Patents

Literature

36results about How to "Improve deinking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deinking agent for display window glass

The invention discloses a deinking agent for display window glass. The deinking agent is prepared from 30-70% of water, 5-20% of inorganic base, 0.5-8% of inorganic corrosion inhibitors, 7.5-16% of organic corrosion inhibitors, 5-20% of solvent and 5-20% of penetrant, and 7-22% of mixtures composed of alkyl alcohol ether polycarboxylate, alkyl polyoxyethylene phosphate and coco glucoside are added. In the heating application process, the deinking agent is capable of preventing a solution from being layered all the time, stable in performance and long in service life; due to the fact that the corrosion inhibitors are added, in the application process of the glass deinking agent, little corrosion is caused to a glass base plate, it is not easy to scratch the window glass, and the yield rate of the panel display window glass obtained after the deinking is raised; meanwhile, the deinking agent is great in penetrability, moderate in alkalinity and high in ink removal speed.

Owner:湖南利尔电子材料有限公司

Neutral deinking method for waste newspaper

InactiveCN1763306AHigh whitenessReduce pollution loadFats/resins/pitch/waxes removal in pulpPaper recyclingInorganic saltsDeinking

The invention discloses a newsprint neutral voiding method in the pulping paper making technique domain with pulping, floating, scrubbing and bleaching procedure, which is characterized by the following: adapting flotation-scrubbing method without alkali; inputting 0.1 úÑ-2.0úÑ voiding agent, 1úÑ-6úÑ inorganic salt in the floating course; controlling the floating paste density between 2 and 18 percent, temperature between 20 and 70 deg.c, pre-impregnated time between 0 to 40 min, floating time between 10 and 60 min, insulating time between 0 and 40 min; The method improves the voiding efficiency and voiding paste whiteness by 16.6 percent as well as reduces the CoDcr in the neutral voiding waste-water by 190mg / l, which lessens the waste-water pollution load.

Owner:QILU UNIV OF TECH

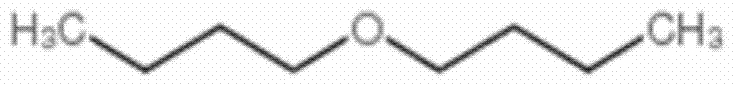

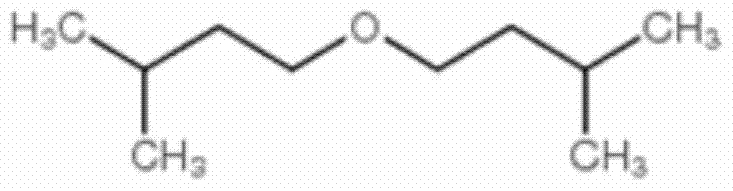

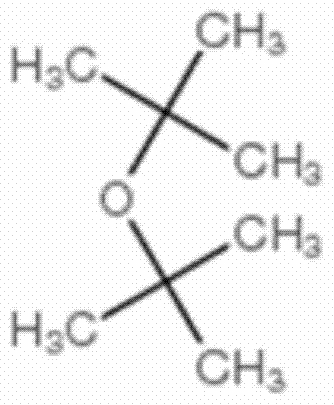

Waste paper deinking agent

ActiveCN101928485AEasy to produceReduce pollutionFats/resins/pitch/waxes removal in pulpChemical paints/ink removersDeinkingEconomic benefits

The invention relates to a waste paper deinking agent, which consists of surfactant, polyoxyethylene ether substance, penetrating agent, fatty acid sodium salt, caustic soda, sodium silicate, water and the like. All chemicals forming the waste paper deinking agent are common chemical products, and are easily purchased in a market. The components are innocuous and can be naturally degraded, namely the waste paper deinking agent meets the requirement of the current environment-friendly policy and has good environment friendliness. Meanwhile, a preparation process for the waste paper deinking agent is simple, easy in operation and good in finished product stability, can be applied to the deinking process of multiple waste papers and has ideal deinking effect; and the waste paper deinking agent is convenient to transport and store and is quickly dissolved in the deinking production process, namely the waste paper deinking agent has good economic benefit. Therefore, the waste paper deinking agent has remarkable environmental benefit and economic benefit.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

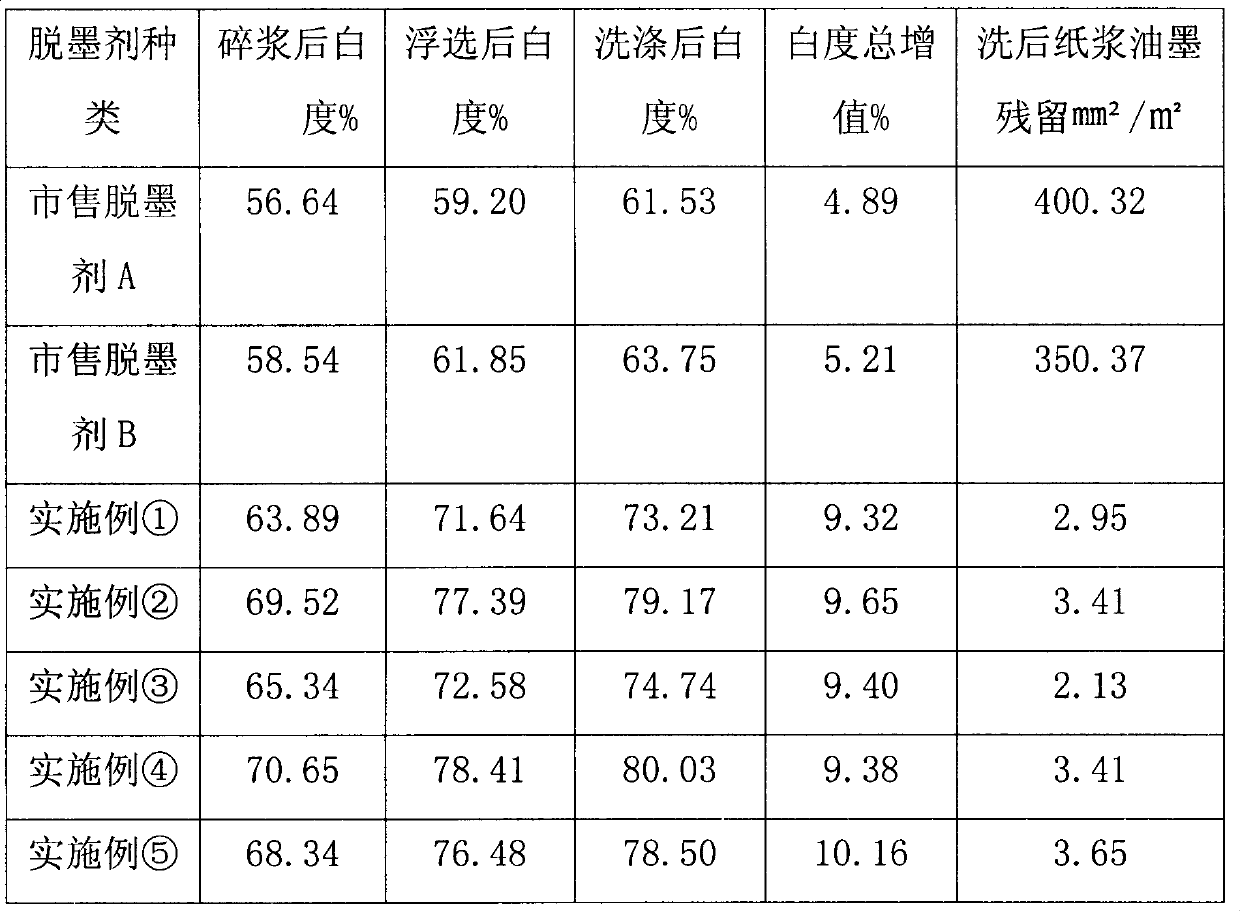

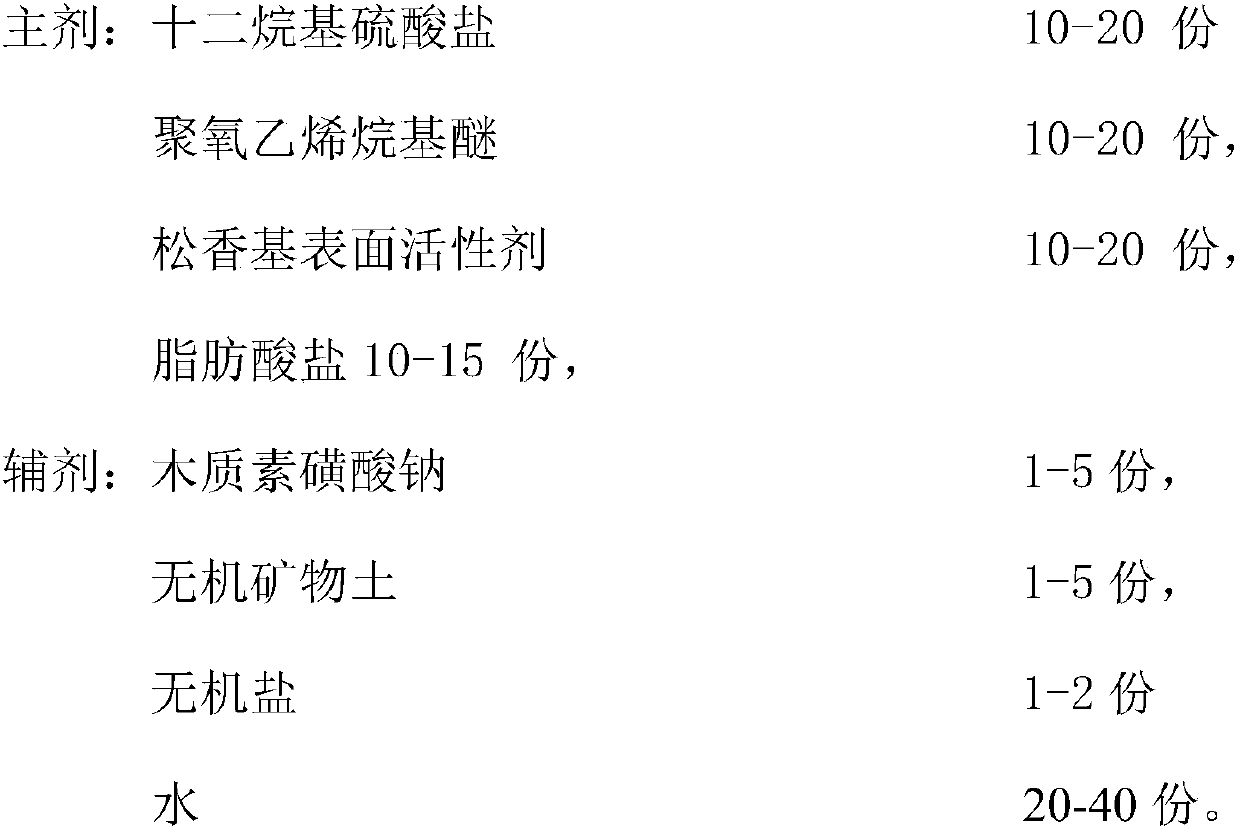

Neutral deinking agent and preparation method thereof

ActiveCN103881467AHigh practical valueOvercoming the problem of low deinking efficiencyChemical paints/ink removersDeinkingInorganic salts

The invention relates to a neutral deinking agent and a preparation method thereof. The neutral deinking agent comprises the following components by weight: 10-20 parts of lauryl sulfate, 10-20 parts of polyoxyethylene alkyl ether, 10-20 parts of a rosin based surfactant, 10-15 parts of fatty acid salt, 1-5 parts of sodium lignosulfonate, 1-5 parts of inorganic mineral soil and 1-2 parts of an inorganic salt, wherein the lauryl sulfate, the polyoxyethylene alkyl ether, the rosin based surfactant and the fatty acid salt are main agents, and the sodium lignosulfonate, the inorganic mineral soil and the inorganic salt are auxiliary agents. The neutral deinking agent is high in deinking efficiency, deinked pulp is high in whiteness and less in ink residues, and the neutral deinking agent has the advantages of being low in production cost, easy in biodegradability and the like, and is suitable for all kinds of waste paper deinking.

