Glutinous rice adhesive subpackagable at high temperature and used for wallpaper, and preparation method thereof

A technology of glutinous rice glue and high temperature, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of reducing the use efficiency of production equipment, large electric energy and production time, and increasing the cost of production enterprises , to achieve the effect of solving secondary pollution defects, reducing energy loss and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

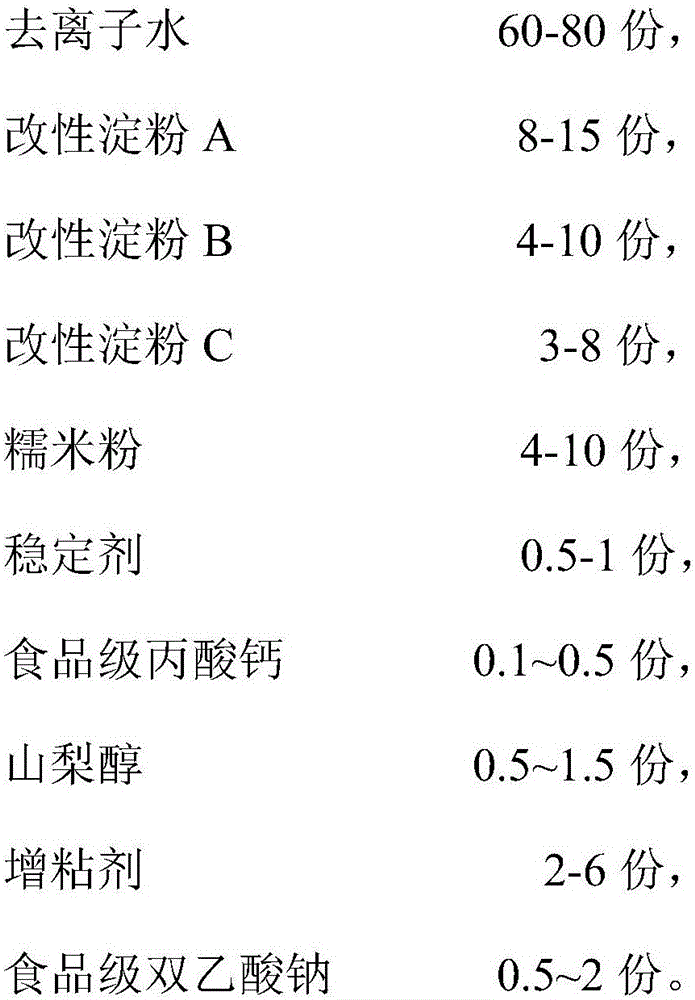

Method used

Image

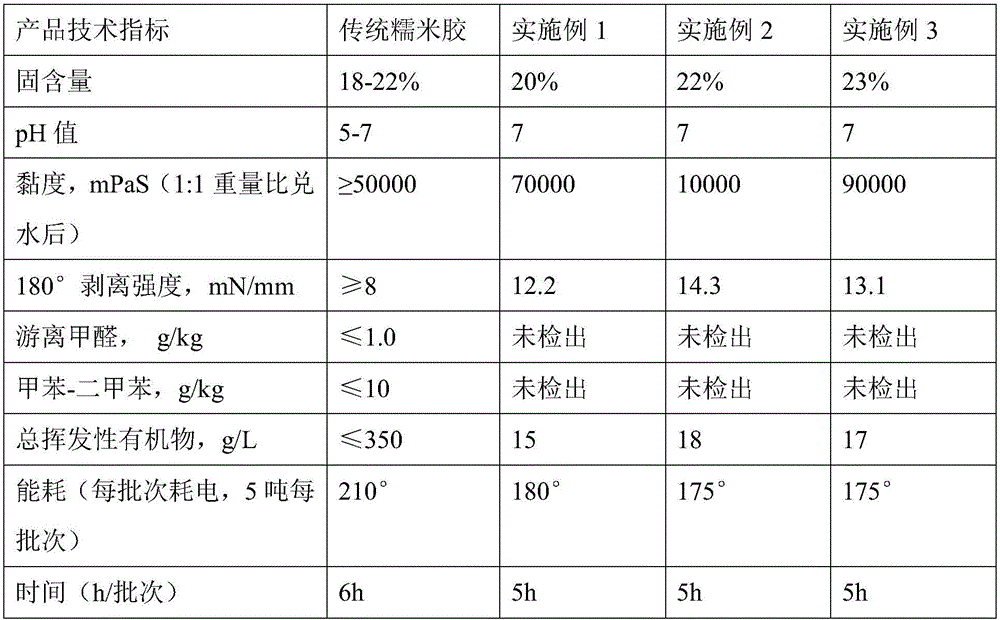

Examples

Embodiment 1

[0025] A preparation method of glutinous rice glue that can be packaged at high temperature specially for wallpaper, the specific process is as follows:

[0026] Step A: sequentially remove 80 parts of ionized water, 12 parts of modified starch A, 5 parts of modified starch B, 3 parts of modified starch C, 2 parts of glutinous rice flour, and 0.5 parts of food-grade trimetaphosphoric acid Sodium, 0.1 part of food-grade calcium propionate, 1 part of sorbitol, 3 parts of food-grade acetylated distarch sodium, and 0.5 part of food-grade sodium diacetate were added to the reaction kettle for slurry mixing, and after stirring evenly, the Slowly heat the reaction kettle to 95°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0027] Step B: At this time, the glutinous rice glue has good fluidity, low energy consumption for stirring and conveying, and is directly filled into finished small packages with an automatic filling m...

Embodiment 2

[0029] Step A: 75 parts of deionized water, 10 parts of modified starch A, 8 parts of modified starch B, 3 parts of modified starch C, 3 parts of glutinous rice flour, 0.5 parts of food-grade trimetaphosphoric acid Add sodium, 0.1 parts of food grade calcium propionate, 0.6 parts of food grade glycerin, 2 parts of food grade sodium acetylated distarch, 1 part of food grade sodium diacetate, and 1.5 parts of sorbitol into the reaction kettle Mix the slurry and stir evenly, then slowly heat the reaction kettle to 85°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0030] Step B: At this time, the glutinous rice glue has good fluidity, low energy consumption for stirring and conveying, and is directly filled into finished small packages with an automatic filling machine, and the packaged small package glue is air-dried for 5 minutes before being transferred into the finished product packaging box In use, take equal weig...

Embodiment 3

[0032] Step A: 75 parts of deionized water, 12 parts of modified starch A, 8 parts of modified starch B, 5 parts of modified starch C, 4 parts of glutinous rice flour, 0.8 parts of food grade sodium trimetaphosphate, 0.1 parts Food-grade calcium propionate, 0.1 parts of food-grade glycerin, 2 parts of thickener, 0.5 parts of food-grade sodium diacetate, 1.0 parts of sorbitol. After stirring evenly, slowly heat the reaction kettle to 90°C, at this time, the glue is in a slightly gelatinized state, and then keep the temperature for 30 minutes;

[0033] Step B: At this time, the glutinous rice glue has good fluidity, low energy consumption for stirring and conveying, and is directly filled into finished small packages with an automatic filling machine, and the packaged small package glue is air-dried for 5 minutes before being transferred into the finished product packaging box In use, take equal weight of water and glutinous rice glue product to dilute, so that the viscosity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com