Aeration type convection mixing ink-removing flotation tank

An aeration type, flotation cell technology, applied in the field of pulping and papermaking equipment, can solve the problem that small and medium-sized waste paper deinking pulp mills are difficult to promote in a large area, the amount of bubble generation and distribution range is difficult to adjust, and the mixing of pulp and gas Unable to adjust the uniformity and other problems, to achieve the effect of small footprint, stable bubbles and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

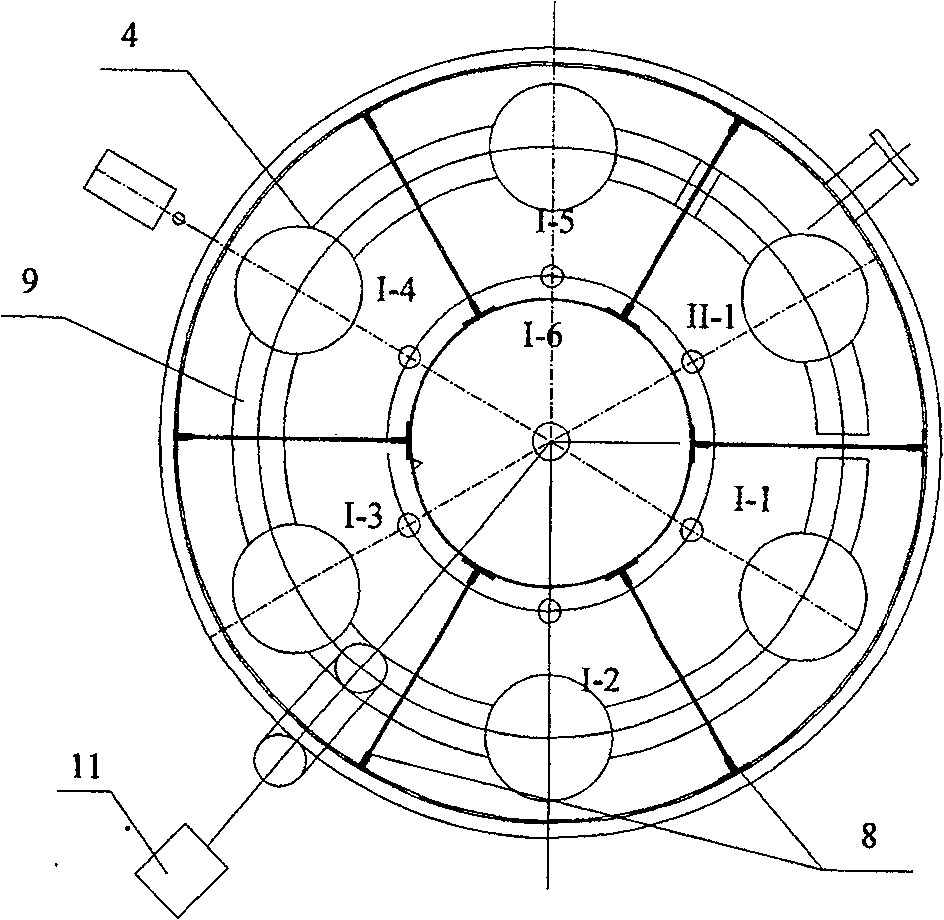

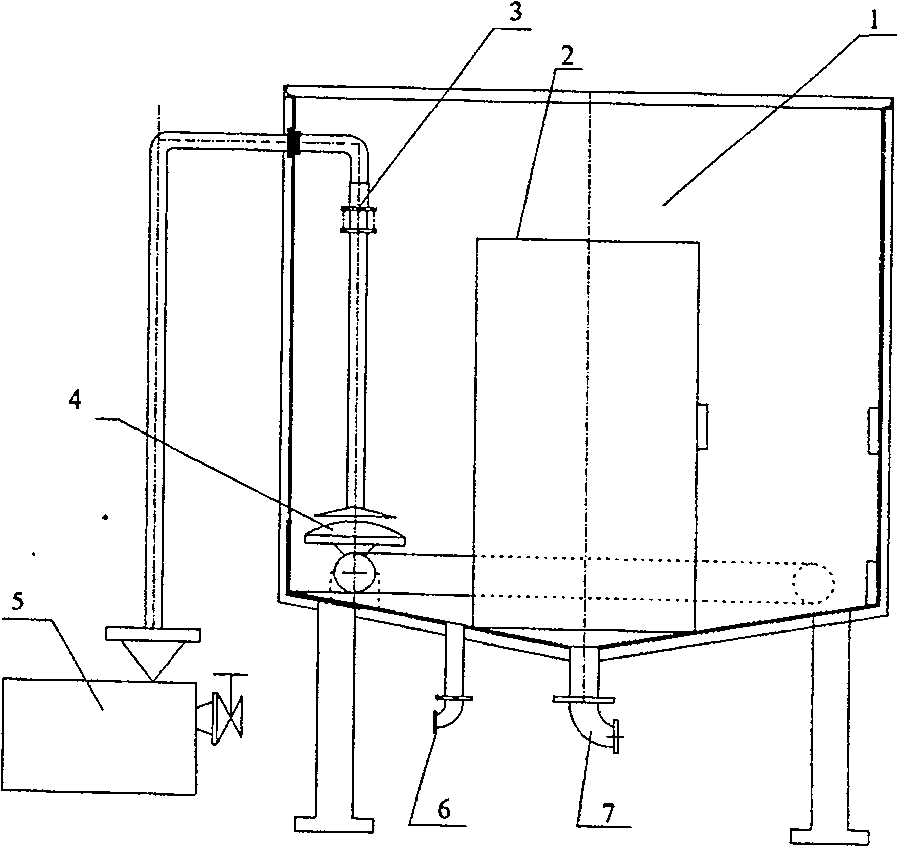

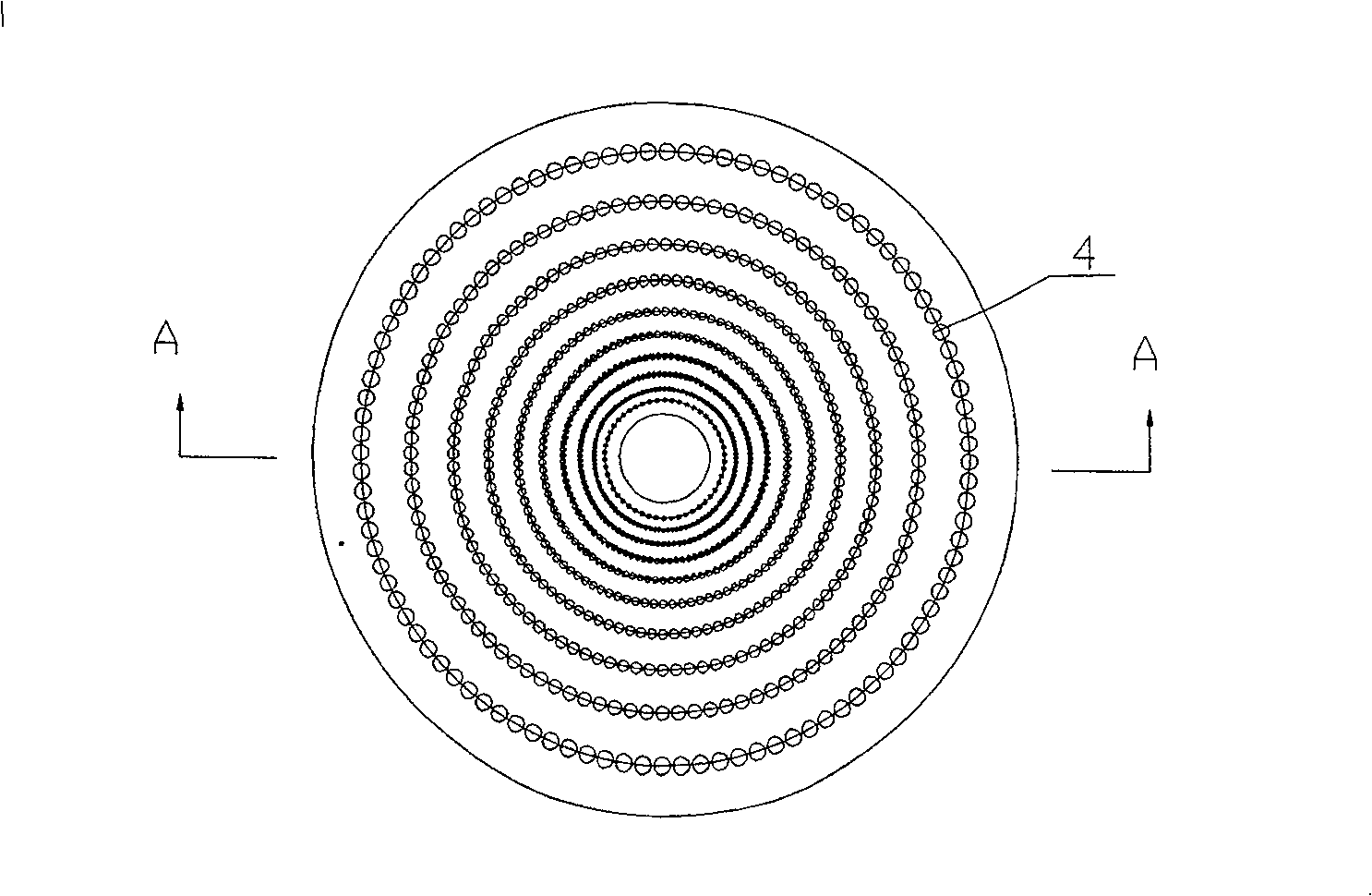

[0029] Such as figure 1 , 2 As shown, the aeration-type convective mixed deinking flotation cell includes a deinking cell body 1, an ink collection tank 2, a slurry inlet pipe 3, an aeration element 4, a slurry pump 5, a good slurry outlet 6, and an ink outlet 7. The ink collection tank 2 is welded in the tank body 1 and is located in the middle of the tank body 1. Between the outer periphery of the ink collection tank 2 and the inner wall of the deinking tank body 1, there are I-1, I-2, I-3, I-4 and I -5 consists of 5 stages of flotation zones, and II-1 is the last flotation zone, which can be used as the sixth stage flotation zone or ink fiber recovery zone according to actual needs. Each flotation zone is provided with an aeration element 4, a slurry inlet pipe fitting 3 and a spray h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com