Method of preparing pulp by deinking ONP/OMG mixed wastepaper blended with paper making white water

A technology for papermaking white water and waste paper deinking, which is applied in the field of papermaking and pulping, can solve the problems of high COD content, aggravated end treatment costs, and difficulty in making full use of workshops, and achieves improved whiteness, good economic and environmental benefits, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

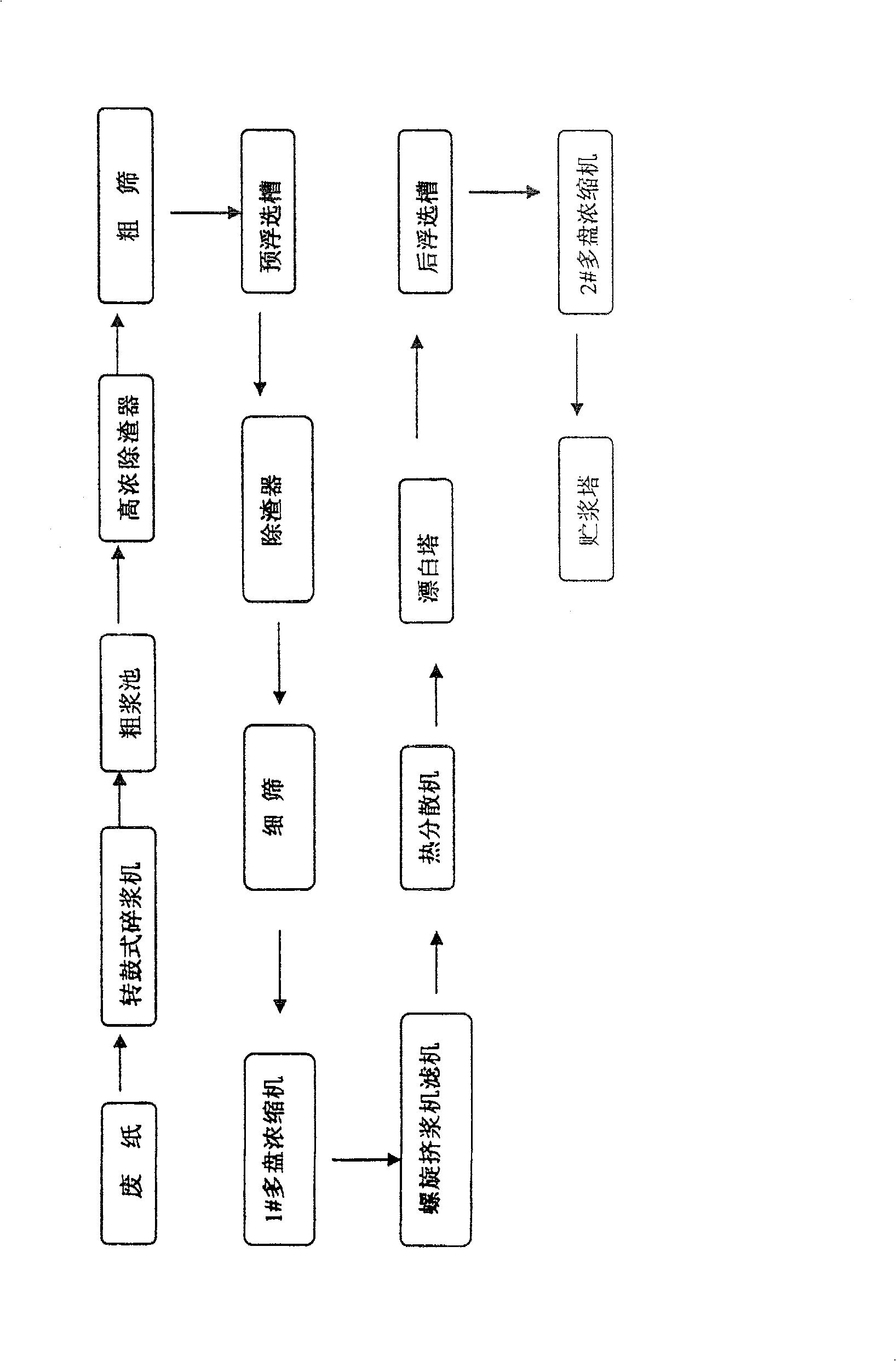

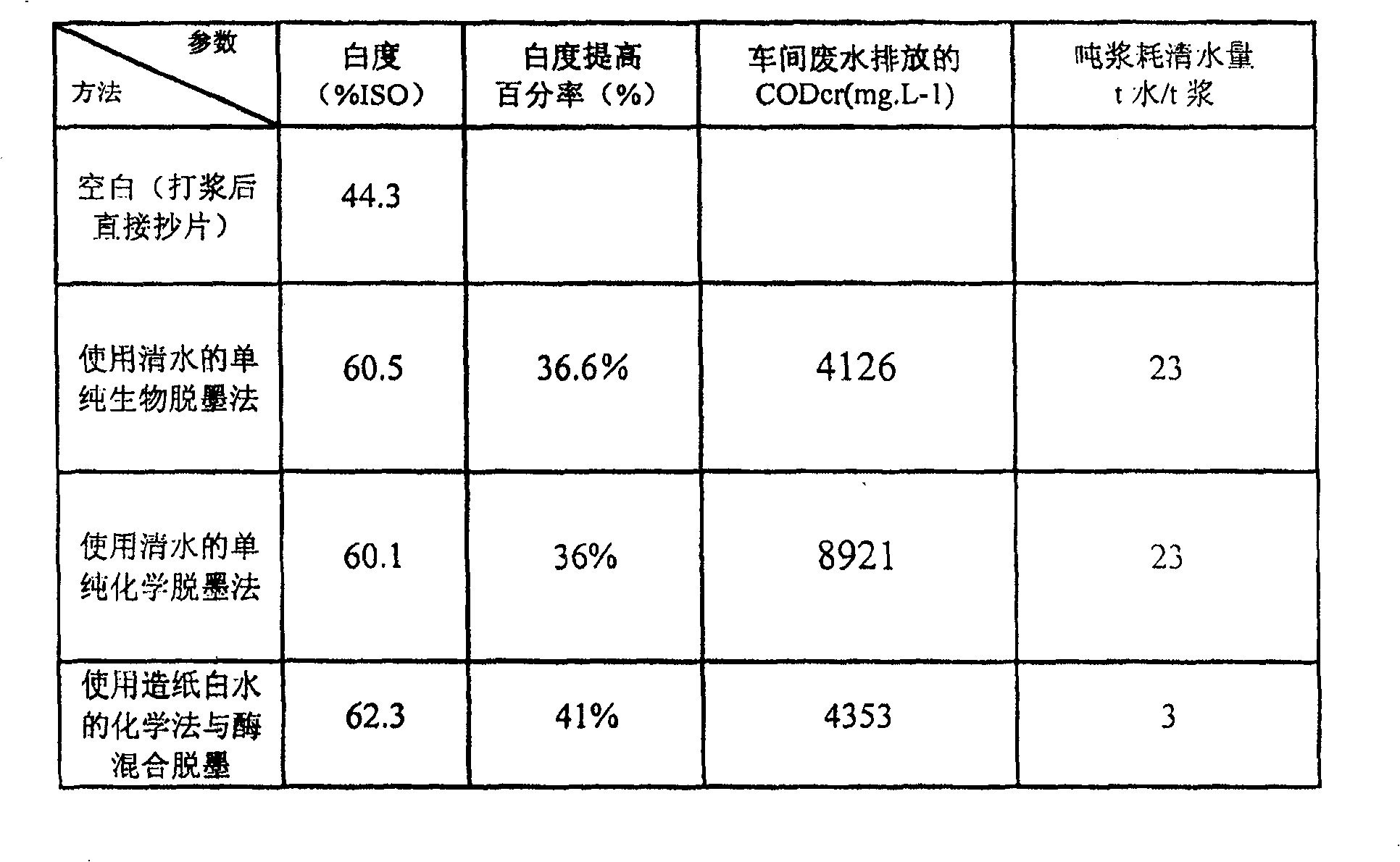

[0020] Raw material: 70% #8 old newspaper (ONP) + 30% #10 old magazine paper (OMG), raw pulp whiteness 44.3% ISO, dustiness 1042mm 2 / m 2 . Add paper-making white water on the deinking production line, the amount of paper-making white water: 20 tons of white water / ton of deinked pulp. In the drum pulper, the conventional process conditions are adjusted: pH range: 10-11; slurry concentration 10-20%; pulping temperature 50-60°C. Then add the biological deinking agent of the present invention, the biological deinking agent can be selected from the existing biological deinking agent according to the waste paper quality, and the consumption is 0.09%~0.1% for pulp; The deinking agent can be selected from the existing chemical deinking agent according to the quality of waste paper, and the dosage is only 50% of that of the simple chemical deinking agent, and it is 0.5% to 0.8% for the pulp. Add chemical deinking agents to the pre-flotation tank and post-flotation tank in the subse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com