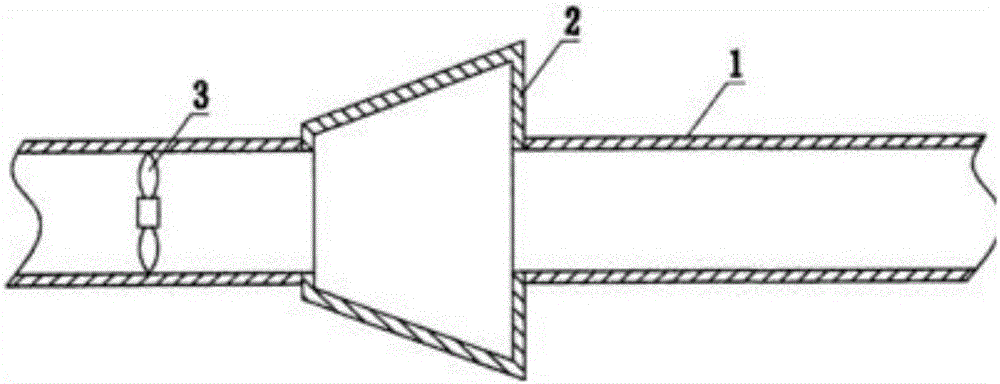

Efficient mixer used for car

InactiveCN106014699AImprove environmental indicatorsGuaranteed uptimeInternal combustion piston enginesFuel supply apparatusMixed fuelExhaust gas

The invention provides an efficient mixer used for a car. The efficient mixer comprises a mixer housing, wherein a fuel gas pressure-regulating chamber for stably conveying mixed fuel gas is mounted on the mixer housing; a fuel gas accelerating and mixing device is further mounted on the mixer housing; and the fuel gas accelerating and mixing device is positioned at a gas inlet side of the fuel gas pressure-regulating chamber. According to the efficient mixer used for the car provided by the invention, the fuel gas accelerating and mixing device can be used for improving mixing efficiency and mixing uniformity of fuel gas and air, so that fuel gas is completely combusted, and therefore, environmental protection indexes of car exhaust gas are favorably improved; and the fuel gas pressure-regulating chamber is arranged, so that flow velocity of mixed fuel gas is uniform, and therefore, stable operation of the car is convenient.

Owner:成都安程通科技有限公司

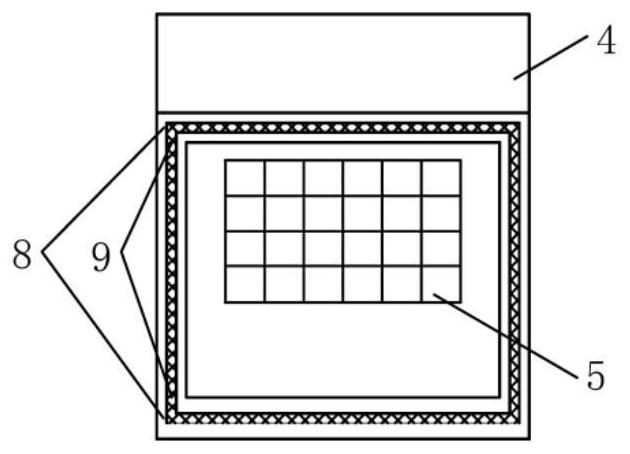

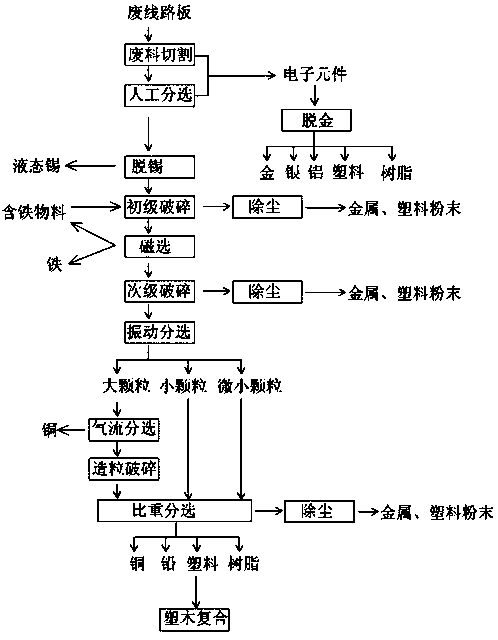

Recycling processing technology for waste circuit board

ActiveCN102671916BRealize recyclingEfficient separationWaste processingSolid waste disposalPrinted circuit boardPollution

