Dressing and smelting combined treatment method for recycling complex copper oxide ore

A combination of dressing and smelting and treatment method, which is applied in the field of combined dressing and smelting treatment of complex copper oxide ore recovery, can solve the problems of uneven embedded distribution, many components, high oxidation rate and bonding rate, and reduce the loss of copper in tailings , reduce the number of selections, and reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The oxidation rate of a copper mine in the Democratic Republic of the Congo is 87.10%. The main copper minerals are malachite, chalcocite, chrysocolla, pseudomalachite, etc. Among them, malachite accounts for 65.21% of the copper oxide, and chrysocolla and pseudomalachite account for 34.79% of the total copper oxide copper content. The gangue minerals are mainly quartz, followed by carbonate minerals and silicate minerals. The particle size of copper sulfide embedding is finer, and the particle size of copper oxide embedding is coarser. The ore slime content is relatively large, and the ore properties are complex. The main valuable element of the raw ore in this embodiment is copper, the content is 5.32%, and the sulfur content is 0.42%;

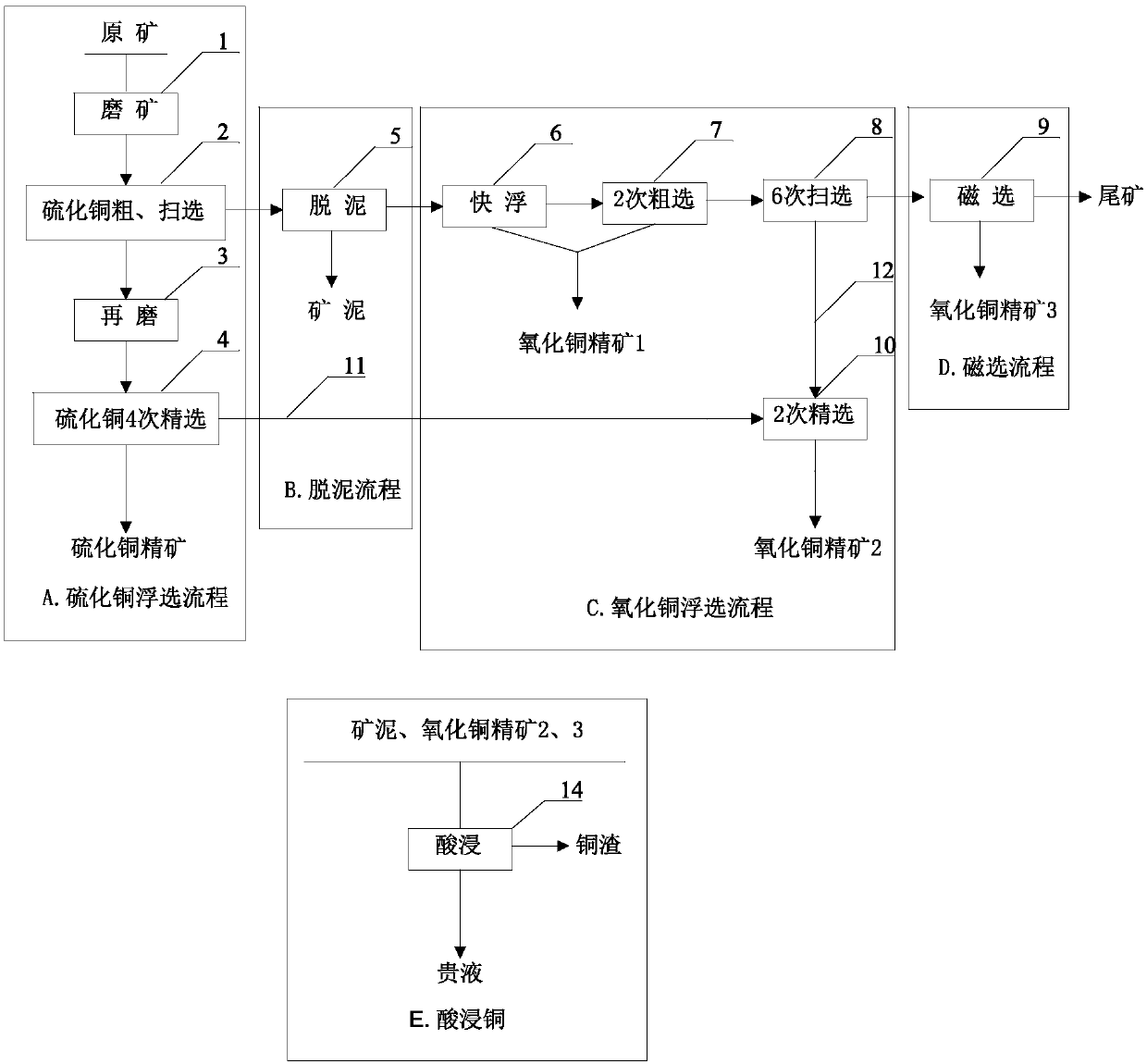

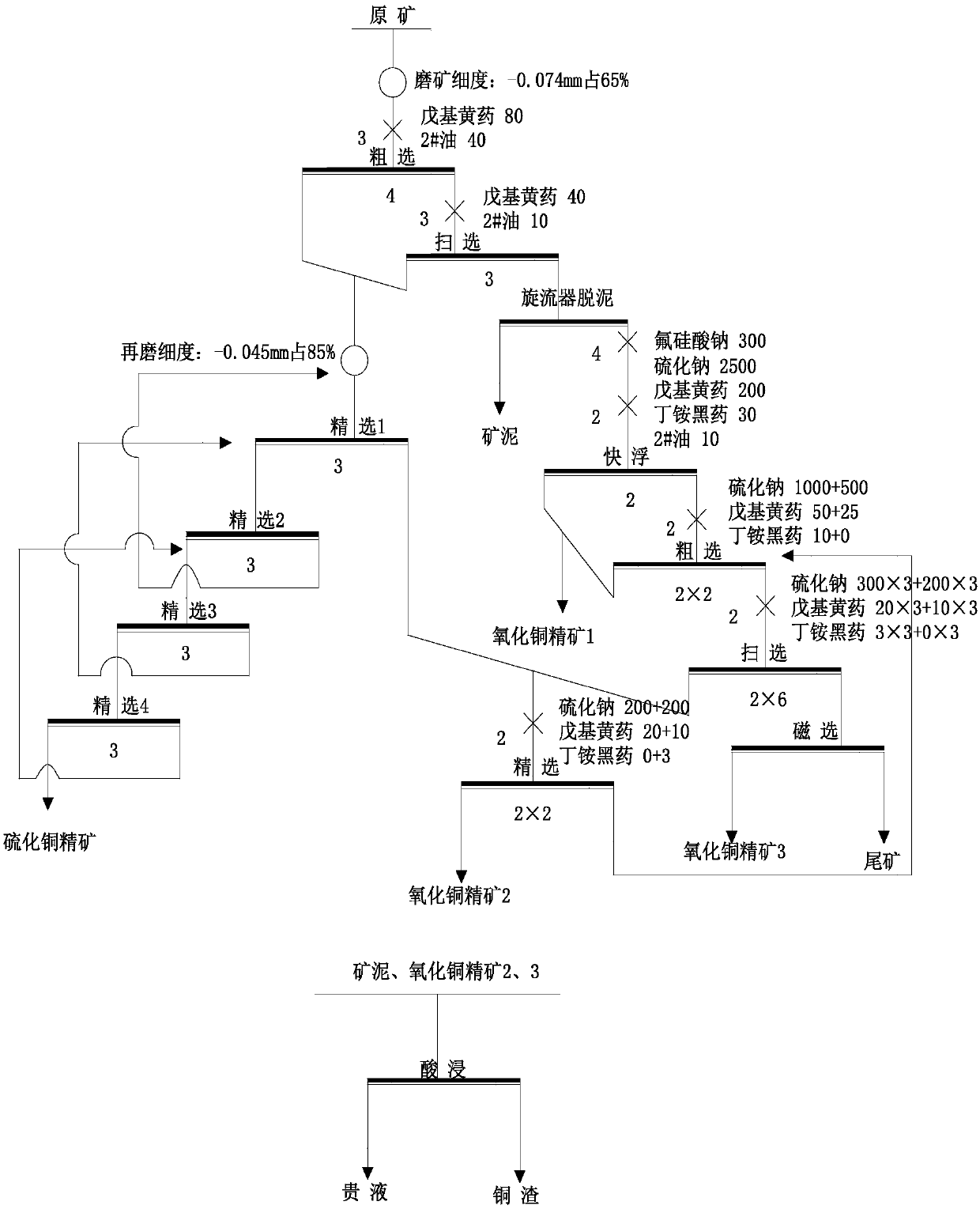

[0053] like figure 1 and figure 2 Shown, apply the present invention to process above-mentioned copper ore, the dressing and smelting combined processing method of reclaiming complex copper oxide ore comprises the following steps...

Embodiment 2

[0072] Test procedure and process parameter, medicament system are exactly the same as embodiment 1. The main valuable elements of the raw ore used in the implementation are copper, with a content of 5.19%, and a sulfur content of 0.39%.

