Treatment method for comprehensive wastewater in circuit board industry

A technology that integrates waste water and treatment methods, applied in the field of printed circuit board manufacturing, can solve problems such as excessive copper ion discharge indicators, high cost, and small alum flowers, so as to reduce the concentration of copper ions, reduce material costs, and avoid fungal poisoning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

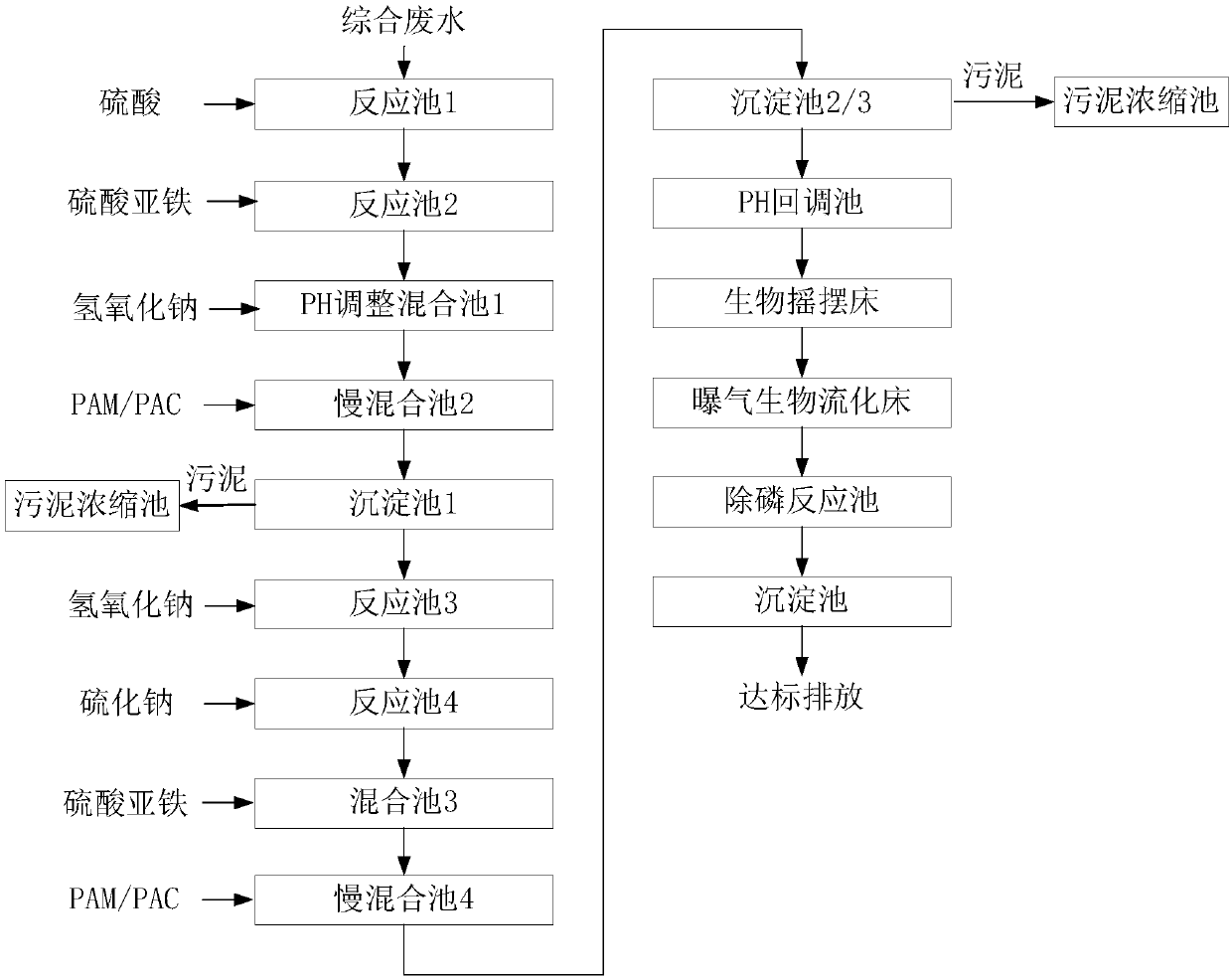

[0019] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

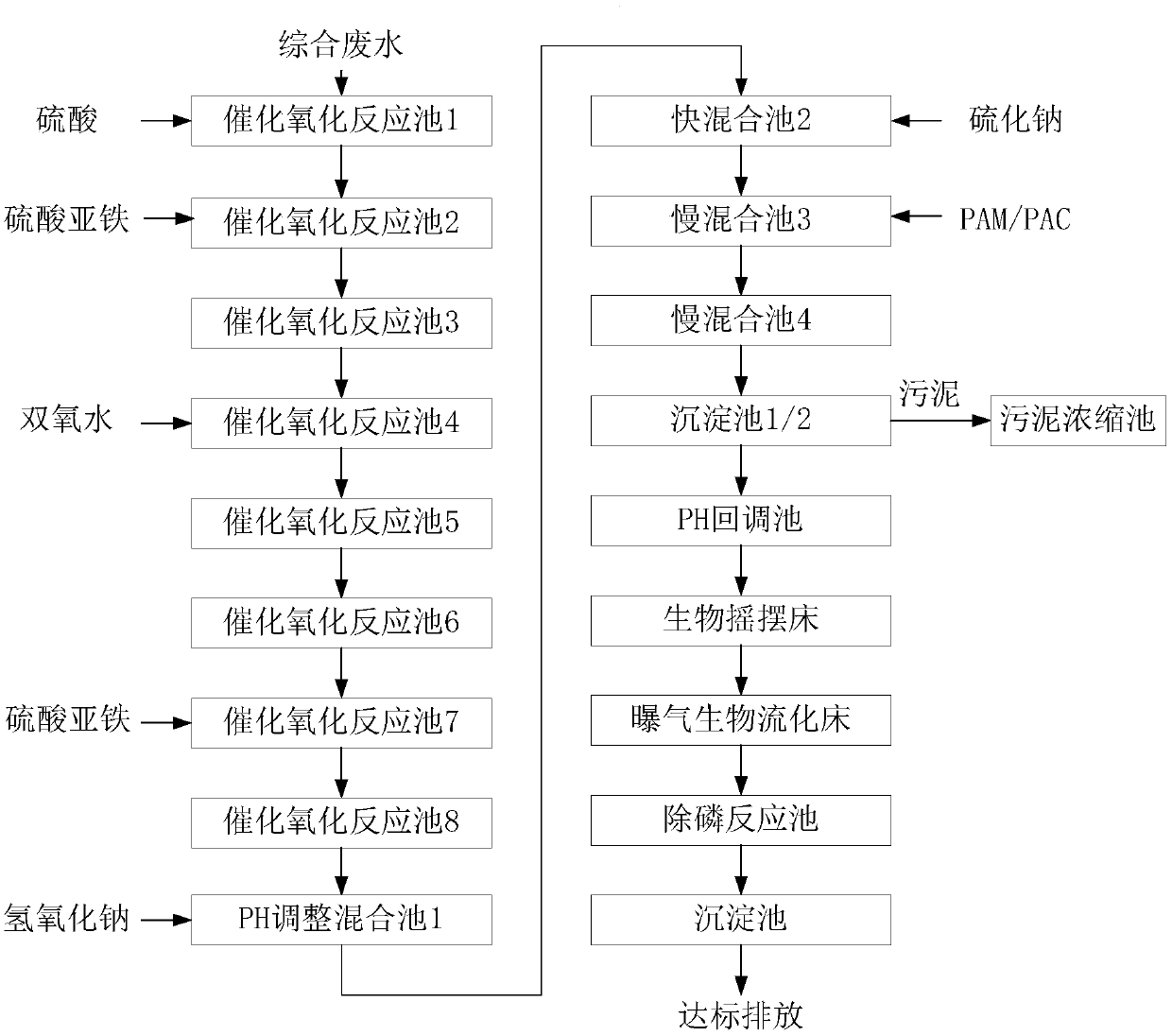

[0020] In the following specific embodiments of the present invention, please refer to figure 2 , figure 2 It is the process flow of comprehensive wastewater treatment in the circuit board industry of the present invention.

[0021] The circuit board industry comprehensive wastewater treatment method of the present invention is characterized in that it comprises the following steps:

[0022] Step S1: add sulfuric acid to the comprehensive wastewater, adjust the pH to 2.5-3.5, add ferrous sulfate, and carry out the decomplexation reaction. The divalent iron ions in ferrous sulfate have reducing properties, which can reduce the divalent copper ions in wastewater to monovalent copper ions, and the complexes formed by monovalent copper ions and ammonia (NH3, EDTA, chloride ions are No longer stable, in the next step the monovalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com