The invention discloses a recycling processing technology for a waste circuit board and relates to the recycling processing technology for waste resources. The recycling processing technology comprises the following steps of: cutting wastes; manually separating; removing gold; removing tin; primarily crushing; magnetically separating; secondarily crushing; separating by vibrating; separating through airflow; crushing pellets; separating according to specific gravity; compounding plastic and wood; and lastly, respectively recycling the matters, such as gold, silver, aluminum, iron, tin, copper, lead, plastic and resins, thereby reusing the matters. The recycling processing technology has the advantages that: (1) the flow line production operation is realized, the degree of automation is high and the yield is high; (2) compared with the traditional processing method, the recycling processing technology effectively reduces the emission of toxic gas and water and improves the environmental protection index; and (3) various matters in the waste circuit board are more effectively separated, the noble metal is recycled, the recycling of resources is realized, the mineral resource exploitation and wood felling are indirectly reduced, and the energy consumption and pollution during the processes of mineral resource exploitation and metallurgy processing are reduced.

Owner:NINGBO HUILONG MACHINERY CO LTD

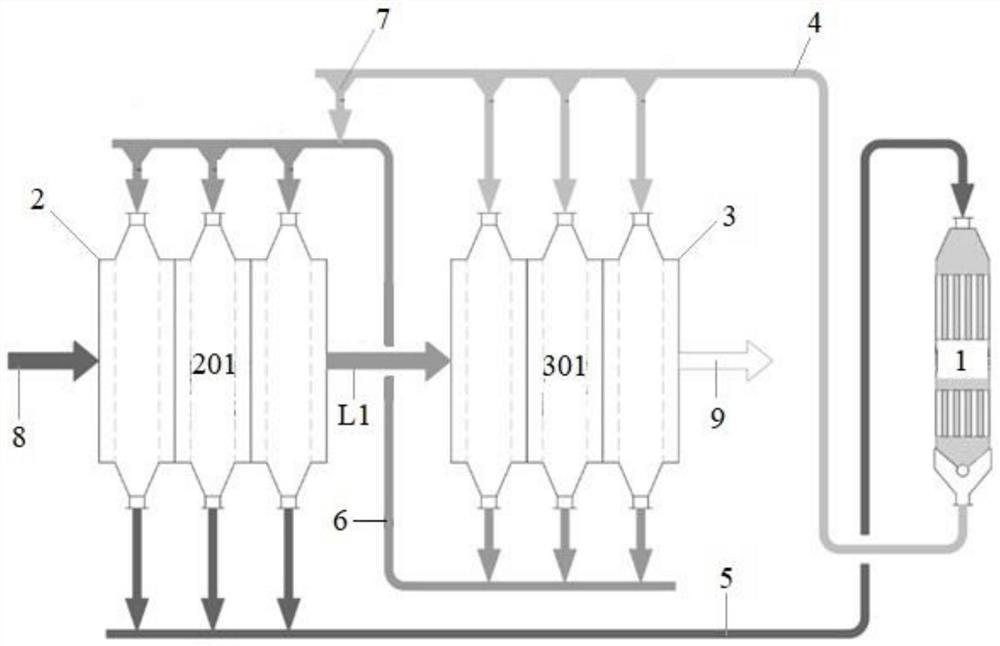

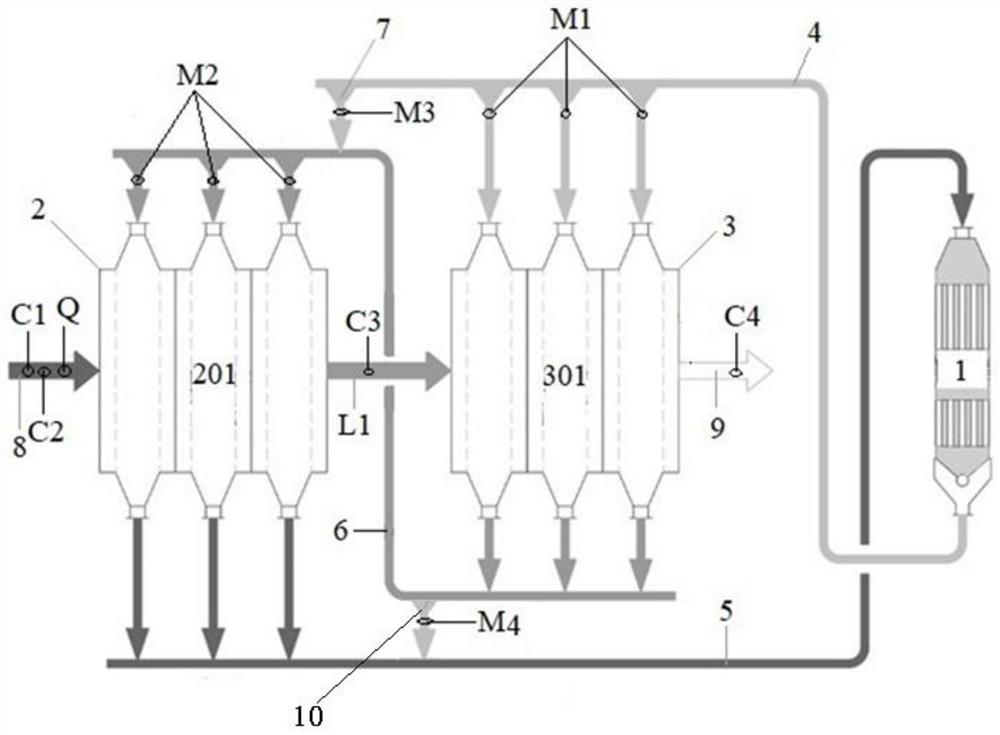

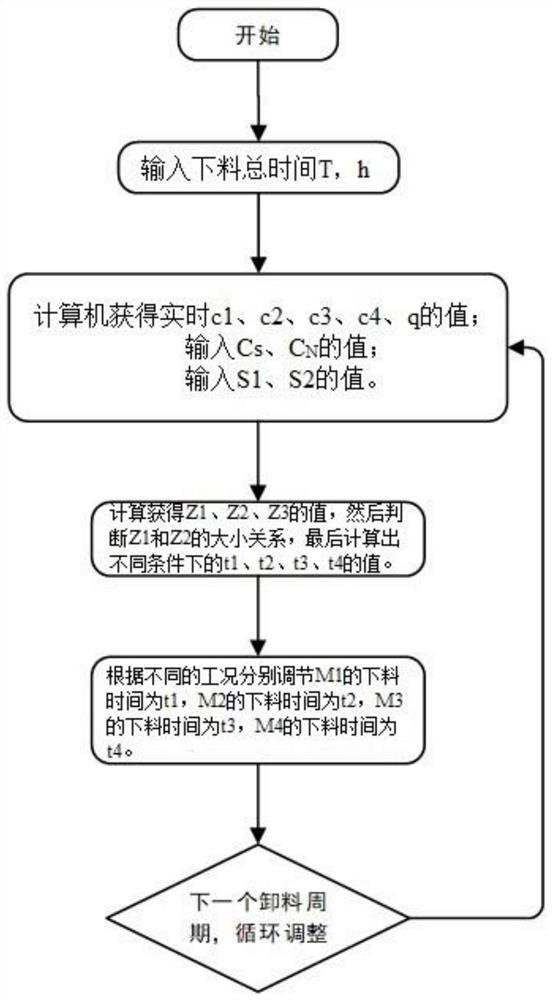

Distributing system and method for flue gas desulfurization and denitrification activated carbon

ActiveCN112403189BPrecise control of circulation volumeReduce total circulationGas treatmentDispersed particle separationActivated carbonFlue gas

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com