Ore separation method for recycling scandium from bayan obo tailings

A beneficiation method and tailings technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of complex composition, waste of rare earth resources, and high production costs, and achieve simple process, reduce production costs, and avoid losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

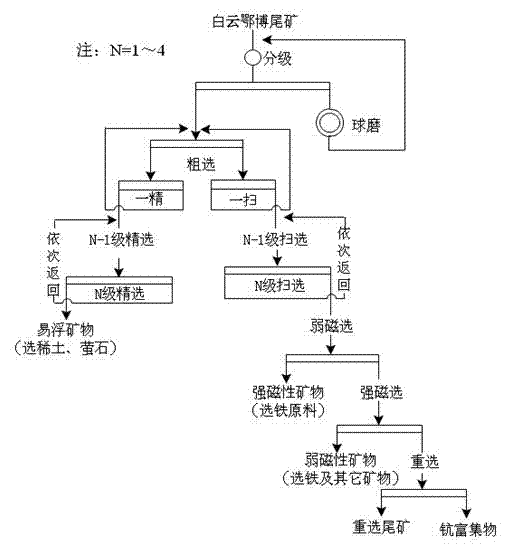

[0024] With the scandium oxide content being 190g / t Baiyun Obo tailings as raw material, utilizing the process technology of the present invention, carry out the following steps, as figure 1 :

[0025] (1) Classification and grinding: the tailings raw materials of Baiyun Obo are classified by a spiral classifier, the +200-mesh coarse-grained ore is finely ground by a ball mill, and returned to classification after grinding, and the -200-mesh ore obtained by the classification is adjusted for flotation ;

[0026] (2) Flotation: Put the -200 mesh Baiyun Obo tailings obtained after grading and grinding into the flotation tank, and carry out the closed-circuit flotation process of roughing, selection, and sweeping in sequence, and select and sweep The number of series is 3; firstly, the tailings after pulping are added to the roughing flotation tank, stirred, and sodium carbonate, water glass and oleic acid are added in turn to carry out roughing, and roughing is used to obtain r...

Embodiment 2

[0030] With the scandium oxide content being 220g / t Baiyun Obo tailings as raw material, utilizing the process technology of the present invention, carry out the following steps, as figure 1 :

[0031](1) Classification and grinding: Baiyun Obo tailings raw materials are classified by a hydrocyclone, the +200 mesh coarse ore is finely ground by a ball mill, and returned to classification after grinding, and the -200 mesh ore obtained by classification is floated select;

[0032] (2) Flotation: The -200 mesh Baiyun Obo tailings obtained after grading and grinding are slurried and added to the flotation tank, followed by a closed-circuit flotation process of roughing, selection, and sweeping. The stages of selection and sweeping are both 2 levels; the mass concentration of the flotation pulp is 55%, the temperature of the pulp is 55°C, the pH of the pulp is 8.5, and the dosage of the flotation reagent is based on the reagent and the -200 mesh added in each roughing. The mass r...

Embodiment 3

[0036] Be that the Baiyan Obo tailings of 240g / t of scandium oxide content is raw material, utilize the technology of the present invention, carry out following steps, as figure 1 :

[0037] (1) Classification and ore grinding: The tailings raw materials of Baiyun Obo are classified by vibrating sieve, and the +200-mesh coarse-grained ore is finely ground by a ball mill. After grinding, it returns to classification, and the -200-mesh ore obtained by classification is mixed for flotation;

[0038] (2) Flotation: The -200 mesh Baiyun Obo tailings obtained after grading and grinding are slurried and added to the flotation tank, followed by a closed-circuit flotation process of roughing, selection, and sweeping. The number of selection stages is 3, and the number of sweeping stages is 2; the mass concentration of the flotation pulp is 65%, the temperature of the pulp is 65°C, and the pH of the pulp is 10.6. The mass ratio of -200 mesh Baiyun Obo tailings is added, and the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com