Disperse blue dye coupling component and preparation method thereof

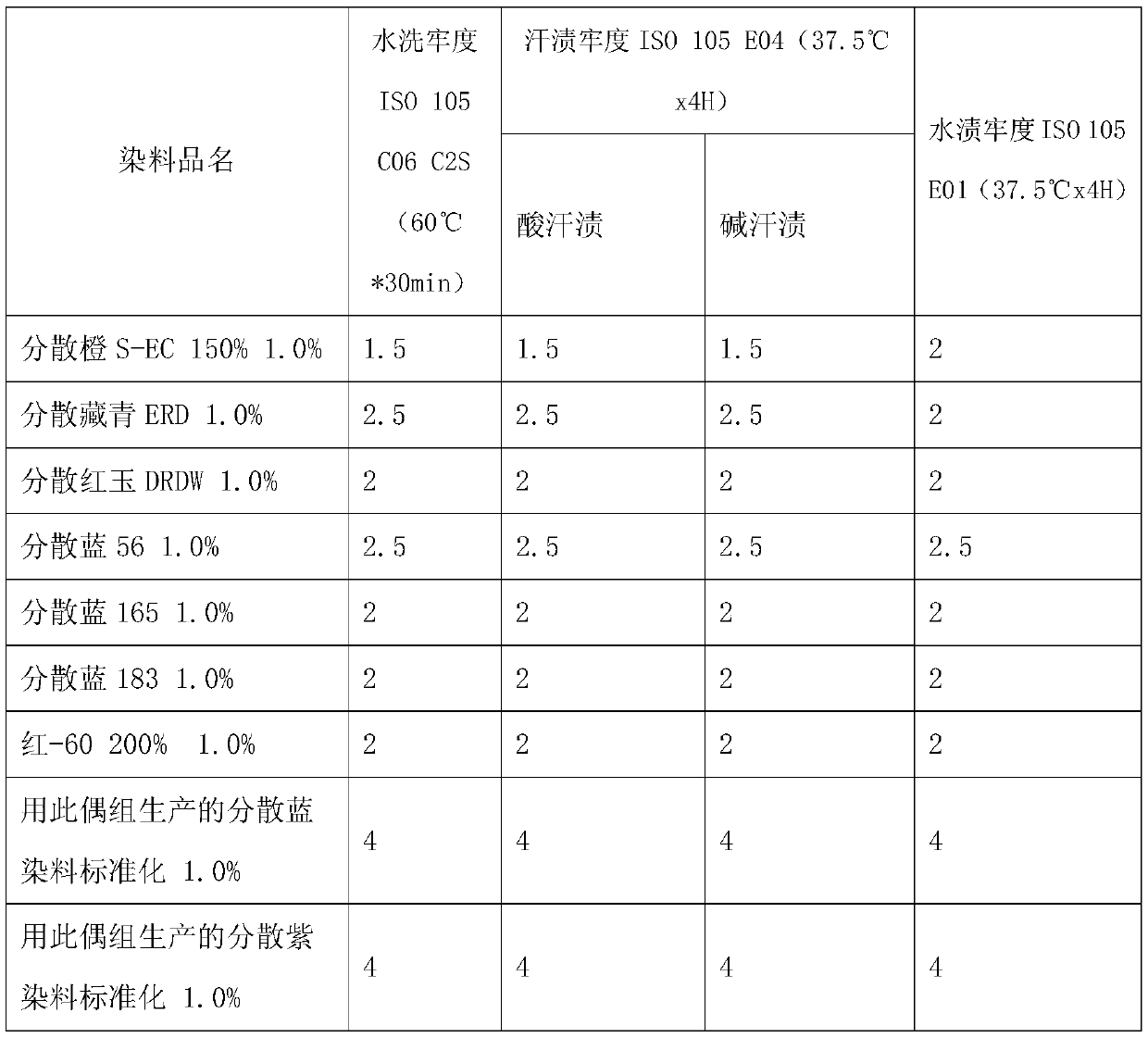

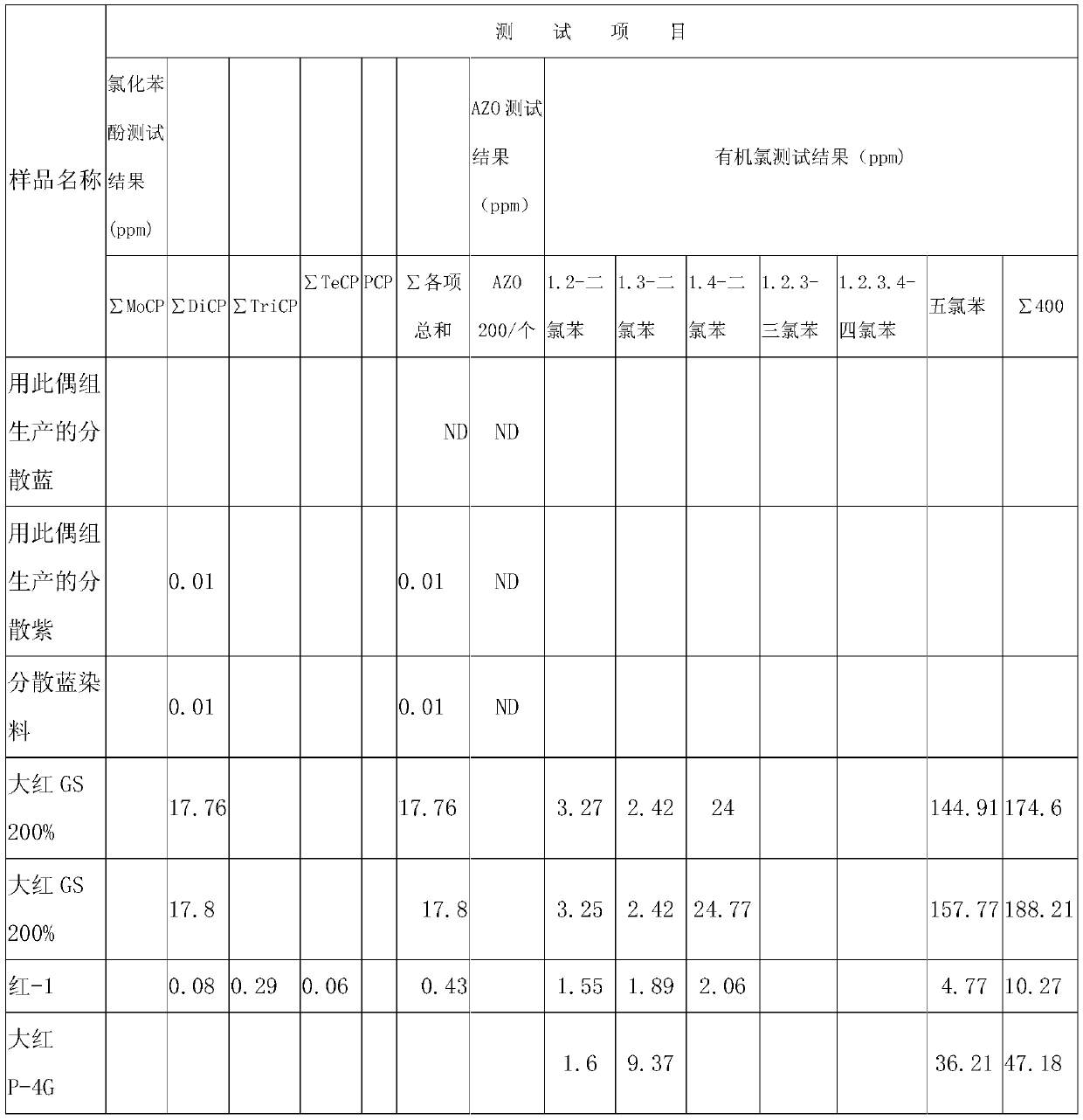

A technology for dispersing blue and dyes, applied in the field of dyes, can solve the problems of low fastness, heavy staining of spandex, low fastness of spandex, etc., and achieves the effects of low cost, high fastness and good environmental protection indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1 Check that the 5000L reactor is in good condition and clean, the condenser is in good condition, the vacuum pump is in good condition, and check the sealing of the equipment used.

[0030] 2 Check whether the code and quantity of the prepared raw materials meet the process requirements, if not, report to the workshop immediately and stop the operation.

[0031] 4 Adjust the temperature below 30 degrees, turn on the tail gas absorption equipment, add 69kg of soda ash, and add 720kg of reducing substances evenly in 45 minutes to 1 hour.

[0032] 5 Add 500kg of soda ash evenly in 45 minutes.

[0033] 6. Add 108kg of sodium bromide and stir for 30 minutes, close the manhole cover, and close the tail gas absorption valve.

[0034] 7 Check the reaction system at the same time, and the entire reaction system is in an empty state.

[0035] 8 Warm up. It takes 3 hours to evenly rise to 98 degrees. Warm up to 35-40 degrees and let it be natural. At about 60 degrees, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com