Owner:朱勇强

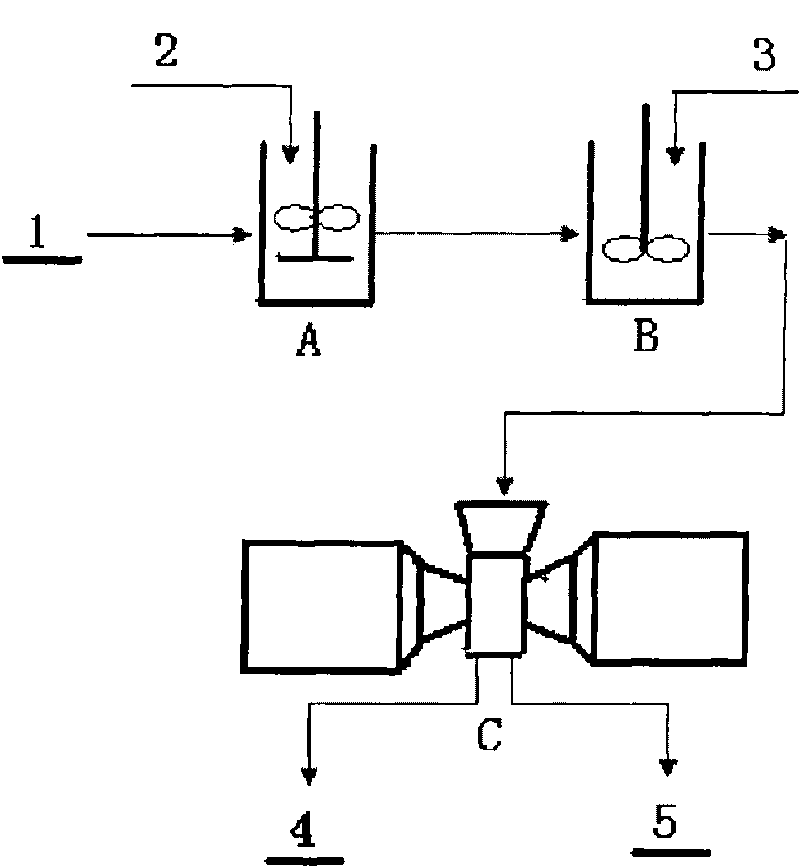

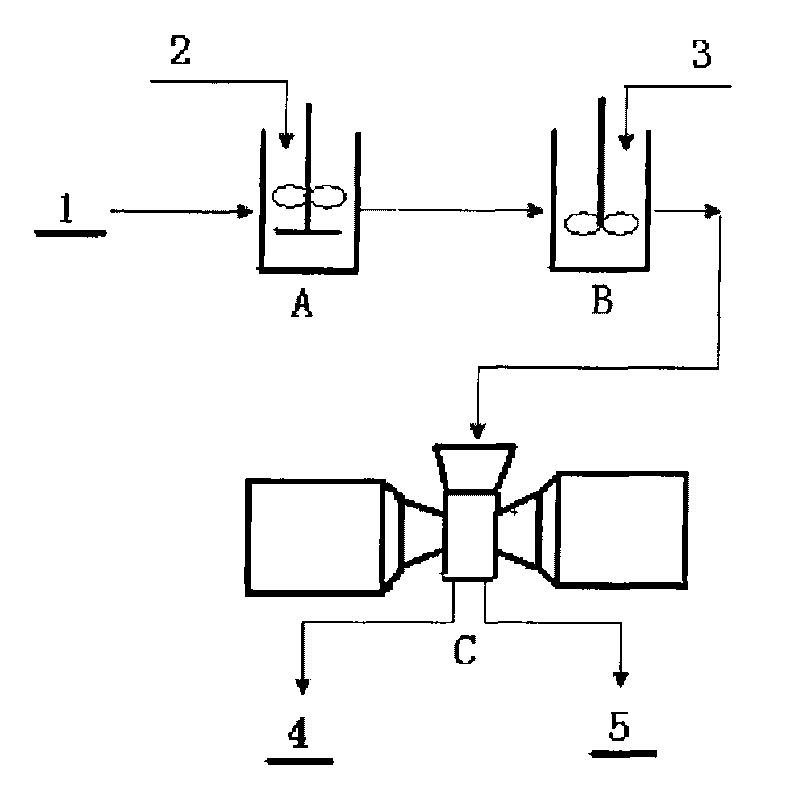

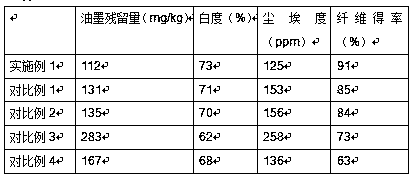

Biological enzyme-based process for deinking wastepaper by neutral-alkaline dual-loop flotation

ActiveCN103437230AReduce pollution loadHigh whitenessPaper recyclingWaste paper working-upFiberDeinking

The invention discloses a biological enzyme-based process for deinking wastepaper by neutral-alkaline dual-loop flotation, which belongs to the technical field of pulping and papermaking processes. The technological characteristics of the process are as follows: in the process, a neutral mixed deinking agent is adopted for deinking in a first-section neutral loop in neutral-alkaline dual loops, wherein the neutral mixed deinking agent comprises biological enzymes and a neutral deinking agent; in a second-section alkaline loop, alkaline hydrogen peroxide is adopted for deinking, and then flotation and washing are conducted on the obtained object so as to obtain wastepaper pulp subjected to deinking. The process disclosed by the invention has the advantages of slight damages on the strength and the opaqueness of wastepaper fibers, large whiteness added value, low pollution load, and difficulty of yellow returning of bleached pulp.

Owner:SOUTH CHINA UNIV OF TECH

Method for making paper from waste paper

InactiveCN106120419AImprove deinking efficiencyImprove the utilization rate of waste paperDryer sectionPaper recyclingWhite rotC constant

The invention further discloses a method for making paper from waste paper. The method includes the following steps of 1, pulping, wherein the waste paper is put in a 60 DEG C constant-temperature water bath tank to be heated, the concentration is adjusted to range from 4% to 6%, and the waste paper is added into a stirrer to be pulped for 40 min; 2, deinking, wherein deinking is carried out through a floatation washing method, wherein a deinking agent is a mixture of an acrylonitrile-butadiene-styrene copolymer, potassium oleate and octaphenyl polyoxyethyiene at the ratio of 3:2:1; 3, impurity removing, wherein printing ink particles in paper pulp are removed; 4, decoloring, wherein the paper pulp is bleached through white rot fungi, printing ink fine particles in the paper pulp are removed again, the PH value is controlled to range from 3 to 5, and the temperature is 40 DEG C; 5, secondary impurity removing, wherein impurities of the bleached paper pulp are removed; 6, forming, wherein wet paper web is formed through a net feeding device; 7, drying, wherein the wet paper web enters a pressure-shoe-shaped squeezing part for dewatering pressing, the squeezed wet paper web enters a drying cylinder to be dried, and the finished paper is obtained after cutting.

Owner:界首市宝洁纸业有限公司

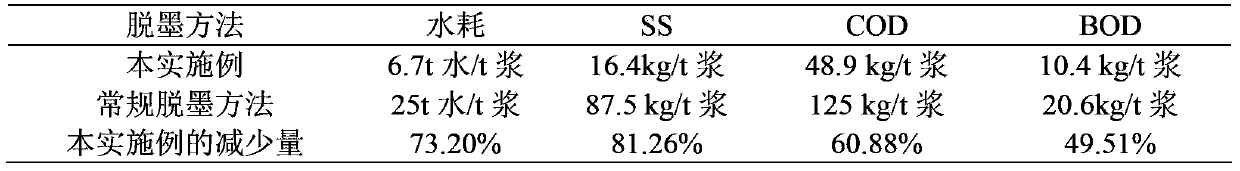

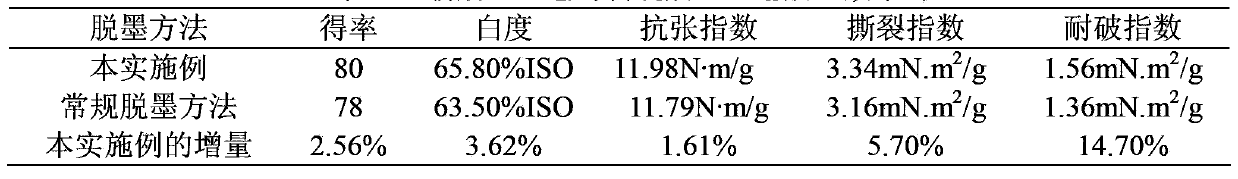

Waste paper deinking and stickies control technique

InactiveCN101760976AImprove deinking efficiencyReduce the number of paper breaksPaper recyclingWaste paper working-upEnzymePrinting ink

The invention relates to a waste paper deinking and stickies control technique which comprises the steps of crushing pulp, high concentration deslagging, coarse screening, fine screening, primary flotation, thermal dispersion, whitening, post-flotation, washing and filtering, wherein 1) adding soap deinking agent KLS-100 in the crushing pulp process; adding the soap deinking agent KLS-100 and polyethers surface active agent PA300 mixed deinking agent in the processes of primary flotation and post-flotation; and 2) in the washing process, adding optimyze 525 bio-enzyme, simultaneously adding resin dispersing agent B2281 while using the bio-enzyme, and controlling the pH value of sizing agent to be 7.0-7.5 in the adding process. The technique is used for waste paper deinking pulp, obviously improves the deinking efficiency, leads the whiteness of the deinking pulp to be increased to 74% ISO from 70% ISO, and reduces the length of printing ink stickies stuck on a paper machine scraper to be 5cm from 30cm, thus obviously reducing the times of cutting off paper of the paper machine, and improving the quality of the paper and the operating efficiency of the paper machine.

