Common deinking method employing cutinase and chemical reagents

一种化学试剂、角质酶的技术,应用在酶工程领域,能够解决酶用量大、成本增加等问题,达到效果好、提高再利用率、减少酶用量以及化学试剂的用量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

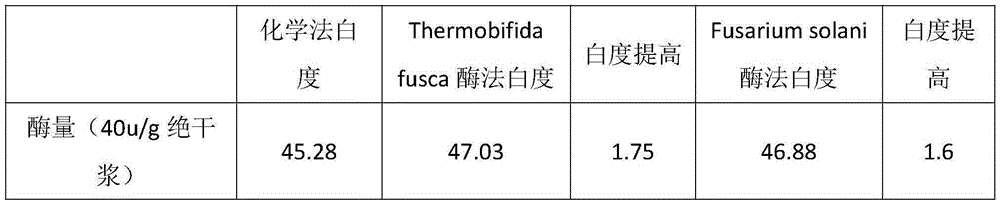

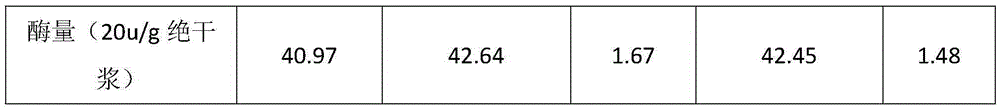

[0035] Embodiment 1: separate cutinase carries out deinking or chemical method deinking

[0036] Thermobifidafusca cutinase deinking:

[0037] 1. Pulping: Take 200g of pulp (absolute dry pulp), adjust the pulp concentration to 10%, the number of revolutions is 225r / min, and the time is 30 minutes.

[0038] 2. Enzyme treatment: In a constant temperature water bath, the temperature is 60°C, the treatment time is 120 minutes, and the hands are rubbed every 10 minutes.

[0039] 3. Slurry washing and dehydration: Dilute the waste paper pulp after bio-enzyme treatment with 5L deionized water, then wash the pulp with a washing bag, and finally tear the pulp cake into small pieces, and air-dry at room temperature.

[0040] 4. Flotation: The waste paper pulp after bio-enzyme treatment is carried out in a laboratory flotation cell, and the flotation conditions: heating water to adjust the slurry concentration to 1%, the temperature is 45°C, and the flotation time is 60min. After flota...

Embodiment 2

[0060] Embodiment 2: adopt Thermobifidafusca cutinase and chemical reagent to carry out deinking jointly

[0061] Cutinase deinking:

[0062] 1. Pulping: take 200g of pulp (absolute dry pulp), adjust the pulp concentration to 10%, the number of revolutions is 225r / min, and the time is 20 minutes.

[0063] 2. Enzyme treatment: In a constant temperature water bath, the temperature is 50°C, the treatment time is 120 minutes, and the hands are rubbed every 10 minutes.

[0064] 3. Chemical treatment: In a constant temperature water bath, the temperature is 50°C, the treatment time is 60min, add 1% Na 2 SiO 3 ,0.2%MgSO 4 ,0.2%EDTA,1%H 2 o 2 .

[0065] 4. Slurry washing and dehydration: Dilute the treated waste paper pulp with 5L of deionized water, then wash the pulp with a washing bag, and finally tear the pulp cake into small pieces, and air-dry at room temperature.

[0066] 5. Flotation: The waste paper pulp after the bio-enzyme treatment is carried out in a laboratory flo...

Embodiment 3

[0074] Embodiment 3: adopt Fusariumsolani cutinase and chemical reagent to carry out deinking jointly

[0075] Cutinase deinking:

[0076] 1. Pulping: take 200g of pulp (absolute dry pulp), adjust the pulp concentration to 10%, the number of revolutions is 225r / min, and the time is 20 minutes.

[0077] 2. Enzyme treatment: In a constant temperature water bath, the temperature is 50°C, the treatment time is 120 minutes, and the hands are rubbed every 10 minutes.

[0078] 3. Chemical treatment: In a constant temperature water bath, the temperature is 50°C, the treatment time is 60min, add 2% Na 2 SiO 3 ,0.1%MgSO 4 ,0.1%EDTA,2%H 2 o 2 .

[0079] 4. Slurry washing and dehydration: Dilute the treated waste paper pulp with 5L of deionized water, then wash the pulp with a washing bag, and finally tear the pulp cake into small pieces, and air-dry at room temperature.

[0080] 5. Flotation: The waste paper pulp after the bio-enzyme treatment is carried out in a laboratory flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com