An anti-crack and anti-seepage composite material for concrete

A composite material and concrete technology, which is applied in the field of building materials, can solve the problems of concrete frost resistance and corrosion resistance that cannot meet the requirements of society, reduce concrete strength, and high production costs, so as to improve the performance of sulfate corrosion resistance and increase the resistance to corrosion. Permeability, improve the effect of frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

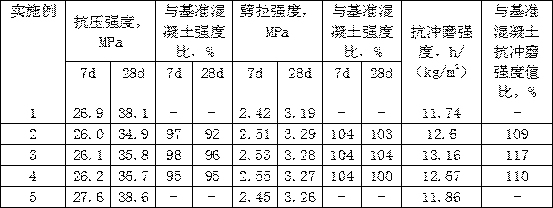

Examples

Embodiment 1

[0017] The anti-cracking and impermeability composite material used in this embodiment for concrete includes the following components in parts by weight: 81 parts of calcium carbonate, 1 part of magnesium carbonate, 0.3 part of titanium dioxide, 5 parts of bone glue powder, 0.2 part of zinc oxide, nitric acid 0.4 parts of lead, 1 part of stearic acid, 0.5 parts of palmitic acid and 0.2 parts of polyethylene glycol; among them, the calcium carbonate is light calcium carbonate with a particle size of 1-3 μm, and the zinc oxide is oxidized with a particle size of 360-420 mesh. Zinc powder.

Embodiment 2

[0019] The anti-cracking and impermeability composite material used in this embodiment for concrete includes the following components in parts by weight: 82 parts of calcium carbonate, 2 parts of magnesium carbonate, 0.3 part of titanium dioxide, 5 parts of bone glue powder, 0.2 part of zinc oxide, nitric acid 0.5 part of lead, 1 part of stearic acid, 0.5 part of palmitic acid and 0.2 part of polyethylene glycol; among them, the calcium carbonate is light calcium carbonate with a particle size of 1-3 μm, and the zinc oxide is oxidized with a particle size of 360-420 mesh. Zinc powder.

Embodiment 3

[0021] The anti-cracking and impervious composite material used in this embodiment for concrete includes the following components in parts by weight: 82.5 parts of calcium carbonate, 3.5 parts of magnesium carbonate, 2.15 parts of titanium dioxide, 5.5 parts of bone glue powder, 0.25 parts of zinc oxide, nitric acid 0.55 parts of lead, 10.5 parts of stearic acid, 0.75 parts of palmitic acid and 0.25 parts of polyethylene glycol; among them, the calcium carbonate is light calcium carbonate with a particle size of 1-3 μm, and the zinc oxide is oxidized with a particle size of 360-420 mesh. Zinc powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com