Owner:WUHAN CHENMING HANYANG PAPER

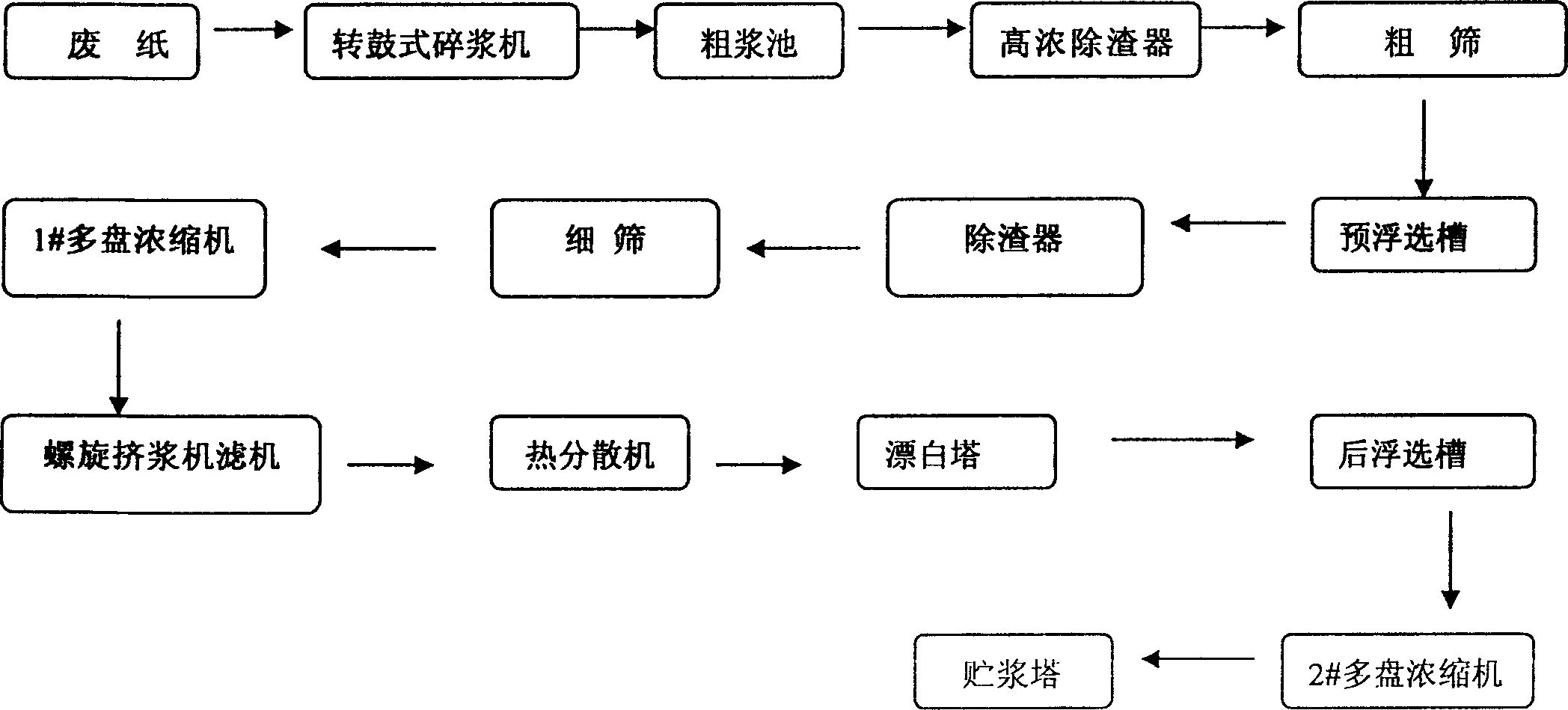

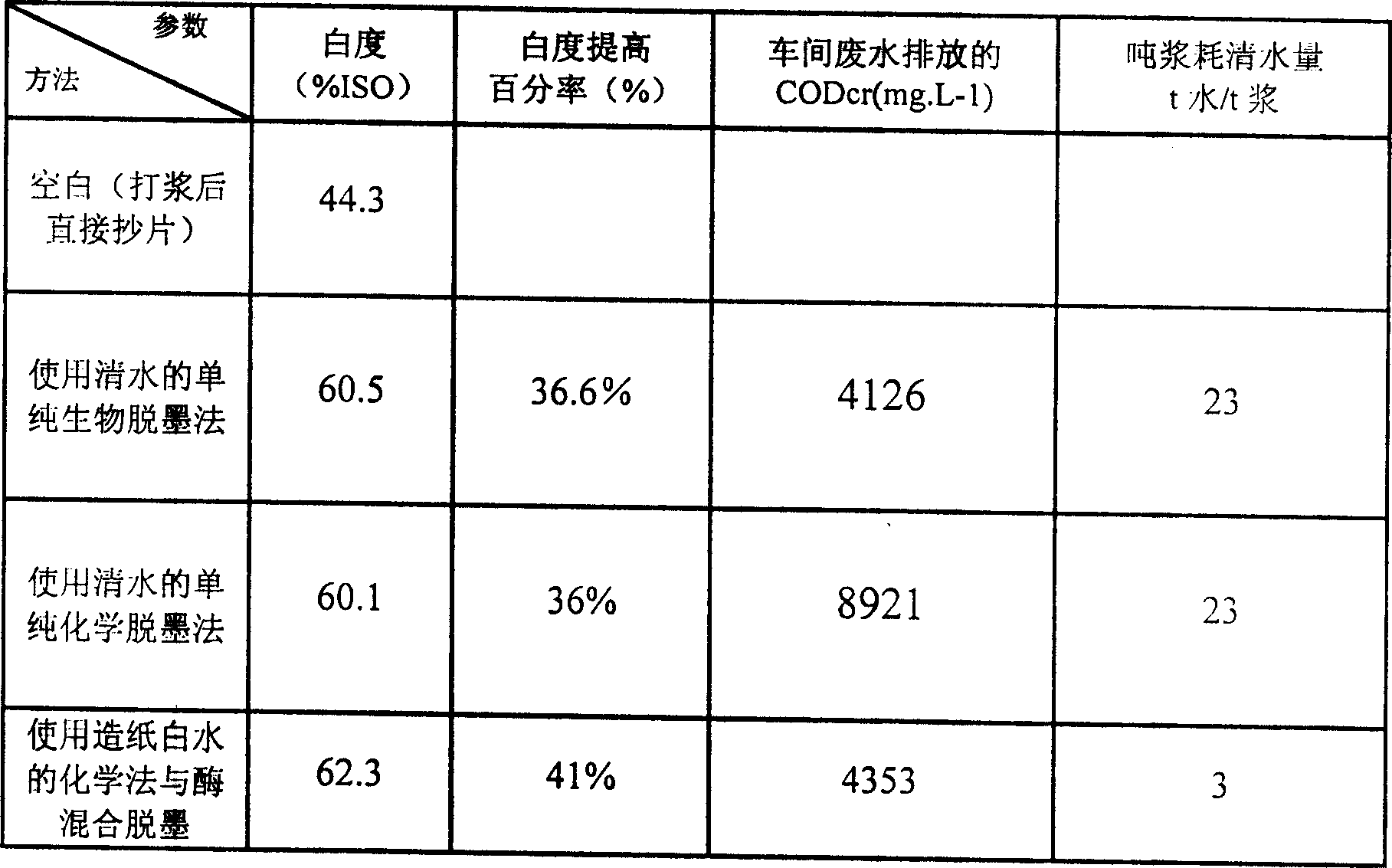

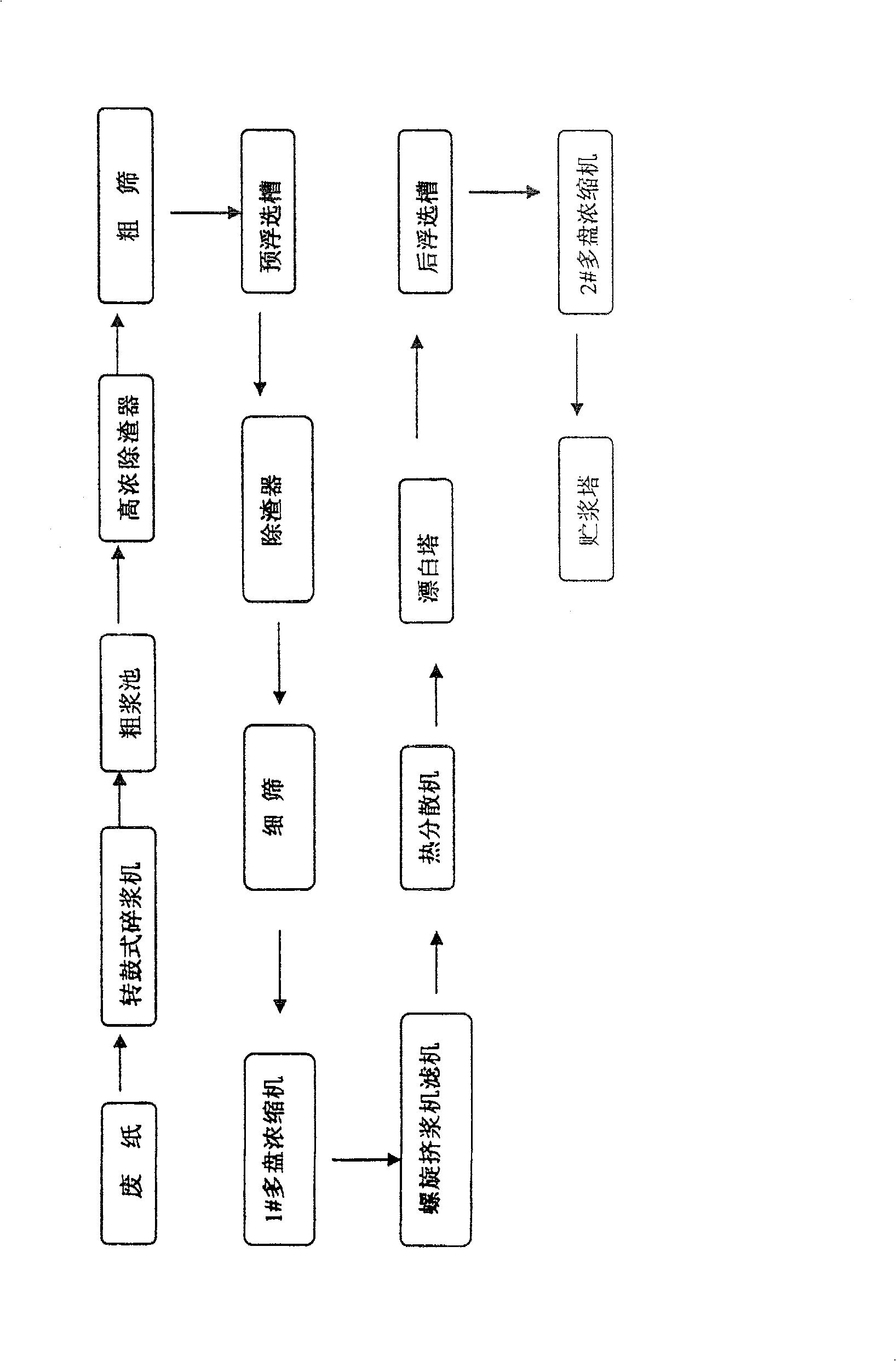

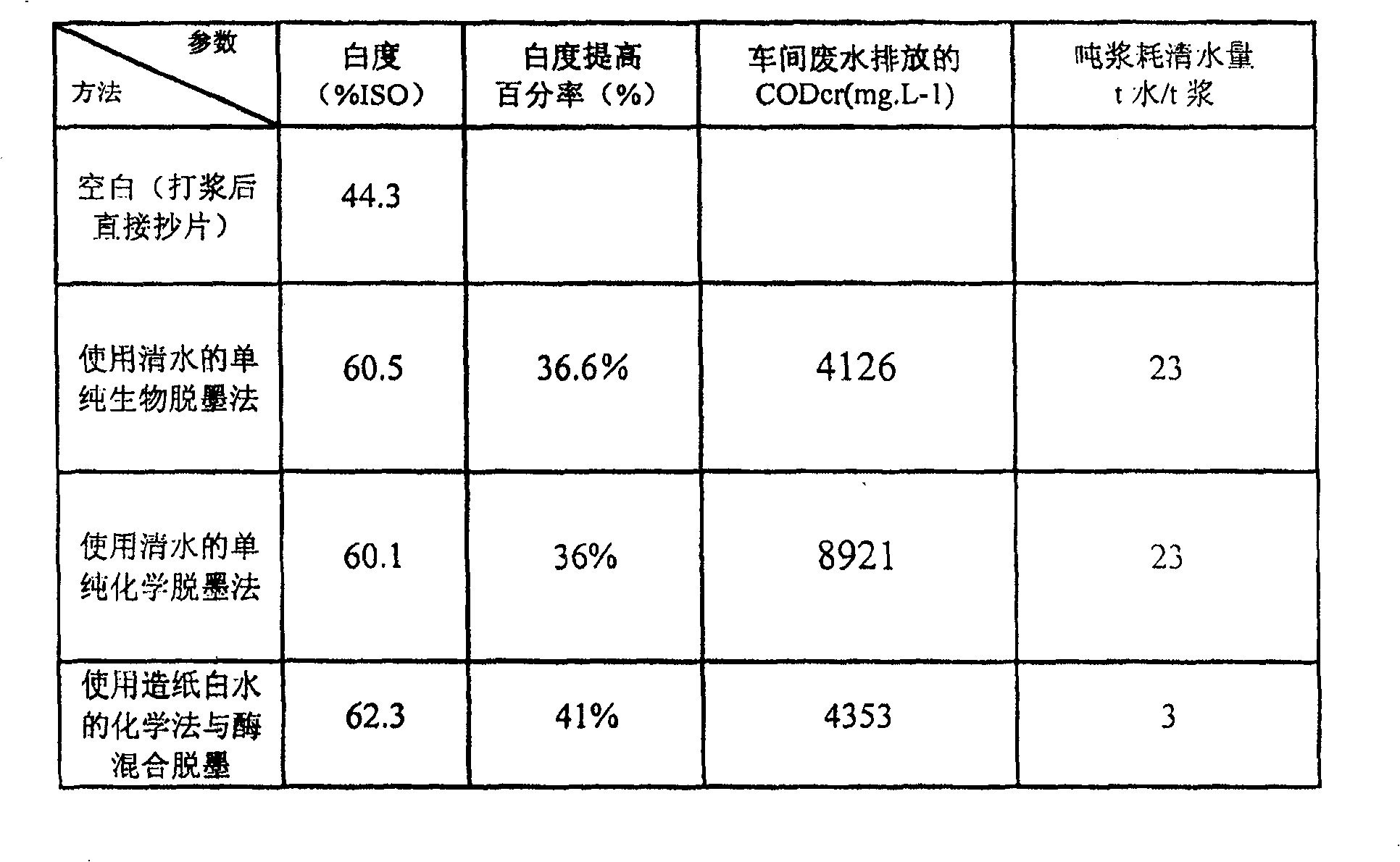

Method of preparing pulp by deinking ONP/OMG mixed wastepaper blended with paper making white water

InactiveCN101016704ALow strengthLittle impact on pulp yieldPulp liquor regenerationPaper recyclingProduction linePulp and paper industry

The invention relates to a method for dipping pulping white water to void ONP / OMG mixed waste paper to produce pulp. The invention is characterized in that 1, using the white water in paper industry into whole void product line, 2, putting biological void agent and chemical void agent into drum pulper on the void product line, while the biological void agent is 0.09-0.1% and the chemical void agent is 0.5-0.8%, putting chemical void agent into pre-floating selecting groove and following floating selecting groove as 0.25-0.5% relative to the pulp, 3, adding alta-mud into white water pool as 5ppm. The invention can reduce clean water consumption, reduce dust and sewage discharge and discharge COD value, to improve white degree for 3-5% and void efficiency.

