Ammonia-nitrogen-free environment-friendly micro-etching pretreatment liquid and treatment method

A pre-treatment liquid, ammonia-free technology, applied in the field of solder resist and tin pre-treatment corrosion, OSP, can solve the problems of short service life and lack of bath liquid, improve utilization rate, promote intergranular reaction, and improve roughness The effect of degree and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

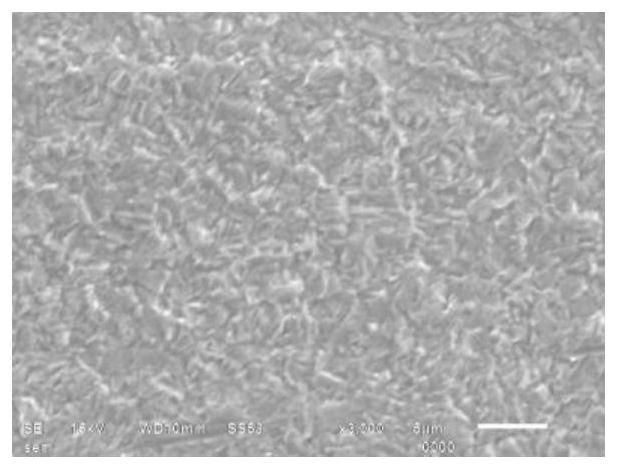

Embodiment 1

[0057] Chemical microetching solution includes: H 2 o 2 (6g / L)+H 2 SO 4 (10g / L), sulfosalicylic acid 5g / L, ethylene glycol 2mL / L, itaconic acid 0.5g / L, corrosion inhibitor phytic acid 0.25g / L, ethanol and emulsifier compound 0.5mL / L, roughening agent is cyclohexanoic acid 0.05g / L.

[0058] The parameters of the above obtained copper sheet include appearance brightness, uniformity of copper surface erosion, maximum copper ion concentration that can be accommodated in the bath, erosion rate and final rate reduction rate, and fingerprint printing and oil removal function. (5 represents excellent, 4 represents good, 3 represents poor, 2 represents poor, 1 represents very poor); erosion uniformity 5 (5 represents excellent uniformity, 4 represents good uniformity, 3 represents poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability); the maximum concentration of copper ions in the bath solution is 40g / L, and the corrosion rate of immersion corrosion...

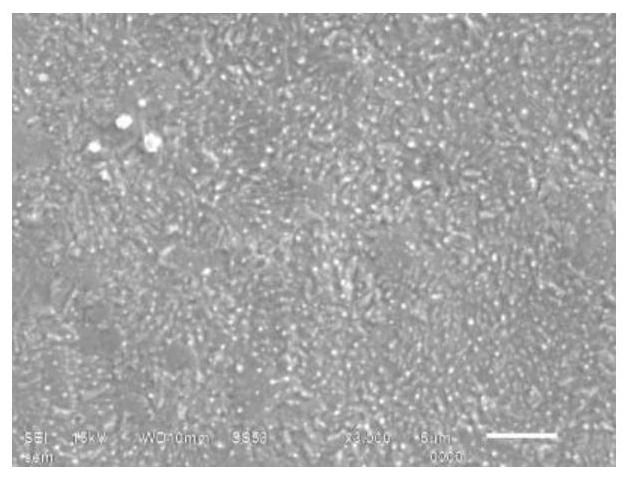

Embodiment 2

[0060] Chemical microetching solution includes: H 2 o 2 (6g / L)+H 2 SO 4 (10g / L), sulfosalicylic acid 5g / L, ethylene glycol 2mL / L, itaconic acid 0.5g / L, corrosion inhibitor phytic acid 0.25g / L, ethanol and emulsifier compound 0.5mL / L, roughening agent is cyclohexanoic acid 0.05g / L.

[0061] The parameters of the above obtained copper sheet include appearance brightness, uniformity of copper surface erosion, maximum copper ion concentration that can be accommodated in the bath, erosion rate and final rate reduction rate, and fingerprint printing and oil removal function. (5 represents excellent, 4 represents good, 3 represents poor, 2 represents poor, 1 represents very poor); erosion uniformity 5 (5 represents excellent uniformity, 4 represents good uniformity, 3 represents poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability; the maximum concentration of copper ions in the bath solution is 40g / L, and the corrosion rate of immersion and corros...

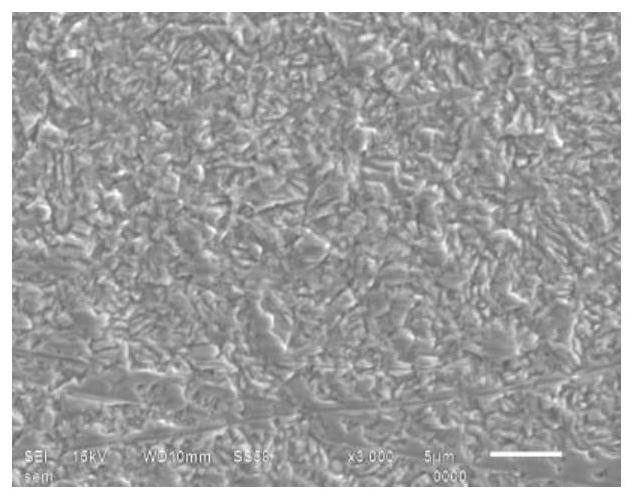

Embodiment 3

[0063] Chemical microetching solution includes: H 2 o 2 (6g / L)+H 2 SO 4 (10g / L), sulfosalicylic acid 15g / L, ethylene glycol 2mL / L, itaconic acid 0.5g / L, corrosion inhibitor phytic acid 0.25g / L, ethanol and emulsifier compound 0.5mL / L, roughening agent is cyclohexanoic acid 0.15g / L.

[0064] The parameters of the above obtained copper sheet include appearance brightness, uniformity of copper surface erosion, maximum copper ion concentration that can be accommodated in the bath, erosion rate and final rate reduction rate, and fingerprint printing and oil removal function. (5 represents excellent, 4 represents good, 3 represents poor, 2 represents poor, 1 represents very poor); erosion uniformity 5 (5 represents excellent uniformity, 4 represents good uniformity, 3 represents poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability); the maximum concentration of copper ions in the bath solution is 40g / L, and the corrosion rate of immersion corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com