A kind of environment-friendly deinking agent and preparation method thereof

A deinking agent and environmental protection technology, applied in the field of environmental protection deinking agent and its preparation, can solve the problems of inability to meet the deinking technology of waste paper, uneven product performance, low ink removal efficiency, etc., and achieve good dispersion and anti-deposition performance. , The effect of high deinking efficiency and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Environmentally friendly deinking agent raw materials (parts by weight): 8 parts of sodium silicate, 15 parts of talc, 15 parts of sodium sulfate, 35 parts of sodium carbonate, 8 parts of ethylene glycol, 8 parts of surfactant, and 8 parts of penetrant.

[0032] Described surfactant is mixed from ethylene glycol monostearate, propylene glycol monostearate, diethylene glycol monostearate, described ethylene glycol monostearate, propylene glycol monostearate The mass ratio of fatty acid ester and diethylene glycol monostearate is 1:1:1.

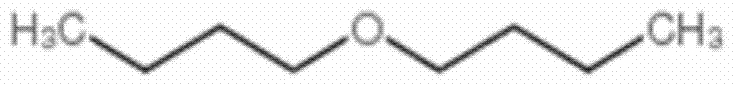

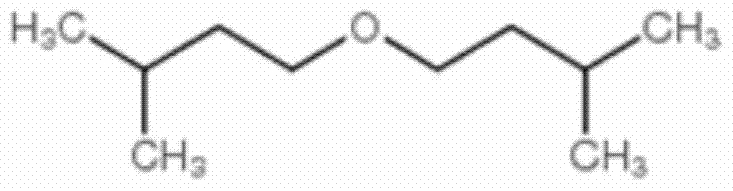

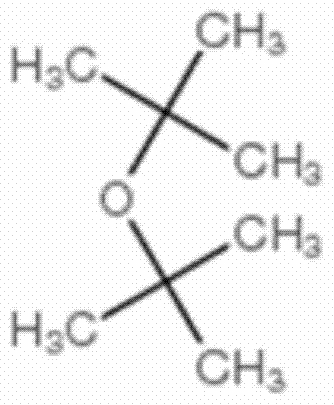

[0033] The penetrant is formed by mixing dibutyl ether, isopentyl ether and di-tert-butyl ether, and the mass ratio of the dibutyl ether, isopentyl ether and di-tert-butyl ether is 1:1:1.

[0034] The preparation method of the environmentally friendly deinking agent: the stirring speed is 300 rpm, first add sodium silicate; then add talc, stir for 5 minutes; then add sodium sulfate, stir for 5 minutes; then add sodium carbonate, stir for...

Embodiment 2

[0036] According to the raw material ratio and method of Example 1, the environmental protection deinking agent is prepared, the difference is only that: the surfactant is mixed with ethylene glycol monostearate and propylene glycol monostearate, and the ethylene glycol monostearate is mixed. The mass ratio of alcohol monostearate and propylene glycol monostearate is 1:1. That is, the environment-friendly deinking agent of Example 2 is obtained.

Embodiment 3

[0038] The environmental protection deinking agent is prepared according to the raw material ratio and method of Example 1. The only difference is that the surfactant is mixed with ethylene glycol monostearate and diethylene glycol monostearate. The mass ratio of ethylene glycol monostearate and diethylene glycol monostearate is 1:1. That is, the environmental protection deinking agent of Example 3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com