Highly efficiency microturbulence celluloid ink flotation cell

A flotation cell and micro-turbulence technology, applied in the field of pulp and paper making, can solve the problems such as the limitation of deinking efficiency of deinking flotation cell, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited to the scope described in the embodiments.

[0031] The improvements of the present invention are as follows:

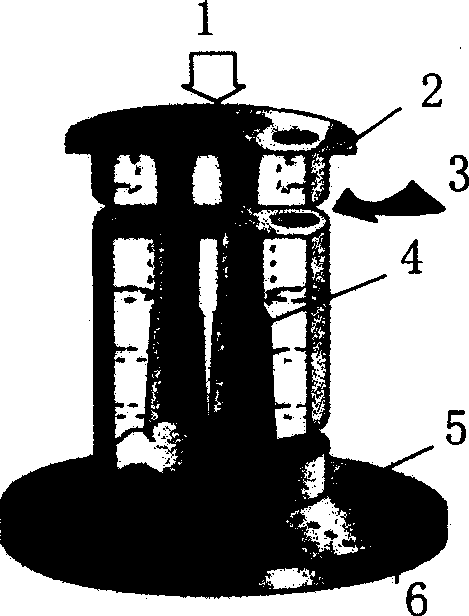

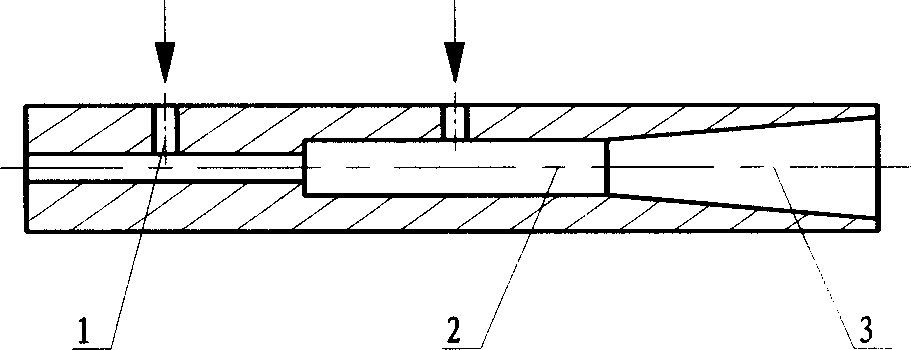

[0032] (1) attached figure 1 It is a schematic structural view of an orifice diffuser in the prior art, consisting of a feed inlet 1, an orifice 2, an air inlet 3, a step diffuser 4, a bottom plate 5 and a discharge outlet 6; the present invention uses The last sudden expansion tube of the stepped diffuser 4 is changed to a gradual expansion tube, as attached image 3 Shown:

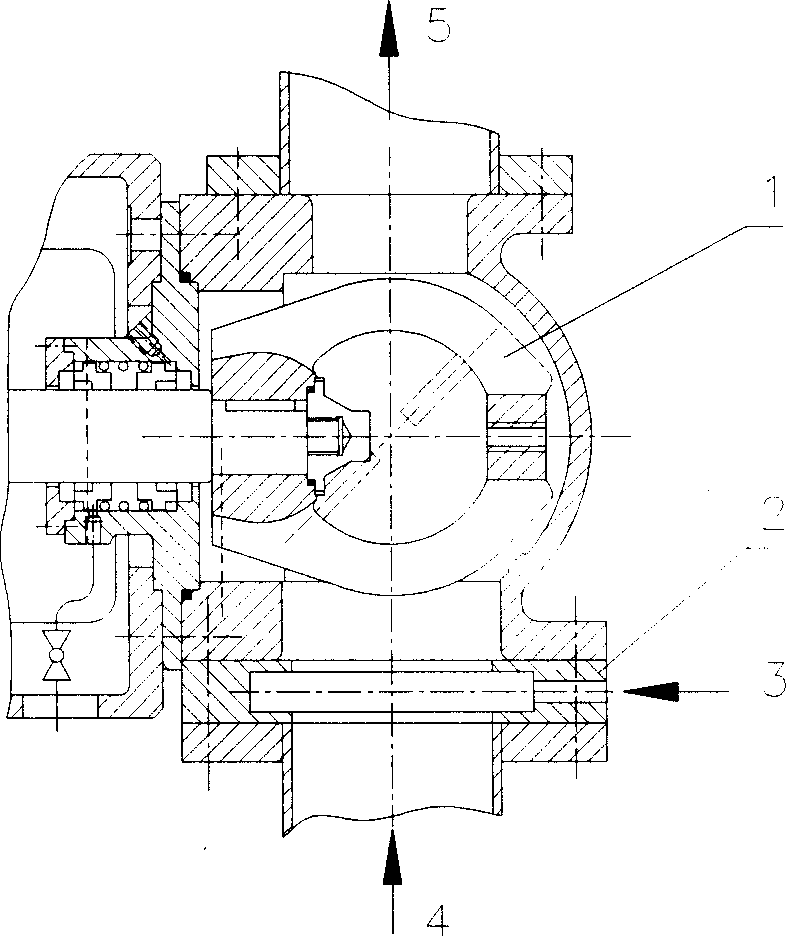

[0033] (2) Add a turbulence generator before the stepped diffuser, as attached figure 2 As shown in the figure, the air bubble forming and uniform mixing device with the slurry is composed of an air-filling element and a turbulent flow generator;

[0034] (3) A deflector is set in the flotation cell to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com