Nitrogen-charging black tea fermenting method

A fermentation method and black tea technology are applied in the field of nitrogen-filled black tea fermentation and can solve problems such as difficult black tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

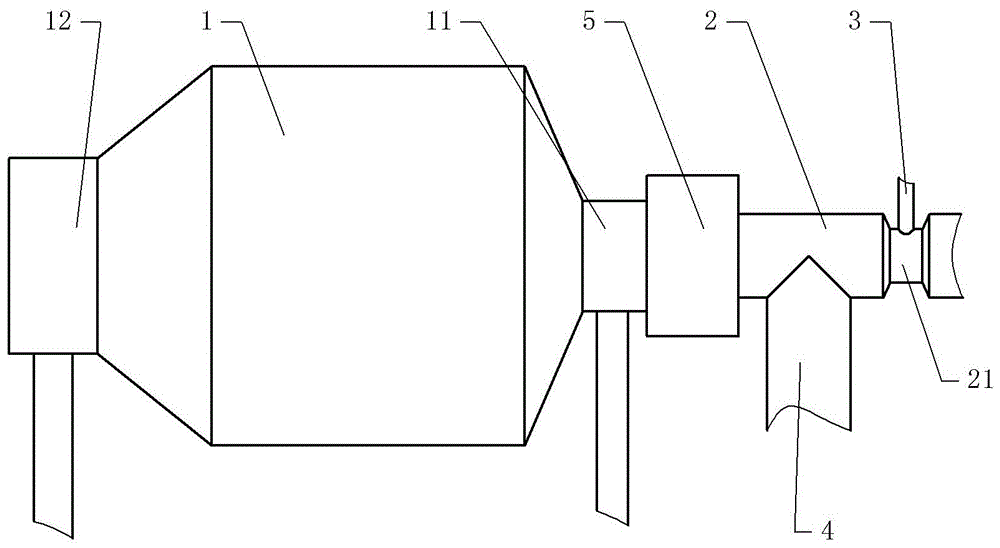

[0030] The nitrogen-filled black tea fermentation method of the present embodiment is carried out in a fermentation device, and the fermentation device includes a support, a fermenter 1, an air pipeline 2, a nitrogen pipeline 4, a nitrogen branch pipe 3 and a water mist nozzle; the fermenter 1 is rotatably connected to the support, The rotating shaft of the fermenter 1 is arranged in the horizontal direction. Both ends of the fermenter 1 are provided with an air inlet 11 and an air outlet 12, and the air pipe 2 is connected to the air inlet 11 through a rotary joint 5, and the middle part of the air pipe 2 is sunken inward to form a throat 21; the nitrogen branch pipe 3 is connected to the The throat 21 of the air pipeline 2 is also communicated with the air pipeline 2, and the nitrogen branch pipe 3 is provided with a throttle valve, which can change the nitrogen flow in the nitrogen branch pipe 3; the nitrogen pipeline 4 is connected to the end of the air pipeline 2 and It c...

Embodiment 2

[0042] When working, proceed as follows:

[0043] Step 1: preheating the temperature in the fermenter 1 to 22°C;

[0044] Step 2: then place 100 kg of black tea greens that are moderately withered and rolled in the fermenter 1, and the rotation frequency of the fermenter 1 is 0.5 r / min;

[0045] Step 3: Only the air pipe 2 and the water mist nozzle are used, the air humidity in the fermenter 1 is maintained at 95%, and the fermentation is carried out for 90 minutes. The temperature in the fermenter 1 is switched between 22° C. and 28° C. every 10 minutes.

[0046] Step 4: On the basis of Step 3, the temperature in the fermenter 1 is switched between 22° C. and 28° C. every 5 minutes.

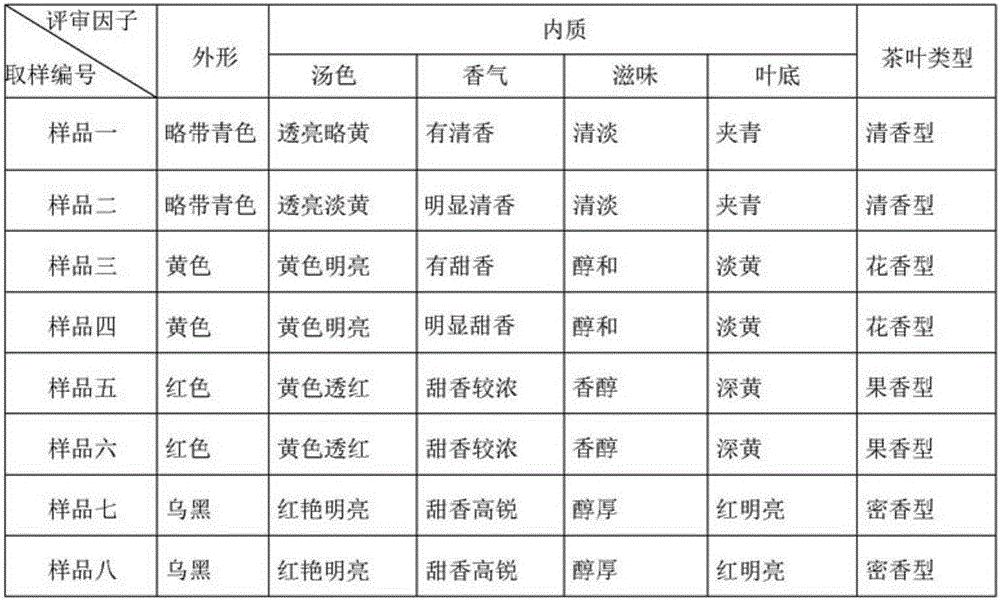

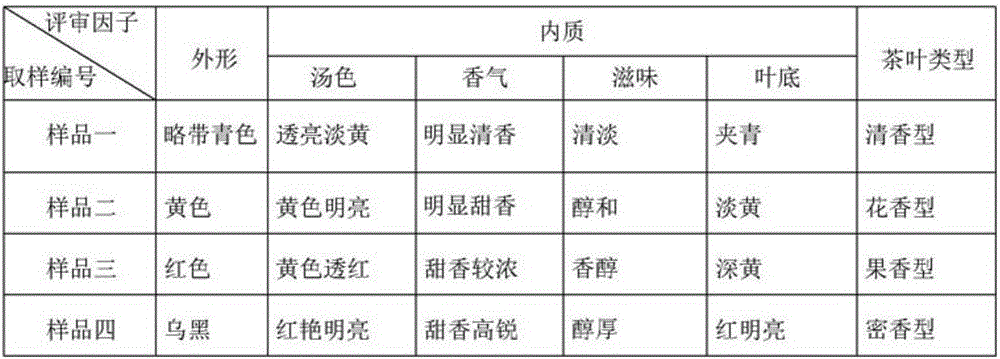

[0047] In step 4, the tea leaves in the fermenter 1 are sampled every 5 minutes, the color and aroma of the tea leaves are compared, and brewing is carried out. This embodiment requires to obtain dense-flavor black tea.

[0048] Step 5: When the air is stopped, close the shut-off valve on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com