Presplitting blasting method for water holes close to high and steep slopes

A technology of pre-splitting blasting and high and steep slopes, which is applied in blasting and other directions, and can solve the problems of many roots, large blocks, low efficiency and high energy consumption, slope stability, etc., to reduce the root rate, reduce large blocks, and simplify construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

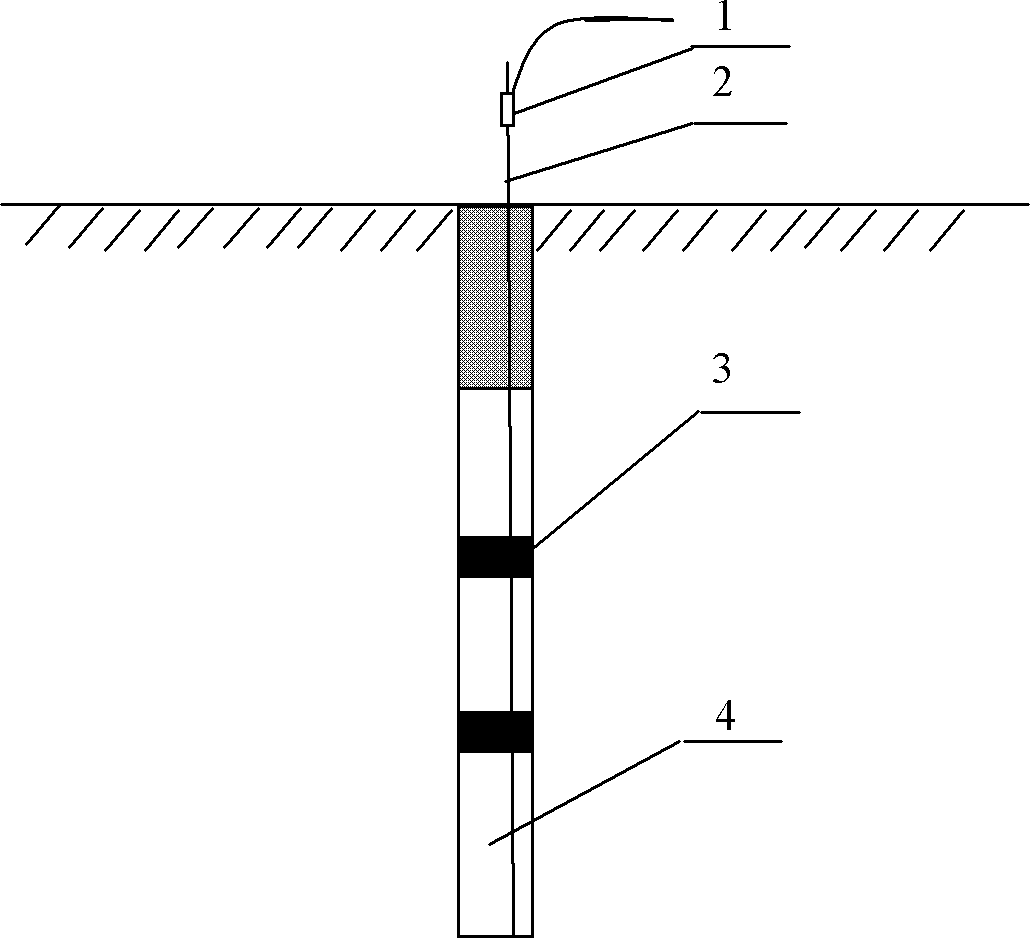

[0026] A water hole pre-splitting blasting method near a high and steep slope, the method is used for ore mining under the F9 fault near a high and steep slope in a certain mine, and the steps are as follows:

[0027] The first step is to determine the location of the production platform according to the requirements of the step layout, measure the profile of the actual slope to be blasted, and determine the chassis resistance line values at different locations.

