Method for separating scandium concentrate from bayan obo tailings

A technology for concentrates and tailings, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve problems such as no economic benefits, difficult extraction, waste of resources, etc., and achieve large-scale production and easy large-scale production , The short and continuous effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

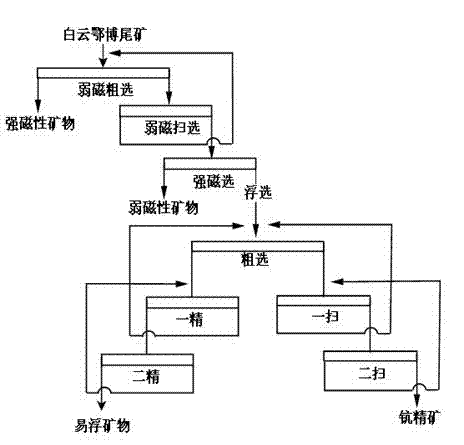

[0024] The composition is TFe 15.2%, REO 6.8%, Sc 2 o 3 The Baiyun Obo tailings of 200ppm are used as raw materials, and the process technology of the present invention is used to separate the scandium enrichment, and the specific steps are as follows figure 1 Shown:

[0025] (1) Weak magnetic separation: Weak magnetic separation is carried out on the Baiyun Obo tailings after slurry adjustment. The mass concentration of the pulp is 10%. The weak magnetic separation roughing concentrate and weak magnetic separation roughing tailings are obtained, the weak magnetic separation roughing concentrate is used as the raw material for further refining iron concentrate, and the weak magnetic separation roughing tailings are subjected to weak magnetic separation sweeping, and the weak magnetic separation The magnetic field strength of magnetic separation and sweeping is 0.3T. Weak magnetic separation and sweeping can obtain weak magnetic separation and sweeping concentrate and weak m...

Embodiment 2

[0030] The composition is TFe 18.2%, REO 5.3%, Sc 2 o 3 The Baiyun Obo tailings of 230ppm are used as raw materials, and the process technology of the present invention is used to separate the scandium enrichment, and the specific steps are as follows: figure 1 Shown:

[0031](1) Weak magnetic separation: Weak magnetic separation is carried out on the Baiyun Obo tailings after slurry adjustment. The mass concentration of the ore pulp is 15%. The weak magnetic separation roughing concentrate and weak magnetic separation roughing tailings are obtained, the weak magnetic separation roughing concentrate is used as the raw material for further refining iron concentrate, and the weak magnetic separation roughing tailings are subjected to weak magnetic separation sweeping, and the weak magnetic separation The magnetic field strength of magnetic separation and sweeping is 0.22T. Weak magnetic separation and sweeping obtain weak magnetic separation and sweeping concentrate and weak ...

Embodiment 3

[0036] The composition is TFe 22.5%, REO 3.9%, Sc 2 o 3 The Baiyun Obo tailings of 250ppm are used as raw materials, and the process technology of the present invention is used to separate the scandium enrichment, and the specific steps are as follows figure 1 Shown:

[0037] (1) Weak magnetic separation: Weak magnetic separation is carried out on the Baiyun Obo tailings after slurry adjustment. The mass concentration of the pulp is 28%. The weak magnetic separation roughing concentrate and weak magnetic separation roughing tailings are obtained, the weak magnetic separation roughing concentrate is used as the raw material for further refining iron concentrate, and the weak magnetic separation roughing tailings are subjected to weak magnetic separation sweeping, and the weak magnetic separation The magnetic field strength of magnetic separation and sweeping is 0.16T. Weak magnetic separation and sweeping obtain weak magnetic separation and sweeping concentrate and weak magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com