Owner:福建省南平南纸有限责任公司

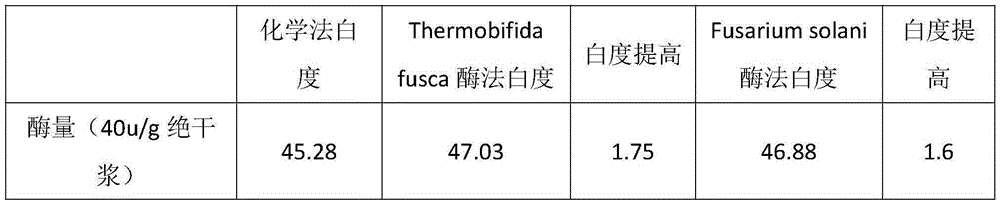

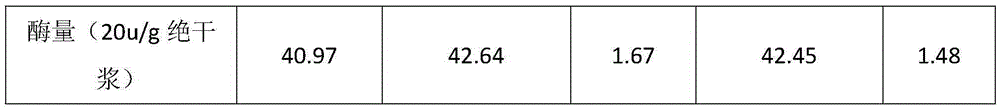

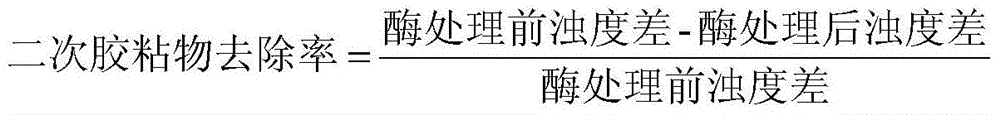

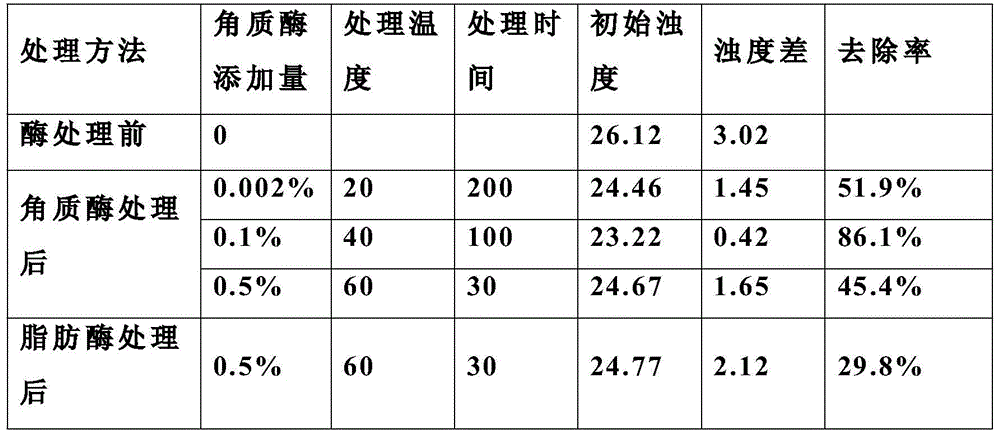

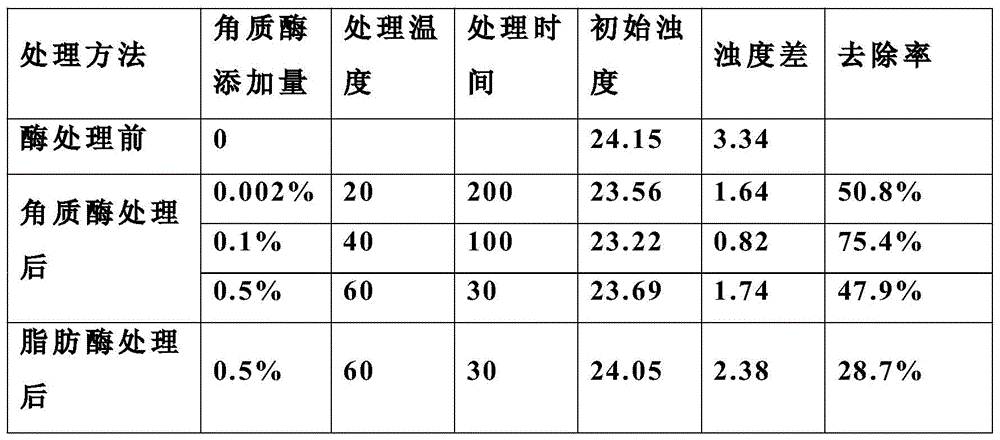

Methods for deinking wastepaper by combined use of cutinase and chemical reagents

ActiveUS20170137995A1Reduce sewage treatment costsIncrease usage ratioWashing/displacing pulp-treating liquorsPulp de-wateringDeinkingChemical treatment

The present invention provides methods for deinking wastepaper by combined use of cutinase and chemical reagents, which relates to the field of enzyme engineering. The method comprises the following steps: pulp preparation, enzymatic hydrolysis, pulp washing and dewatering, and flotation. The enzyme for enzymatic hydrolysis is cutinase at a concentration of 10-20 U / g absolute dry pulp; and 0.5-4% Na2SiO3, 0.1-0.8% MgSO4, 0.1-0.8% EDTA, 0.1-4% H2O2 are used in the chemical treatment. With combined use of enzymatic and chemical treatment, the present invention has solved the problem of the current enzymatic method for deinking that requires large dosage of enzymes and thus high cost. Through proper choice of the kind and the amount of chemical reagents, synergistic effects of the enzymatic and chemical treatment can be achieved, thus increasing the effectiveness of the deinking process. In addition, this method does not require alkaline chemicals, which alleviates the problem of sewage treatment associated with conventional deinking methods.

Owner:JIANGNAN UNIV

Deinking separating agent with multiple combined systems

InactiveCN103897475ABarrier rebondingImprove deinking efficiencyPaper recyclingChemical paints/ink removersCelluloseGlycine

The invention discloses a deinking separating agent with multiple combined systems. The deinking separating agent comprises an anionic surfactant, a nonionic surfactant and an ampholytic surfactant, wherein the anionic surfactant comprises sodium salt, ammonium salt, amine salt, alkamine salt and magnesium salt, the nonionic surfactant comprises methacrylamide, and the ampholytic surfactant is selected from C10-C24 alkyl acylamino C3-C8 alkyl glycine betaine, sulpho glycocoll betaine and the like. The separating agent can effectively inhibit ink particles from rebinding with the cellulose after separation, thus improving the deinking efficiency.

Owner:CHANGSHU YOUYOU MATERIAL TECH

Magnetic separation and deinking method for waste paper

InactiveCN101736635AImprove deinking efficiencyReduce fiber lossPaper recyclingWaste paper working-upChemistrySodium silicate

The invention relates to a magnetic separation and deinking method for waste paper, comprising the following steps: (1) adding waste paper and magnetic seeds in a pulper, adding water, sodium silicate and NaOH for repulping, wherein the repulping conditions are as follows: the magnetic seed dosage is 0.05-0.2wt%, the dosage of sodium silicate is 2-10wt%, NaOH is used to regulate the pH value to be 7-10, and the pulp concentration is 10-15wt%; (2) adding water for diluting after water paper repulping until the pulp concentration to be 0.5-4wt%, adding flocculant which accounts for 0.01-0.1wt% of dry paper into the pulp after repulping for magnetic seed flocculation, enabling the deciduous ink particles to be adhered with magnetic seeds, wherein the pH value is 7.0-11.0, the time is 10-30min, and the stirring speed is 200-1000rpm; and (3) separating the flocculated ink particles from the pulp by a deinking device for size after magnetic seed flocculation. The method in the invention can obviously improve pulp whitness and fiber yield of water paper, and can be used for producing deinking pulp with high whiteness and high deinking rate and small amount of paper fiber loss.

Owner:有研资源环境技术研究院(北京)有限公司

Common deinking method employing cutinase and chemical reagents

ActiveCN105386352AHigh reuse rateReduce dosagePaper recyclingChemical paints/ink removersDeinkingChemical treatment

The invention discloses a common deinking method employing cutinase and chemical reagents, and belongs to the technical field of enzyme engineering. The method comprises the following steps: repulping, enzyme treatment, chemical treatment, pulp washing and dewatering, and flotation, wherein the cutinase is utilized in the enzyme treatment; the amount of the cutinase is 10-20U / g oven dry stock; and the chemical treatment is treatment by adding 0.5%-4% of Na2SiO3, 0.1%-0.8% of MgSO4, 0.1%-0.8% of EDTA and 0.1%-4% of H2O2. Through combined deinking of an enzymic method and a chemical method, the problems of large enzyme amount and high cost in deinking of an existing enzymic method can be solved; the synergistic effect is generated by the enzymic method and the chemical reagent method through selection of the variety and the amount of the chemical reagents; and the deinking treatment effect is significantly enhanced. In addition, an alkaline matter does not need to use, so that the problem of sewage treatment in deinking in a conventional method is solved.

Owner:JIANGNAN UNIV

Waste paper deinking method

InactiveCN108978306AIncrease surface areaReduce crystallinityPaper recyclingWaste paper working-upDeinkingCellulose

The invention discloses a waste paper deinking method. The method comprises the following specific steps: 1) smashing waste paper, and transferring the smashed waste paper into an acid solution for soaking; 2) taking the soaked material out, and centrifuging to obtain paper pulp; 3) transferring the paper pulp into a container, and adding a material treatment agent and performing ultrasonic oscillation treatment; 4) adding water into the treated paper pulp for diluting, and performing flotation deinking; 5) washing the deinked paper pulp with a high-speed pulp washer. By adopting the waste paper deinking method provided by the invention, the paper pulp is treated with the material treatment agent to damage a part of hydrogen bonds among cellulose molecules, so that the cellulose structurebecomes loose and expands, degradation of ink permeating into cellulose through a deinking agent is facilitated, and the deinking efficiency is improved. Thus, the paper pulp yield is improved.

Owner:HEFEI LONGFA PACKING CO LTD

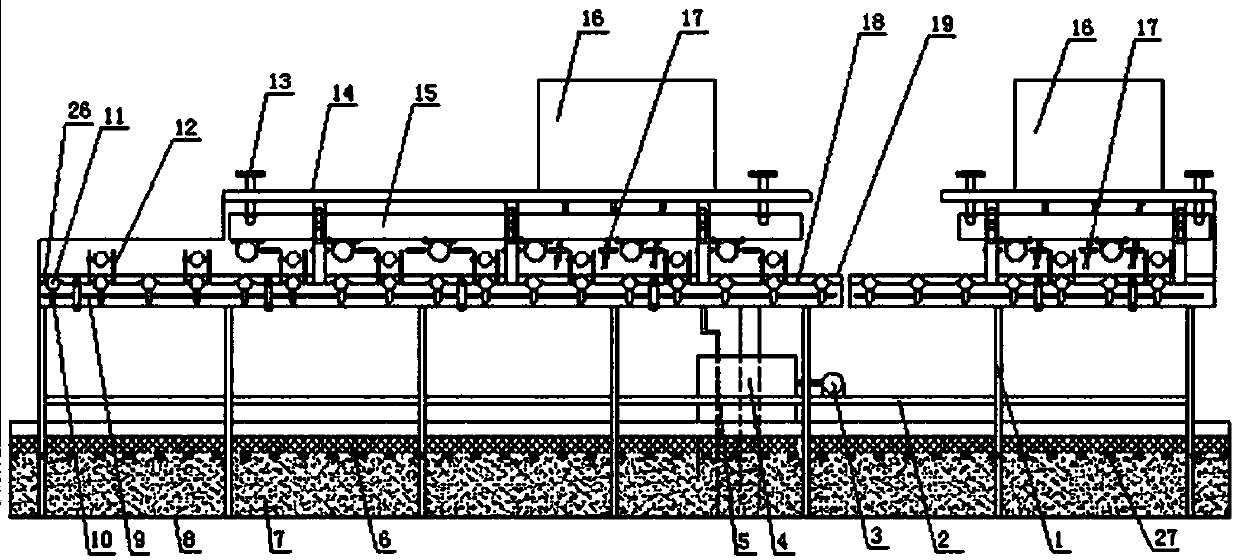

Highly efficiency microturbulence celluloid ink flotation cell

The invention unfurls a kind of float choosing slot for taking off ink of high effect. Compared with the current technique, the invention makes these changes: (1) add water current occur fix in front of the stairs spreading fix, the mixing equipment is made by air fix and water current occur fix; (2) change the last tube of the stairs spreading fix to the gradual spreading tube; (3) in the float choosing slot, there is float board and formatting the paragraph. By the float board, we can control the liquid stopping time in the float choosing slot, make the ink grains float to the surface, collect them by most in the spirit collection slot.

