Beneficiation method for comprehensively using vanadium-bearing titanomagnetite low-grade lean ore and ore below cut-off grade

A technology of vanadium titanomagnetite and beneficiation method, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as poor resource utilization effect, improve resource utilization rate, improve mining efficiency, reduce stripping The effect of picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 (applicable to the south where the rainy season is longer and rainfall is more)

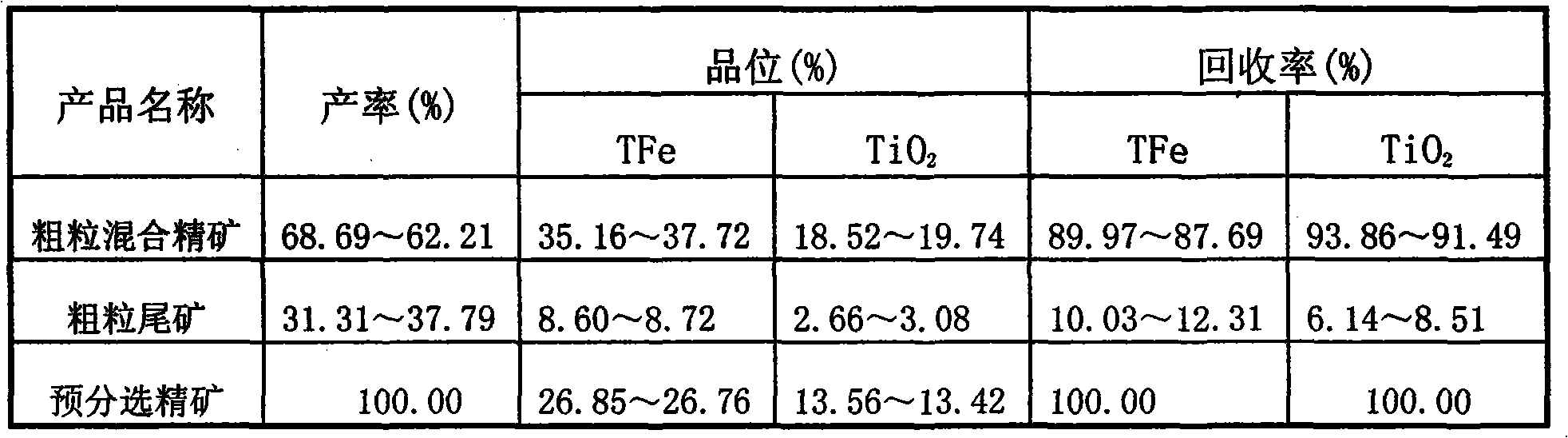

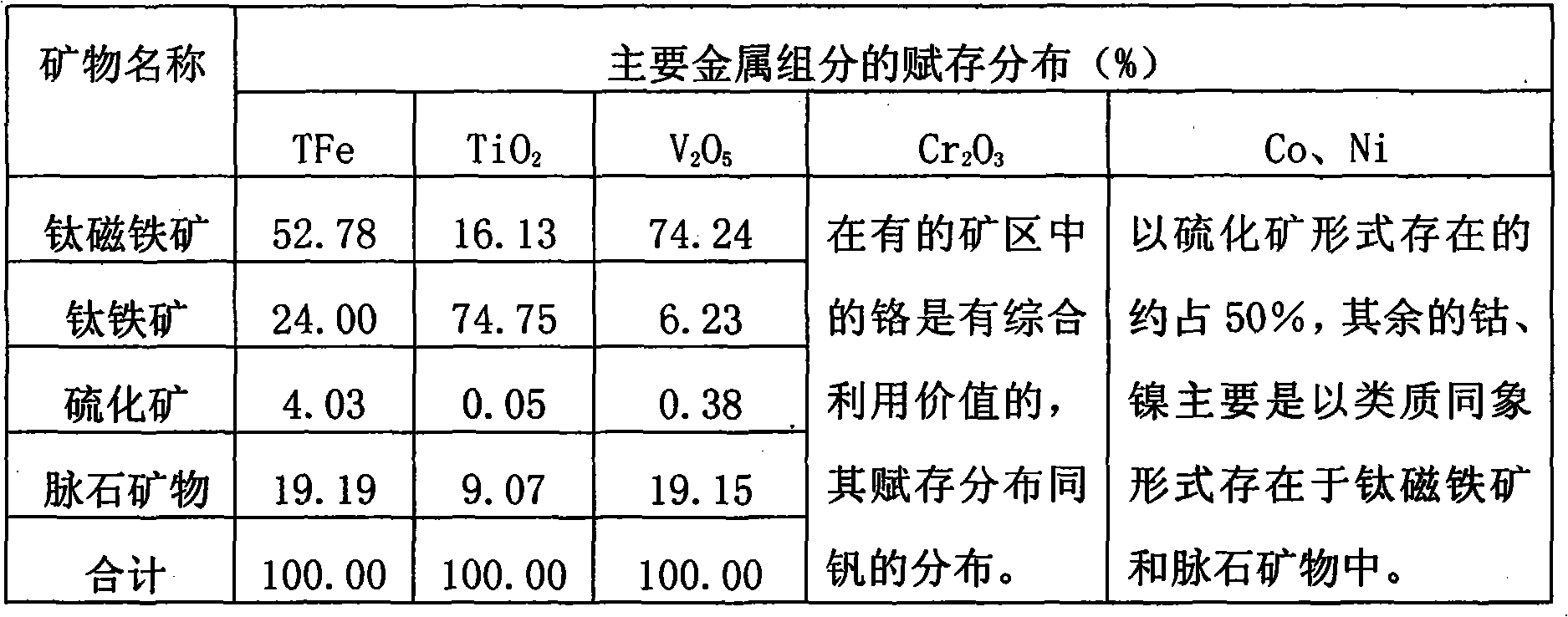

[0042] For the mixed ore mined from the surface ore and the surface ore, the three-stage crushing-screening closed-circuit crushing process is adopted, and the particle size is -10mm 100%. For the crushed products with a water content greater than 3%, wet-type drum permanent magnets are used. Weak magnetic roughing and strong magnetic sweeping technology for pre-separation, fully enrich and recover metal minerals in the form of mineral aggregates, mainly titano-magnetite and ilmenite, and obtain a pre-separation with a yield of 68.12% For concentrate, discard the pre-sorting tailings with a yield of 31.88%. For the pre-sorting concentrate, use the grinding-screening and grading closed-circuit process to carry out the I-stage rod grinding, and grind to the particle size of -1mm 100%. For the I-stage Grinding products are subjected to wet permanent magnetic weak magnetic separat...

Embodiment 2

[0043] Embodiment 2 (applicable to the south where the rainy season is longer and rainfall is more)

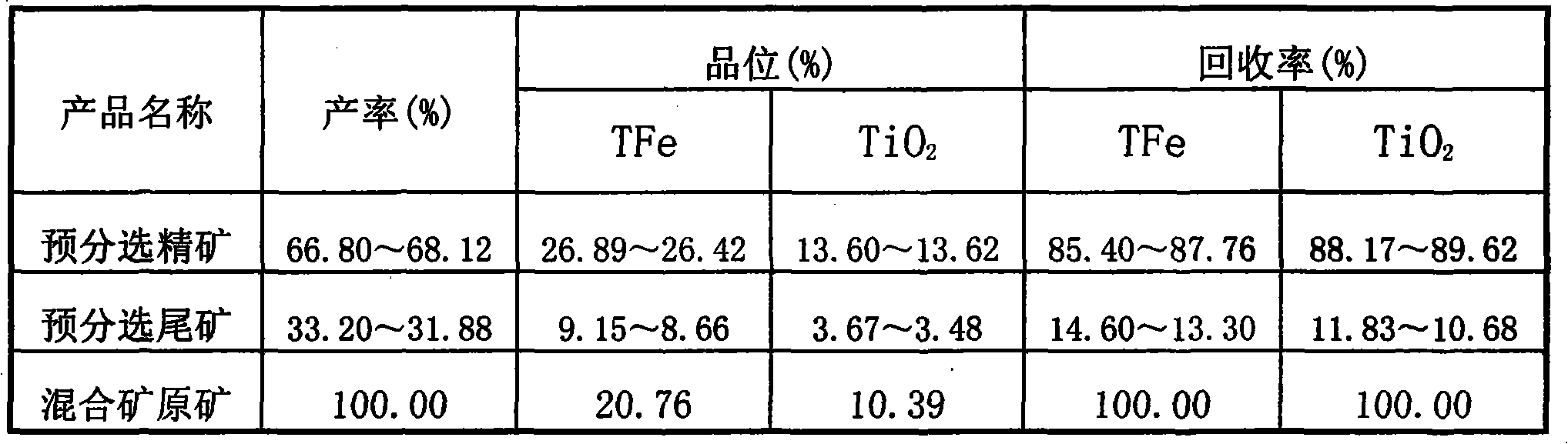

