Patents

Literature

51results about How to "Good technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

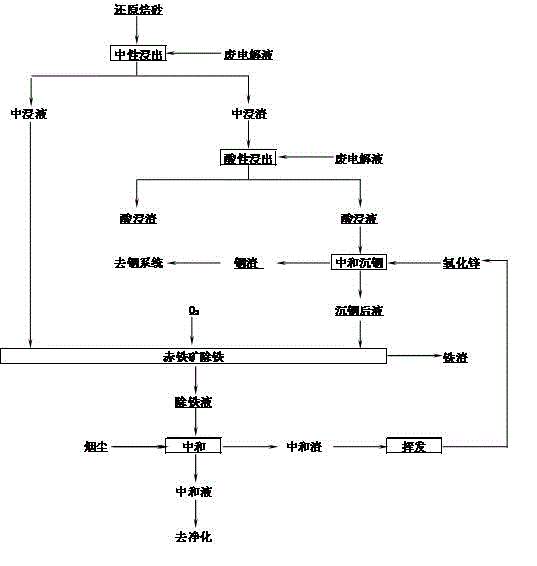

Method for extracting indium and zinc from high-iron indium-containing zinc calcine and preparing iron oxide

InactiveCN102560087AImprove leaching performanceExcellent leaching indexFerric oxidesProcess efficiency improvementSlagOre concentrate

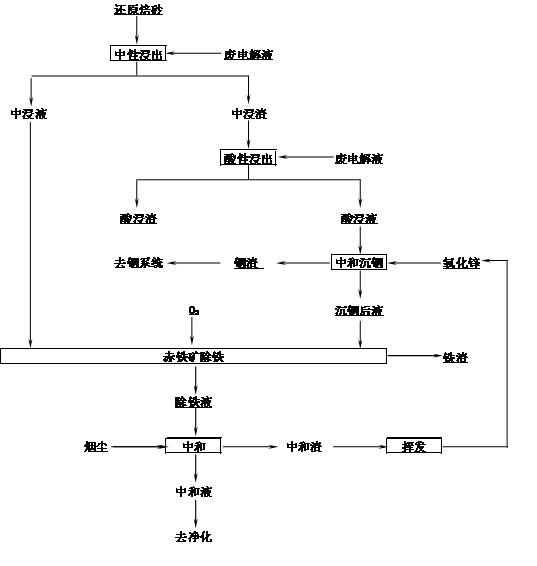

The invention relates to a method for extracting indium and zinc from high-iron indium-containing zinc calcine and preparing iron oxide. A zinc ferrite structure in the high-iron indium-containing zinc calcine is damaged by reduction roasting, elements such as zinc, iron and indium in the reduced calcine are obtained by neutral leaching and acid leaching, indium-rich slag is obtained by neutralization for precipitating indium, the iron grade of slag obtained by removing iron from hematite under high pressure is high, an industrial iron oxide product can be obtained by acid washing and roasting, and liquid obtained after the iron is removed can be directly purified and electrolyzed after being neutralized by smoke. A technical route of maximally extracting base metal such as the indium, the zinc and the like and recycling associated iron minerals simultaneously is provided, and the problems that the recovery rate of the indium is low and the iron cannot be recycled in the process of smelting a high-iron indium-containing zinc concentrate at present are solved; and a clean production technology which combines effective extraction of the base metal with effective utilization of associated iron is provided for treating the indium, the zinc and other high-iron non-ferrous metal materials.

Owner:广西冶金研究院有限公司

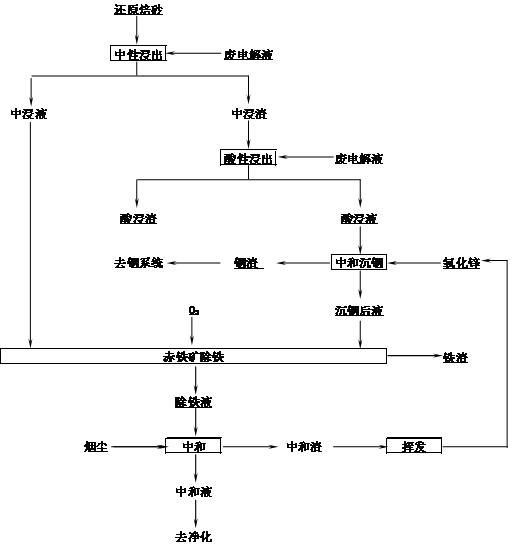

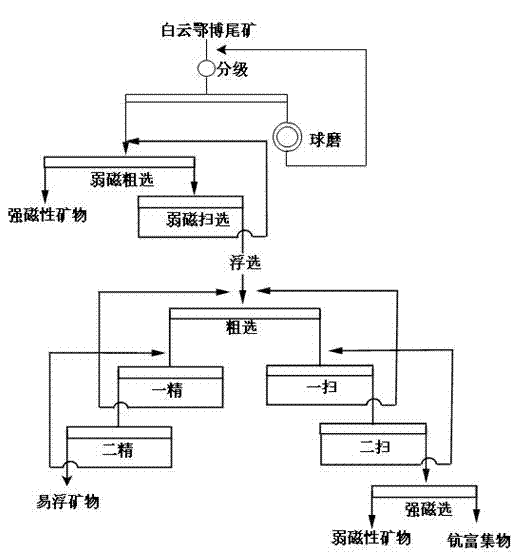

Ore separation method for recycling scandium from bayan obo tailings

The invention discloses an ore separation method for recycling scandium from bayan obo tailings. According to the ore separation method, the bayan obo tailings are graded firstly, and then the obtained coarse ore grains are ground and then returned to be graded and fine ore grains are pulped and then subjected to floatation, thus forming a closed circuit grinding flow; floatation is the closed circuit flow of fractionation and comprises rough floatation, fine floatation and scavenging, wherein the floatation concentrates are easily floating minerals such as fluorite and rare earth; the floatation tailings are subjected to magnetic separation including low intensity magnetic separation and high intensity magnetic separation, and light ore grains obtained after the non magnetic ore obtained through magnetic separation is separated again are scandium concentrates, wherein the obtained scandium concentrates has high scandium content being more than 500g / t and the recycling rate being higher than 60%. The method creates a breakthrough for directly recycling scandium from bayan obo tailings, is simple in process and also provides high-grade bayan obo tailings from which rare earth, fluorite and iron can be recycled.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

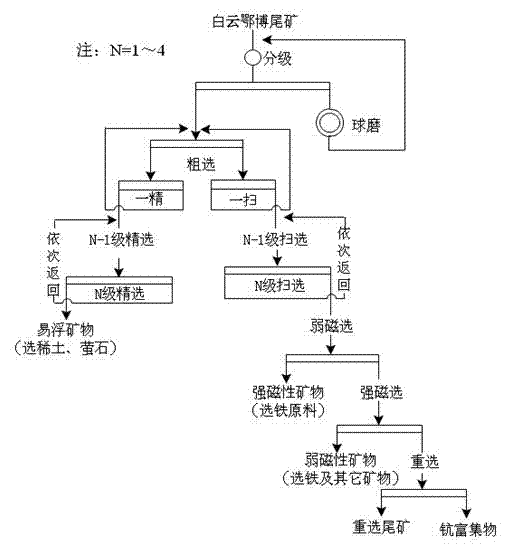

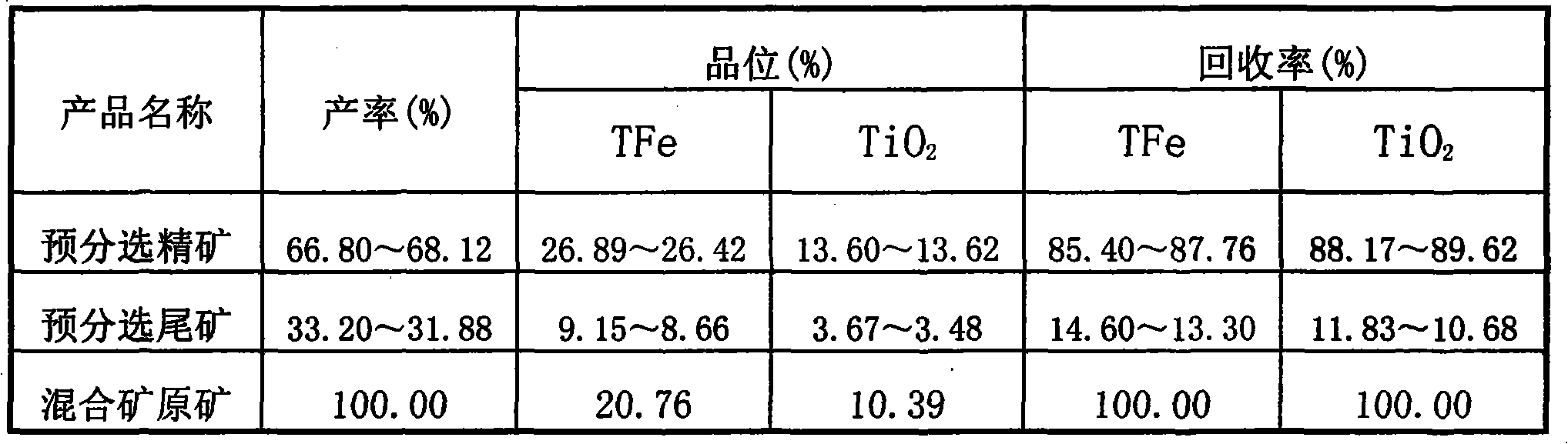

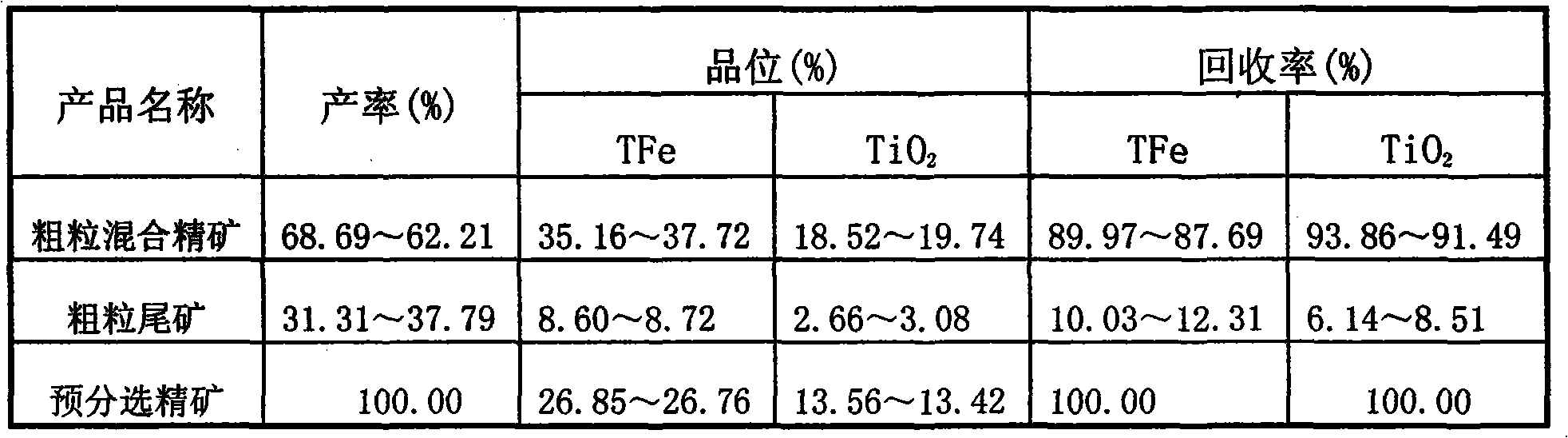

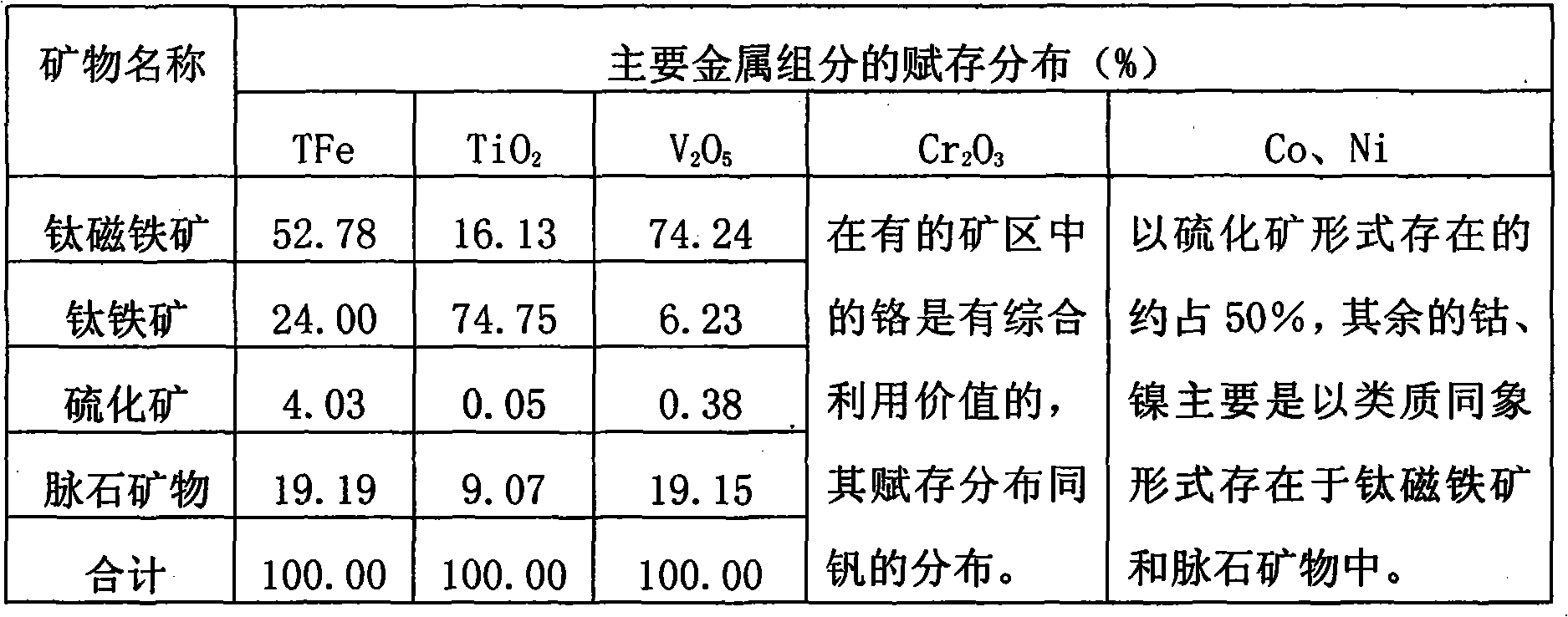

Beneficiation method for comprehensively using vanadium-bearing titanomagnetite low-grade lean ore and ore below cut-off grade

ActiveCN102166542AReduce stripping ratioImprove resource utilizationWet separationBeneficiationLow graded

The invention discloses a beneficiation method for comprehensively using vanadium-bearing titanomagnetite. The method comprises the following steps of: performing mixed exploiting of ore above cut-off grade and ore below cut-off grade; crushing the mixed ore into ore with the granularity of 10mm completely, performing weak magnetic rough flotation or medium magnetic rough flotation on the crushedproduct to select out mineral aggregates of which the main component is the anadium-bearing titanomagnetite, performing strong magnetic scavenging on rougher tailings to select out the mineral aggregates of which the main component is ilmenite, combining the mineral aggregates into a pre-sorted concentrate, and discarding gangue of which the yield is 31.88 to 33.20 percent; performing I section coarse grinding the concentrate into concentrate with the granularity of 1mm completely, performing weak, medium and strong magnetic separation, discarding coarse gangue, performing II section fine grinding on the obtained coarse mixed concentrate to grind the obtained concentrate into concentrate with the granularity of 0.15mm completely, adding a modifier, a yellow catching agent and a foaming agent into the product of the II section ore grinding to perform flotation for a sulfide ore and obtain high-quality linnaeite; performing weak magnetic separation on titanomagnetite on tailings of the flotation for the sulfide ore to obtain high-quality iron ore concentrate; and performing strong magnetic titanium separation on tailings of iron separation, further gathering the ilmenite to obtain strong magnetic separation concentrate, and adding the modifier, sodium aliphatate and an auxiliary catching agent into the strong magnetic separation concentrate to perform flotation for the ilmenite and obtain high-quality titanium concentrate.