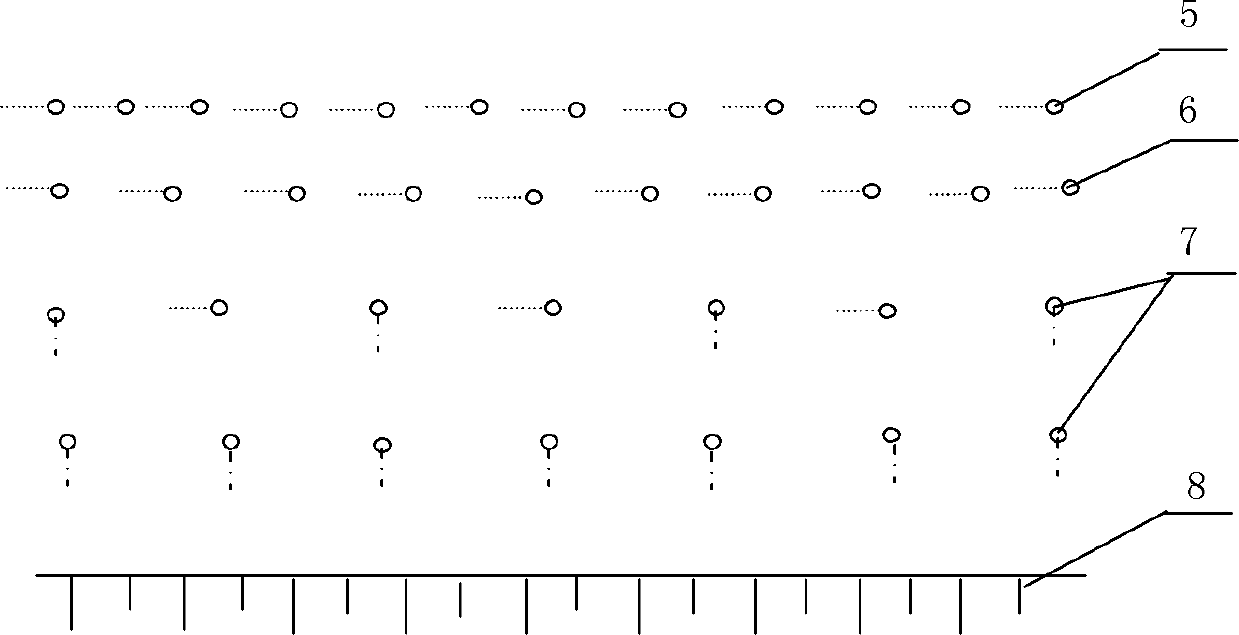

[0028] In the second step, according to the profile of the slope, the holes are arranged in the way of reversing holes. The specific technical parameters are:

[0029] 1. The non-coupling coefficient of the water hole pre-splitting hole 5 is 1.5-3.0;

[0030] 2. The distance between the 5 pre-splitting holes of the water hole is 1.5-2.5m;

[0031] 3. The row spacing between the water hole pre-splitting hole 5 and the buffer hole 6 is 2.5 to 3 meters;

[0032] 4. The charge density of the water hole pre-splitting ...

Embodiment 2

[0041] A water hole pre-splitting blasting method near a high and steep slope. This method is except following steps, all the other are with embodiment 1.

[0042] In the second step, according to the profile of the slope, the holes are arranged in the way of reversing holes. The specific technical parameters are:

[0043] 1. The non-coupling coefficient of the water hole pre-splitting hole 5 is 3.0-4.5;

[0044] 3. The distance between the 5 pre-splitting holes of the water hole is 2.0-3.0m;

[0045] 3. The row spacing between the water hole pre-splitting hole 5 and the buffer hole 6 is 2.5 to 3 meters;

[0046] 4. The charge density of the water hole pre-splitting hole 5 line is 2.0-3.0kg / m;

[0047] 5. The parameters of the main gun hole 7 hole network are 4×5~6×5m 2 .

[0048] The third step, the charging structure of this embodiment is a full detonating cord charging structure: first, the explosive 4 is loaded into the bottom of the water hole pre-splitting hole 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com