Formation method of dual damascene structure

A patterned, bottom anti-reflection layer technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that the inner wall of the double damascene structure is not flat enough, affects the quality of the metal layer, and affects the performance of the metal interconnection structure, etc. , to achieve the effects of improving electrical connection performance, avoiding damage, and uniform etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

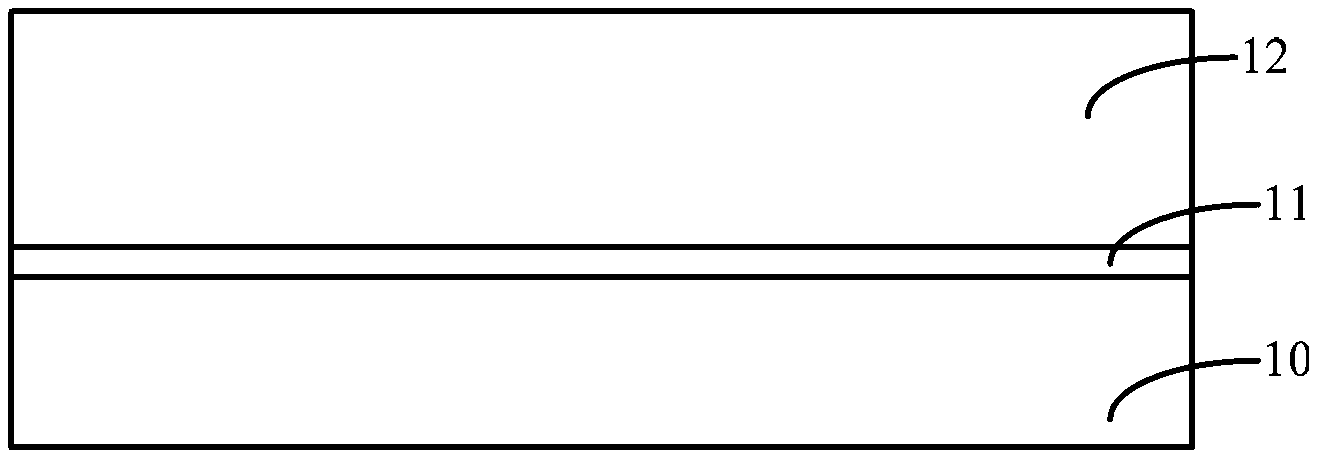

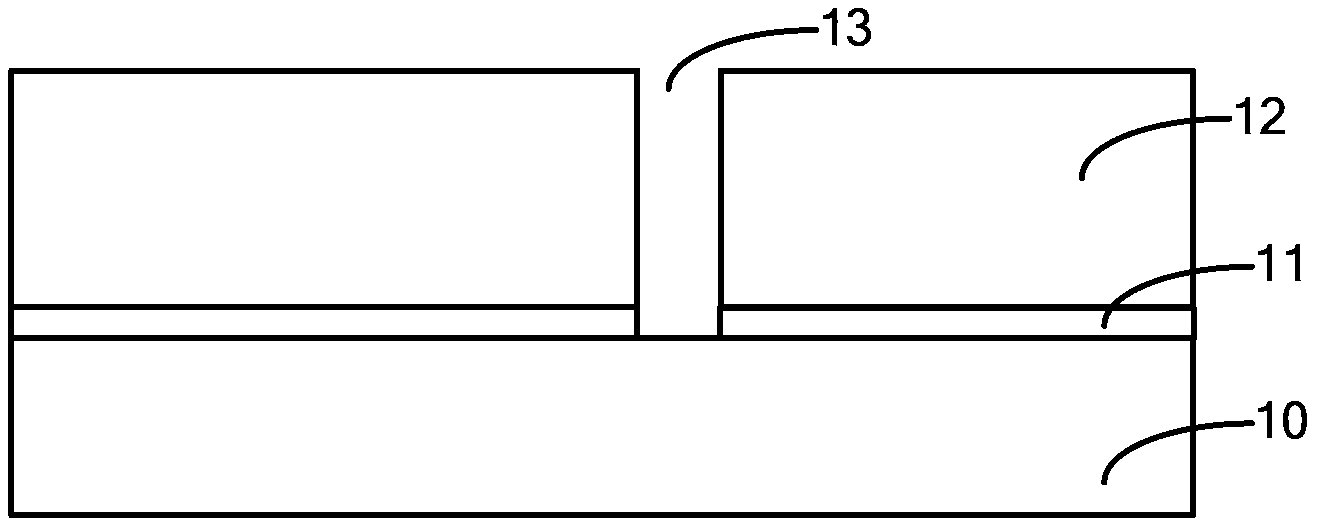

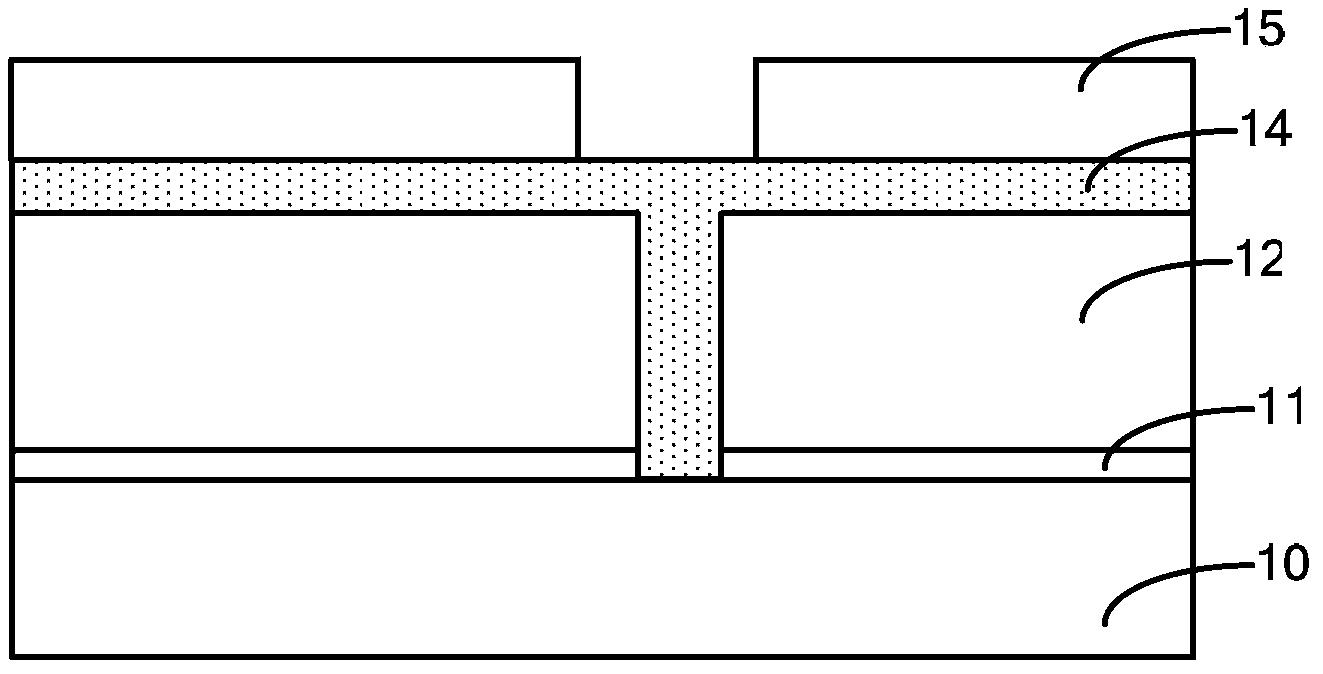

[0037] As mentioned in the background art, the inner wall of the double damascene structure formed in the prior art is not smooth enough, which affects the performance of the subsequently formed metal interconnection structure.

[0038] The study found that due to the via-first dual-damascene process, it is necessary to form a via structure with a large aspect ratio in the dielectric layer first. Due to the large depth of the through hole, in the subsequent process of removing the bottom anti-reflection layer filling the through hole, more etching gas is exposed above the through hole, and the etching rate is relatively high, which will cause damage to the dielectric layer. A certain amount of etching, but less etching gas enters the lower part of the through hole, which will cause a certain residue of the anti-reflection layer at the bottom, making the inner wall of the double damascene structure uneven, resulting in the formation of voids in the subsequent filling of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com