Owner:SICHUAN LOMON MINING & METALLURGY +1

Preparation method of macromolecule resin composite bipolar plate for ion exchange membrane fuel battery

The invention belongs to the fuel battery technique, relating to a method for preparing proton exchange membrane fuel battery with high polymer resin composite bipolar plate. The preparing method comprises: adding globular graphite in 70-80wt%, thermoplastic polyimide resin in 15-25wt%, coupling agent (KH-560) in 0.5-1.5wt% and polar plate fiber reinforcing agent (staple carbon fiber) in 3-10wt% into mixing machine to be mixed for 15-35 minutes; mixing and heating to 80-100Deg. C, to be put into the mould which has been heated to 80-100Deg. C; the vacuum degree of vacuum hydraulic presser is -0.085MPa, the compression molding temperature of mixed material is controlled in 120-180Deg. C, the compression molding pressure is 0.5-15MPa, and the warm-keeping time of composite dipolar plate in the hydraulic presser is controlled in 2-50 minutes; the product is demoulded and laid into oven for final treatment while the temperature is in 80-180 Deg. C, and the time is 0.2-2 hours, then extracting the product to be cooled in room temperature to attain the final product. The quality index of invention can meet the standard of composite bipolar plate of proton exchange membrane fuel battery.

Owner:ZHEJIANG UNIV

Preparation method, application and using process of floating agent prepared from drainage oil

The invention relates to a preparation method, application and using process of a floating agent prepared from drainage oil, wherein the preparation method of the floating agent comprises the following steps of: (a) purifying the drainage oil; (b) carrying out hydrolysis reaction on the purified drainage oil obtained from the step (a) to obtain the floating agent used for floating ores. When the floating agent used by the invention and prepared from the drainage oil is used as a collecting agent for floating the ores, the selectivity of the collecting agent can be enhanced, and the technical indicator and the economic indicator of flotation are enhanced favorably; and in addition, because a raw material used for the preparation of the floating agent is the drainage oil, the technical scheme provided by the invention has important significance on the aspects of preventing environmental pollution, simplifying production process, reducing food security threat, and the like.

Owner:鄂尔多斯市君致清环境科技有限公司

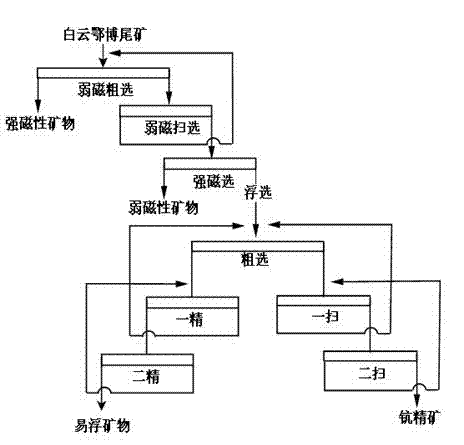

Method for separating scandium from bayan obo tailings

The invention discloses a method for separating scandium from bayan obo tailings, which belongs to the field of mineral separation. The method takes the bayan obo tailings are raw materials and comprises the following steps of: grading the raw materials; grinding obtained coarse granular ores, and then returning and grading the ground ores; carrying out size mixing on fine granular ores, then performing low intensity magnetic separation on the fine granular ores to form a closed circuit grinding process; performing floatation on the selected tailings subjected to the low intensity magnetic separation; and then carrying out high intensity magnetic separation on ore pulp of the tailings subjected to the flotation, thus obtaining non-magnetic ores which are the concentrated scandium. According to the method disclosed by the invention, the fractionation and mineral separation method is adopted, the technology is simple and scientific, the concentrated scandium with the content of scandium oxide being more than 420ppm and the recovery rate being more than 65% can be obtained, and other recyclable resources in the bayan obo tailings can be further concentrated when the concentrated scandium is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for separating scandium concentrate from bayan obo tailings

InactiveCN102886310AScandium oxide contentHigh recovery rateFlotationMagnetic separationScandium oxideMineralogy

The invention discloses a method for separating scandium concentrate from bayan obo tailings, belonging to the field of ore separation. According to a fractionation ore separation method, bayan obo tailings generated after iron separation or rare earth separation are firstly subjected to low intensity magnetic separation, then the tailings obtained through low intensity magnetic separation are subjected to high intensity magnetic separation to obtain non-magnetic ore, and finally the non-magnetic ore is subjected to flotation to obtain scandium concentrate with scandium oxide content being higher than 400ppm, wherein the recycling rate is higher than 65%. The method is simple in separation flow, reasonable in process, and can enrich other recyclable resources in the bayan obo tailings to some extent while recycling scandium; therefore, the method can be used for comprehensively recycling pare and dispersed element scandium from the bayan obo tailings.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

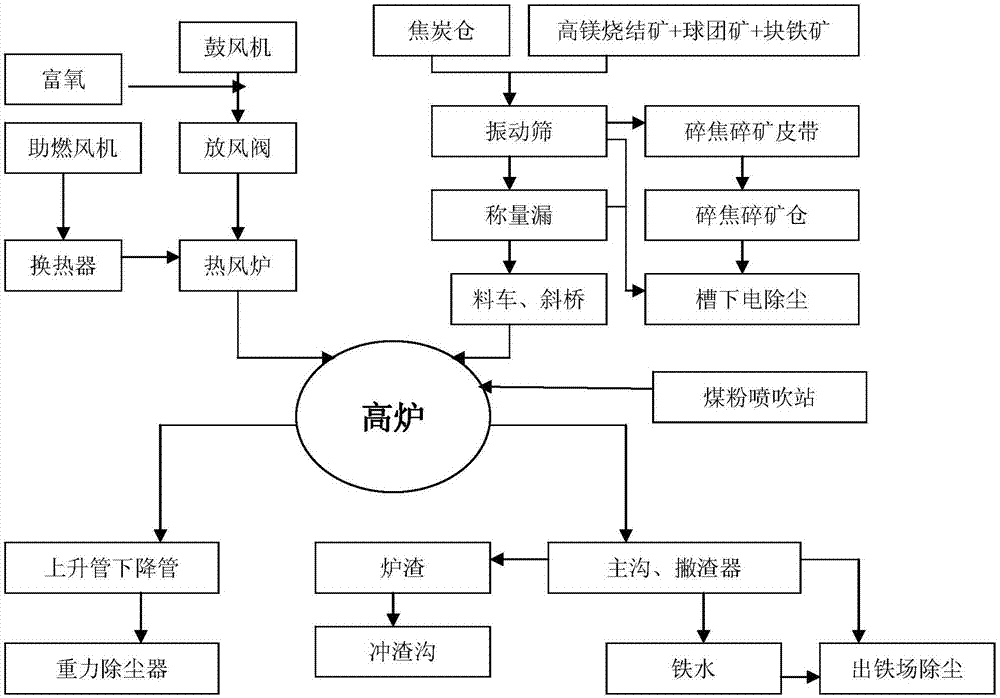

Blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates

A blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates comprises the following steps that (1) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, iron ore concentrate powder, magnesite, lime, return mines and fuel are mixed, and high-magnesium sintered ore is made; (2) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, bentonite and fuel are compacted to be pellets; (3) the high-magnesium sintered ore and the pellets are mixed, lump iron is added, and blast furnace burden materials are made; (4) blast furnace smelting is started, and blast furnace smelting comprises a charging system, an air blowing system, a thermal system and a slag forming system; the wind-warm syndrome is 1100-1200 DEG C, the coke ratio is 330-380 kg / t, and the coal ratio is 160-200 kg / t; and (5) tapping is conducted on molten iron every 70-90 min, and the temperature of the molten iron is 1430-1500 DEG C. According to the blast furnace smelting method of the high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates, the proportion of the high-vanadium chromium-contained type vanadium-titanium iron ore concentrates in blast furnace smelting raw materials is improved, and the ironmaking cost is reduced; and the blast furnace utilization factor is improved, the comprehensive coke ratio is greatly reduced, and meanwhile the metal yield is kept at a high level.

Owner:NORTHEASTERN UNIV

Production of strong abrasive band paper

InactiveCN101074547AGood technical indicatorsMeet the use requirementsSpecial paperPulp beating methodsSulfateSlurry

The invention relates to a method of potent abrasive belt base paper production which is to make paper in multicylinder and multiple nets paper machine, spray amylum and gelatinize the surface in the net of the machine continuously ; the production process is: preparing the main raw material of unbleached pulpboard, bleached sulfate pulpboard firstly; then adding light calcium, and smashing pulp by hydraulic pulper before entering mill pond, then entering into slurry pond after refining by the double-mill, and then transferring it into the plasm adjusting box while adding AKD, PAE, the heat-resistant agent and anti-oil agent; the adjusted pulp is got rid of waste by cleaner and was added in the retention agent and dyes which enters into the nets of the multicylinder and multiple nets paper machine by the pulp pump and rotor screen; after spraying amylum in nets, it is covered with the glue on machine surface after passing the press and dry parts; last it is dried by the dry part and passes the pressed polish part and batching part to get the product. The invention has the good technique index after detecting.

Owner:郭友实

Efficient environment-friendly concrete preservative

The invention relates to an efficient environment-friendly concrete preservative, which comprises the following components in portion by weight: 10 to 18 portions of various benzoic acids and boric acids, 20 to 40 portions of silica fume, 20 to 35 portions of alkalis; 35 to 50 portions of ethanolamine, and 15 to 20 portions of active components. The preservative can be widely applied to various building materials, especially to concrete and cement, and is reliable in rust prevention and corrosion resistance and good in environmental indexes. The preservative has the advantages of containing no mineral oil, containing no nitrite, chromate and the like harmful to human body, adapting to compressive strength (50 MPa in general) of actual requirements, improving strength, durability and heat resistance and meeting the requirements for high-performance concrete, along with no toxicity, no stimulation, no pollution, good construction performance, high dimensional stability, less shrinkage and no cracking in the hardening process.

