Groove type liquid-seal blast cooling device and method for sintered ores

A technology of blast cooling and sintering, which is applied in the field of ironmaking and can solve problems such as environmental pollution, no sealing cover device, and atmospheric particulate matter pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

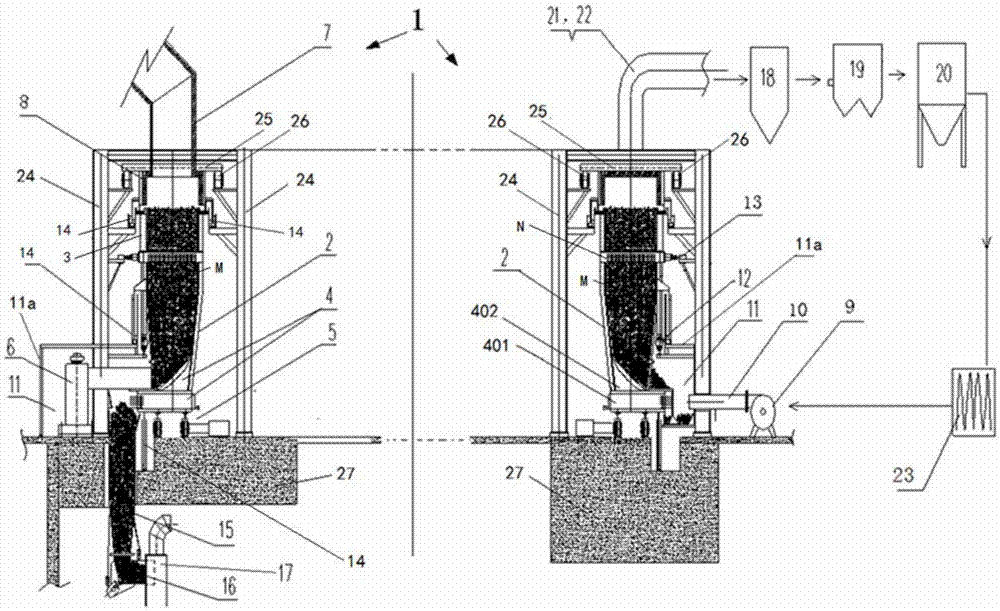

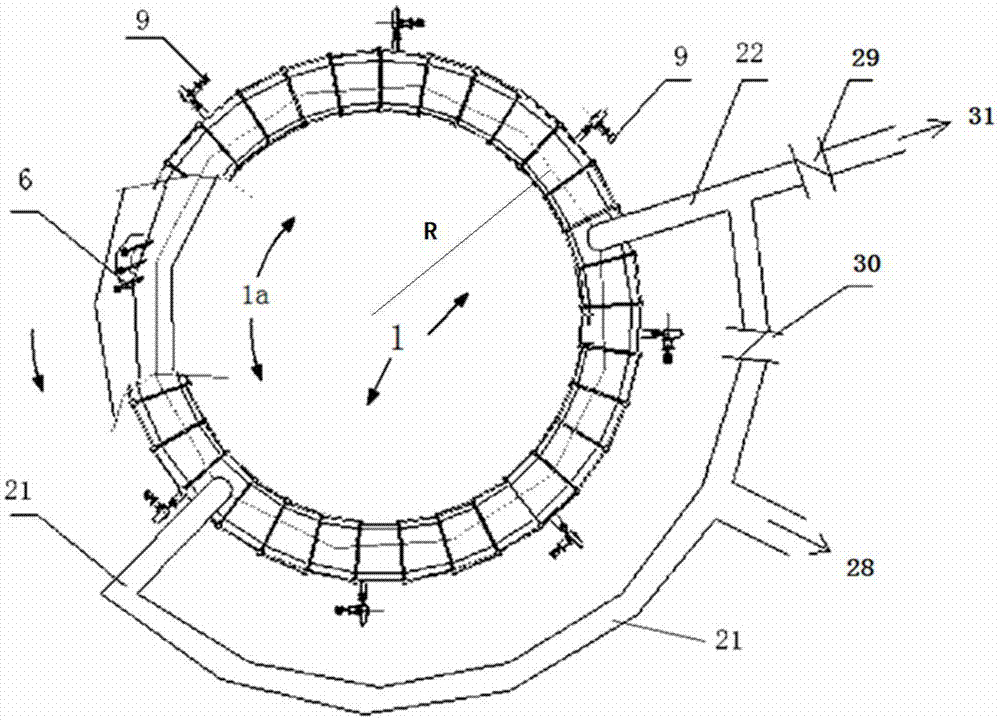

[0072] Such as Figure 1-11 As shown in , a trough-type liquid-sealed blast cooling device 1 for sinter is provided, which includes:

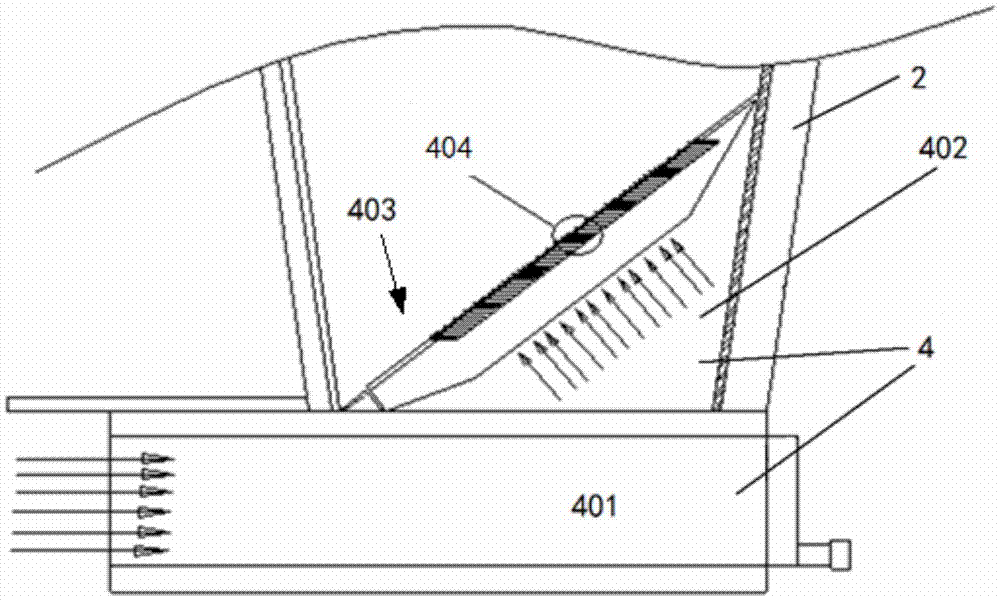

[0073] 1) The sintered ore from the sintering machine is piled up from the top, and at the same time discharged from the lower peripheral annular discharge port, the box body includes the inner ring wall 2, the outer ring wall 3 and the bottom. Circle ring tray 4;

[0074] 2) a wheel-rail driving device 5 for driving the above-mentioned annular groove-shaped stacking box to make a rotary motion in the horizontal direction;

[0075] 3) An annular machine cover (or called a protective cover) 8 provided on the above-mentioned annular groove-shaped stacking box to cover the upper part of the above-mentioned stacking box;

[0076] 4) at least one air outlet duct (preferably at least two air outlet ducts, such as 1-10, such as 2-6 or 2-4) connected to the top of the above-mentioned hood 8; preferably, there are at least two The air outlet duct is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com