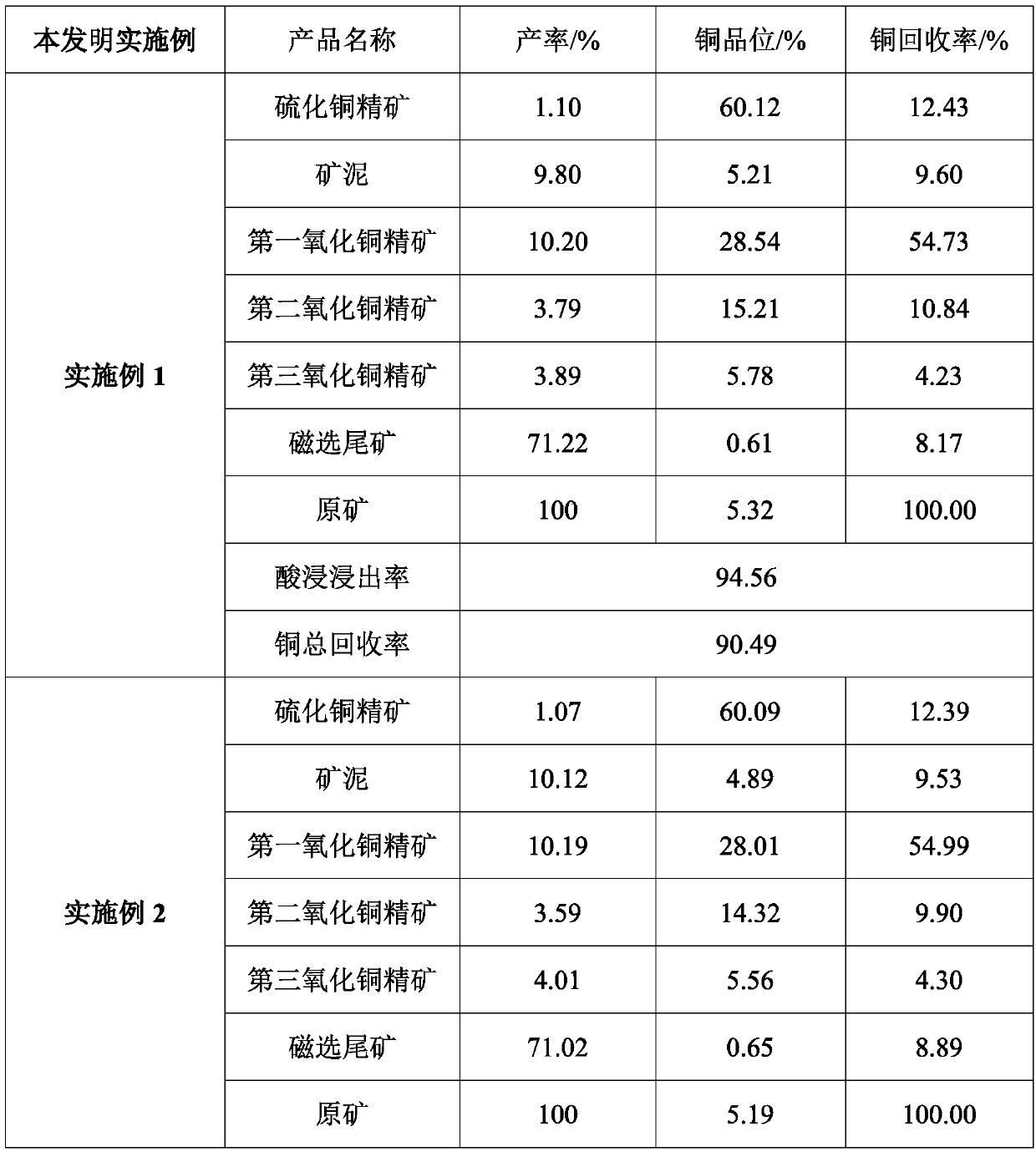

[0073] Embodiment 1 of the present invention, embodiment 2 concrete process index see table 1 below

[0074] Table 1 embodiment of the present invention technological index

[0075]

[0076]

[0077] The results of Example 1 and Example 2 shown in Table 1 show that the flotation process for efficiently reclaiming copper oxide ore of the present invention, the raw ore copper grade in Example 1 is 5.32%, and the available yield is 1.10%. High-grade copper sulfide concentrate with a copper recovery rate of 60.12% and a copper recovery rate of 12.43%; a yield rate of 9.8%, a copper grade of 5.21% and a copper recovery rate of 9.60% ore slime; a yield rate of 10.20% and a copper grade of 28.54%, copper recovery rate of 54.73% of high-grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com