Owner:凌明明

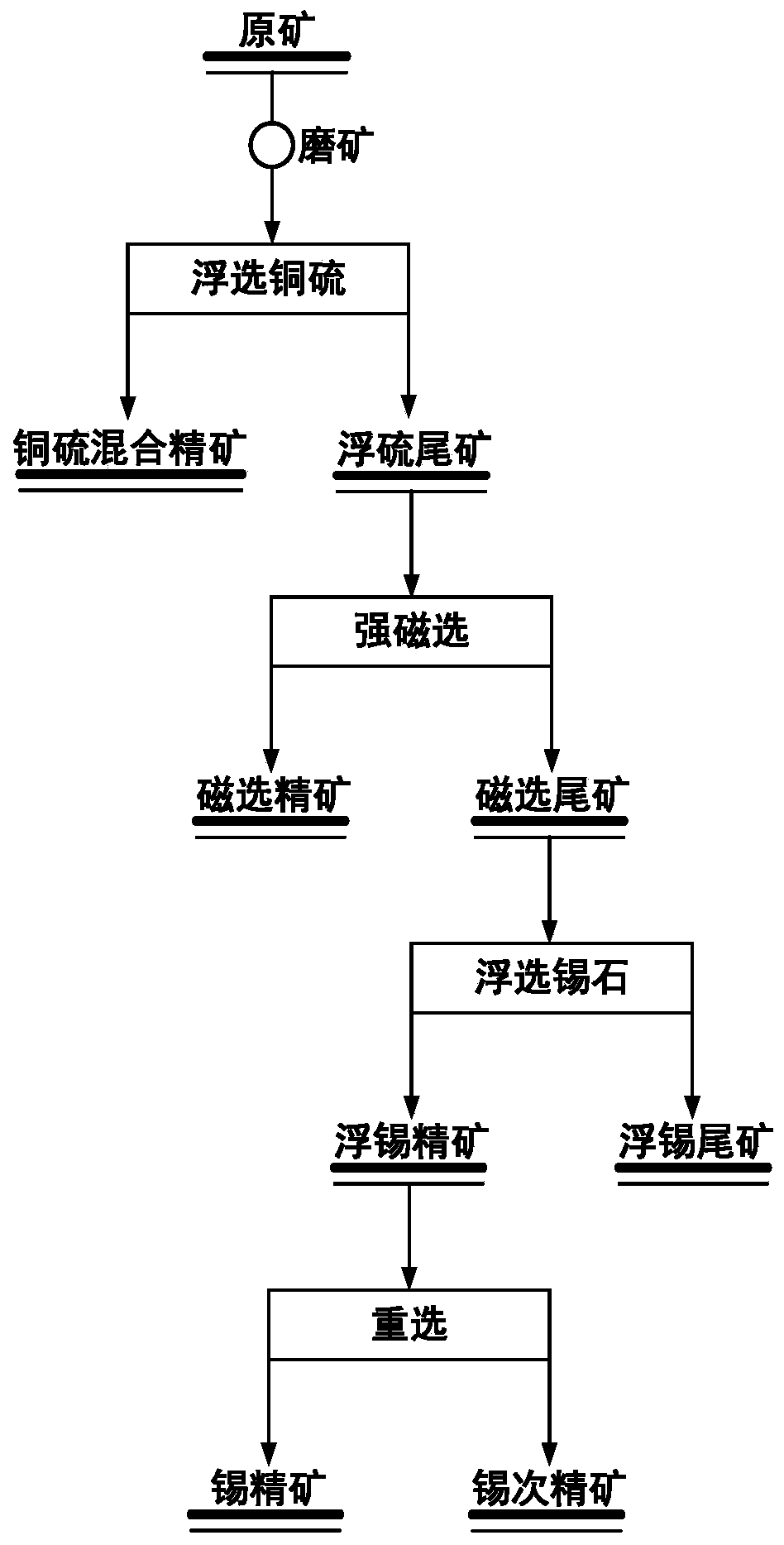

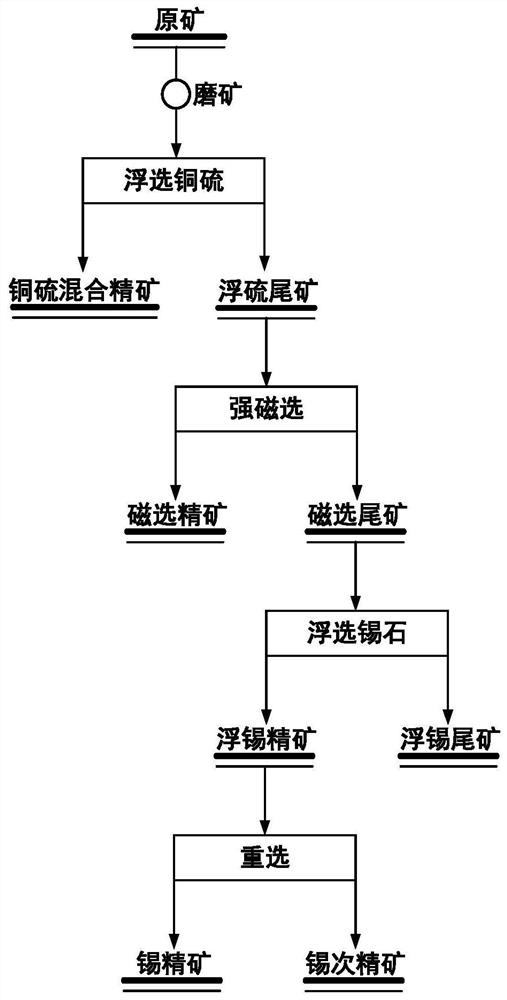

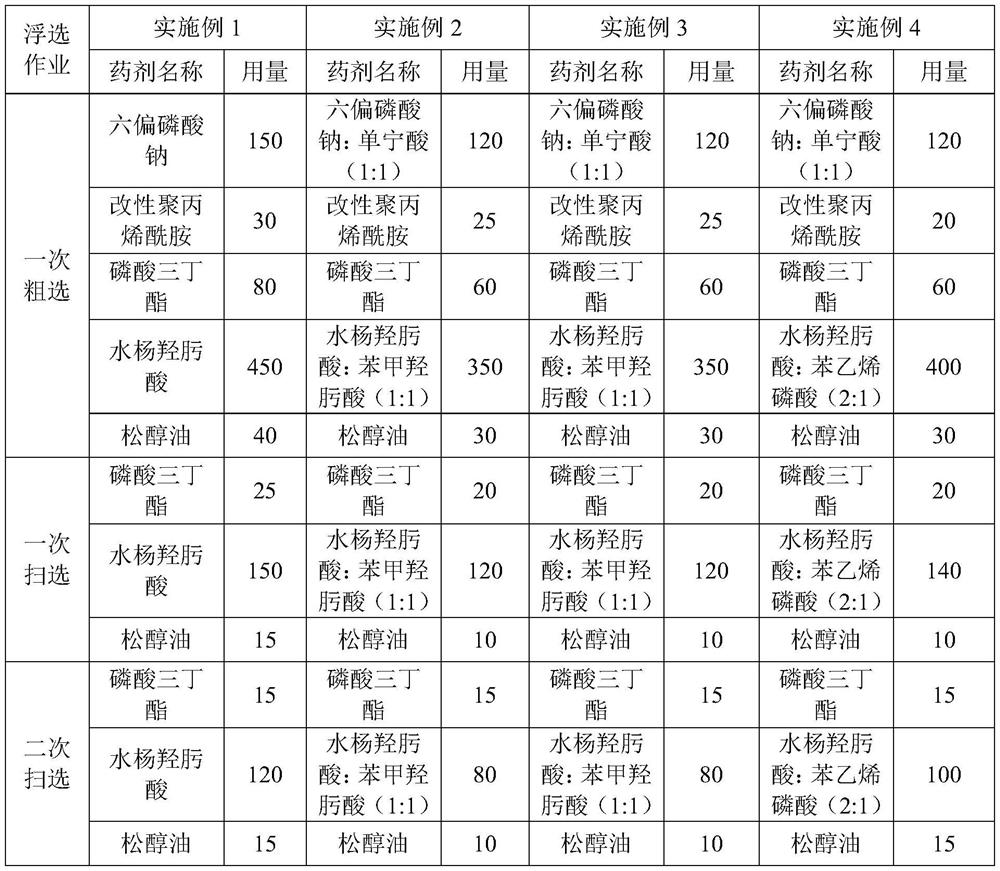

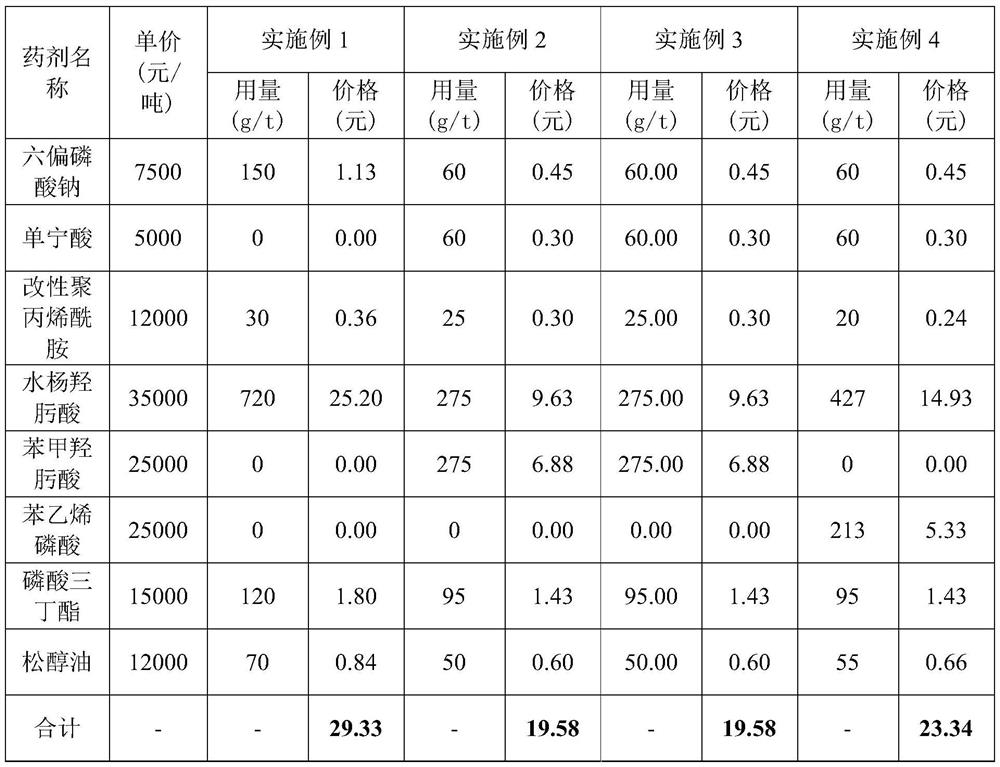

Mineral separation method for recovering cassiterite from tin-copper paragenic ore

ActiveCN110170381AReduce distractionsImprove flotation environmentDifferential sedimentationFlotationFlocculationCassiterite

The invention discloses a mineral separation method for recovering cassiterite from tin-copper paragenic ore. The method includes the steps of conducting ore grinding on raw ore, conducting flotationon copper sulfur to obtain copper-sulfur bulk concentrates and flotation sulfur tailings, conducting magnetic separation on the flotation sulfur tailings to obtain magnetic separation concentrates andmagnetic separation tailings, conducting flotation on the magnetic separation tailings through a specific agent to obtain tin flotation concentrates and tailings, and conducting centrifugal separation on the tin flotation concentrates to obtain tin concentrates and tin secondary concentrates. According to the method, in the flotation process of cassiterite, through the selective flocculation of fine cassiterite, by means of a specifically-combined inhibitor, the consumption of a collector can be reduced, the cost of the agent is reduced, and meanwhile it is ensured that the recovery grade andrecovery rate of the cassiterite are not reduced, the tin grade is higher than 40% and the total recovery rate is larger than 85%. According to the method, by means of the non-desliming bulk flotation, efficient cassiterite enrichment is realized, and the method is short in technological process, good in technical index and excellent in recycled product structure and has high application value incassiterite recovery.

Owner:广东省资源综合利用研究所

Magnetic separation and deinking method for waste paper

InactiveCN101736635AImprove deinking efficiencyReduce fiber lossPaper recyclingWaste paper working-upChemistrySodium silicate

The invention relates to a magnetic separation and deinking method for waste paper, comprising the following steps: (1) adding waste paper and magnetic seeds in a pulper, adding water, sodium silicate and NaOH for repulping, wherein the repulping conditions are as follows: the magnetic seed dosage is 0.05-0.2wt%, the dosage of sodium silicate is 2-10wt%, NaOH is used to regulate the pH value to be 7-10, and the pulp concentration is 10-15wt%; (2) adding water for diluting after water paper repulping until the pulp concentration to be 0.5-4wt%, adding flocculant which accounts for 0.01-0.1wt% of dry paper into the pulp after repulping for magnetic seed flocculation, enabling the deciduous ink particles to be adhered with magnetic seeds, wherein the pH value is 7.0-11.0, the time is 10-30min, and the stirring speed is 200-1000rpm; and (3) separating the flocculated ink particles from the pulp by a deinking device for size after magnetic seed flocculation. The method in the invention can obviously improve pulp whitness and fiber yield of water paper, and can be used for producing deinking pulp with high whiteness and high deinking rate and small amount of paper fiber loss.

Owner:有研资源环境技术研究院(北京)有限公司

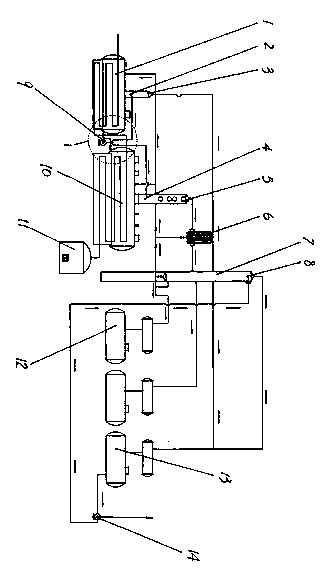

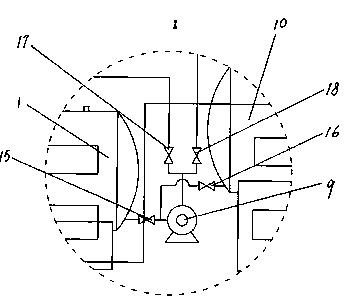

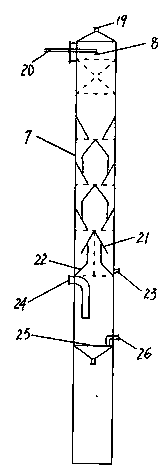

Continuous flash process equipment for waste oil

InactiveCN103725307AEliminate secondary pollutionAdvanced production technologyHydrocarbon distillationProcess equipmentEconomic benefits

The invention provides continuous flash process equipment for waste oil. The continuous flash process equipment comprises a hot-blast stove, a preheating kettle, a gas collection column, a flash kettle, a flash column, a fractionating column, etc.; an oil pump is mounted between the preheating kettle and the flash column; a tee joint is arranged at an inlet of the oil pump, wherein one end of the tee joint is connected to the bottom part of the preheating kettle through a valve, while the other end of the tee joint is connected with the bottom part of the flash kettle through another valve; another tee joint connected to an outlet of the oil pump is respectively connected to the bottom part of the gas collection column above the preheating kettle and the bottom part of the flash column above the flash kettle through connecting pipes; the outlet in the top part of the flash column is connected to the middle part of the exposed fractionating column through an oil stopper; a diesel tank, the preheating kettle and the flash kettle are connected to the bottom part of the oil stopper through the pipelines. The continuous flash process equipment for waste oil is convenient to operate, high in degree of automation, high in processing precision, fast in flash speed, no any fuel, and high in output, and saves fuel; the produced oil has technical index and additional value higher than those produced by common distillation way; the produced oil can replace the raw material of a large ship oil plant and the crude oil of base oil, so that the economic benefit is great, and the resource and energy are saved.

