Application of a kind of cutinase in paper industry

A technology of cutinase and process, applied in the field of enzyme engineering, can solve the problems of non-sticky, difficult to remove, difficult to control, etc., and achieve the effects of reducing dosage, reducing equipment damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

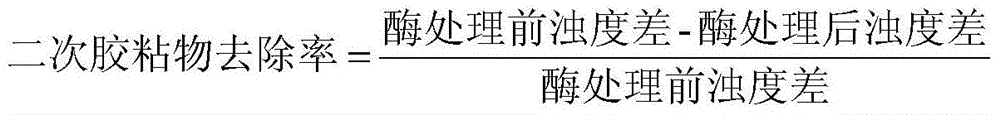

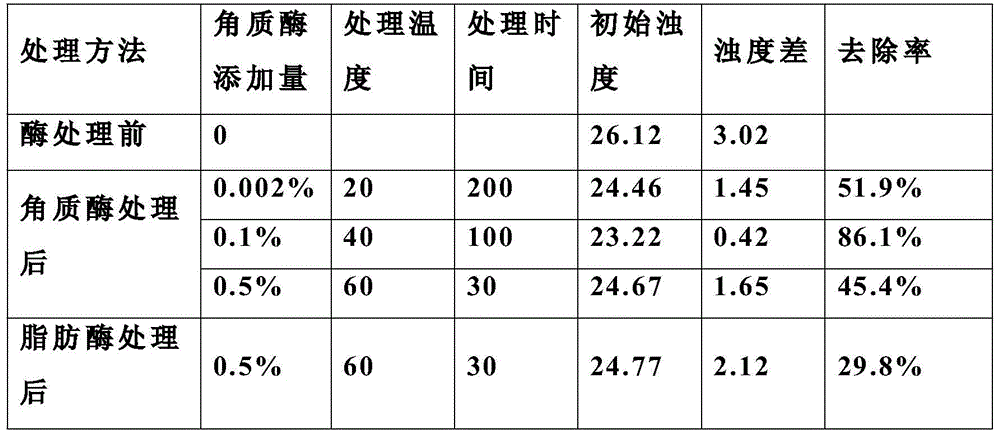

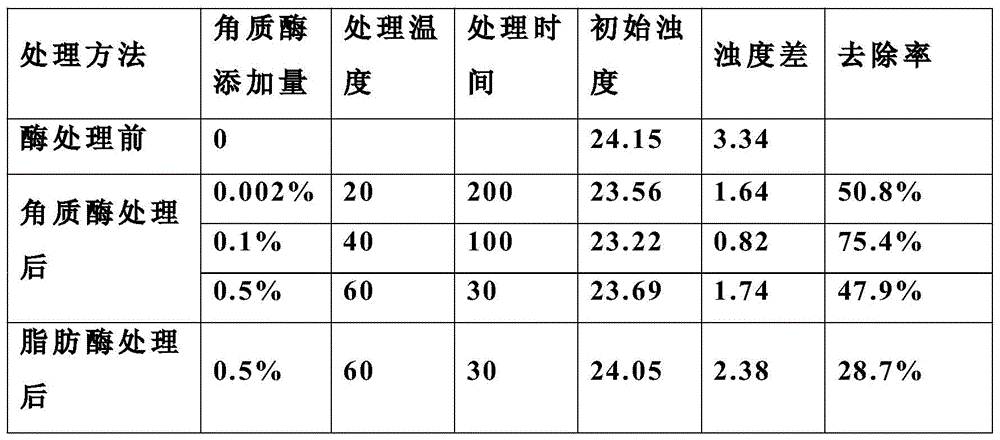

[0040] Example 1: Using cutinase to control secondary stickies in waste paper pulp production process

[0041] Take 200ml of old newsprint DIP and OCC pulp white water and treat them with different cutinase additions, set up parallel experiments, and carry out mathematical statistics. The enzyme activity of cutinase is 400U / mL, the addition amount is 0.001-0.5% of the weight of DIP and OCC dry pulp, the temperature is 20-60°C, and the time is 30-200min. The cutinase is Thermobifida fusca cutinase, the amino acid sequence of which is shown in Genbank No. AAZ54920.1 or AAZ54921.1.

[0042] Centrifuge the treated pulp white water at 3000r / min for 10 minutes to remove components such as fine fibers; test the cation demand and turbidity of the white water after centrifugation, and then use sulfuric acid to adjust the pH to 4 before measuring the turbidity, and calculate the pH before and after adjustment difference in turbidity. The test results when the enzyme dosage is 0.002%, ...

Embodiment 2

[0050] Embodiment 2: adopt cutinase to carry out deinking

[0051] Cutinase deinking:

[0052] 1. Pulping: Take 200g of pulp (absolute dry pulp), adjust the pulp concentration to 10%, the number of revolutions is 225r / min, and the time is 20 minutes.

[0053] 2. Enzyme treatment: control temperature at 40-60°C, treatment time 100-200min, add enzyme amount 10-100U / g dry pulp.

[0054] Preferably, in a constant temperature water bath, the temperature is 50°C, the treatment time is 120 minutes, the amount of enzyme is added to 40 U / g of dry pulp, and it is manually kneaded every 10 minutes.

[0055] 3. Slurry washing and dehydration: Dilute the waste paper pulp after bio-enzyme treatment with 5L deionized water, then wash the pulp with a washing bag, and finally tear the pulp cake into small pieces, and air-dry at room temperature.

[0056] 4. Flotation: The waste paper pulp after bio-enzyme treatment is flotation in a laboratory flotation cell. The flotation conditions are: he...

Embodiment 3

[0067] Embodiment 3: adopt cutinase to carry out the simulated white water treatment with polyacrylate as substrate

[0068] 1. Preparation of polyacrylic acid resin solution: Use a 10ml pipette to pipette 10ml of polyacrylic acid resin solution with a solid content of 50% into a 500ml volumetric flask, constant volume, shake well to obtain a solution with a concentration of 1%, and set aside. Then use a 10ml pipette to pipette the polyacrylic acid resin solution with a concentration of 1% into a 50ml volumetric flask, constant volume, shake well to obtain a solution with a concentration of 0.1%, and set aside.

[0069] 2. Take 10ml of polyacrylate solution with a concentration of 0.1% and a 25ml Erlenmeyer flask with a stopper, add a certain amount of cutinase or lipase, put it in a water bath shaker at 30°C, 150rpm, react for 2 hours, and add no The reaction was terminated by water and ethanol, and the turbidity change of the solution was measured by a turbidimeter.

[0070...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com