Owner:SOUTH CHINA UNIV OF TECH

Application of a kind of cutinase in paper industry

ActiveCN103757960BIncrease the proportionHigh reuse rateFats/resins/pitch/waxes removal in pulpPaper recyclingDeinkingControl treatment

Owner:JIANGNAN UNIV

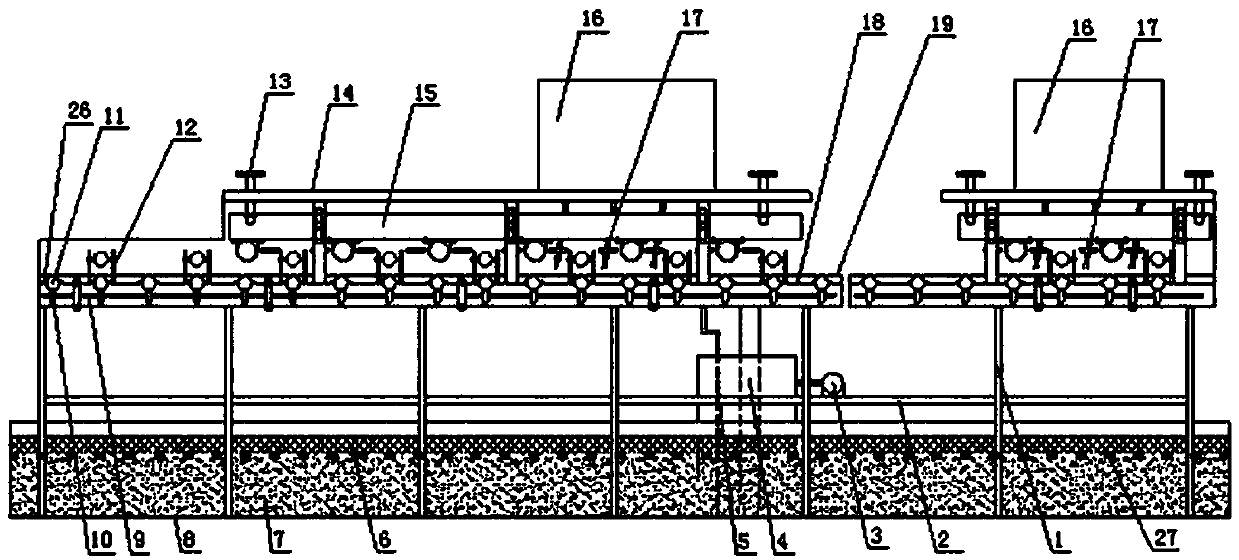

Glass deinking equipment

The invention discloses glass deinking equipment. The glass deinking equipment comprises a machine frame which is arranged above a deinking tank, a conveying mechanism which is fixedly arranged on themachine frame, a deinking cleaning mechanism which is fixedly arranged on the machine frame, and a housing which is fixedly arranged on the machine frame; a platform is arranged on the machine framebelow a glass moving horizontal plane; a pumping mechanism which is used for pumping deinking solution in the deinking tank onto the platform is fixedly arranged on the machine frame; the deinking cleaning mechanism comprises a first grade immersion mechanism, a second grade deinking mechanism, and a third grade water washing mechanism which are connected successively; the first grade immersion mechanism, the second grade deinking mechanism, and the third grade water washing mechanism comprises a plurality of brush heads and spray pipes which are fixedly arranged on the upper part of the platform along glass moving direction alternatively. The glass deinking equipment is capable of realizing glass deinking line production, reducing worker labor intensity and deinking cost greatly, increasing glass deinking efficiency greatly, and is suitable for glass deinking.

Owner:济宁市博韬玻璃制品有限公司

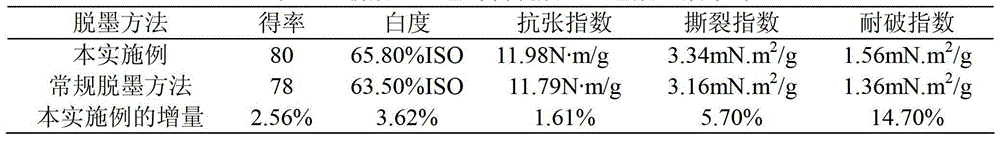

Production method with function of improving deinking efficiency and for corrugating medium paper

ActiveCN109629297AImprove ink removal rateImprove the efficiency of physical deinkingPulp liquor regenerationWashing/displacing pulp-treating liquorsFiberDeinking

The invention discloses a production method with the function of improving the deinking efficiency and for corrugating medium paper. The production method comprises the steps of soaking and activating, hydraulic repulping, sifting and slag removal, rubbing and centrifugal deinking, bleaching, washing and concentrating and pulp storage. A neutral deinking agent is utilized for directly rubbing andcentral deinking on waste paper fibers, through technological cooperation between printing ink activating and centrifugal deinking, printing ink is separated, the use amount of an alkaline deinking agent is reduced, the production cost for waste paper making is further reduced, the deinking efficiency is improved, the deinking rate is increased, the whiteness is improved, and the pollution to theenvironment is reduced.

Owner:东莞顺裕纸业有限公司

Method of preparing pulp by deinking ONP/OMG mixed wastepaper blended with paper making white water

InactiveCN100478518CImprove deinking efficiencyReduce COD valuePulp liquor regenerationPaper recyclingProduction linePulp and paper industry

The invention relates to a method for dipping pulping white water to void ONP / OMG mixed waste paper to produce pulp. The invention is characterized in that 1, using the white water in paper industry into whole void product line, 2, putting biological void agent and chemical void agent into drum pulper on the void product line, while the biological void agent is 0.09-0.1% and the chemical void agent is 0.5-0.8%, putting chemical void agent into pre-floating selecting groove and following floating selecting groove as 0.25-0.5% relative to the pulp, 3, adding alta-mud into white water pool as 5ppm. The invention can reduce clean water consumption, reduce dust and sewage discharge and discharge COD value, to improve white degree for 3-5% and void efficiency.

Owner:福建省南平南纸有限责任公司

A kind of display window glass deinking agent

ActiveCN105153788BStable chemical propertiesLess corrosiveChemical paints/ink removersAlkalinityDeinking

Owner:湖南利尔电子材料有限公司

Deinking process of medium-alkali double-circuit flotation waste paper based on biological enzyme

ActiveCN103437230BReduce pollution loadHigh whitenessPaper recyclingWaste paper working-upFiberDeinking

The invention discloses a biological enzyme-based process for deinking wastepaper by neutral-alkaline dual-loop flotation, which belongs to the technical field of pulping and papermaking processes. The technological characteristics of the process are as follows: in the process, a neutral mixed deinking agent is adopted for deinking in a first-section neutral loop in neutral-alkaline dual loops, wherein the neutral mixed deinking agent comprises biological enzymes and a neutral deinking agent; in a second-section alkaline loop, alkaline hydrogen peroxide is adopted for deinking, and then flotation and washing are conducted on the obtained object so as to obtain wastepaper pulp subjected to deinking. The process disclosed by the invention has the advantages of slight damages on the strength and the opaqueness of wastepaper fibers, large whiteness added value, low pollution load, and difficulty of yellow returning of bleached pulp.