Owner:SHANGQIU TENGLONG ENVIRONMENTAL PROTECTION EQUIP

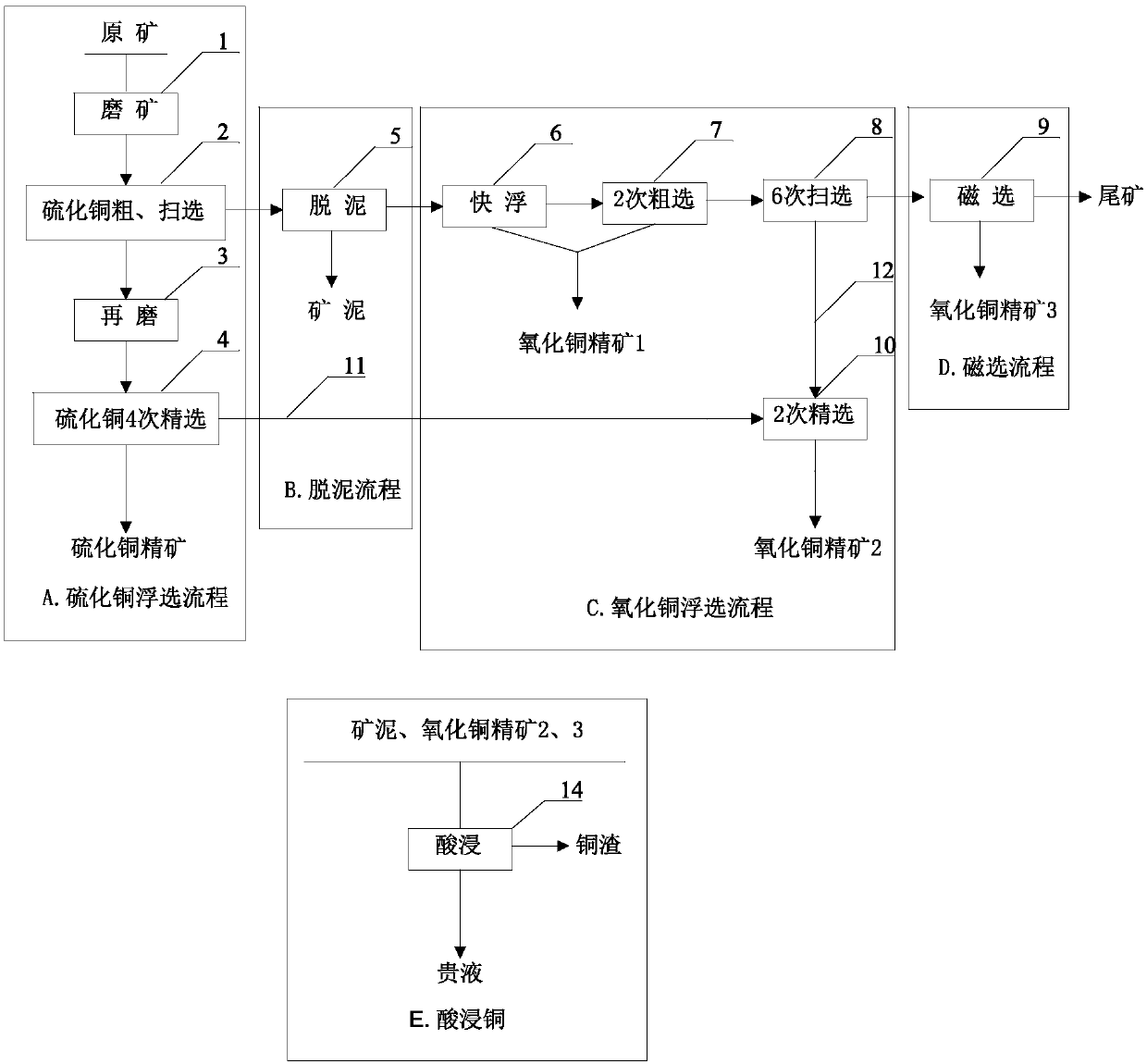

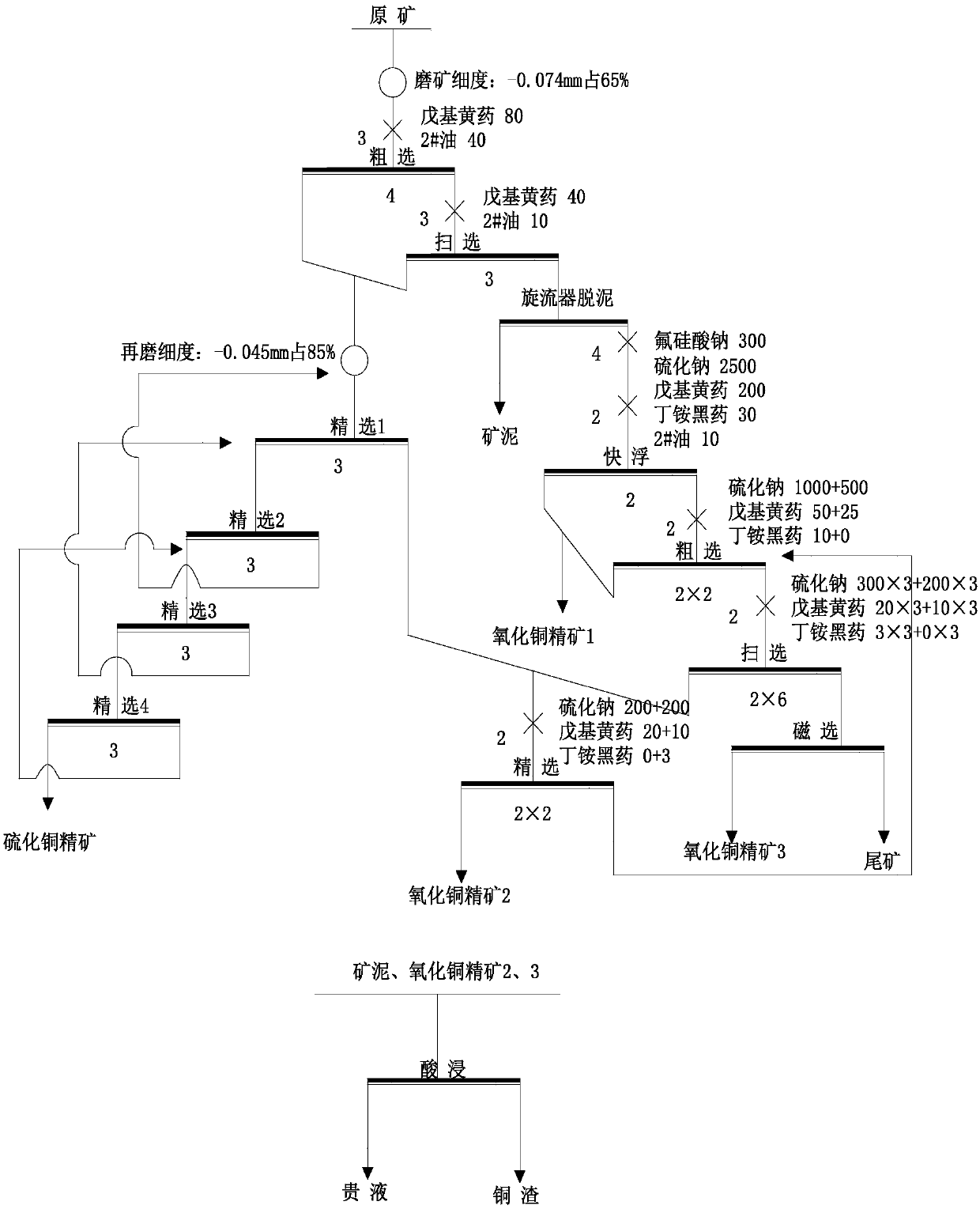

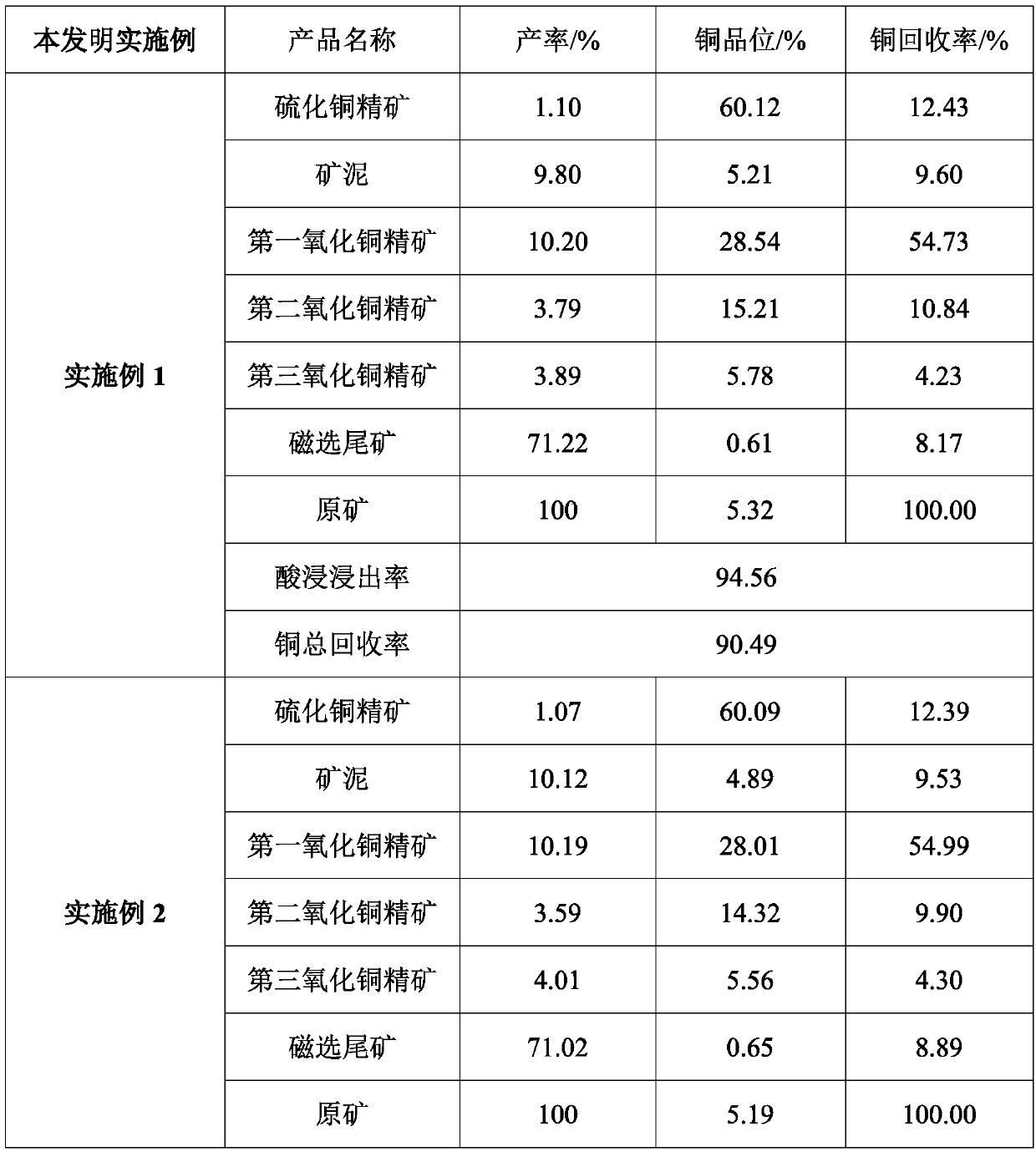

Dressing and smelting combined treatment method for recycling complex copper oxide ore

The invention discloses a dressing and smelting combined treatment method for recycling complex copper oxide ore. The method comprises the following steps of (1) copper sulfide flotation flowsheet; (2) desliming flowsheet; (3) copper oxide flotation flowsheet; (4) magnetic separation flowsheet; and (5) hydrometallurgy of copper. According to the dressing and smelting combined treatment method forrecycling the complex copper oxide ore, the sulfur and copper oxide ore step flotation process is adopted, the inhibition of copper sulfide by sodium sulfide is reduced, and high-grade copper sulfideconcentrate is obtained; and raw ore containing about 5.30% copper can adopt the method, the recycling rate of the total copper can reach 90% or above, and obtained technical indexes are good.

