Recycling processing technology for waste circuit board

A technology of waste circuit boards and processes, which is applied in the field of processing, recycling and reuse of waste resources, can solve the problems of unrecyclable, low output, long leaching time, etc., achieve resource regeneration and recycling, reduce energy consumption and pollution, Reduces the effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the above-mentioned drawings and specific embodiments.

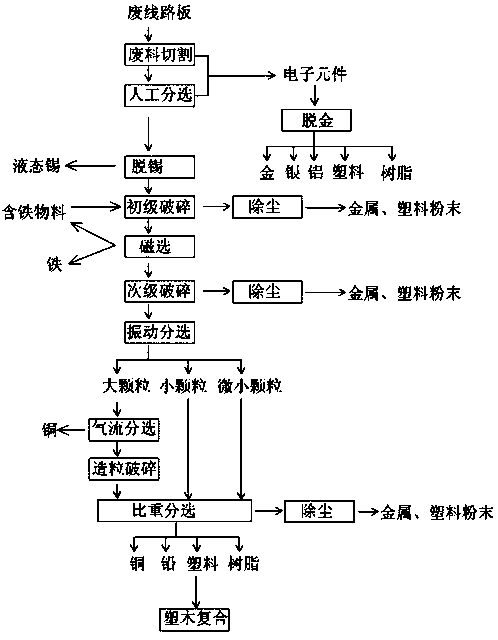

[0024] like figure 1 As shown, the waste circuit board treatment and recycling process mainly includes the following steps:

[0025] ⑴Scrap cutting: use a semi-automatic cutting machine to cut waste circuit boards, and initially separate electronic components from the substrate;

[0026] ⑵Manual sorting: the substrates with some electronic components left after the preliminary separation in step 1 are manually removed;

[0027] (3) Degolding: The electronic components collected in step 1 and step 2 are separated into gold, silver, aluminum, plastic and resin for preservation through degolding equipment, and platinum and palladium will also be separated from them according to the composition of electronic components , zinc and other precious metals;

[0028] (4) Detinning: Put the substrate after removing the electronic components in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com