Owner:SOUTH CHINA UNIV OF TECH

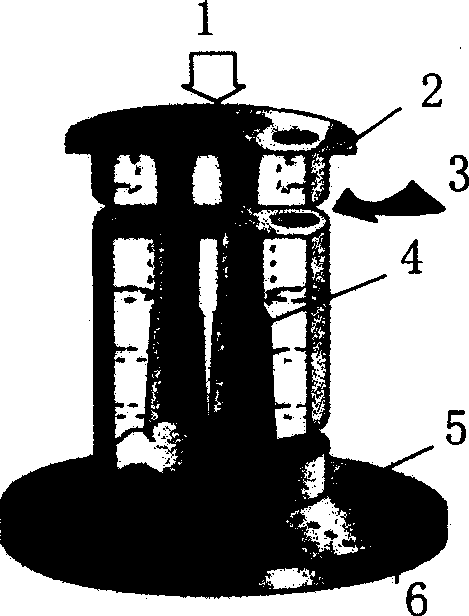

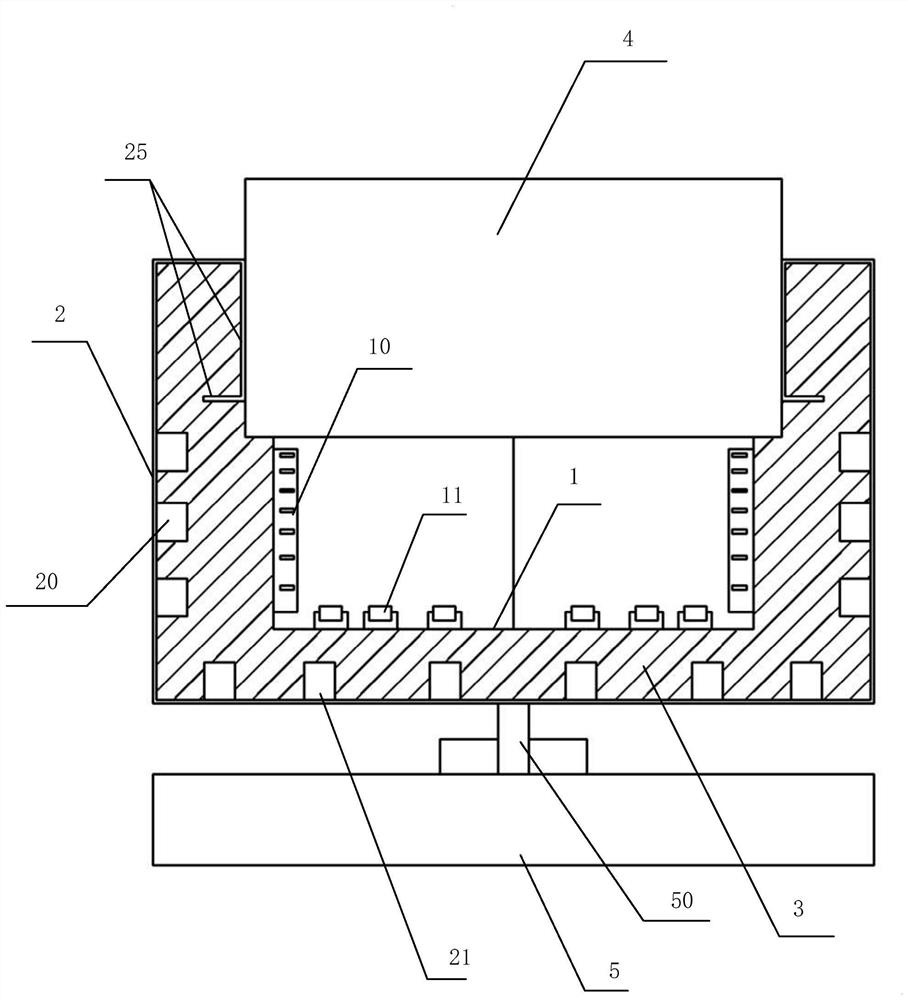

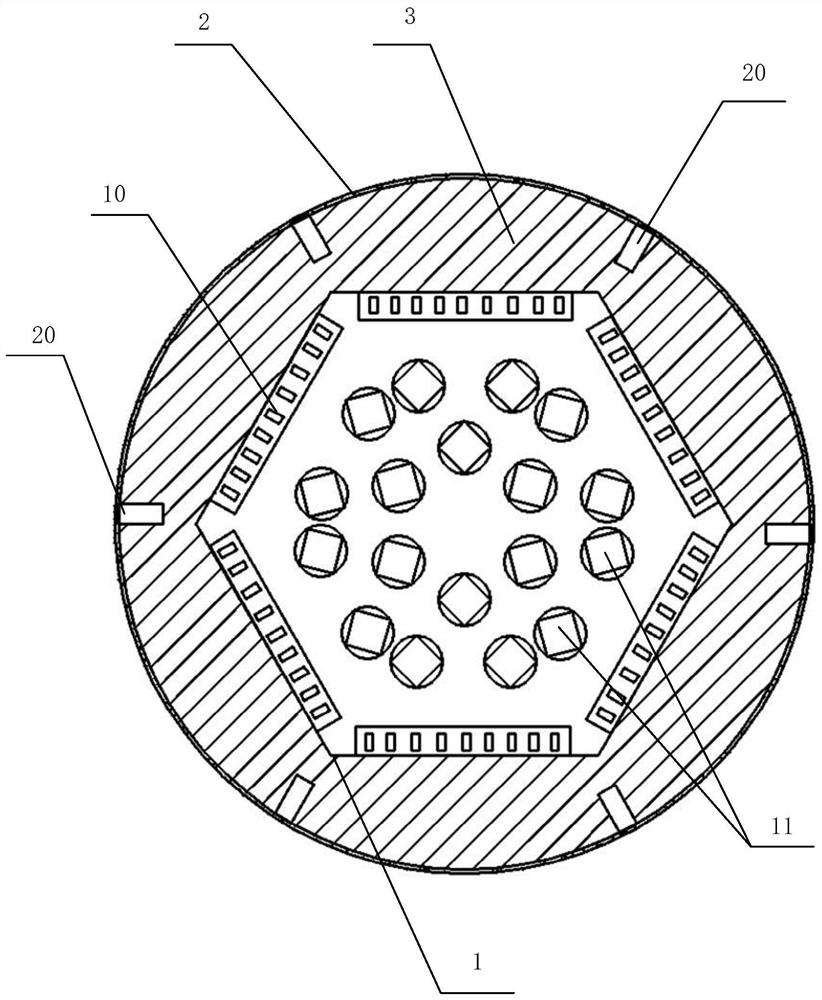

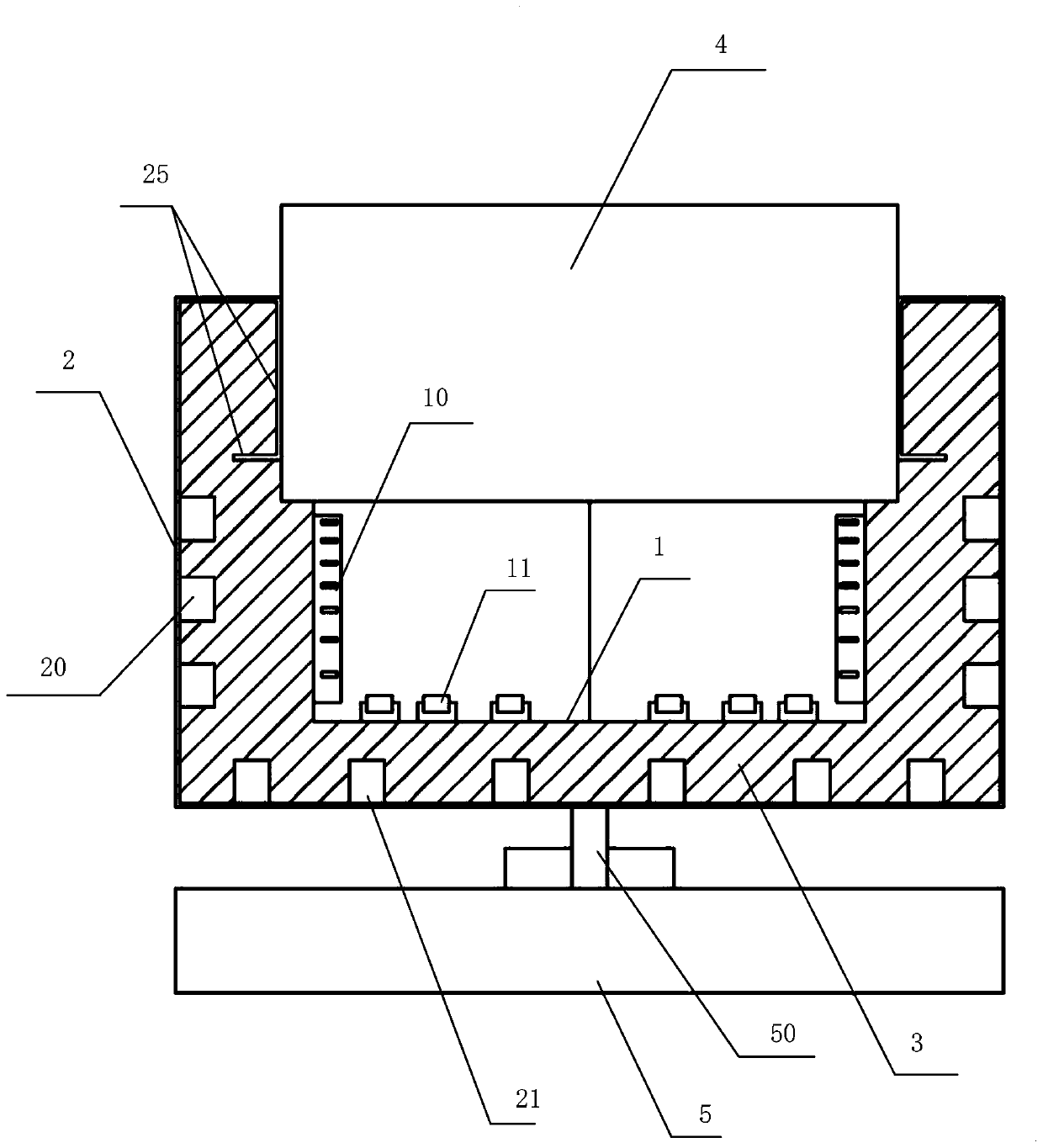

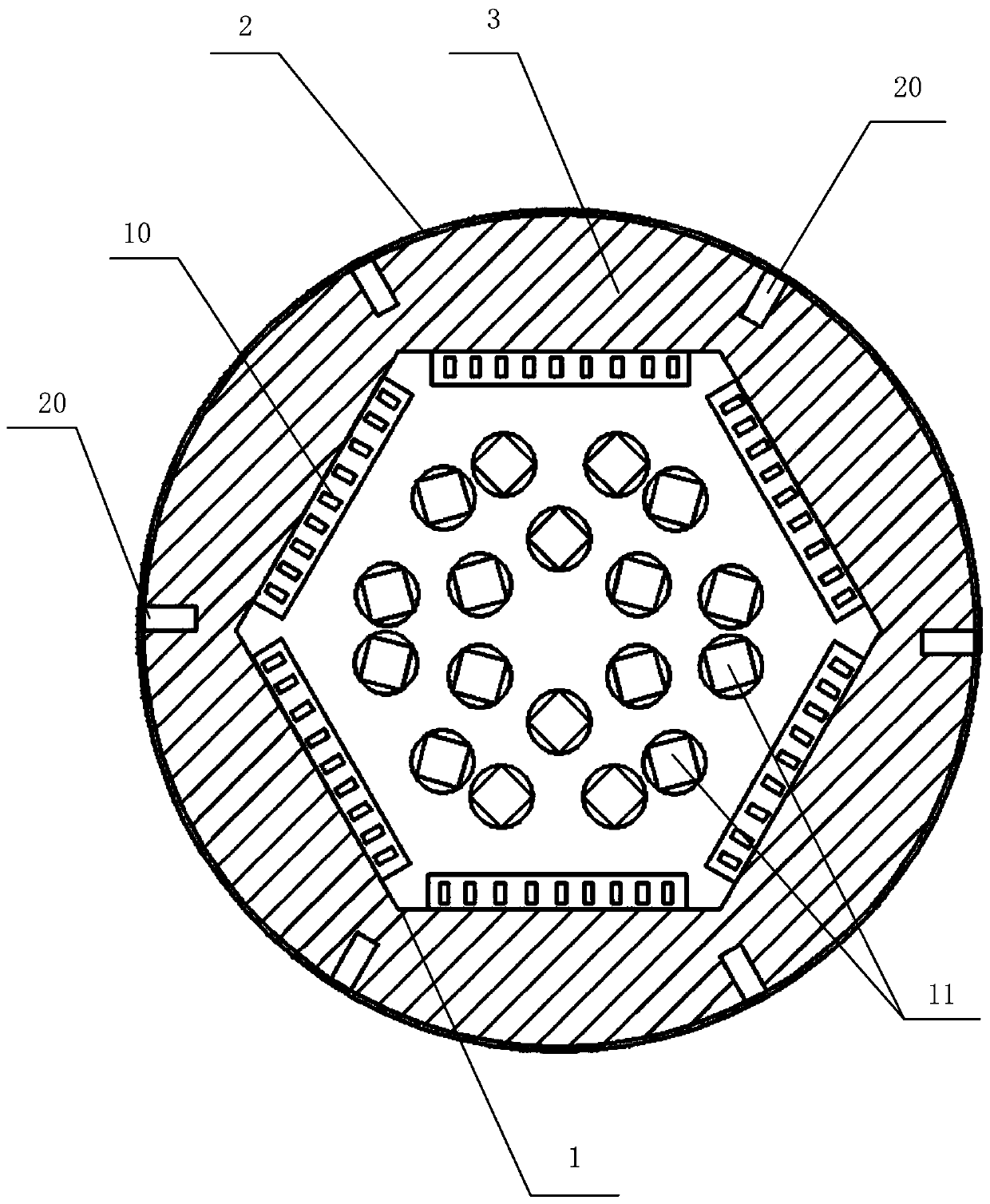

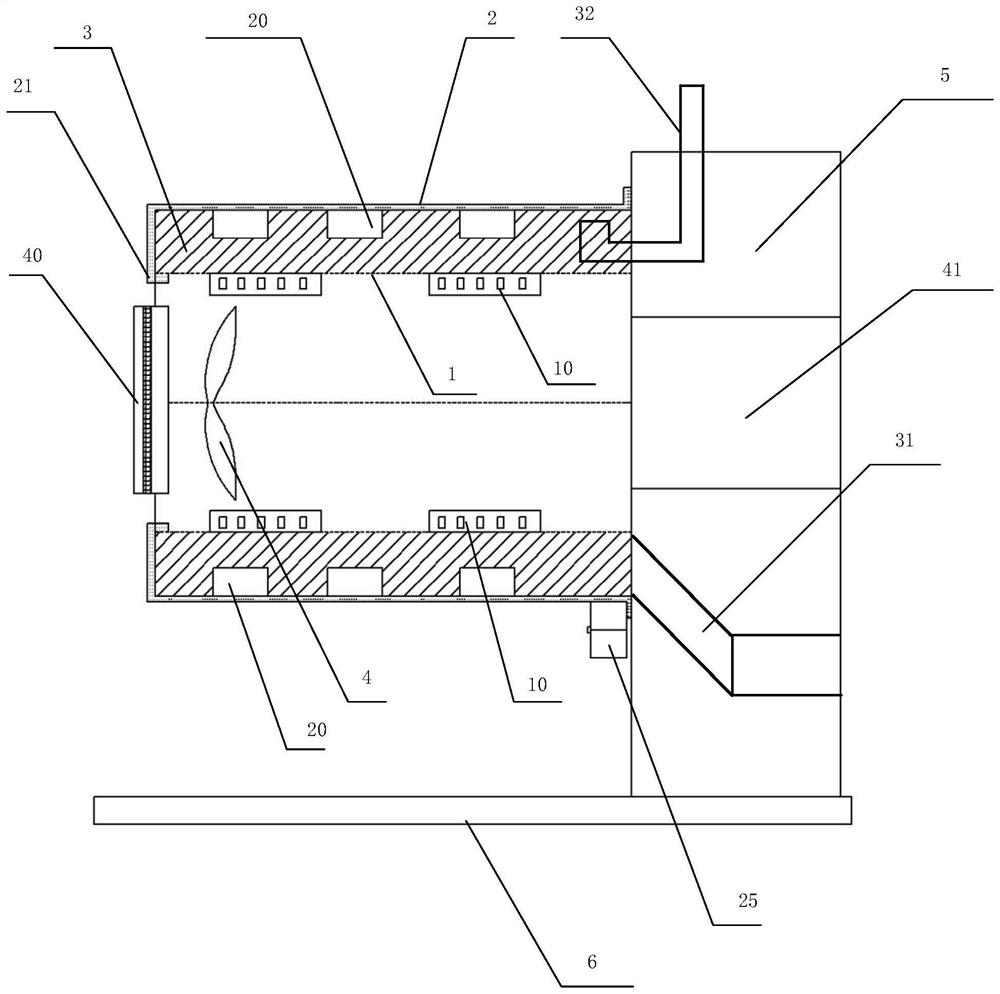

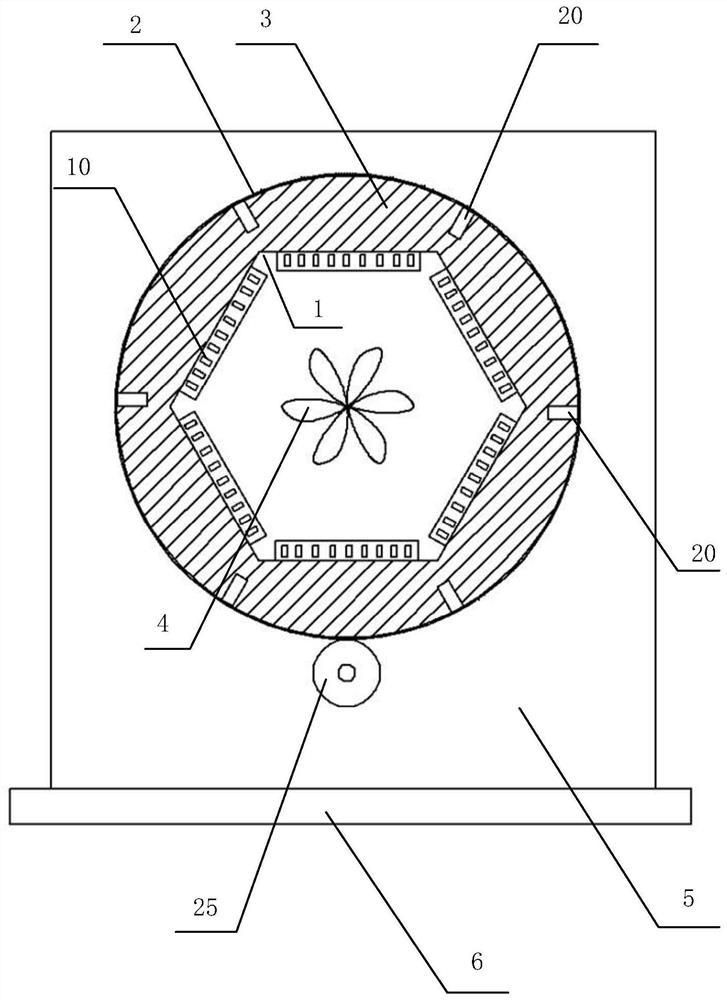

Laboratory ultrasonic waste paper deinking equipment

ActiveCN110055791BIncrease setup densityReduce dosagePaper recyclingWaste paper working-upDeinkingUltrasonic cavitation

The invention relates to the technical field of experimental equipment manufacturing and provides laboratory ultrasonic waster paper deinking equipment. The equipment comprises a stirring drum and a reactor, the stirring drum is capable of rotating horizontally, the top of the stirring drum is provided with an opening, the reactor comprises a regular polygonal structure and a cylinder, the regularpolygonal structure is used for being inserted into the stirring drum, and the cylinder is used for sealing the opening. The regular polygonal structure is an airtight cavity, and a plurality of ultrasonic transducers are arranged on the inner wall of the airtight cavity. The inner side wall of the stirring drum is provided with a plurality of crushing teeth, and the bottom of the stirring drum is provided with a plurality of defibering teeth. By arrangement of the ultrasonic transducers in the reactor, great ultrasonic action nearby the inner wall of the stirring drum can be achieved throughthe hollow structure of the reactor; under the dual actions of stirring and ultrasonic, waste paper is deinked through compression water flow and ultrasonic cavitation, and great deinking performances and high treatment speed are realized.

