Continuous flash process equipment for waste oil

A process equipment and flash evaporation technology, applied in the petroleum industry, hydrocarbon distillation, etc., can solve the problems of unstable chemical properties of oil products, endangering the safety of operators, and large loss of economic benefits, achieving the elimination of secondary pollution and a high degree of automation. , the effect of fast flash evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

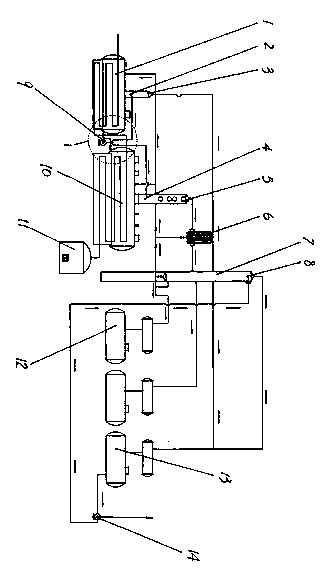

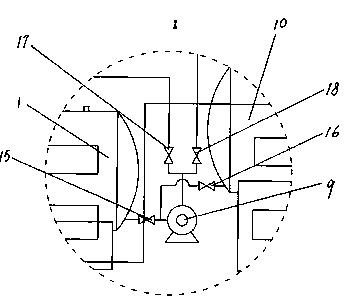

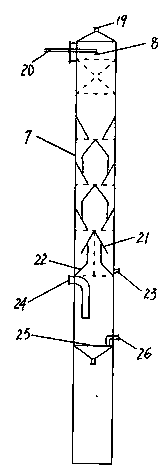

[0009] as attached figure 1 As shown, the process equipment is mainly composed of a hot blast stove 11, a preheating kettle 1, a gas collecting tower 3, a flash kettle 10, a flash tower 5, a fractionating tower 7, a condenser and each oil tank 12, 13. An oil pump 9 is installed between the kettle 1 and the flash kettle 10. The inlet of the oil pump 9 has a three-way connection. One end is connected to the bottom of the preheating kettle 1 through a valve 15, and the other end is connected to the bottom of the flash kettle 10 through a valve 16. The oil pump 9. The outlet is connected to a tee, and connected to the bottom of the gas collecting tower 3 above the preheating kettle 1 and the bottom of the flash tower 5 above the flash kettle 10 through connecting pipes, and valves 17 and 18 are respectively installed on the connecting pipes; The pipes at the bottom of the gas collecting tower 3 and the bottom of the flash tower 5 are inserted into the bottom of the tower, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com