Method for separating scandium from bayan obo tailings

A tailings and roughing technology, which is applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems that are rare, ore dressing patents have not been reported, and achieve continuous process, good technical indicators, simple and scientific process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

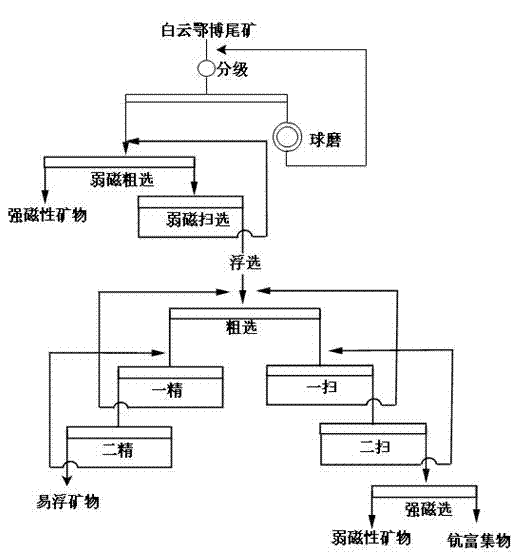

[0024] The raw material of Baiyan Obo tailings in Baotou Iron and Steel tailings dam was determined to contain Sc 2 o 3 200ppm, utilize technology of the present invention to sort scandium enrichment, concrete steps are as follows figure 1 :

[0025] (1) Classification: Classify the tailings of Baiyun Obo, separate the coarse-grained ore from the fine-grained ore, finely grind the coarse-grained ore with a ball mill, and return it to the classifier after grinding. The fine-grained ore is used as a raw material for weak magnetic separation, and fine-grained ore is required Ore particle size -200 mesh accounts for more than 95%;

[0026] (2) Weak magnetic separation: Weak magnetic separation is carried out after the fine-grained ore obtained by classification and accounting for more than 95% of -200 mesh has a pulping mass concentration of 12%. Weak magnetic separation includes primary roughing and primary sweeping. First carry out weak magnetic separation roughing, the magn...

Embodiment 2

[0031] The raw material is Baiyun Obo tailings after iron separation in Baotou Iron and Steel West Mine. It has been determined that the raw material contains Sc 2 o 3 180ppm, utilize technology of the present invention to sort scandium enrichment, concrete steps are as follows figure 1 :

[0032](1) Classification: Classify the tailings of Baiyun Obo, separate the coarse-grained ore from the fine-grained ore, finely grind the coarse-grained ore with a ball mill, and return it to the classifier after grinding. The fine-grained ore is used as a raw material for weak magnetic separation, and fine-grained ore is required Ore particle size -200 mesh accounts for more than 95%;

[0033] (2) Weak magnetic separation: Weak magnetic separation is carried out after the fine-grained ore obtained by classification is -200 mesh accounting for more than 95% and the mass concentration is 15%. The weak magnetic separation includes primary roughing and primary sweeping. First carry out we...

Embodiment 3

[0038] The raw material is the Baiyan Obo tailings after the rare earth selection by Baotou Iron and Steel Co., Ltd., and it has been determined that the raw material contains Sc 2 o 3 150ppm, utilizing the process technology of the present invention to sort scandium enrichment, concrete steps are as follows figure 1 :

[0039] (1) Classification: Classify the tailings of Baiyun Obo, separate the coarse-grained ore from the fine-grained ore, finely grind the coarse-grained ore with a ball mill, and return it to the classifier after grinding. The fine-grained ore is used as a raw material for weak magnetic separation, and fine-grained ore is required Ore particle size -200 mesh accounts for more than 95%;

[0040] (2) Weak magnetic separation: Weak magnetic separation is carried out after the graded fine-grained ore with -200 mesh accounting for more than 95% has a mass concentration of 25%. The weak magnetic separation includes primary roughing and primary sweeping. First ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com