Owner:NANNING UNIV

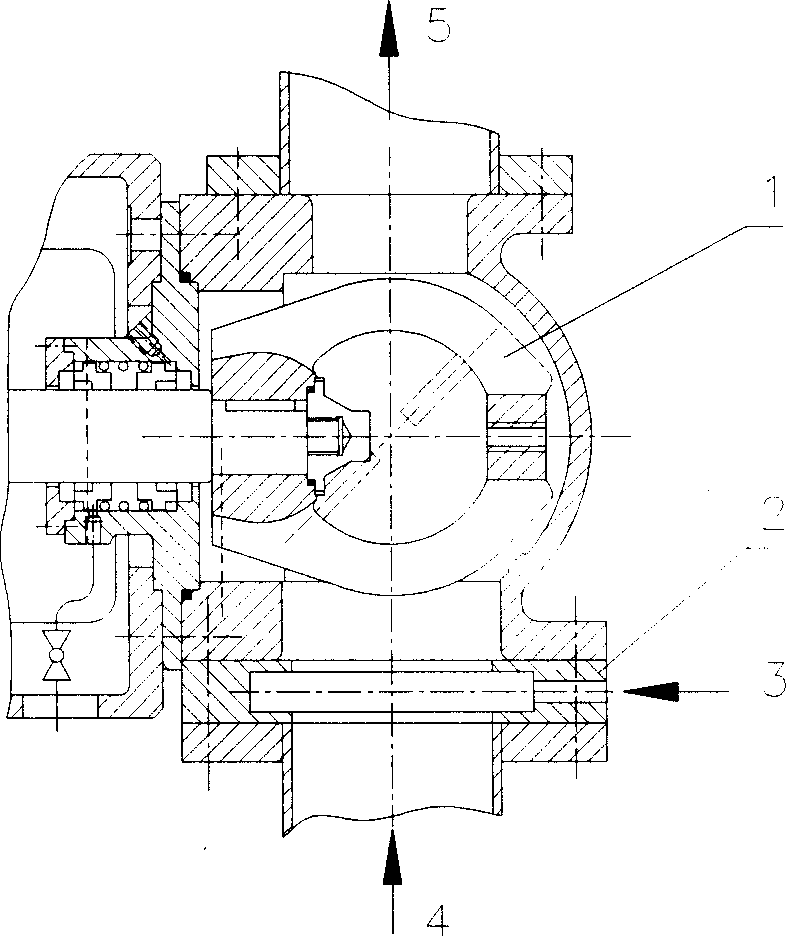

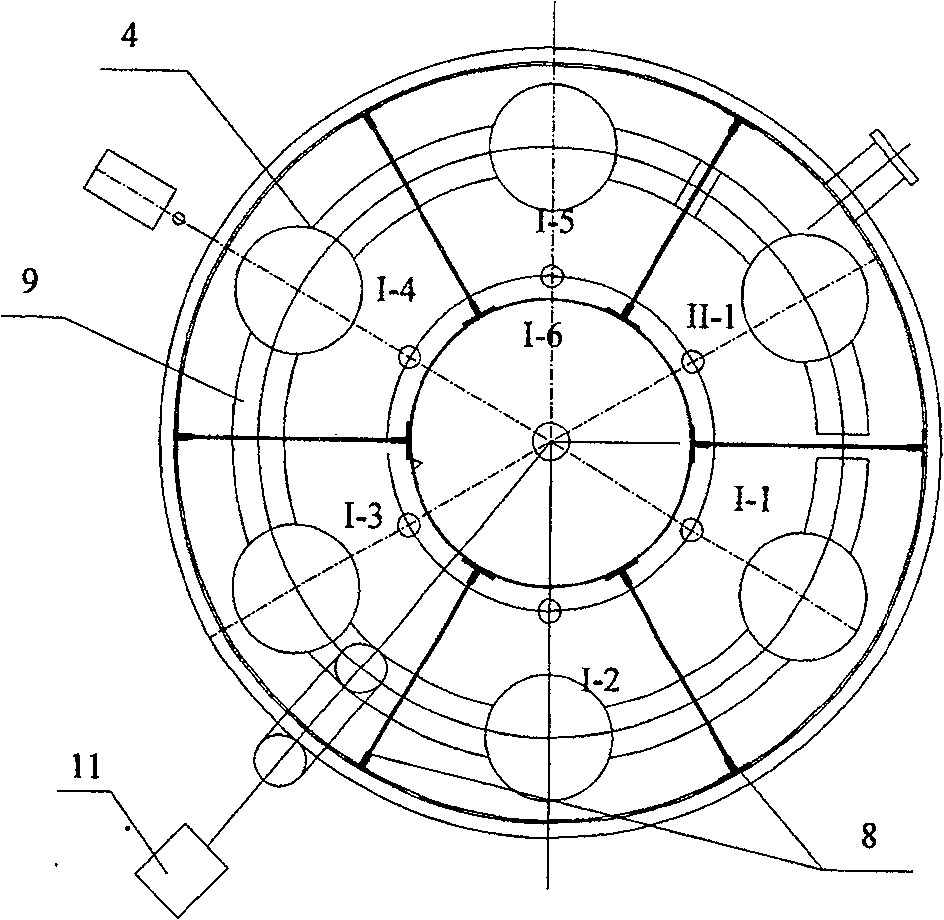

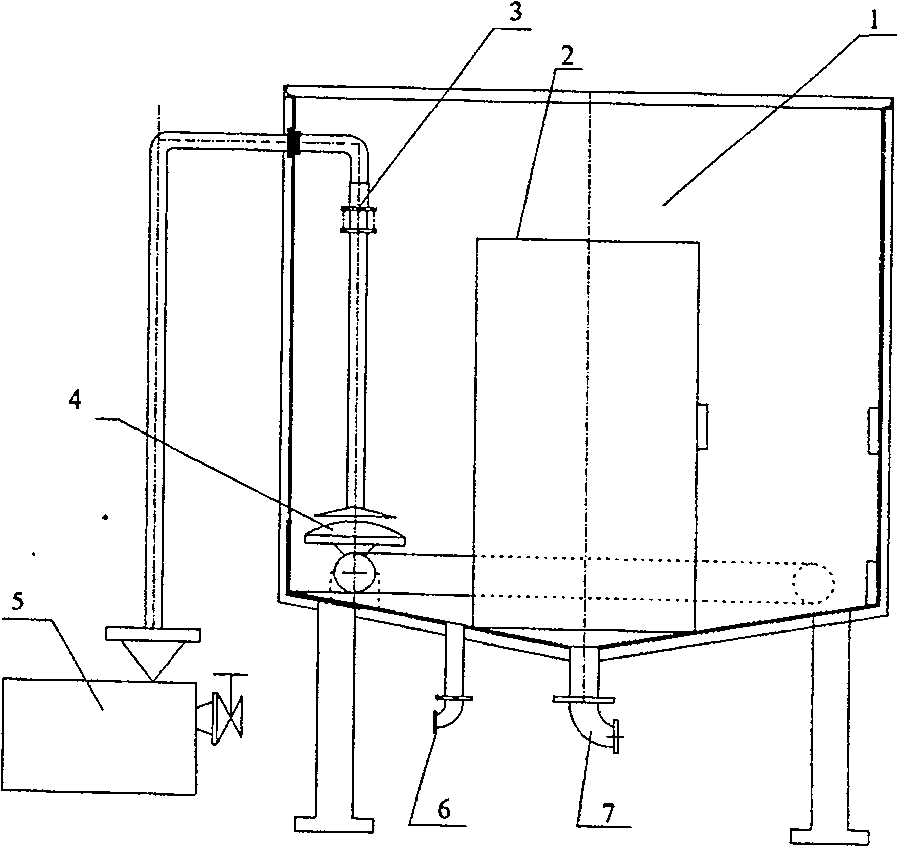

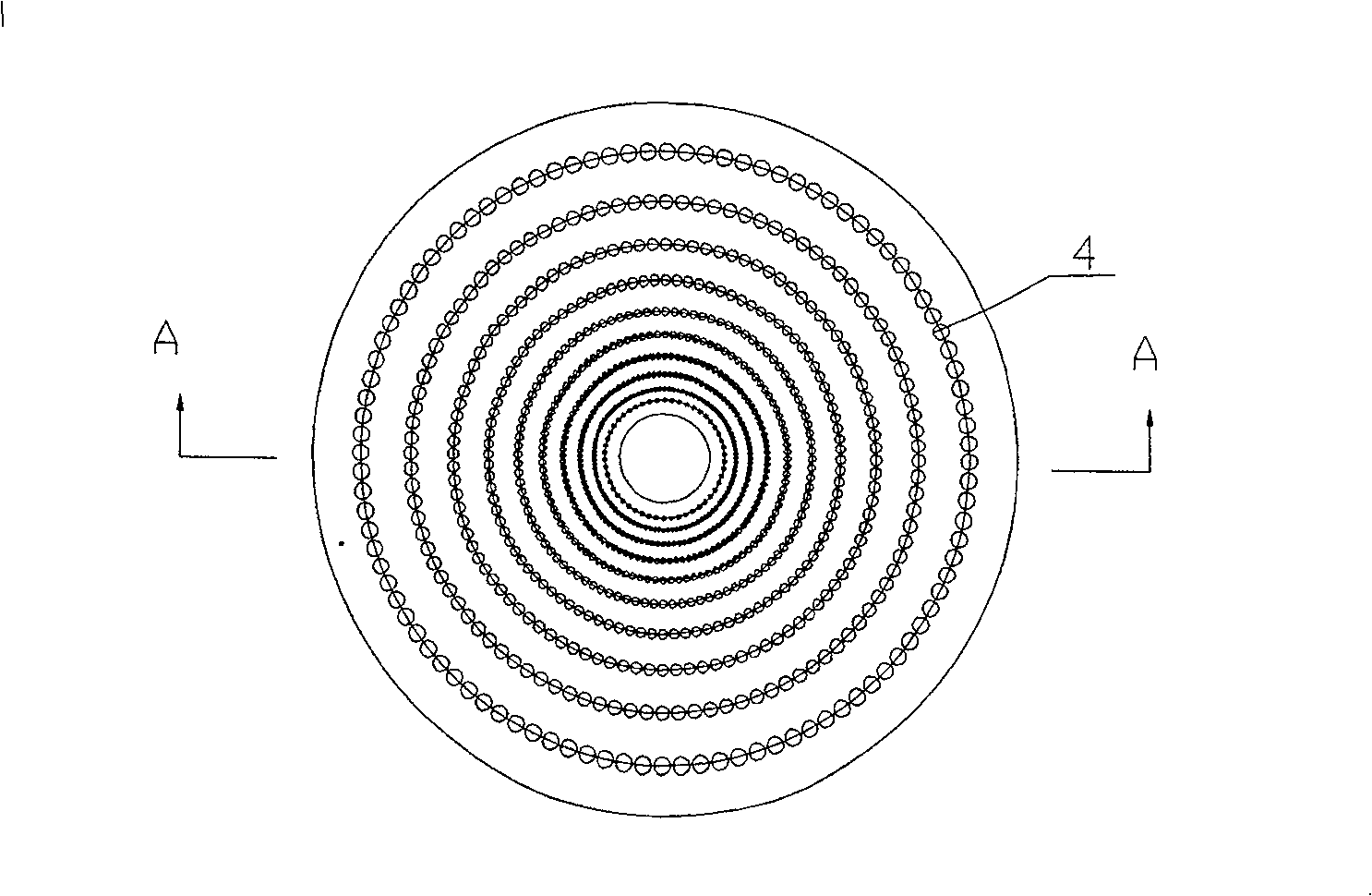

Aeration type convection mixing ink-removing flotation tank

InactiveCN100535238CGood deinking effectOvercome the disadvantages of uneven flotationPaper recyclingWaste paper working-upPipe fittingSpray nozzle

The invention discloses an aeration-type countercurrent- mixing deinking floatation cell, comprising deinking groove body, printing ink collecting cell, pulp inlet pipe fitting, aeration component, pulp pump, good pulp outlet, and printing ink outlet, where the aeration component comprises aeration diaphragm, fan and connecting pipe, the aeration diaphragm is densely distributed with 0.2-1 mm small holes and connected with the fan through the connecting pipe; the pulp inlet pipe fitting comprises pulp pipe, bend, steel pipe and regulating flange, the pulp pipe is welded through the bend onto the steel pipe with somewhat larger diameter, the steel pipe is connected with the regulating flange, the regulating flange is connected through the pulp pipe with a pulp spray nozzle. And it adopts highly regulable pulp inlet pipe fitting and diaphragm aeration component and makes countercurrent mixing of air bubbles and pulp, thus increasing the possibility of air bubbles capturing printing ink particles and improving floatation deinking effect. And it has characters of low energy consumption, compact structure, simple flow, a complete set of easy-to-manufacture equipment, and suitable for small and medium-size waste paper deinking factories.

