Method for pre-treating wastewater from ultraviolet absorber production

A technology for the production of wastewater and absorbents, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of poor biodegradability, difficult treatment, and high concentration of organic matter. Achieve the effects of improved biodegradability, simple and reasonable process, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

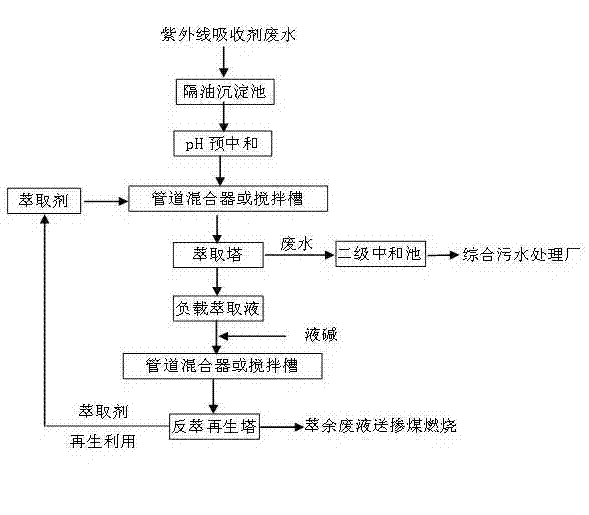

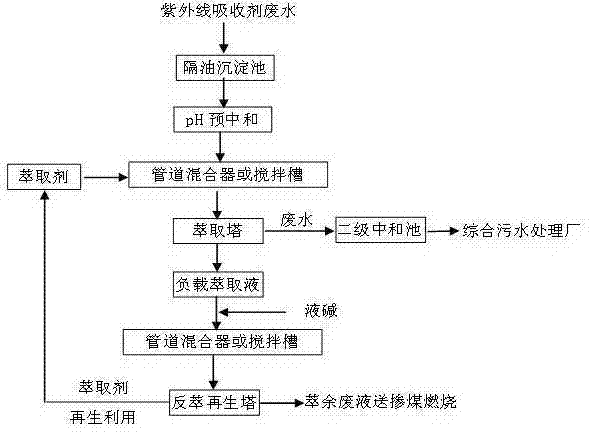

[0025] Example 1, refer to figure 1 , a kind of ultraviolet absorber production wastewater pretreatment method, and its steps are as follows:

[0026] (1) First carry out oil separation and precipitation treatment on the wastewater to remove oil slicks and suspended solids contained in the wastewater;

[0027] (2) Pre-neutralize the wastewater treated by oil separation and precipitation, and adjust the pH value of the wastewater to 0.1 with lime emulsion or liquid alkali;

[0028] (3) The extraction process is used for treatment, and the extractant used in the extraction is HLE phenol-containing wastewater extractant; the weight ratio of extractant to wastewater during extraction is 4:1, and the extraction temperature is 0 °C; the extractant and wastewater pass through static pipelines After mixing by a mixer or mechanical stirring, the layers are layered in the extraction tower; the mixing time of the extractant and the wastewater is 5min; the layering time after the extract...

Embodiment 2

[0031] Example 2, refer to figure 1 , a kind of ultraviolet absorber production wastewater pretreatment method, and its steps are as follows:

[0032] (1) First carry out oil separation and precipitation treatment on the wastewater to remove oil slicks and suspended solids contained in the wastewater;

[0033] (2) Pre-neutralize the wastewater treated by oil separation and precipitation, and adjust the pH value of the wastewater to 4 with lime emulsion or liquid alkali;

[0034] (3) The extraction process is used for treatment, and the extractant used in the extraction is HLE phenol-containing wastewater extractant; the weight ratio of the extractant to the wastewater during extraction is 1:8, and the extraction temperature is 60 °C; the extractant and wastewater pass through static pipelines After mixing by a mixer or mechanical stirring, the layers are layered in the extraction tower; the mixing time of the extractant and the wastewater is 60min; the layering time after the...

Embodiment 3

[0037] Example 3, refer to figure 1 , a kind of ultraviolet absorber production wastewater pretreatment method, and its steps are as follows:

[0038] (1) First carry out oil separation and precipitation treatment on the wastewater to remove oil slicks and suspended solids contained in the wastewater;

[0039] (2) Pre-neutralize the wastewater that has been treated by oil separation and precipitation, and adjust the pH of the wastewater to 1 with lime emulsion or liquid alkali;

[0040](3) The extraction process is used for treatment, and the extractant used in the extraction is HLE phenol-containing wastewater extractant; the weight ratio of the extractant to the wastewater during extraction is 2:1, and the extraction temperature is 20 °C; the extractant and wastewater pass through static pipelines After mixing by mixer or mechanical stirring, the layers are layered in the extraction tower; the mixing time of the extractant and the wastewater is 10min; the layering time afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com