Owner:厦门紫金矿冶技术有限公司

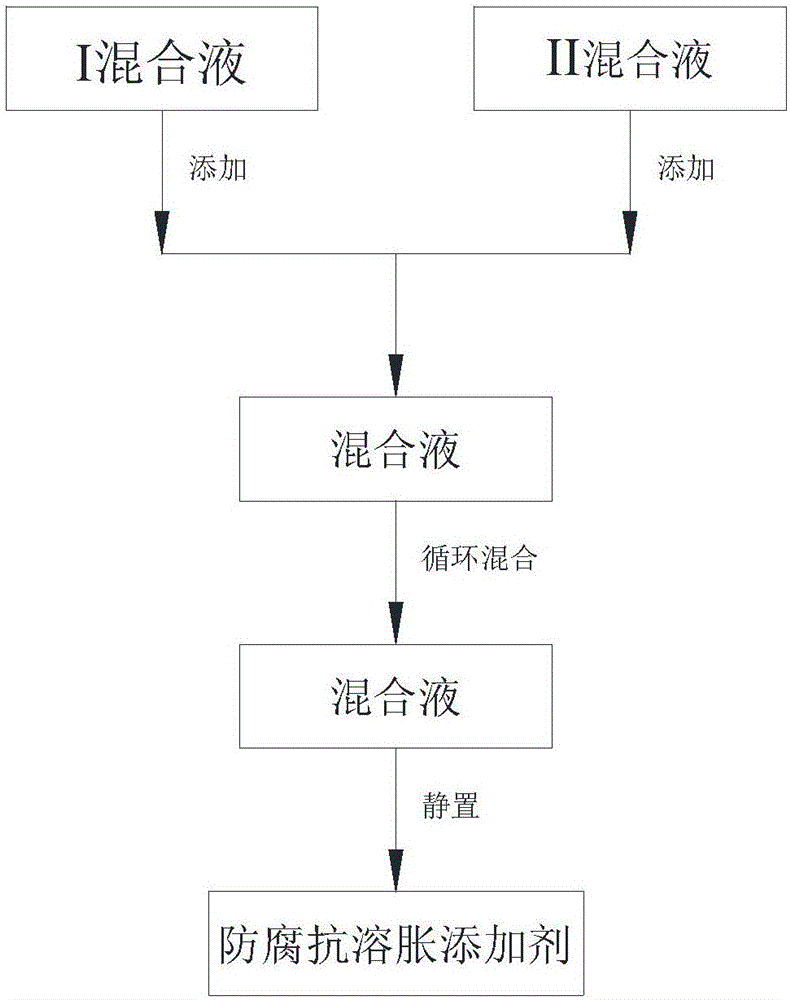

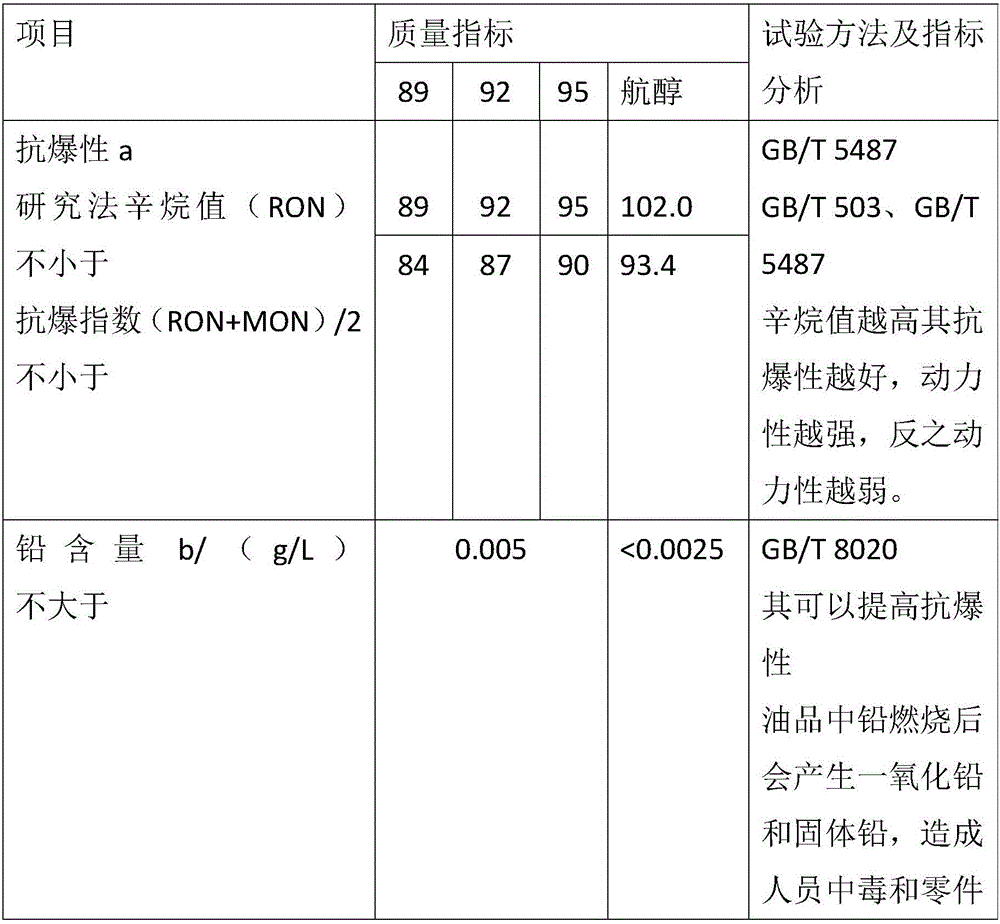

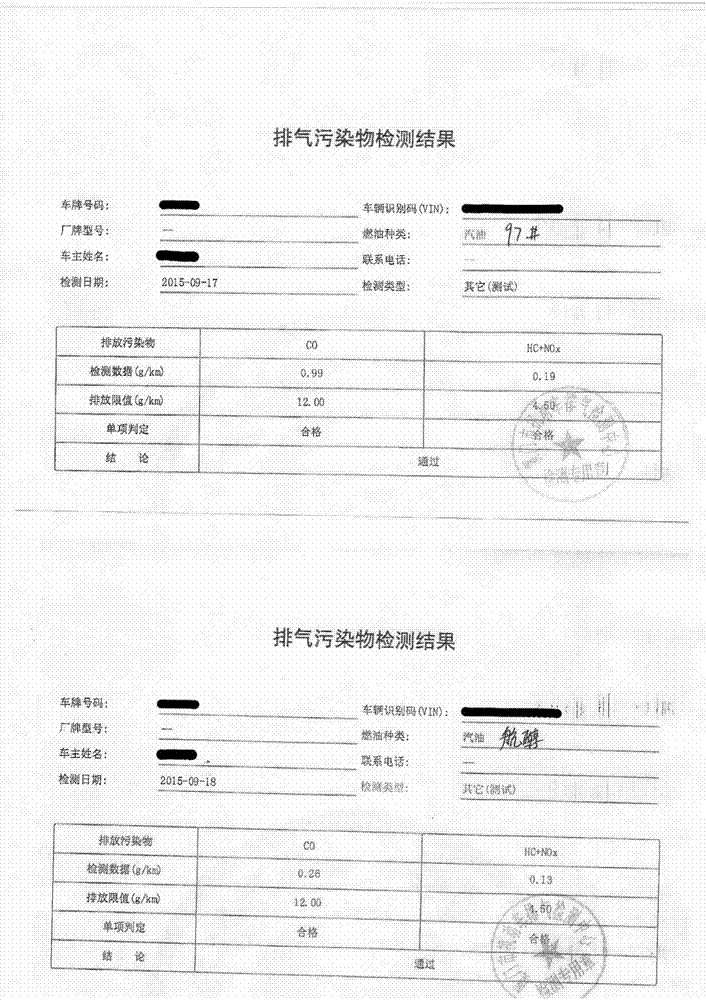

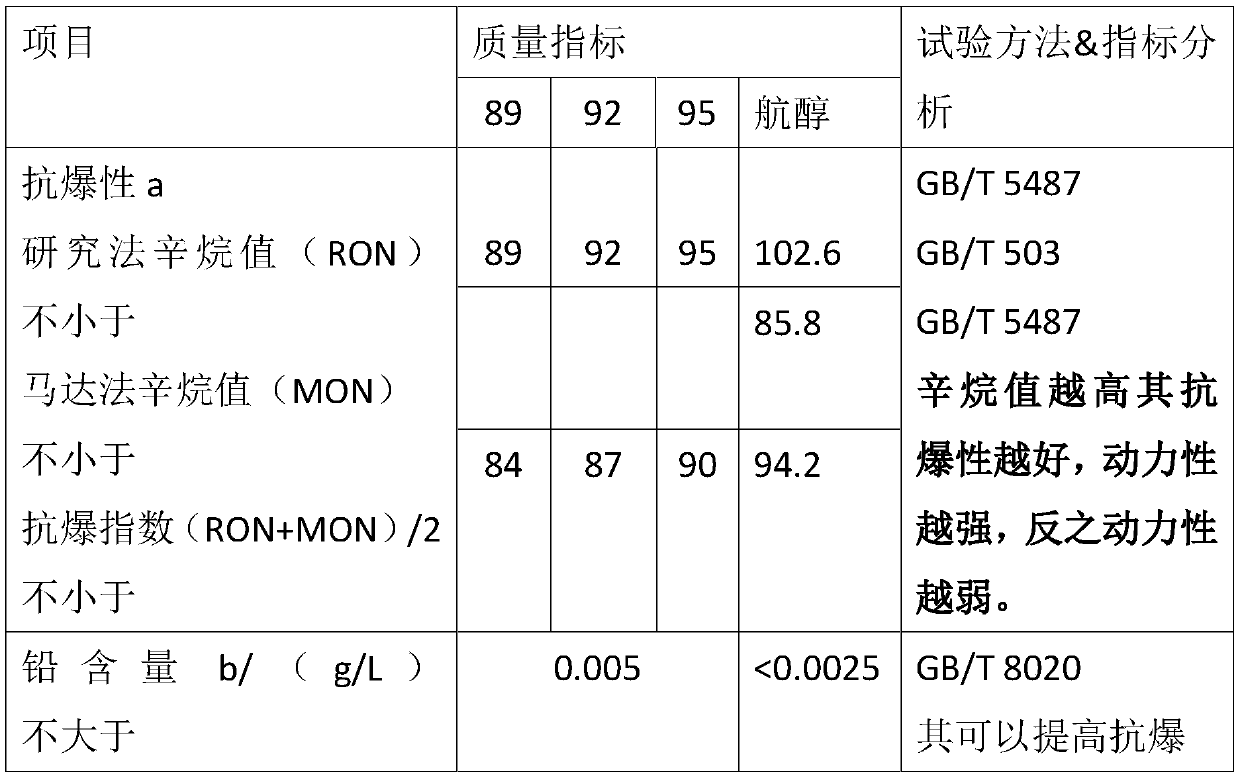

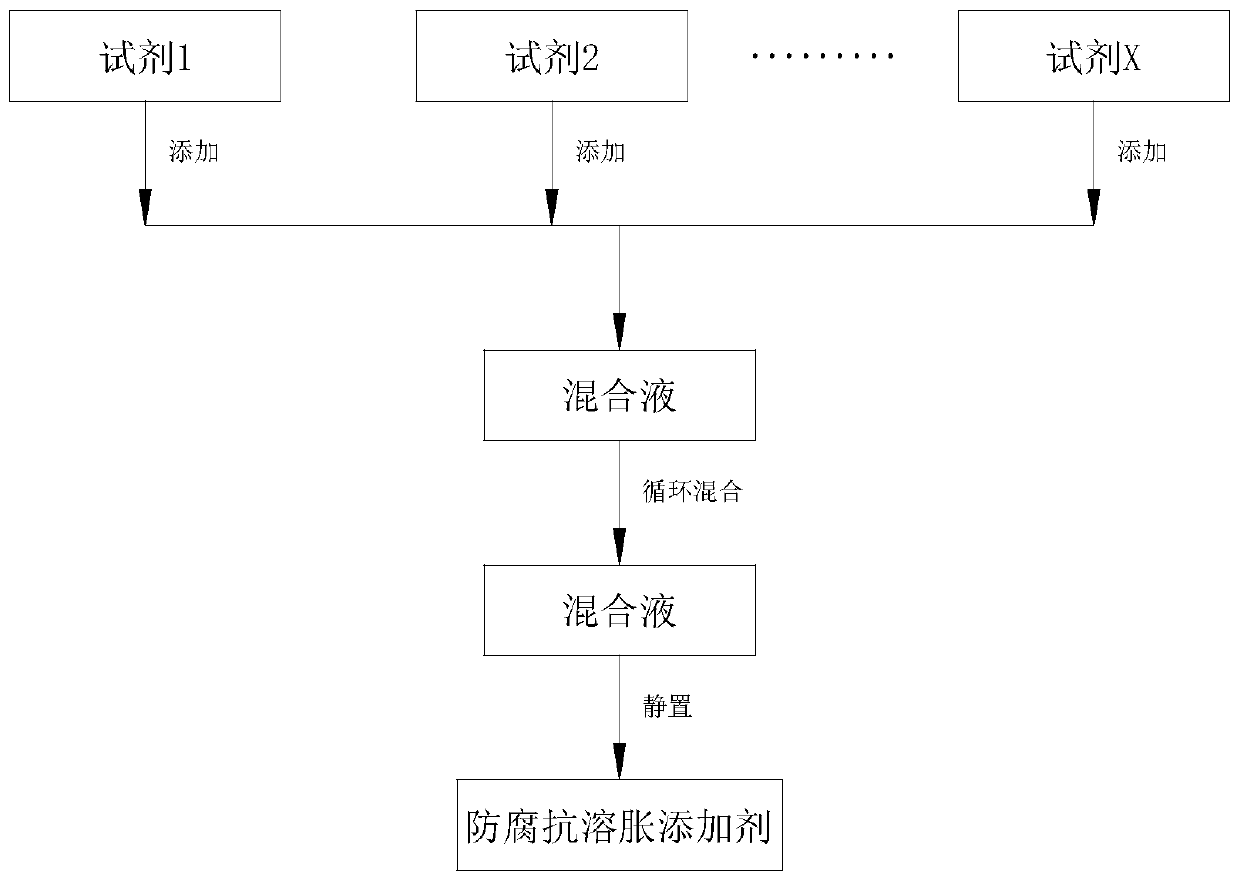

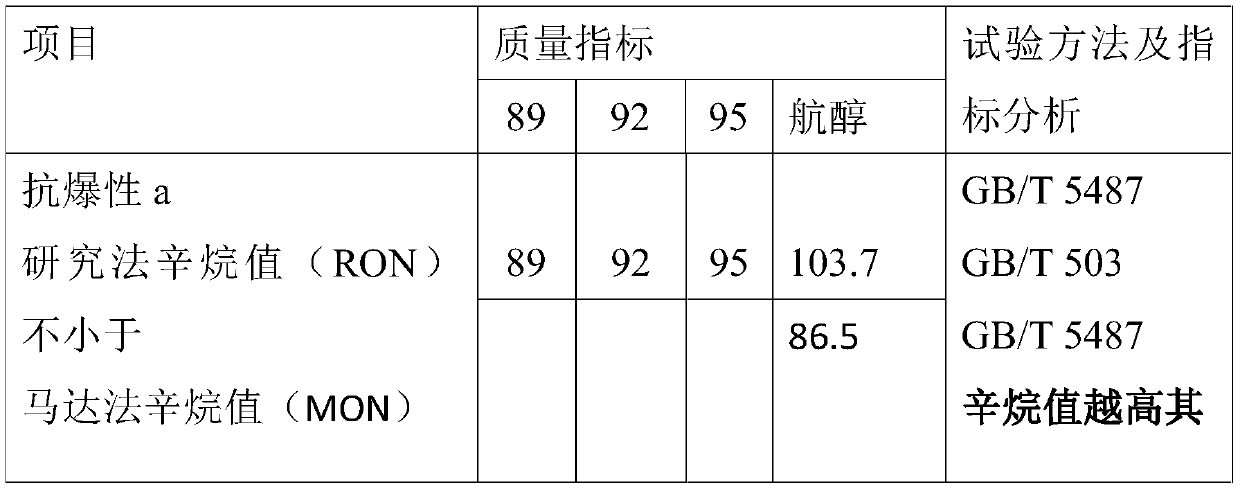

Navigation alcohol fuel preservative anti-swelling additive for vehicle and preparation method thereof

InactiveCN106833770AAvoid corrosionPromotes full combustionLiquid carbonaceous fuelsFuel additivesAlcohol fuelCorrosion

The invention discloses a navigation alcohol fuel preservative anti-swelling additive for a vehicle, and solves the technical problem of corrosion of a metal part of an engine caused by existing methanol gasoline. The preservative anti-swelling additive is prepared from the following components in parts by weight: more than one reagent of 1 to 5 parts of 2-mercaptobenzothiazole, 1 to 5 parts of benzotriazole, 1 to 20 parts of xylene and 1 to 20 parts of alcohols, and at least more than two reagents of 1 to 20 parts of triethanolamine, 1 to 5 parts of trimer acid, 1 to 5 parts of calcium sulphonate and 1 to 20 parts of pyrazolone. The methanol gasoline which is prepared by using the navigation alcohol fuel preservative anti-swelling additive can inhibit the formation of an organic acid by external and internal water and navigation alcohol gasoline during manufacturing, storing and transporting processes, and can prevent the engine from being corroded, promote full combustion of the fuel and reduce the production of an acid and formaldehyde during a using process.

