Unit plant control system and method based on real-time online analysis of coal quality

A unit unit, coal quality technology, applied in the direction of controlling combustion, combustion method, adjusting fuel supply, etc., can solve problems such as inability to obtain coordination and combustion, poor calibration matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail below in conjunction with accompanying drawing:

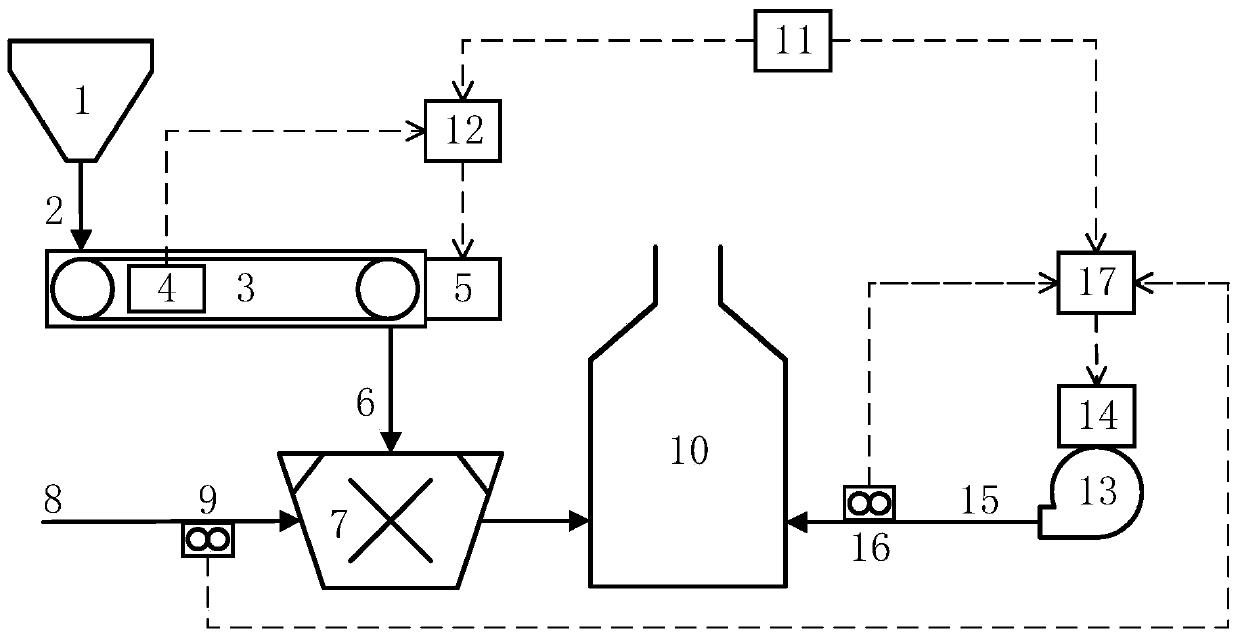

[0047] Such as image 3 As shown, a unit unit control system based on real-time online analysis of coal quality provided by the present invention includes a raw coal hopper 1, a raw coal hopper outlet pipeline 2, a coal feeder belt 3, a weighing instrument 4, a coal feeder variable speed motor 5, Coal feeder outlet pipe 6, coal mill 7, coal mill inlet primary air duct 8, primary air volume measuring element 9, boiler furnace 10, coal quality online monitoring module 11, coal feeding controller 12, blower 13, blower variable output Element 14 , air supply duct 15 , secondary air volume measuring element 16 and secondary air controller 17 .

[0048] Among them, the coal in the raw coal hopper 1 falls on the coal feeder belt 3 through the raw coal hopper outlet pipe 2, and the coal feeder variable speed motor 5 changes the motor speed according to the demand of the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com