Glass deinking equipment

A glass and equipment technology, which is applied in the field of glass deinking equipment, can solve the problems of limited glass placement, high manual labor intensity, and high deinking cost, so as to achieve increased deinking efficiency, reduced deinking cost, and reduced manual labor intensity. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

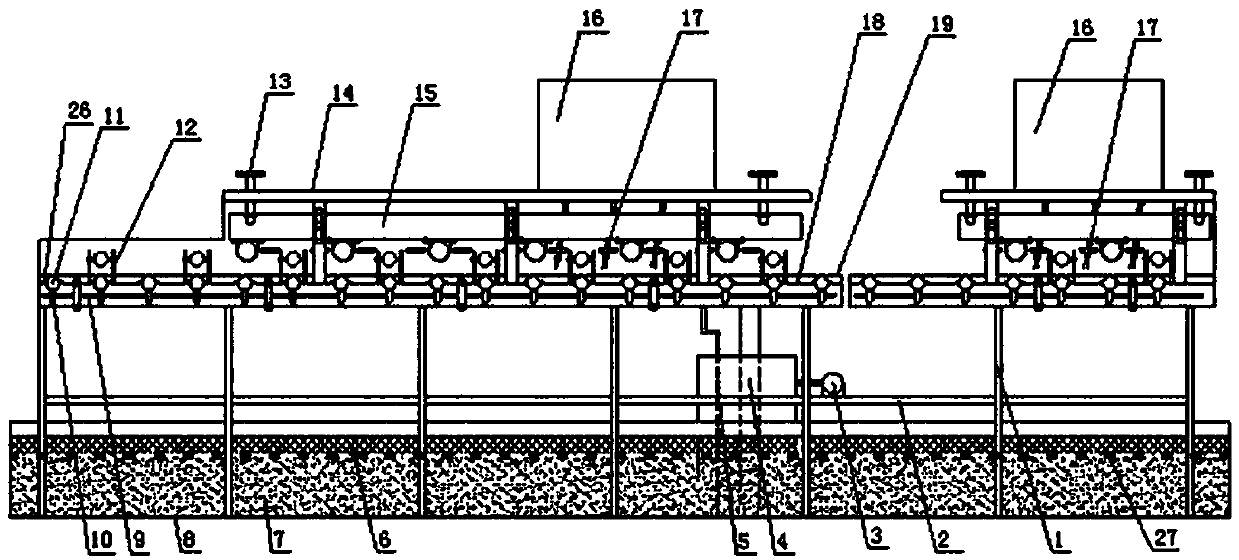

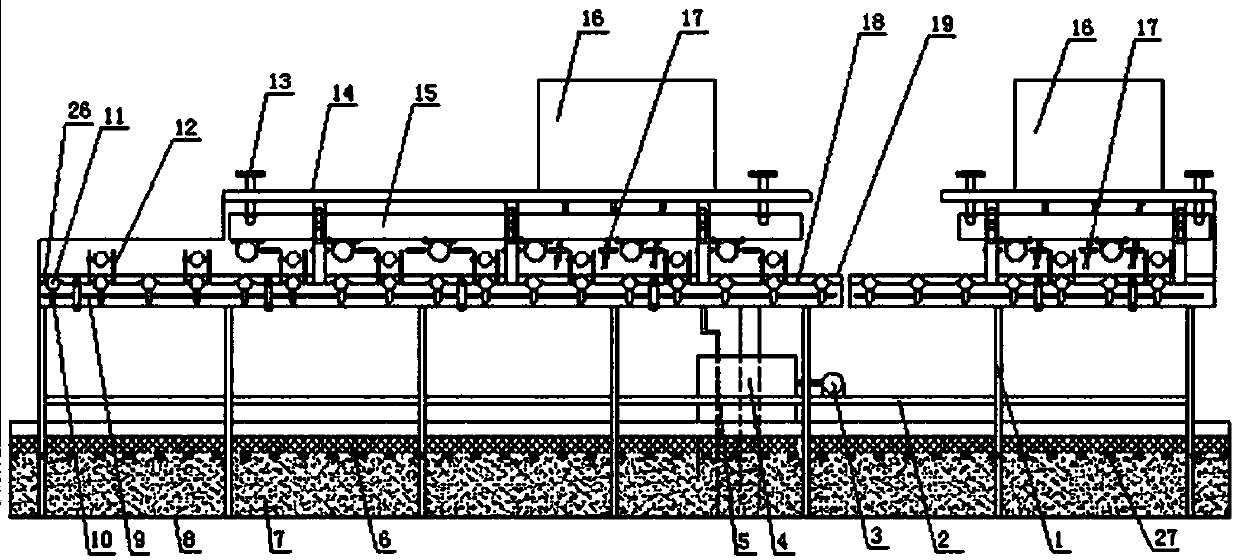

[0032] A kind of glass deinking equipment, structure such as Figure 1-2 As shown, it includes a frame 1 , a conveying mechanism, a deinking and cleaning mechanism, a pumping mechanism, and a casing 14 .

[0033] 1. The frame 1 is fixed above the deinking tank 8 . The top of the frame 1 is provided with a platform 22 extending in the horizontal direction, and the lower part of the frame 1 is provided with a supporting edge 2 above the deinking tank 8 . Both sides of the platform 22 are respectively fixed with baffles 19 extending along the length direction of the platform 22 . A flat plate 18 extending outward along the horizontal direction is fixed on the outer side of each baffle plate 19 . Both sides of the platform 22 are respectively provided with horizontal support 15 extending along the length direction of the platform 22 above the baffle plate 19. The horizontal support 15 is fixed on the top of the shell 14 through a plurality of screw rods 13. The horizontal suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com