Industrial waste paper deinking equipment

A technology for deinking and equipment of waste paper, which is applied in the processing of waste paper, paper making, paper recycling, etc. It can solve the problems of poor performance and large amount of recycled paper, reduce chemical consumption, increase power density, and save equipment space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

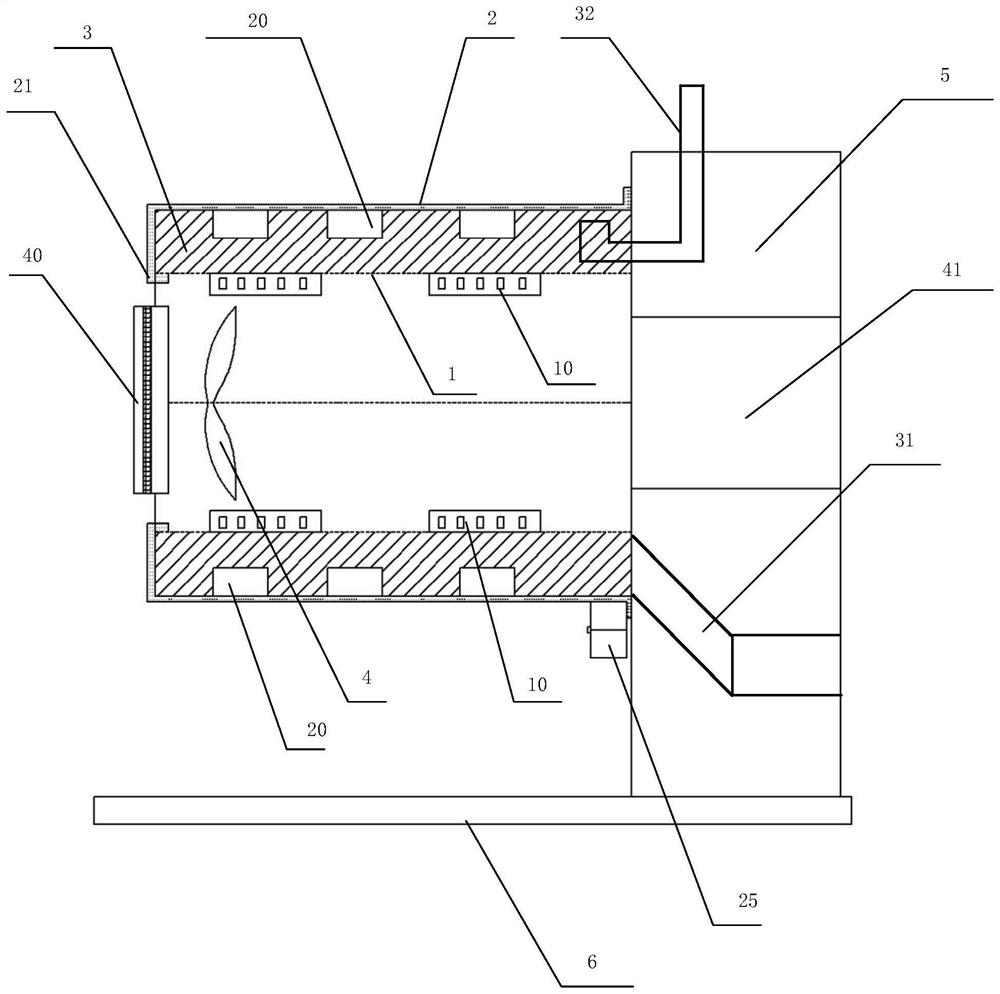

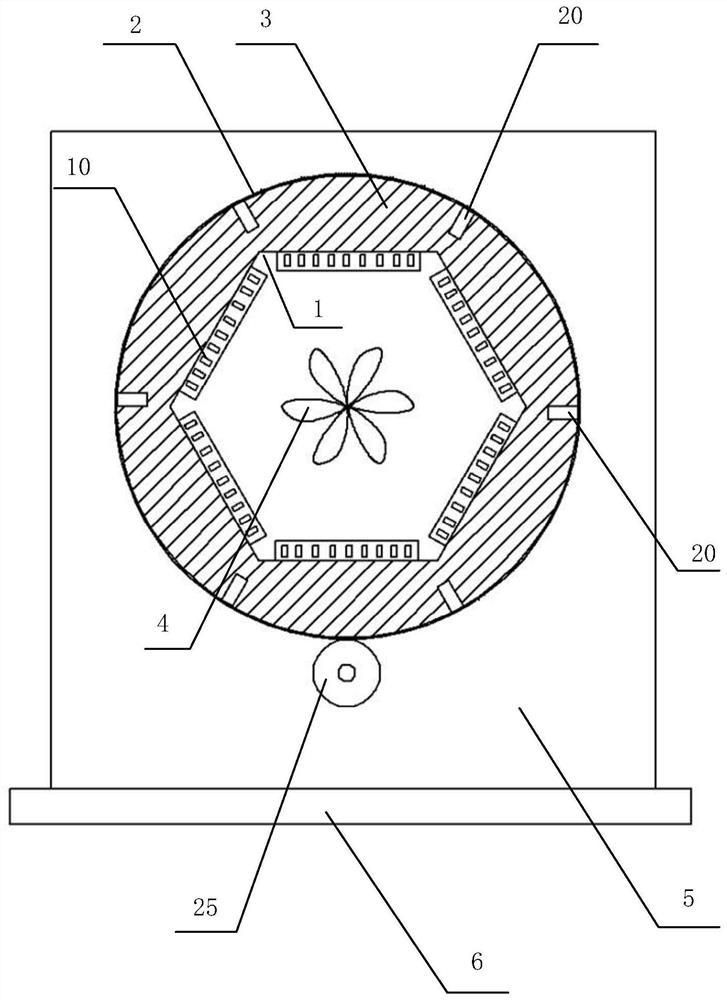

[0023] Such as figure 1 shown, and refer to figure 2 The industrial waste paper deinking equipment of the embodiment of the present invention includes: a reactor 1, and a stirring drum 2 set outside the reactor 1. The vertical cross-section of the mixing tank 2 is circular, and the vertical cross-section of the reactor 1 is polygonal, and the positions of the central points of the two cross-sections are the same.

[0024] The reactor 1 is a tubular structure arranged horizontally, and the vertical section of the reactor 1 is a regular polygonal structure; the regular polygonal structure can make the waste paper solution locally and continuously compressed and decompressed during the stirring process of the mixing tank , very helpful to improve the stirring performance of the waste paper solution.

[0025] Generally, the regular polygonal structure is regular pentagon, regular hexagon, regular heptagon or regular octagon; preferably regular hexagon and regular heptagon; opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com