[0044]For the mixed ore mined from the surface ore and the surface ore, the three-stage crushing-screening closed-circuit crushing process is adopted, and the particle size is -10mm 100%. For the crushed products with a water content greater than 3%, wet-type drum permanent magnets are used. The technology of medium magnetic roughing and strong magnetic sweeping is used for pre-separation to obtain the pre-separated concentrate with a yield of 66.80%, and discard the tailings with a yield of 33.20%; the pre-separated concentrate is ground-screened Classification closed-circuit process carries out stage I coarse grinding and grinding to particle size -1mm100%. Wet permanent magnetic weak magnetic separation is performed on the coarsely ground products of stage I, and wet permanent magnetic medium magnetic separation is carried out on the tailings of weak magnetic separation. Th...

Embodiment 3

[0045] Embodiment 3 (applicable to the north where the perennial drought and little rain in the north)

[0046] For the mixed ore mined from the surface ore and the surface ore, a three-stage crushing-screening closed-circuit crushing process is adopted to crush to a particle size of -10mm 100%, and the water content of the crushed product is less than 3%. Pre-separation is carried out with the technology of conventional weak magnetic roughing and strong magnetic sweeping to obtain the pre-separated concentrate with a yield of 68.12%, and discard the tailings with a yield of 31.88%; the pre-separated concentrate is ground-screened The graded and closed-circuit process is used to carry out coarse grinding and grinding in stage I until the particle size is -1mm 100%. Wet permanent magnetic weak magnetic separation is performed on the coarsely ground products in stage I, and wet permanent magnetic medium magnetic separation is carried out on the tailings of weak magnetic separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com