Edible environmentally-friendly glutinous rice glue composition used for pasting wallpapers, and production method thereof

A technology of composition and glutinous rice glue, applied in the directions of starch adhesives, starch-derived adhesives, polymer adhesive additives, etc., can solve the problems of insufficient environmental protection level of auxiliary agents, and achieve the solution of secondary pollution defects and improve Product quality and brand image, the effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

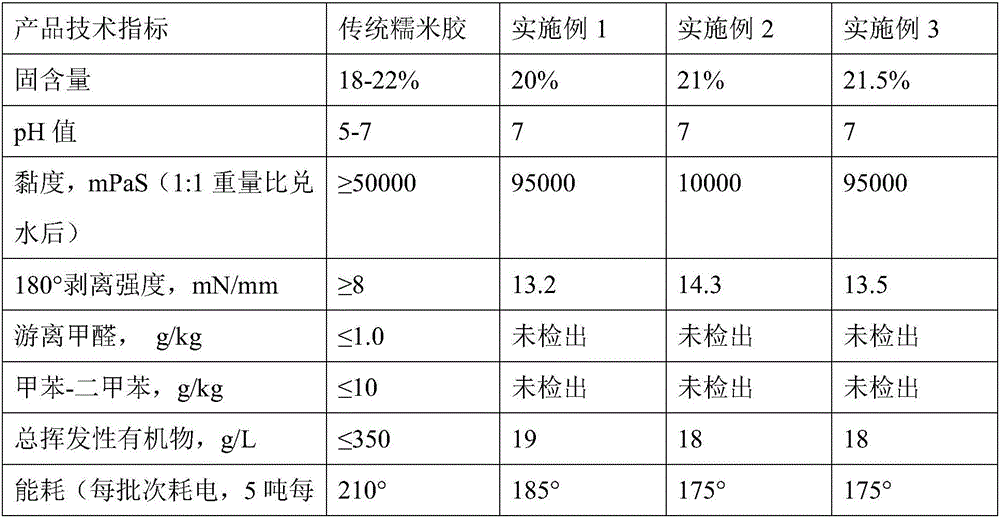

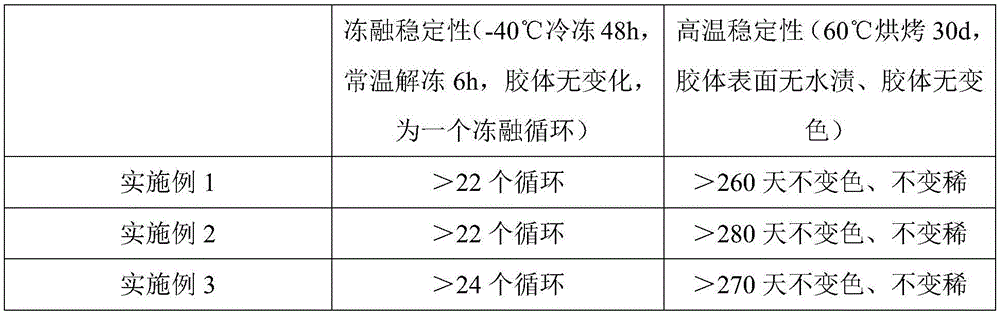

Examples

Embodiment 1

[0019] A kind of preparation method of glutinous rice glue composition for pasting edible grade environment-friendly wallpaper, concrete process is as follows:

[0020] Step A: Put the raw materials into the reaction kettle to adjust the slurry, after stirring evenly, slowly heat the reaction kettle to 95°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0021] The raw material formula is (total weight is 100%): modified starch A 5%, modified starch B 8%, waxy rice starch 8%, waxy corn starch 10%, sodium trimetaphosphate 1%, antiseptic antifungal agent 2%, 0.3% of monoglyceride, 2% of gluconolactone, 1% of sorbitol, 2% of thickener, 0.6% of citric acid, 0.15% of stabilizer, and the balance is deionized water. The stabilizer is 0.1% of monoglyceride laurate and 0.05% of EDTA-disodium. The anticorrosion and antifungal agent is 0.5% of potassium sorbate, 0.5% of calcium propionate, 0.2% of sodium benzoate, 0.6% of natam...

Embodiment 2

[0024] A kind of preparation method of glutinous rice glue composition for pasting edible grade environment-friendly wallpaper, concrete process is as follows:

[0025] Step A: Put the raw materials into the reaction kettle to make slurry, stir evenly, then slowly heat the reaction kettle to 85°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0026] The raw material formula is (total weight is 100%): 8% of modified starch A, 3% of modified starch B, 10% of waxy rice starch, 5% of waxy corn starch, 0.5% of sodium trimetaphosphate, 0.9% of antiseptic and antifungal agent, 0.1% of monoglyceride, 3% of gluconolactone, 0.2% of sorbitol, 2% of thickener, 1.2% of citric acid, 0.03% of stabilizer, and the balance is deionized water. The stabilizer is acetylated monoglyceride fatty acid ester. The antiseptic and antifungal agent comprises 0.5% of potassium sorbate, 0.2% of natamycin and 0.2% of chitosan.

[0027] Step B: At...

Embodiment 3

[0029] A kind of preparation method of glutinous rice glue composition for pasting edible grade environment-friendly wallpaper, concrete process is as follows:

[0030] Step A: Put the raw materials into the reactor to make slurry, stir evenly, then slowly heat the reactor to 90°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0031] The raw material formula is (total weight is 100%): 6% of modified starch A, 6% of modified starch B, 46% of waxy rice starch, 15% of waxy corn starch, 0.5% of sodium trimetaphosphate, 3% of antiseptic and antifungal agent, 0.5% monoglyceride, 1% gluconolactone, 0.6% sorbitol, 2% thickener, 0.5% citric acid, 0.10% stabilizer, and the balance is deionized water. The stabilizer is 0.05% of monoglyceride laurate and 0.05% of EDTA-tetrasodium. The anticorrosion and antifungal agent comprises 0.5% of potassium sorbate, 0.5% of calcium propionate, 0.5% of sodium benzoate, 0.6% of natamycin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com