Deinking process of medium-alkali double-circuit flotation waste paper based on biological enzyme

A dual-circuit, bio-enzyme technology, applied in waste paper processing, papermaking, paper recycling, etc., can solve the problems of increasing waste paper fiber damage and pollution load, inability to completely remove new inks, etc., and achieve good deinking effect and strength performance Less damage to opacity and improved deinking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

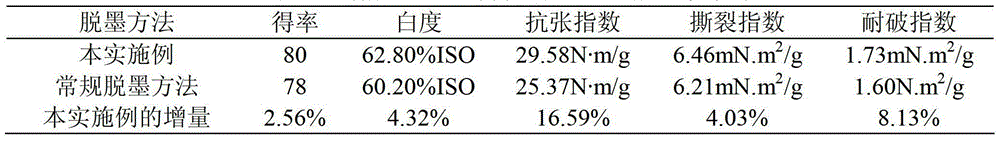

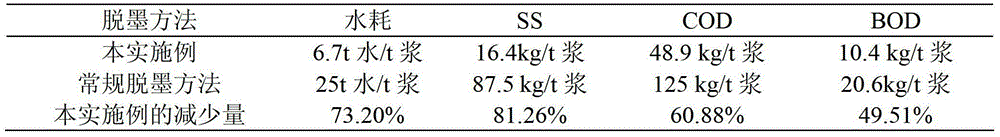

Embodiment 1

[0030] In this embodiment, 200 g of waste newsprint (ONP) (moisture content 80%) is taken, and the following steps are used for deinking:

[0031] (1) Pulping: pulping in a hydraulic pulper, the pulping conditions are: pulping concentration 15%wt, pulping time 35min, pulping temperature 50°C, speed 300r / min.

[0032](2) Deinking: Add lipase and fatty alcohol polyoxyethylene ether sodium sulfate (AES), coconut acid diethanolamide ( 6501) and fatty alcohol polyoxyethylene ether (AEO-9), the amount of lipase and neutral deinking agent is 0.7u / g and 0.8% respectively (both relative to the mass of dry pulp) , Deinking after fully mixing, the deinking conditions are: the slurry concentration is 10%wt, the deinking temperature is 35°C, and the deinking time is 40min. After the waste paper pulp is deinked in the first stage, the second stage of alkaline hydrogen peroxide deinking is carried out directly. The deinking conditions are: the amount of NaOH is 2%, H 2 o 2 The dosage is 2...

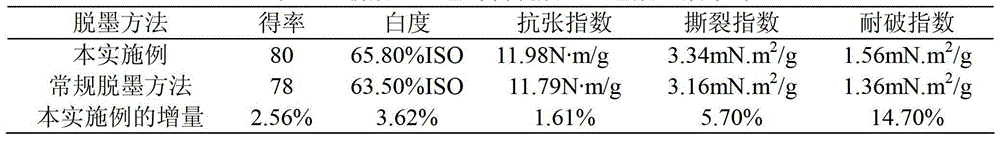

Embodiment 2

[0043] In this example, 200g of mixed office waste paper (MOW) (moisture content 80%) was taken, and the following steps were used for deinking:

[0044] (1) Pulping: pulping in a hydraulic pulper, the pulping conditions are: pulping concentration 12%wt, pulping time 40min, pulping temperature 50°C, speed 300r / min.

[0045] (2) Deinking: Add lipase and fatty alcohol polyoxyethylene ether sodium sulfate (AES), coconut acid diethanolamide ( 6501) and fatty alcohol polyoxyethylene ether (AEO-9) neutral deinking agent, the amount of lipase and neutral deinking agent are 0.8u / g and 1% respectively (both relative to the quality of dry pulp) , Deinking after fully mixing, the deinking conditions are: the slurry concentration is 10%wt, the deinking temperature is 40°C, and the deinking time is 45min. After the waste paper pulp is deinked in the first stage, it is directly deinked in the second stage with alkaline hydrogen peroxide. The deinking conditions are as follows: the amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com