Deinking agent for display window glass

A technology of window glass and deinking agent, which is applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of accelerating the removal of window glass ink, deinking agent delamination and stable performance, and achieves long service life , Stable performance and effect, not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

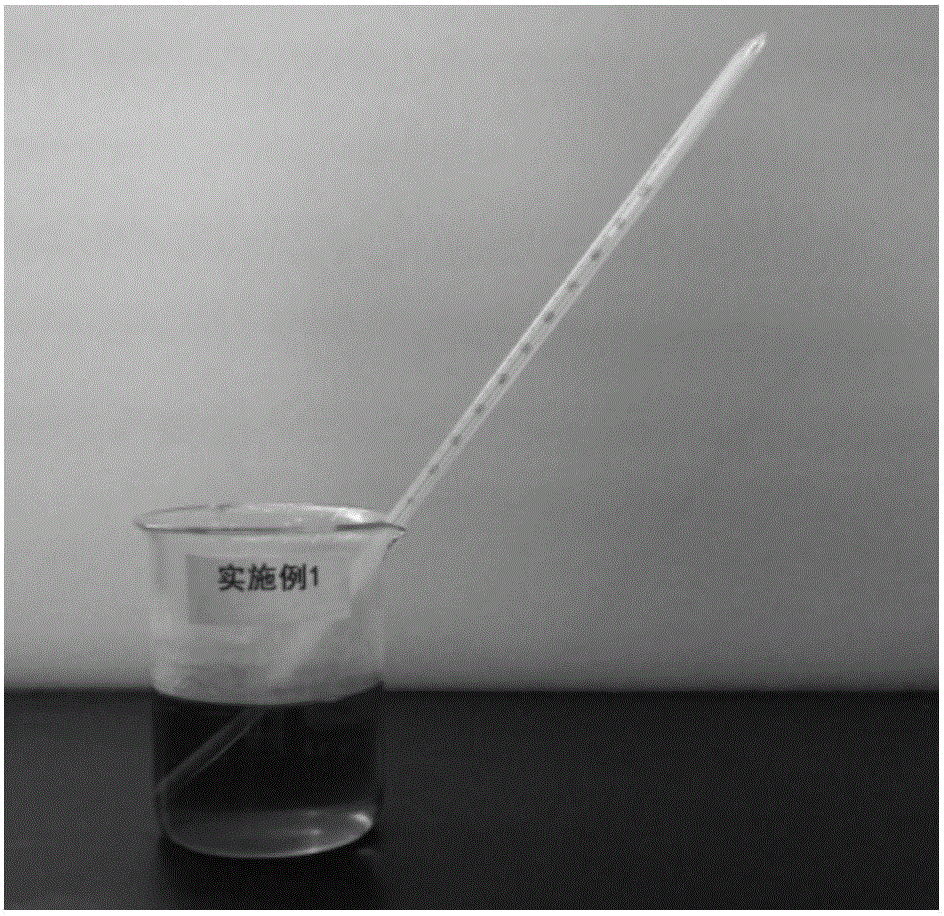

Embodiment 1

[0035] Add 35.5 parts of pure water, 14 parts of potassium hydroxide, 1.5 parts of sodium silicate, and 1 part of sodium borate to the reaction tank made of PPE in sequence, stir and cool to below 40°, then add 3 parts of sodium gluconate and 6 parts of triethanolamine Parts, 3 parts of glycerin, 3 parts of alkyl alcohol ether carboxylate, 2 parts of alkyl polyoxyethylene ether phosphate, 3 parts of cocoyl glucoside, 15 parts of ethylene glycol monoethyl ether, 10 parts of ethanol, ethyl 3 parts of diol, stir the above raw materials evenly.

