Laboratory ultrasonic waste paper deinking equipment

A waste paper deinking and laboratory technology, which is applied in waste paper processing, paper making, paper recycling, etc., can solve the problems of poor performance of recycled paper, and achieve the effects of increasing installation density, improving efficiency, and reducing chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

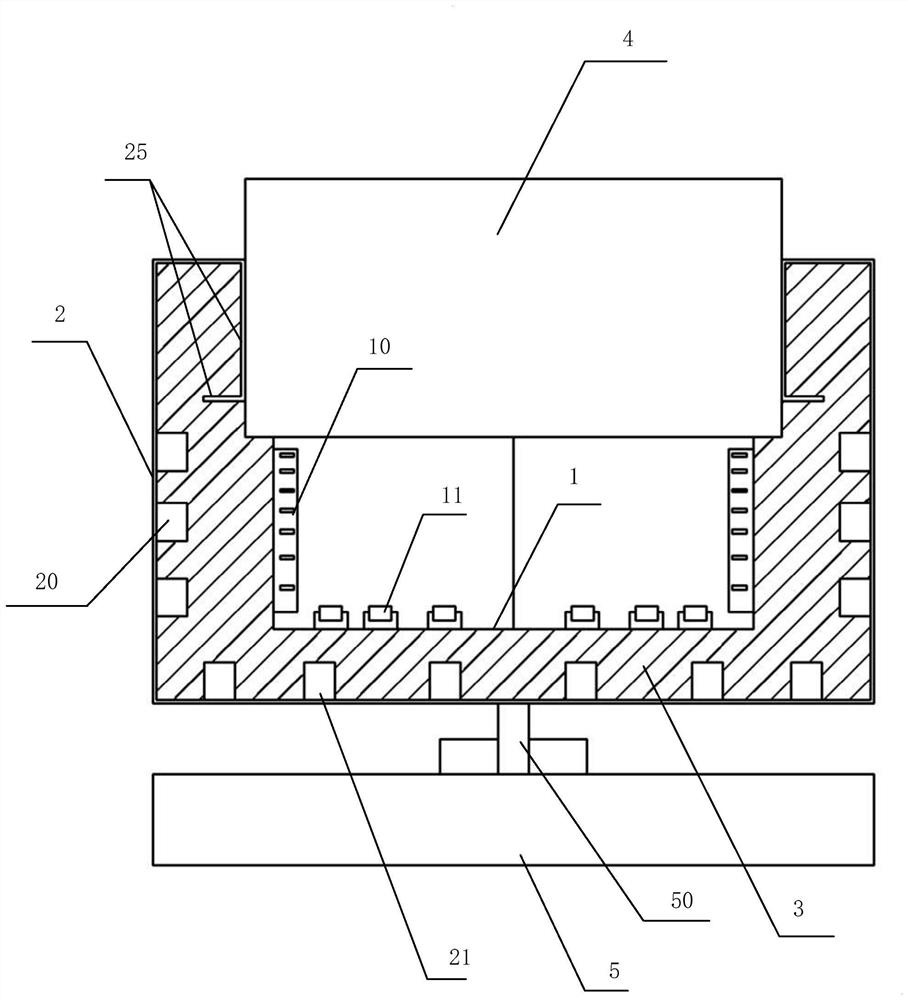

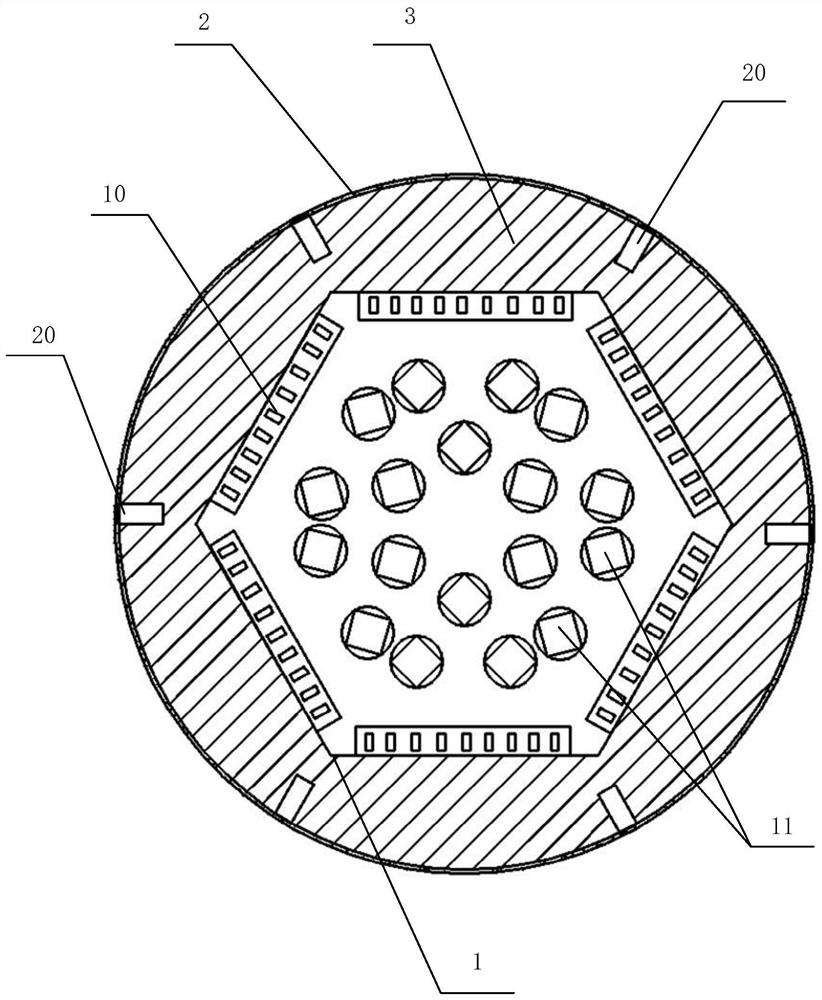

[0021] Such as figure 1 shown, and refer to figure 2 The laboratory ultrasonic waste paper deinking equipment of the embodiment of the present invention includes: a mixing tank 2 that can be rotated horizontally (rotating relative to a horizontal plane), and a reactor that can move up and down relative to the mixing tank 2; the reactor can pass through the relative Insert or remove mixing bowl 2 with movement.

[0022] The top of the mixing bucket 2 is provided with a circular opening; obviously, the mixing bucket 2 has a cylindrical structure and is a container for holding waste paper solution.

[0023] The reactor comprises: a regular polygonal structure 1 for inserting into the mixing tank 2, and a cylinder 4 for sealing the opening; the regular polygonal structure 1 is fixed on the lower end of the cylinder 4, so The regular polygonal structure 1 is a closed cavity; the inner wall of the regular polygonal structure 1 is provided with a plurality of ultrasonic transducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com