Autoclaved aerated concrete block and preparation process thereof

A concrete block and autoclaved aerated technology, which is applied in the direction of ceramic products, other household utensils, applications, etc., can solve the problem of unstable production process of autoclaved aerated concrete blocks, small application range of products, unstable production process, etc. To achieve the effect of promoting the recycling of solid waste resources, solving the instability of production process, and the uniform size and distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

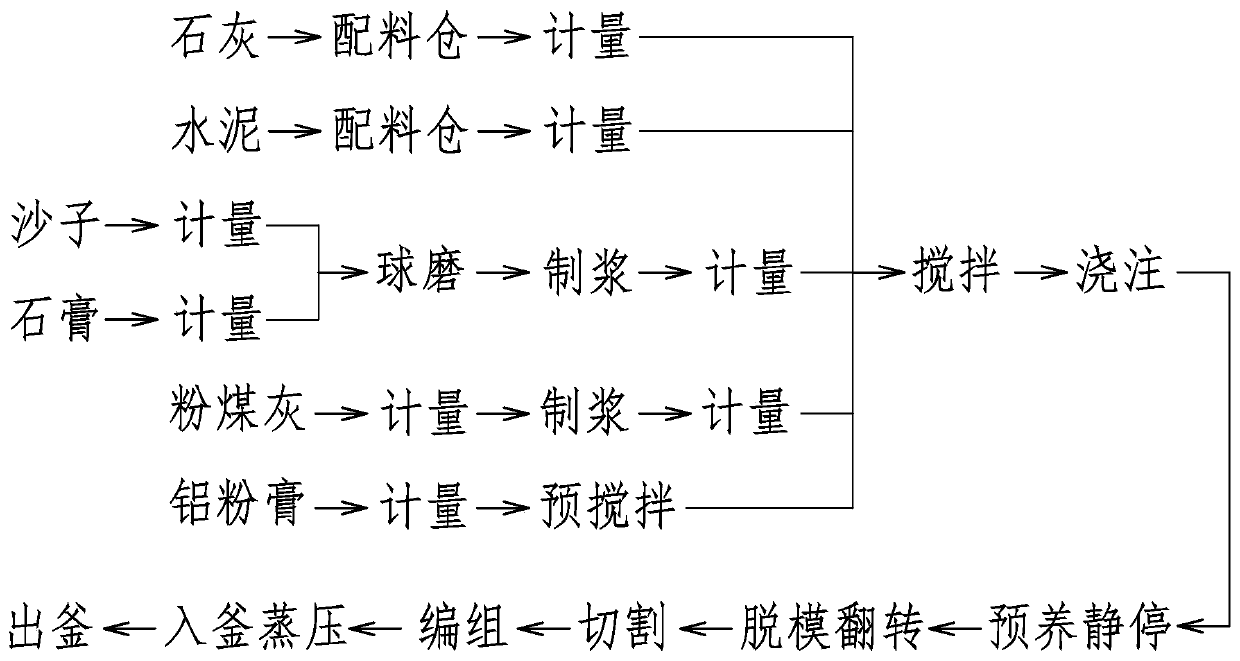

Method used

Image

Examples

Embodiment 1

[0025] In Example 1, an autoclaved aerated concrete block, its formula is in parts by weight, including the following components: 120 parts of fly ash, 280 parts of river sand, 10 parts of desulfurized gypsum, 75 parts of lime, cement 80 parts, 0.6 parts of aluminum powder paste; wherein the content of silicon dioxide in fly ash is 32.57%, the content of aluminum oxide is 21.28%, the content of ferric oxide is 5.22%, and the content of calcium oxide is 24.57% ; The content of silica in river sand is 77.0%, and the mud content is 7.0%.

[0026] In Comparative Example 1, the formula of the autoclaved aerated concrete block, in parts by weight, includes the following components: 200 parts of fly ash, 200 parts of river sand, 10 parts of desulfurized gypsum, 75 parts of lime, and 85 parts of cement , 0.6 part of aluminum powder paste; Wherein the quality index of fly ash is identical with embodiment 1.

[0027] In Comparative Example 2, the formula of the autoclaved aerated concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com