Owner:SOUTH CHINA UNIV OF TECH

Laboratory ultrasonic waster paper deinking equipment

ActiveCN110055791AIncrease setup densityReduce dosagePaper recyclingWaste paper working-upDeinkingUltrasonic cavitation

The invention relates to the technical field of experimental equipment manufacturing and provides laboratory ultrasonic waster paper deinking equipment. The equipment comprises a stirring drum and a reactor, the stirring drum is capable of rotating horizontally, the top of the stirring drum is provided with an opening, the reactor comprises a regular polygonal structure and a cylinder, the regularpolygonal structure is used for being inserted into the stirring drum, and the cylinder is used for sealing the opening. The regular polygonal structure is an airtight cavity, and a plurality of ultrasonic transducers are arranged on the inner wall of the airtight cavity. The inner side wall of the stirring drum is provided with a plurality of crushing teeth, and the bottom of the stirring drum is provided with a plurality of defibering teeth. By arrangement of the ultrasonic transducers in the reactor, great ultrasonic action nearby the inner wall of the stirring drum can be achieved throughthe hollow structure of the reactor; under the dual actions of stirring and ultrasonic, waste paper is deinked through compression water flow and ultrasonic cavitation, and great deinking performances and high treatment speed are realized.

Owner:NANNING UNIV

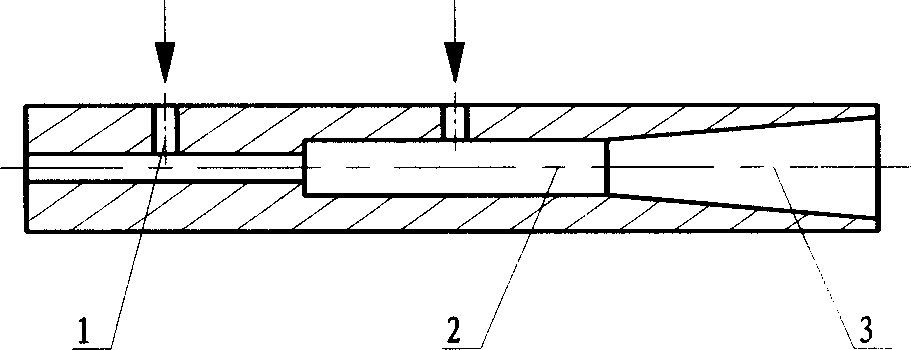

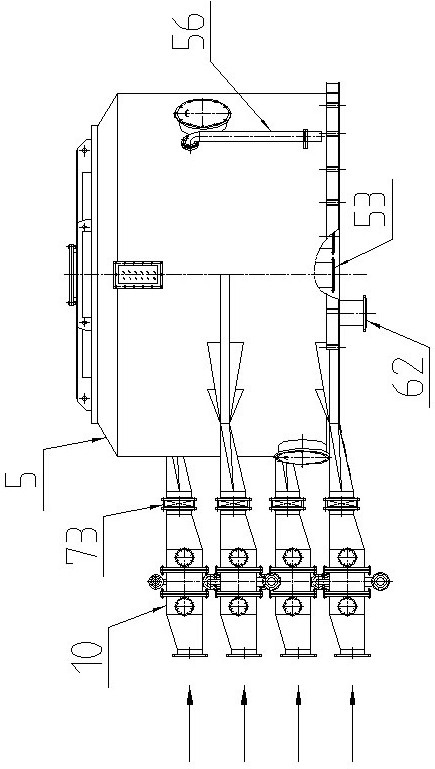

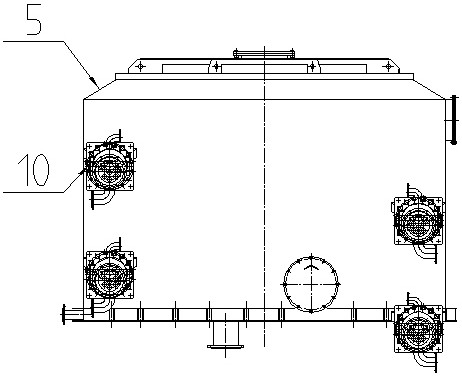

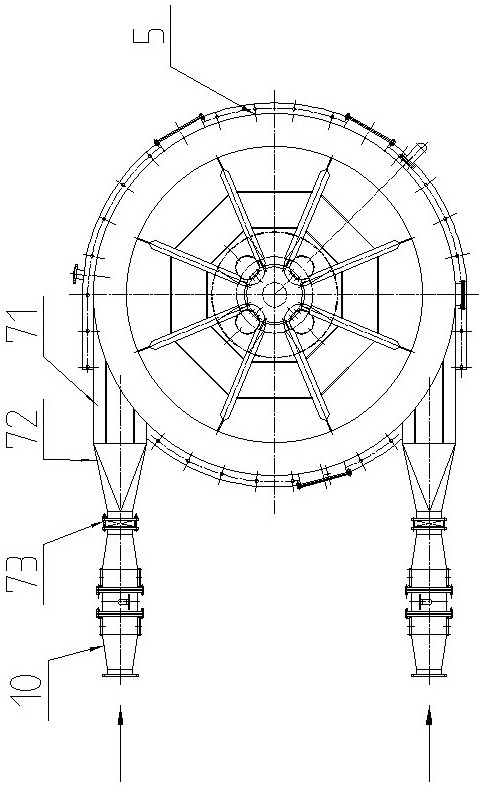

Flotation deinking machine for removing ink in waste paper pulp by utilizing air flotation principle

PendingCN112391864AIncrease profitImprove deinking efficiencyPaper recyclingRaw material divisionSmall footprintMultiple stages

The invention discloses a flotation deinking machine for removing ink in waste paper pulp by utilizing an air flotation principle, wherein the flotation deinking machine comprises a closed flotation tank body, the flotation tank body comprises an outer cylinder body and an inner cylinder body, an ink discharging device is arranged in the inner cylinder body, and a plurality of accepted pulp conical grooves are arranged outside the inner cylinder body in the axial direction at intervals; a flow guide ring is arranged between the periphery of each accepted pulp conical groove and the outer cylinder body, the flotation tank body is divided into multiple stages of flotation units which are arranged up and down by the flow guide rings, pulp inlet jet distributors are arranged at the positions,corresponding to the flotation units, of the outer wall of the outer cylinder body, and spiral ascending ladder type pulp inlet flow channels are formed in the flow guide rings; a cone-like reinforcing device is arranged in each accepted pulp conical groove; each pulp inlet jet flow distributor is of a three-body structure formed by sequentially connecting a pulp inlet conical pipe, a distributionpipe and a pulp outlet conical pipe. The flotation deinking machine has the remarkable advantages of high deinking efficiency, high whiteness of deinked pulp, good brightness, high concentration of discharged ink, little fiber loss, small occupied area and the like, and meets the requirements of the modern paper making industry on the quality of paper pulp.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Industrial waste paper deinking equipment

ActiveCN110144748BReduce dosageImprove power densityPaper recyclingWaste paper working-upDeinkingUltrasonic cavitation

The invention provides an industrial deinking device for waste paper, and relates to the technical field of waste-paper processing device manufacturing. The device comprises a reactor and a stirring barrel; the reactor has a horizontally-arranged tubular structure, and the vertical cross section of the reactor has a regular polygonal structure; the reactor comprises a plurality of ultrasonic wavevibration plates installed on the inner wall of the reactor, and a fan arranged in the reactor; two ends of the tubular structure are respectively provided with a gas inlet and a gas discharge outlet;the stirring barrel rotates relative to the reactor; a closed cavity is formed between the stirring barrel and the reactor; and a plurality of stirring teeth are arranged on the inner side wall of the stirring barrel. According to the device provided by the invention, the ultrasonic wave vibration plates are arranged in the reactor, and a hollow structure of the reactor is utilized, so that ultrasonic waves well act near the inner wall of the stirring barrel; through double action of stirring and the ultrasonic waves, a compressed water flow and ultrasonic cavitation are utilized for deinkingof the waste paper; and the device has excellent deinking performance and a high-efficiency processing speed.

Owner:NANNING UNIV

A kind of coated paper and its preparation method

ActiveCN108425268BLoose structureReduce intensityCoatings with pigmentsPaper recyclingAmylaseMicrosphere

The invention discloses coated paper and a preparation method thereof, and belongs to the field of paper products. Glutaraldehyde is adopted to fix mixed enzymes of cellulase and alpha-amylase on silica gel, the fixed enzymes are adopted to deink waste printing paper, and coarse-pore microspherical silica gel which is prepared by using sodium silicate and hydrochloric acid is used as a raw material, and silica sol which is adopted as a binder is added into the coarse-pore microspherical silica gel; the mixture of the silica gel and silica sol is made into pellets, one end of glutaraldehyde isattached to an amino group of the enzymes, and the other end is attached to a hydroxyl group of the silica gel, so that immobilized enzymes are achieved, the stability of the enzymes are ensured, theutilization rate for removal is improved, separation and recycling are facilitated, and the cost for preparing base paper of the coated paper is reduced; the preparation method comprises the steps of:adopting styrene, methyl acrylate, divinyl benzene and the like as raw materials, preparing composite emulsion by using a non-soap seeded emulsion polymerization technology, coating coating color ofthe coated paper on the base paper of the coated paper on a coating machine, and performing drying to obtain the coated paper.

Owner:ZHEJIANG GAODU ENVIRONMENTAL PROTECTION TECH CO LTD

A production method of corrugated medium paper with improved deinking efficiency

ActiveCN109629297BImprove deinking efficiencyHigh Ink Removal RatePulp liquor regenerationWashing/displacing pulp-treating liquorsDeinkingFiber

The invention discloses a production method of corrugated medium paper with improved deinking efficiency, which comprises a soaking activation step, a hydraulic pulping step, a screening and slag removal step, a rubbing centrifugal deinking step, a bleaching step, a washing and concentrating step and a pulp storage step. Use a neutral deinking agent to directly rub the waste paper fibers for centrifugal deinking, and separate the ink through the process cooperation between activated ink and centrifugal deinking, which reduces the amount of alkaline deinking agent used and further reduces waste paper making The production cost is reduced, the deinking efficiency and ink removal rate are improved, the whiteness is improved, and the pollution to the environment is reduced.

Owner:东莞顺裕纸业有限公司

A kind of environment-friendly deinking agent and preparation method thereof

The invention discloses an environment-friendly deinking agent. The environment-friendly deinking agent is prepared from, by weight, 5-10 parts of sodium silicate, 10-20 parts of talcum powder, 10-20 parts of sodium sulfate, 30-40 parts of sodium carbonate, 5-10 parts of ethylene glycol, 5-10 parts of a surface active agent and 5-10 parts of a penetrant. The environment-friendly deinking agent has simple components, the preparation method is simple, the deinking efficiency is high, meanwhile, damage to fiber is small, no pollution is caused to the environment, and meanwhile energy is saved.

Owner:SHAANXI UNIV OF TECH

A kind of neutral deinking agent and preparation method thereof

ActiveCN103881467BHigh practical valueOvercoming the problem of low deinking efficiencyChemical paints/ink removersAdjuvantPOLYOXYETHYLENE ETHER

The invention relates to a neutral deinking agent and a preparation method thereof. The weight ratio of the components of the neutral deinking agent is: the main agent is 10-20 parts of lauryl sulfate, 10-20 parts of polyoxyethylene alkyl ether, 10-20 parts of rosin-based surfactant and fat 10-15 parts of sodium lignosulfonate, 1-5 parts of sodium lignosulfonate, 1-5 parts of inorganic mineral soil and 1-2 parts of inorganic salt as auxiliary agents. The neutral deinking agent of the invention has the advantages of high deinking efficiency, high whiteness of pulp after deinking, little ink residue, low production cost of the deinking agent and easy biodegradation, etc., and is suitable for deinking various waste papers.

Owner:朱勇强

Neutral deinking method for waste newspaper

InactiveCN1325724CHigh whitenessReduce pollution loadFats/resins/pitch/waxes removal in pulpPaper recyclingDeinkingInorganic salts

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com