Owner:寇延华

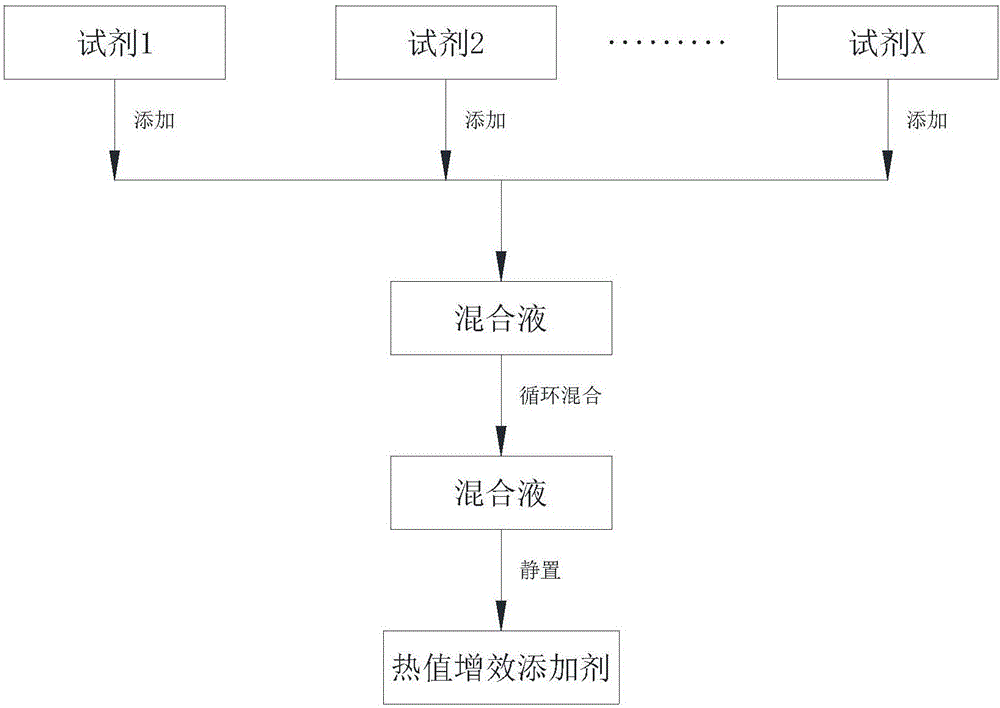

Automotive navigation alcohol fuel heat value synergistic additive and method for manufacturing same

InactiveCN106811246AHigh calorific valueBurn fullyLiquid carbonaceous fuelsFuel additivesMethylanilineMarine navigation

The invention discloses an automotive navigation alcohol fuel heat value synergistic additive. By the aid of the automotive navigation alcohol fuel heat value synergistic additive, the technical problem of insufficient power of existing methanol fuel during use can be solved. The automotive navigation alcohol fuel heat value synergistic additive comprises at least two types of reagents including, by weight, 5-20 parts of acetone, 5-20 parts of cyclohexane, 6-18 parts of octane, 3-18 parts of methylaniline, 1-5 parts of nitrobenzene and 1-3 parts of cyclohexanone. The automotive navigation alcohol fuel heat value synergistic additive has the advantages that a fuel heat value of methanol gasoline with the automotive navigation alcohol fuel heat value synergistic additive can be increased, sufficient combustion of fuel can be promoted, and accordingly the dynamic performance of engines of automobiles can be enhanced.

Owner:寇延华

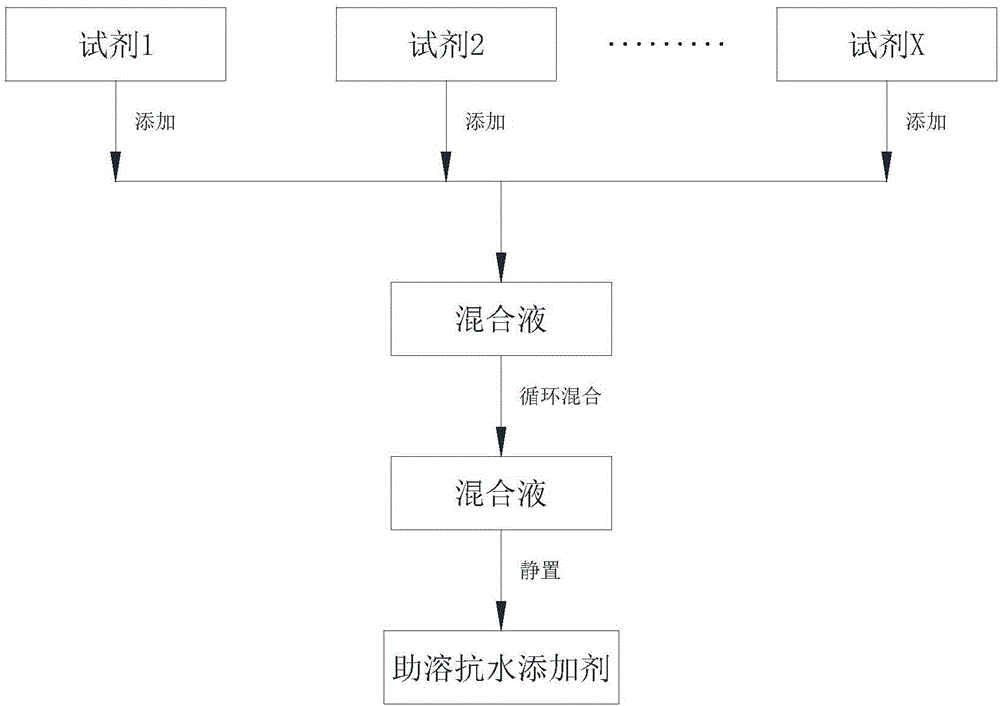

Navigation alcohol fuel dissolving-assisting water-resistant additive and preparation method thereof

InactiveCN106833771AGood stabilityConvenient storage and transportationLiquid carbonaceous fuelsFuel additivesChemistryEther

The invention discloses a navigation alcohol fuel dissolving-assisting water-resistant additive, and solves the technical problem that existing methanol gasoline layers frequently during using and storing processes. The dissolving-assisting water-resistant additive is prepared from the following components in parts by weight: more than two reagents of 0 to 40 parts of isopropyl alcohol, 5 to 15 parts of ethylene glycol butyl ether, 3 to 20 parts of dimethyl carbonate, 1 to 10 parts of ethyl phenol polyoxyethylene ether, 5 to 20 parts of ethylene glycol, 5 to 20 parts of butanediol and 5 to 20 parts of ethylene glycol monomethyl ether. The methanol gasoline which is prepared by utilizing the dissolving-assisting water-resistant additive does not layer easily, is not affected by low temperature or high temperature, and can be stored for a long time.

Owner:寇延华

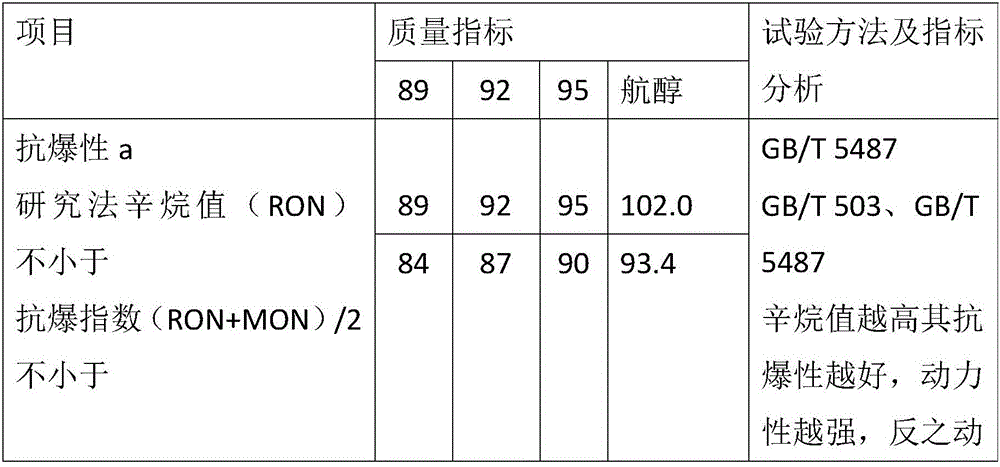

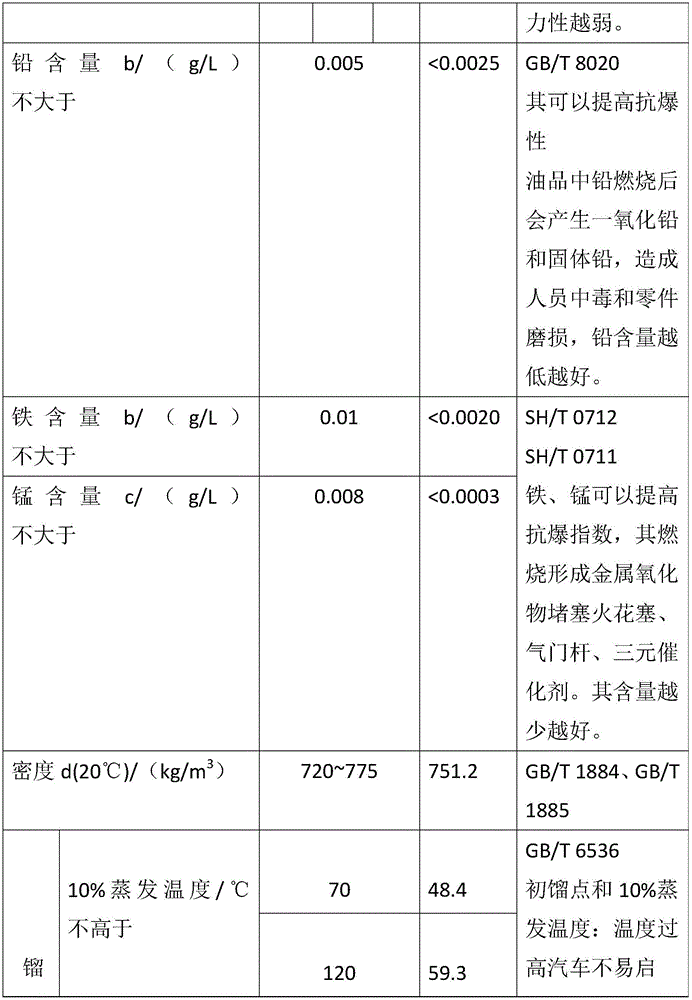

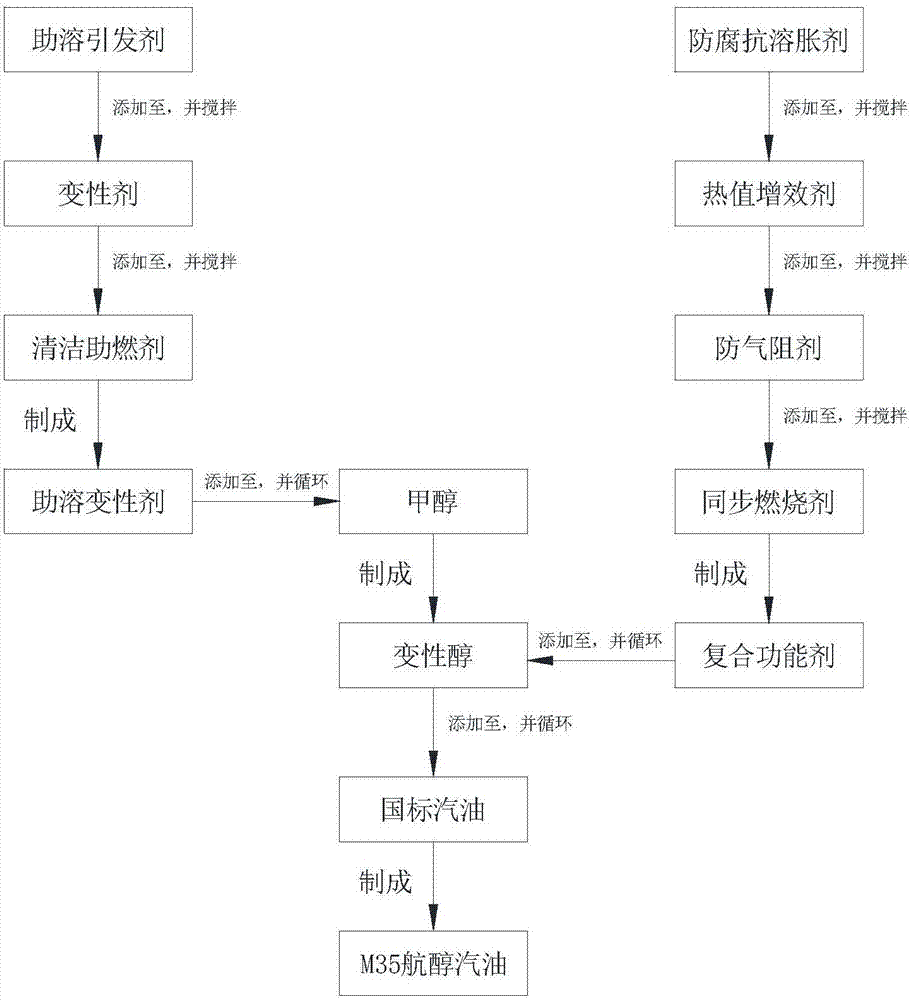

Vehicle EPM35 aerosol gasoline and production method thereof

InactiveCN107245354AReduce consumptionReduce pollutionLiquid carbonaceous fuelsFuel additivesComposite functionGasoline

The invention discloses a vehicle EPM35 aerosol gasoline. A purpose of the present invention is to solve a plurality of technical problems of storage and transportation stratification, low temperature cold starting, high temperature vapor lock, low antiknock property in the existing methanol gasoline. The aerosol gasoline comprises, by mass, 95% of a main combustion agent, 0.5-4% of a solubilizing denaturation agent, and 1-4.5% of a composite functional agent, wherein the main combustion agent comprises methanol and national standard gasoline, the methanol content is 30-40%, the national standard gasoline is 55-65%, the solubilizing denaturation agent comprises a solubilizing initiator, a denaturation agent and a cleaning combustion-supporting agent, and the composite functional agent comprises a heat value synergist, an anticorrosive anti-swelling agent, an anti-vapor lock agent and a synchronous combustion agent. The vehicle EPM35 aerosol gasoline of the present invention is not easily layered during storage and transportation, can avoid high temperature vapor lock and low temperature cold start, does not produce metal corrosion and non-metallic swelling, and further has advantages of environmental protection emission and the like.

Owner:寇延华

Method for extracting indium and zinc from high-iron indium-containing zinc calcine and preparing iron oxide

InactiveCN102560087BTo achieve the purpose of decomposing zinc ferriteImproved leachingFerric oxidesProcess efficiency improvementIndiumSlag

The invention relates to a method for extracting indium and zinc from high-iron indium-containing zinc calcine and preparing iron oxide. A zinc ferrite structure in the high-iron indium-containing zinc calcine is damaged by reduction roasting, elements such as zinc, iron and indium in the reduced calcine are obtained by neutral leaching and acid leaching, indium-rich slag is obtained by neutralization for precipitating indium, the iron grade of slag obtained by removing iron from hematite under high pressure is high, an industrial iron oxide product can be obtained by acid washing and roasting, and liquid obtained after the iron is removed can be directly purified and electrolyzed after being neutralized by smoke. A technical route of maximally extracting base metal such as the indium, the zinc and the like and recycling associated iron minerals simultaneously is provided, and the problems that the recovery rate of the indium is low and the iron cannot be recycled in the process of smelting a high-iron indium-containing zinc concentrate at present are solved; and a clean production technology which combines effective extraction of the base metal with effective utilization of associated iron is provided for treating the indium, the zinc and other high-iron non-ferrous metal materials.

