Browning waste liquid treatment method

A waste liquid treatment and browning technology, which is applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of high energy consumption, low copper ion removal rate, and difficult electrolysis, etc., to achieve The treatment process is simple, the treatment effect is remarkable, and the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

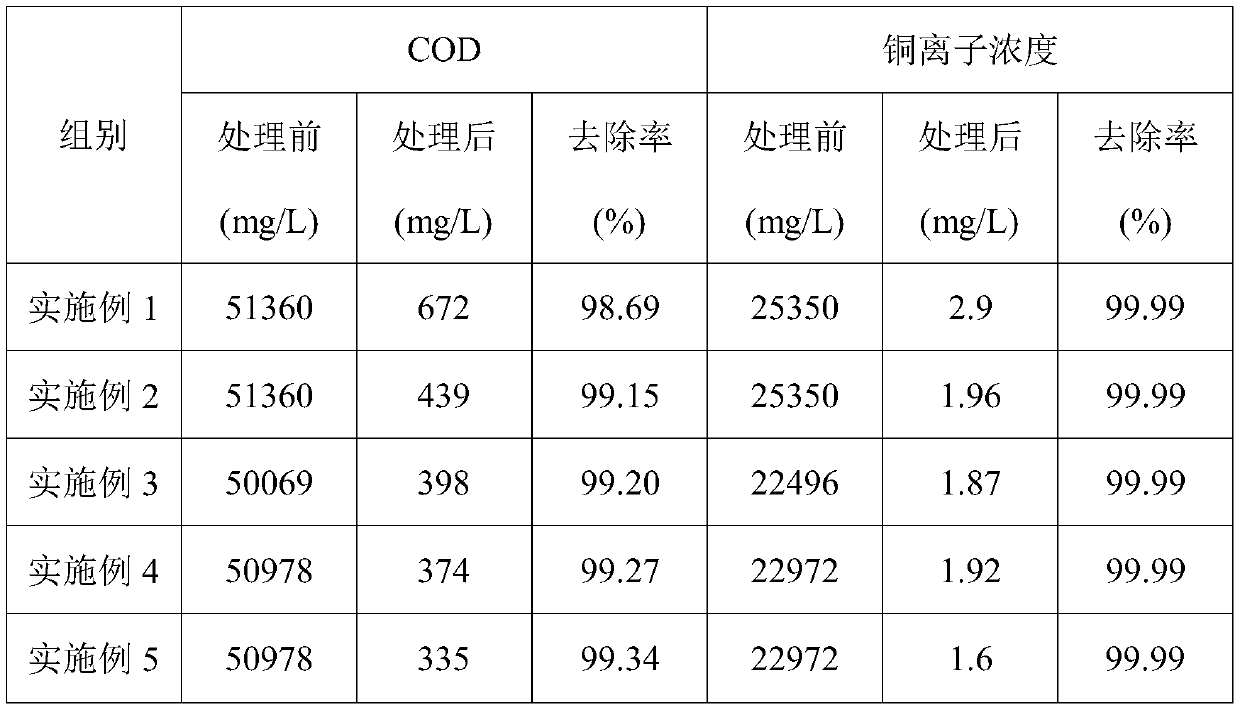

Examples

Embodiment 1

[0027] This embodiment provides a kind of browning waste liquid treatment method, and it comprises the following steps:

[0028] (1) Add mass concentration to 1000ml browning waste liquid and be 40% sodium hydroxide, until the pH value of browning waste liquid is stable at 7.0, and stir 60min according to the stirring speed of 120rpm, let browning waste liquid Silane is fully hydrolyzed, and can fully react and neutralize various inorganic acids and organic acids; the specific chemical reaction process is as follows:

[0029] h 2 SO 4 +2NaOH→Na 2 SO 4 +2H 2 O,

[0030] HNO 3 +NaOH→NaNO 3 +H 2 O,

[0031] h 3 PO 4 +3NaOH→Na 3 PO 4 +3H 2 O,

[0032] CH 3 COOH+NaOH→CH 3 COONa+H 2 O,

[0033] C 6 h 8 o 7 +NaOH→C 6 h 7 o 7 Na+H 2 O,

[0034] C 2 h 4 o 3 +NaOH→C 2 h 3 o 3 Na+H 2 O,

[0035] CH 4 o 3 S+NaOH→CH 3 o 3 SNa+H 2 O;

[0036] In addition, silane usually exists in the form of hydrolysis in neutral aqueous solution, and its specific ch...

Embodiment 2

[0049] This embodiment provides a kind of browning waste liquid treatment method, and it comprises the following steps:

[0050] (1) Add mass concentration to 1000ml browning waste liquid and be 40% sodium hydroxide, until the pH value of browning waste liquid is stable at 6.5, and stir 60min according to the stirring speed of 120rpm, let browning waste liquid Silane is fully hydrolyzed and can fully react to neutralize various inorganic and organic acids.

[0051] (2) In the above stirring process, continue to add sodium hydroxide with a mass concentration of 40% in the browning waste liquid until the pH value of the browning waste liquid rises to a stable value of 9.6, then proceed at a stirring speed of 120rpm Stir for 60 minutes to completely precipitate the copper ions and zinc ions in the browning waste liquid to form a precipitate.

[0052] (3) Next, add a flocculant and a coagulant to the browning waste liquid with precipitates, let stand for stratification, and then ...

Embodiment 3

[0054] This embodiment provides a kind of browning waste liquid treatment method, and it comprises the following steps:

[0055] (1) Add slaked lime to 1000ml browning waste liquid until the pH value of the browning waste liquid is stable at 7.0, and stir at a stirring speed of 120rpm for 60 minutes to fully hydrolyze the silane in the browning waste liquid and fully react Neutralizes various inorganic and organic acids.

[0056] (2) During the above stirring process, continue to add slaked lime to the browning waste liquid until the pH value of the browning waste liquid rises to a stable value of 9.6, then stir for 60 minutes at a stirring speed of 120 rpm to make the browning waste liquid The copper ions and zinc ions in the solution are completely precipitated to form a precipitate.

[0057] (3) Next, add a flocculant and a coagulant to the browning waste liquid with precipitates, let stand for stratification, and then filter with a plate and frame filter press to separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com