Vehicle navigation alcohol fuel anti-corrosive anti-swelling additive and production method

A vehicle-used aviation alcohol and anti-swelling technology, applied in fuel additives, fuels, liquid carbon-containing fuels, etc., can solve problems such as cracks, ineffective effects, and wear, and achieve the effect of overcoming rubber expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, a vehicle aviation alcohol fuel anti-corrosion anti-swelling additive comprises the following components by weight:

[0027] 1-20 parts of ethanolamine, 1-5 parts of dimercaptopropithiazole, 1-5 parts of dihydroimidazole, 1-10 parts of N,N-disalicylidene propylenediamine, 5-15 parts of dibutyl sebacate 1-20 parts of cyclohexylamine, 1-5 parts of pyrazolone, 0.5-8 parts of 2,6-dimethyl tert-butyl ether, and 1-12 parts of polyisobutylene barium salt reagent.

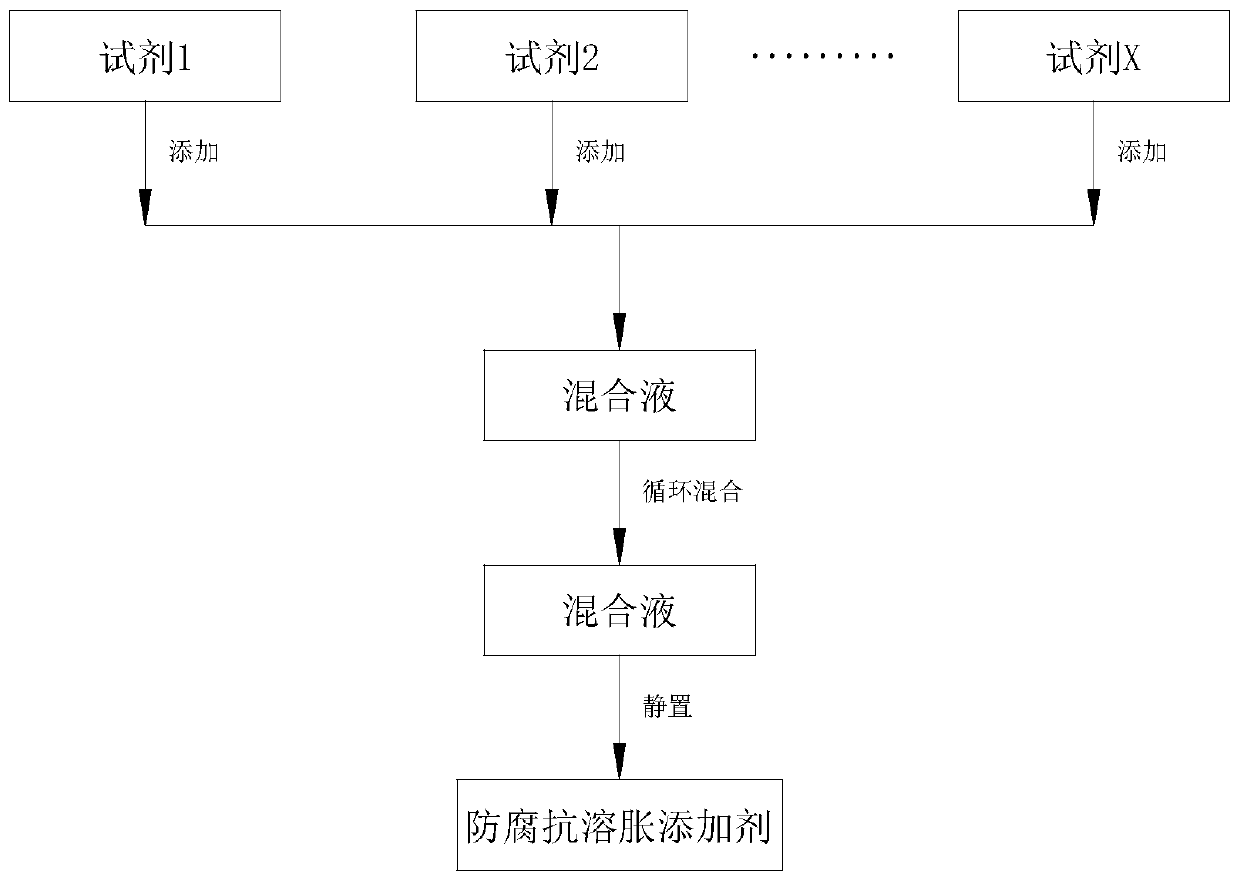

[0028] The production method flow is as follows figure 1 shown.

[0029] Step 1. Mixing two or more of the reagents at normal temperature and pressure;

[0030] Step 2. Circulating and mixing the mixed reagent through a circulation device for a certain period of time, and standing for a certain period of time to prepare the anti-corrosion and anti-swelling additive.

[0031] Among them, the processing temperature and pressure: normal temperature and pressure (23±3°C); the mixing time is more ...

Embodiment 2

[0039] In this embodiment, a vehicle aviation alcohol fuel anti-corrosion anti-swelling additive comprises the following components by weight:

[0040] 10-20 parts of ethanolamine, 2-5 parts of dimercaptopropithiazole, 3-5 parts of dihydroimidazole, 5-10 parts of N,N-disalicylidene propylenediamine, 7-15 parts of dibutyl sebacate 10-20 parts of cyclohexylamine, 2-5 parts of pyrazolone, 0.5-8 parts of 2,6-dimethyl tert-butyl ether, and 1-12 parts of polyisobutylene barium salt reagent.

[0041] The production method is as described in Example 1.

[0042] Technical effect is as described in embodiment 1.

Embodiment 3

[0044] In this embodiment, an anti-corrosion and anti-swelling additive for aviation alcohol fuel for vehicles comprises the following components by weight:

[0045] 10-20 parts of ethanolamine, 2-5 parts of dimercaptopropithiazole, 1-2 parts of dihydroimidazole, 1-10 parts of N,N-disalicylidene propylenediamine, 7-15 parts of dibutyl sebacate 10-20 parts of cyclohexylamine, 1-2 parts of pyrazolone, 0.5-8 parts of 2,6-dimethyl tert-butyl ether, and 1-12 parts of polyisobutylene barium salt reagent.

[0046] The production method is as described in Example 1.

[0047] Technical effect is as described in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com