Embodiment 2

[0037] Add 30 parts of pure water, 18 parts of potassium hydroxide, 3 parts of sodium silicate, and 2 parts of sodium borate to the reaction tank made of PPE in sequence, stir and cool to below 40°, then add 3 parts of sodium gluconate and 7 parts of triethanolamine Parts, 4 parts of glycerin, 6 parts of alkyl alcohol ether carboxylate, 5 parts of alkyl polyoxyethylene ether phosphate, 9 parts of cocoyl glucoside, 7 parts of ethylene glycol monoethyl ether, 3 parts of ethanol, ethyl 3 parts of diol, stir the above raw materials evenly. ,Can

Embodiment 3

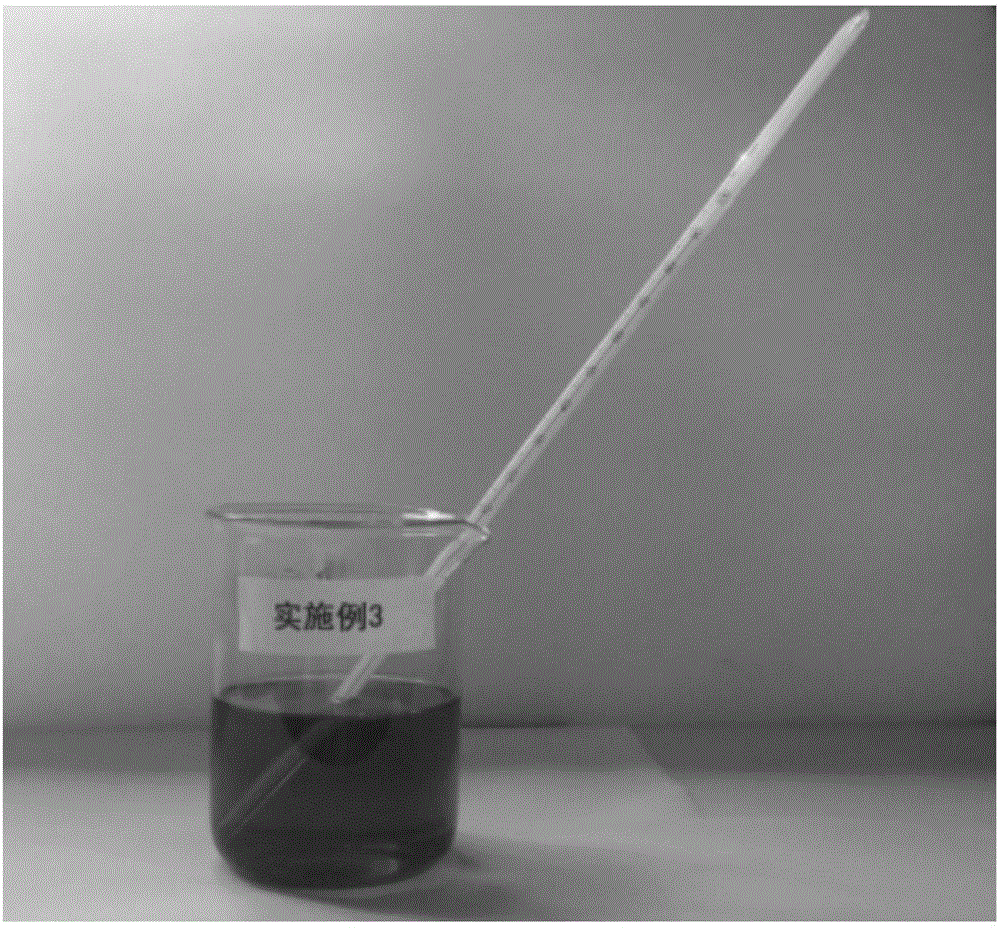

[0039]Add 54.5 parts of pure water, 7 parts of potassium hydroxide, 0.5 parts of sodium silicate, and 0.5 parts of sodium borate to the reaction tank made of PPE in sequence, stir, cool to below 40°, then add 1.5 parts of sodium gluconate, 4 parts of triethanolamine 2 parts of glycerol, 4 parts of alkyl alcohol ether carboxylate, 3 parts of alkyl polyoxyethylene ether phosphate, 5 parts of cocoyl glucoside, 10 parts of ethylene glycol monoethyl ether, 3 parts of ethanol, ethyl 5 parts of diol, stir the above raw materials evenly. ,Can

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com