Waste paper deinking method

A waste paper deinking and waste paper technology, which is applied in the field of papermaking, can solve the problems of bio-enzyme-refractory inks and high ink residues, and achieve the effects of increasing surface area, improving efficiency, and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

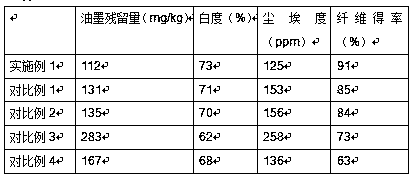

Examples

Embodiment 1

[0023] A method for deinking waste paper, the specific steps are as follows:

[0024] 1) Collect waste paper and crush it, pour it into a clear water pool, add 0.5mol / L dilute sulfuric acid solution, adjust the pH to 5.0, and soak for 50 minutes;

[0025] 2) Take out the soaked material and centrifuge to remove impurities in the material and make pulp;

[0026] 3) Move the pulp to the container, add material treatment agent, stir evenly, and then carry out ultrasonic water bath oscillation dispersion in a magnetic field with a magnetic induction intensity of 3500GS. The water bath temperature is 70°C, the oscillation power is 600W, and the oscillation time is 25min;

[0027] 4) Dilute the treated pulp with water and move it to a flotation tank, add a deinking agent, and perform flotation deinking under 500W ultrasonic waves;

[0028] 5) After the deinked waste paper pulp is washed by a high-speed pulp washer, it can be made into qualified pulp.

[0029] Preferably, in step 1...

Embodiment 2

[0039] A method for deinking waste paper, the specific steps are as follows:

[0040] 1) Collect waste paper and crush it, pour it into a clear water pool, add 0.7mol / L dilute sulfuric acid solution, adjust the pH to 5.5, and soak for 70 minutes;

[0041] 2) Take out the soaked material and centrifuge to remove impurities in the material and make pulp;

[0042] 3) Move the pulp to the container, add material treatment agent, stir evenly, and then carry out ultrasonic water bath oscillation dispersion in a magnetic field with a magnetic induction intensity of 4500GS. The temperature of the water bath is 75°C, the oscillation power is 600W, and the oscillation time is 30min;

[0043] 4) Dilute the treated pulp with water and move it to a flotation tank, add a deinking agent, and perform flotation deinking under 550W ultrasonic waves;

[0044] 5) After the deinked waste paper pulp is washed by a high-speed pulp washer, it can be made into qualified pulp.

[0045] Preferably, in...

Embodiment 3

[0055] A method for deinking waste paper, the specific steps are as follows:

[0056] 1) Collect waste paper and crush it, pour it into a clear water pool, add 1mol / L dilute sulfuric acid solution, adjust the pH to 6.0, and soak for 80 minutes;

[0057] 2) Take out the soaked material and centrifuge to remove impurities in the material and make pulp;

[0058] 3) Move the pulp to the container, add material treatment agent, stir evenly, and then carry out ultrasonic water bath oscillation dispersion in a magnetic field with a magnetic induction intensity of 5500GS. The water bath temperature is 80°C, the oscillation power is 700W, and the oscillation time is 35min;

[0059] 4) Dilute the treated pulp with water and move it to a flotation tank, add a deinking agent, and perform flotation deinking under 600W ultrasonic waves;

[0060] 5) After the deinked waste paper pulp is washed by a high-speed pulp washer, it can be made into qualified pulp.

[0061] Preferably, in step 1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com