Owner:广西冶金研究院有限公司

Pre-laid self-adhesive film coiled material composite waterproof sheet as well as preparation method and application thereof

ActiveCN113787793AImprove aging resistanceNo reduction in peel strengthSynthetic resin layered productsCopolymerHigh-density polyethylene

The invention relates to the field of waterproof materials, in particular to a pre-laid self-adhesive film coiled material composite waterproof sheet and a preparation method and application thereof.The composite waterproof sheet comprises a composite layer and a high-density polyethylene layer which are arranged in a stacked mode, and the material for forming the composite layer is a vinyl polar copolymer; and the high-density polyethylene layer is made of high-density polyethylene. The pre-laid self-adhesive film coiled material composite waterproof sheet provided by the invention has excellent aging resistance, peel strength and puncture resistance, and meanwhile, the preparation method is simple, pollution-free and environment-friendly.

Owner:KESHUN WATERPROOF TECH CO LTD

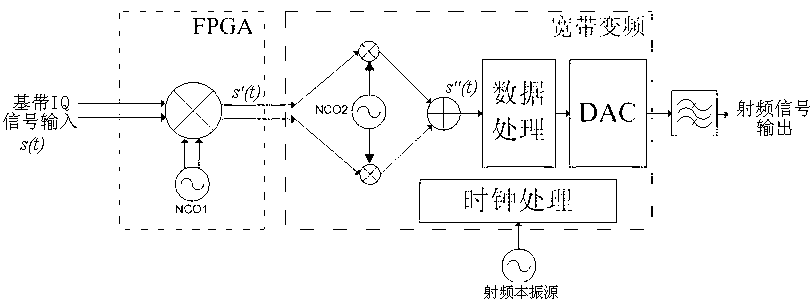

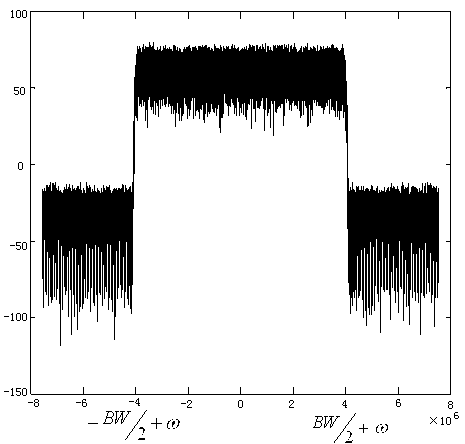

Broadband up-converter and up-conversion method

ActiveCN102176656BMeet the requirements of frequency conversionReduce in quantityMulti-frequency-changing modulation transferenceFrequency changerFrequency spectrum

The invention discloses a broadband up-converter and an up-conversion method. The invention relates to the technical field of communication, in particular to a digital broadband up-converter and a digital up-conversion method in a digital wireless broadcast technology. The up-conversion method is mainly characterized by comprising the following steps of: carrying out first up-conversion on a digital baseband I / Q (In-phase / Quadrature) signal by adopting a complex multiplier and a digital controlled oscillator I, namely a frequency spectrum shift with small step; then carrying out secondary up-conversion on the digital signal subjected to the frequency spectrum shift with small step to shift the signal frequency spectrum to the needed high frequency section; finally, further processing the signal and then converting the signal into a simulated radio-frequency signal, and wirelessly transmitting the simulated radio-frequency signal to a receiving end by an emitter. In the invention, the up-conversion method can realize broadband up-conversion of with small step adjustment and the broadband up-converter has the advantages of simple structure and good reliability.

Owner:CHENGDU KAITENG SIFANG DIGITAL RADIO & TELEVISION EQUIP CO LTD

An anti-crack and anti-seepage composite material for concrete

The invention relates to an anti-cracking and anti-permeability composite material for concrete. The composite material comprises the following components in parts by weight: 82 to 83 parts of calciumcarbonate, 2 to 5 parts of magnesium carbonate, 0.3 to 4 parts of titanium dioxide, 5 to 6 parts of bone glue powder, 0.2 to 0.3 part of zinc oxide, 0.5 to 0.6 part of lead nitrate, 1 to 20 parts ofstearic acid, 0.5 to 1.0 part of palmatic acid, and 0.2 to 0.3 part of polyethylene glycol. The composite material has the advantages that the composite material has a self-cleaning function and can effectively improve the anti-frost property and erosion resistance of concrete.

Owner:不二新材料科技有限公司

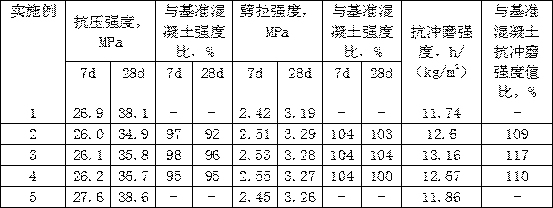

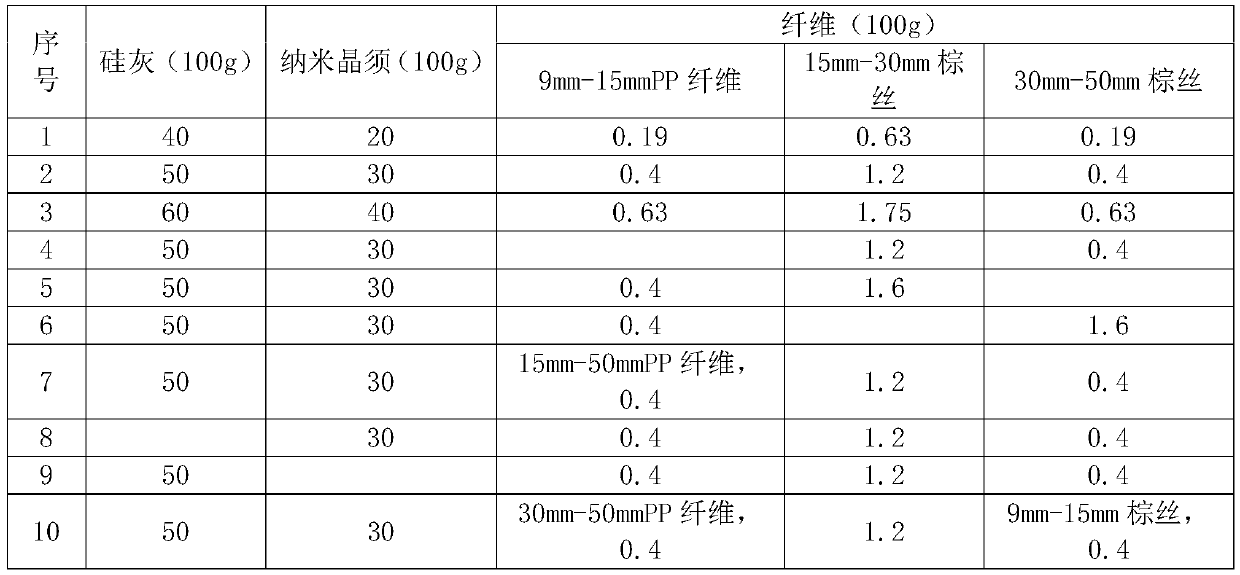

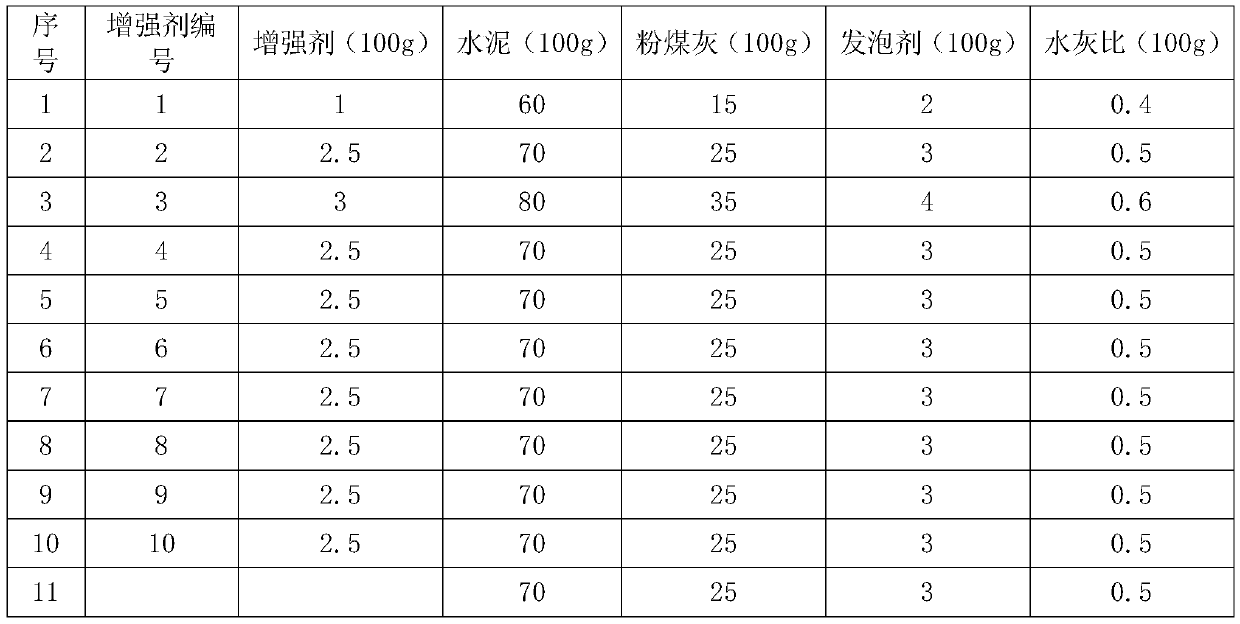

Partition board internally provided with reinforcements and production method thereof

InactiveCN111170684AStrong toughnessGood technical indicatorsConstruction materialWallsFiberFoaming agent

The invention discloses a partition board internally provided with reinforcements, and a production method thereof. The partition board comprises a partition board body, the reinforcements arranged ina network shape are arranged in the partition board body, and the partition board body comprises the following raw materials in parts by mass: 60-80 parts of cement, 15 to 35 parts of fly ash; 1-3 parts of a reinforcing agent; and 2-4 parts of a foaming agent; based on the mass of the reinforcing agent, the reinforcing agent is prepared from the following raw materials in parts by mass: 40 to 60parts of silica fume; 20 to 40 parts of nano crystal whisker; and 1-3 parts of fibers. According to the production method of the partition board, the reinforcements are arranged in foamed cement to form a material which is enough in strength and can be independently used as the partition board, and due to the fact that the internally-attached reinforcements and the adopted material of the partition board body have high strength and toughness, the whole foamed cement partition board has very good technical indexes.

Owner:山东晟世达科技有限公司

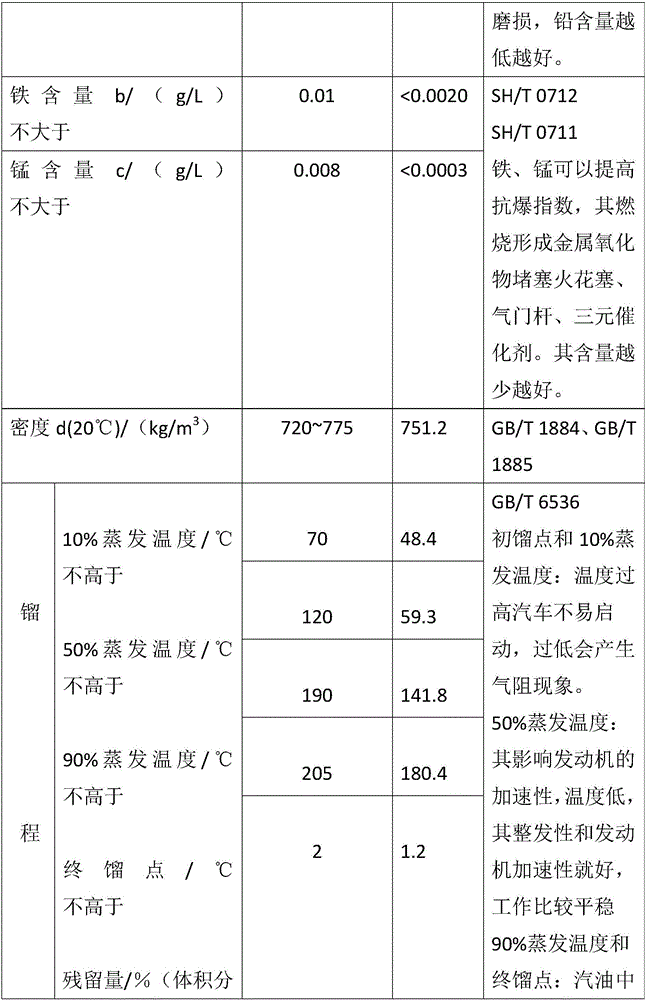

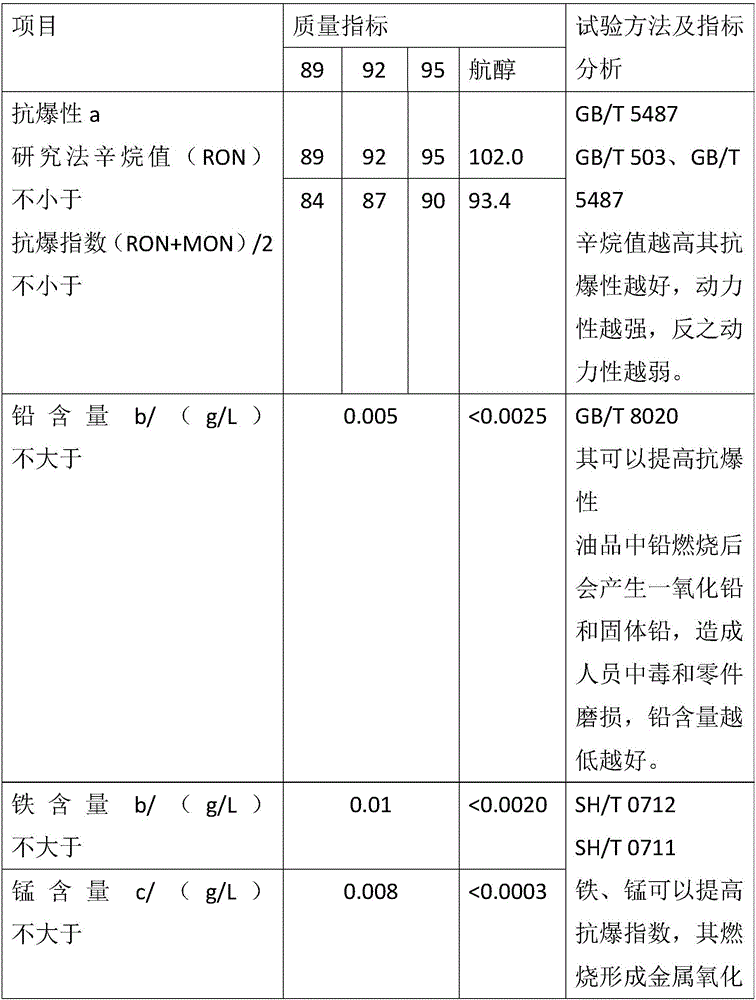

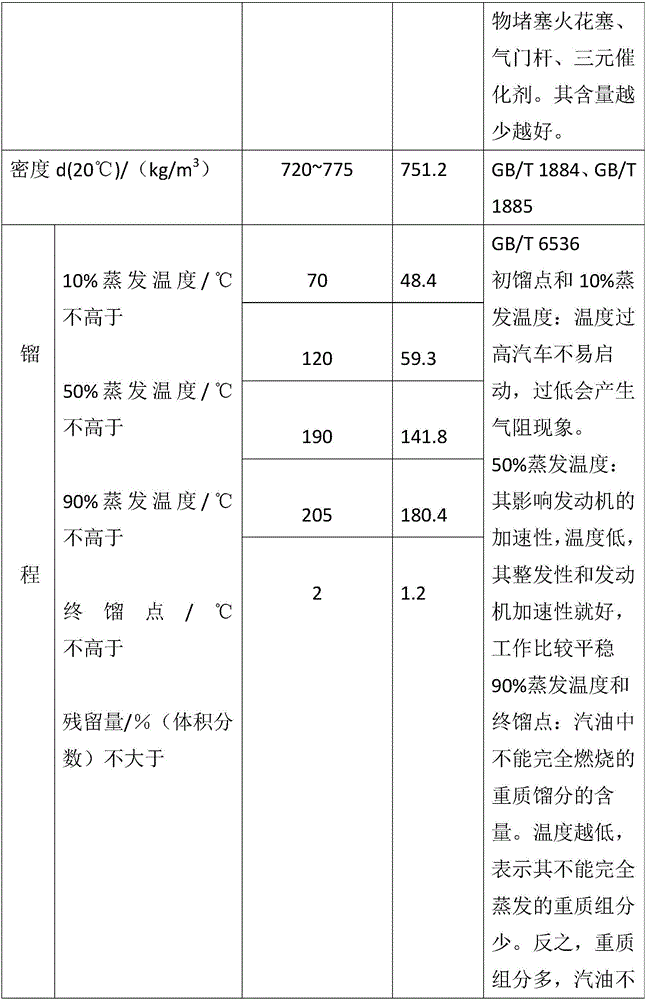

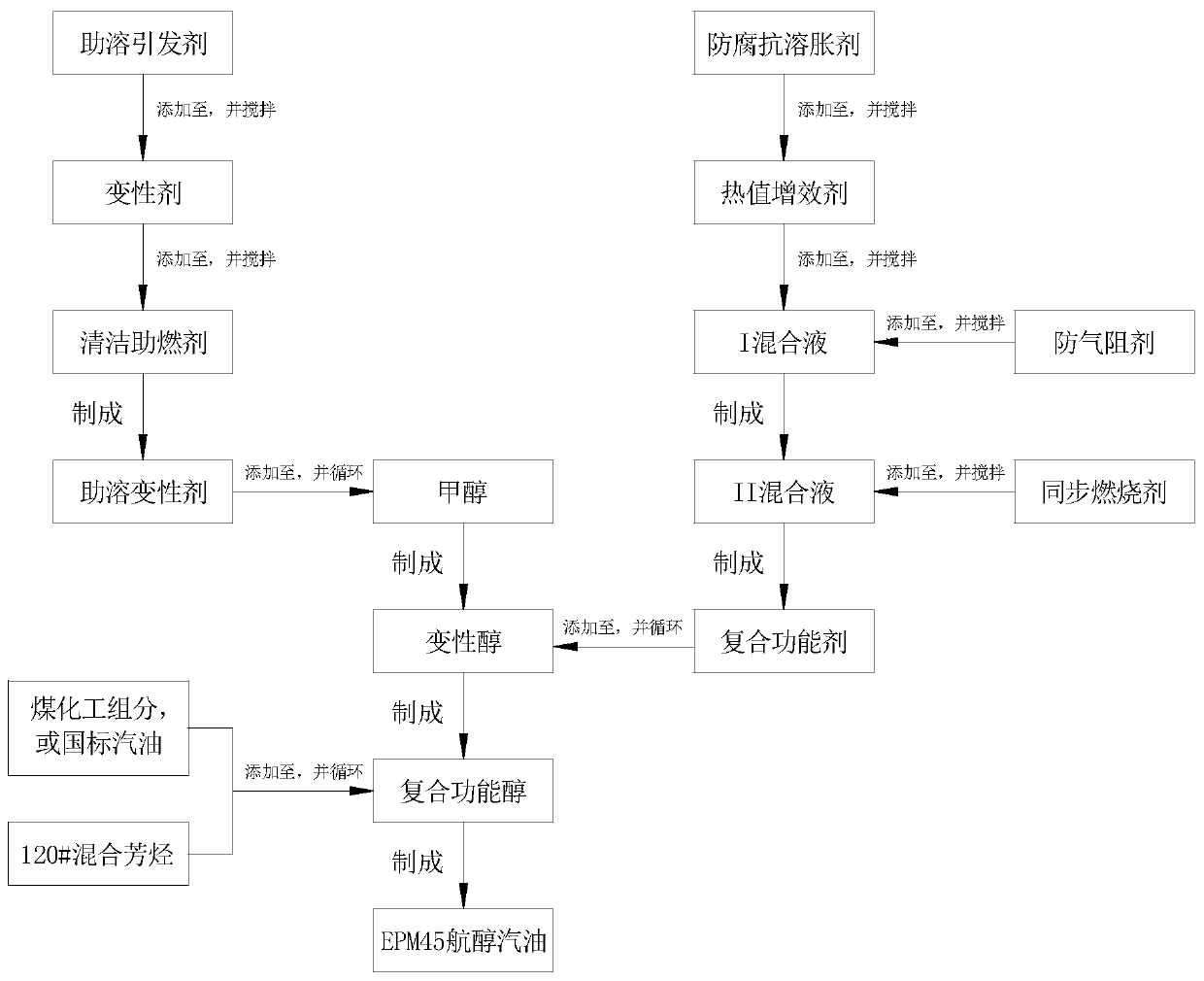

EPM45 navigation alcohol fuel for automobile and preparation method of EPM45 navigation alcohol fuel

InactiveCN110157498AReduce consumptionReduce pollutionLiquid carbonaceous fuelsEnvironmental resistanceAlcohol fuel

The invention discloses an EPM45 navigation alcohol fuel for an automobile, and solves the technical problems that current navigation alcohol fuel has a plurality of technical problems, such as stratification during storage and transportation, low-temperature cold starting, high-temperature air lock, and low explosion resistance. The navigation alcohol fuel comprises the following components, in percentages by mass: 95% of a main combustion agent, 1%-5% of a solubilization denaturing agent, and 1%-4.5% of a composite functional agent, wherein the main combustion agent includes 40-55% of methanol, 30-40% of a coal chemical component or Chinese standard gasoline and 5-20% of 120# mixed aromatic hydrocarbons; the solubilization denaturing agent includes a solubilization initiator, a denaturing agent and a clean combustion improver; and the composite functional agent includes a calorific value synergist, an antiseptic anti-swelling agent, an air lock prevention agent and a synchronous combustion agent. The EPM45 navigation alcohol fuel provided by the invention has the advantages of being not easy to stratify during storage and transportation, avoiding high-temperature air lock and low-temperature cold starting, and being free of metal corrosion and non-metal swelling, and friendly to environment during emission, and the like.

Owner:寇延华

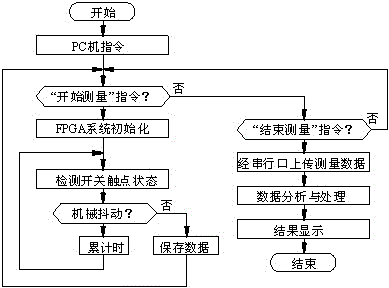

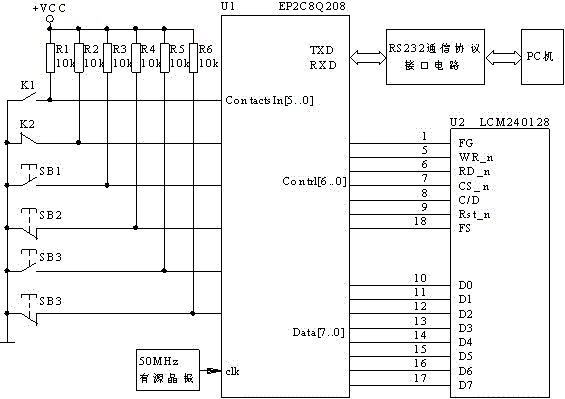

Method and device for measuring jitter time of mechanical switch contacts

InactiveCN103576084BImprove measurement accuracySimple and fast operationCircuit interrupters testingMicrocomputerStable state

Owner:HUNAN UNIV OF TECH

Preparation method, application and using process of floating agent prepared from drainage oil

The invention relates to a preparation method, application and using process of a floating agent prepared from drainage oil, wherein the preparation method of the floating agent comprises the following steps of: (a) purifying the drainage oil; (b) carrying out hydrolysis reaction on the purified drainage oil obtained from the step (a) to obtain the floating agent used for floating ores. When the floating agent used by the invention and prepared from the drainage oil is used as a collecting agent for floating the ores, the selectivity of the collecting agent can be enhanced, and the technical indicator and the economic indicator of flotation are enhanced favorably; and in addition, because a raw material used for the preparation of the floating agent is the drainage oil, the technical scheme provided by the invention has important significance on the aspects of preventing environmental pollution, simplifying production process, reducing food security threat, and the like.

Owner:鄂尔多斯市君致清环境科技有限公司

A kind of beneficiation method of recovering cassiterite from tin-copper symbiotic ore

ActiveCN110170381BReduce distractionsReduce adverse effects of flotationDifferential sedimentationFlotationFlocculationCassiterite

The invention discloses a beneficiation method for recovering cassiterite from tin-copper symbiotic ore. The method is as follows: first grinding the raw ore; obtaining copper-sulfur mixed concentrate and floating sulfur tailings by flotation of copper and sulfur; then magnetically separating the floating sulfur tailings to obtain magnetic separation concentrate and magnetic separation tailings; The magnetic separation tailings are flotation with specific reagents to obtain the floating tin concentrate and tailings; finally, the floating tin concentrate is centrifugally separated to obtain tin concentrate and tin sub-concentrate. In the flotation process of cassiterite, the method of the present invention uses selective flocculation of fine-grained cassiterite and uses a specific combination of inhibitors, which can reduce the use of collectors, reduce the cost of agents, and ensure the recovery of cassiterite The grade and recovery rate are not reduced, the tin grade is greater than 40%, and the total recovery rate is greater than 85%. The method adopts full flotation without desliming to realize efficient enrichment of cassiterite, with short process flow, good technical indicators, and excellent structure of recovered products. It has high application value in the recovery of cassiterite.

Owner:广东省资源综合利用研究所

A kind of pre-laid self-adhesive film composite waterproof sheet and its preparation method and application

ActiveCN113787793BImprove aging resistanceNo reduction in peel strengthSynthetic resin layered productsPolymer scienceHigh density

Owner:KESHUN WATERPROOF TECH CO LTD

Light burning system and method of magnesite

ActiveCN102190449BHigh degree of automationImprove labor productivityLime productionRefractoryEngineering

The invention relates to a light burning system of magnesite, particularly to a magnesite light burning system and a light burning method in the refractory industry. The magnesite light burning system comprises an ore crushing and grinding system which sends ores into a calcinator system through material-charging and conveying equipment. The calcinator system, connected to a fuel supply system, outputs lightly-burnt magnesia powders by material-discharging and conveying equipment. The system of the invention has the advantages of: low heat consumption, with 44%-56% energy saved compared with a reverberatory furnace; great capacity of production; lower dust concentration of less than or equal to 50mg / Nm3 in exhaust emissions, about 90%-95% lower than the dust concentration of a reverberatory furnace; good quality of products; low labor intensity; high labor productivity which is more than 49 times of the productivity of a reverberatory furnace; high utilization of magnesite, for a reverberatory furnace only being capable of lightly burning lump ore materials, but a gaseous suspension calcinator, a fluidized flash calcinator or a circulating calcinatory being able to lightly burn fine ore materials.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Vehicle navigation alcohol fuel anti-corrosive anti-swelling additive and production method

InactiveCN110157510AInhibit swellingInhibition formationLiquid carbonaceous fuelsFuel additivesDibutyl sebacateBarium salt

The invention discloses a vehicle navigation alcohol fuel anti-corrosive anti-swelling additive. The technical problem of corrosion, brought by existing navigation alcohol fuel, to engine metal partsis solved. The anti-corrosive anti-swelling additive comprises at least two agents of the following components in parts by weight: 1-20 parts of ethanolamine, 1-5 parts of 2-mercaptobenzothiazole, 1-5parts of dihydroimidazole, 1-10 parts of N,N-bis(salicylidene)propanediamine, 5-15 parts of dibutyl sebacate, 1-20 parts of cyclohexylamine, 1-5 parts of pyrazolone, 0.5-8 parts of 2,6-dimethyl tert-butyl ether and 1-12 parts of a barium salt of phosphosulfurized polyisobutylene. By using navigation alcohol fuel produced from the vehicle navigation alcohol fuel anti-corrosive anti-swelling additive, in production, storage and transportation processes, organic acid formed by external and internal water and the navigation alcohol fuel can be inhibited; and in a use process, corrosion to an engine can be prevented, full combustion of the fuel is promoted, and acid and formaldehyde are reduced.

Owner:寇延华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com