Catalytic ozonization method

A technology of ozone catalytic oxidation and ozone oxidation, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem that the oxidation effect cannot meet the COD effluent standard, etc., and achieve the effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

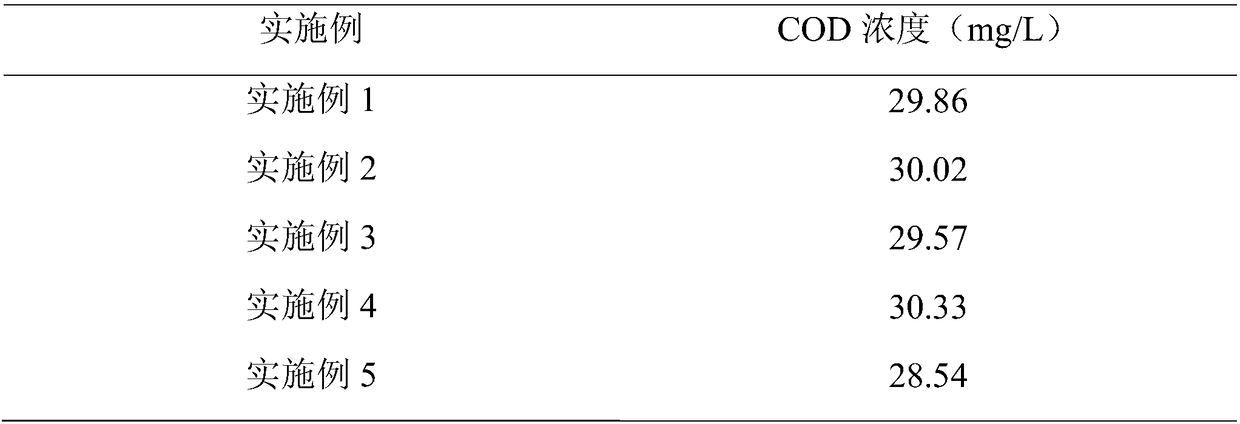

Embodiment 1

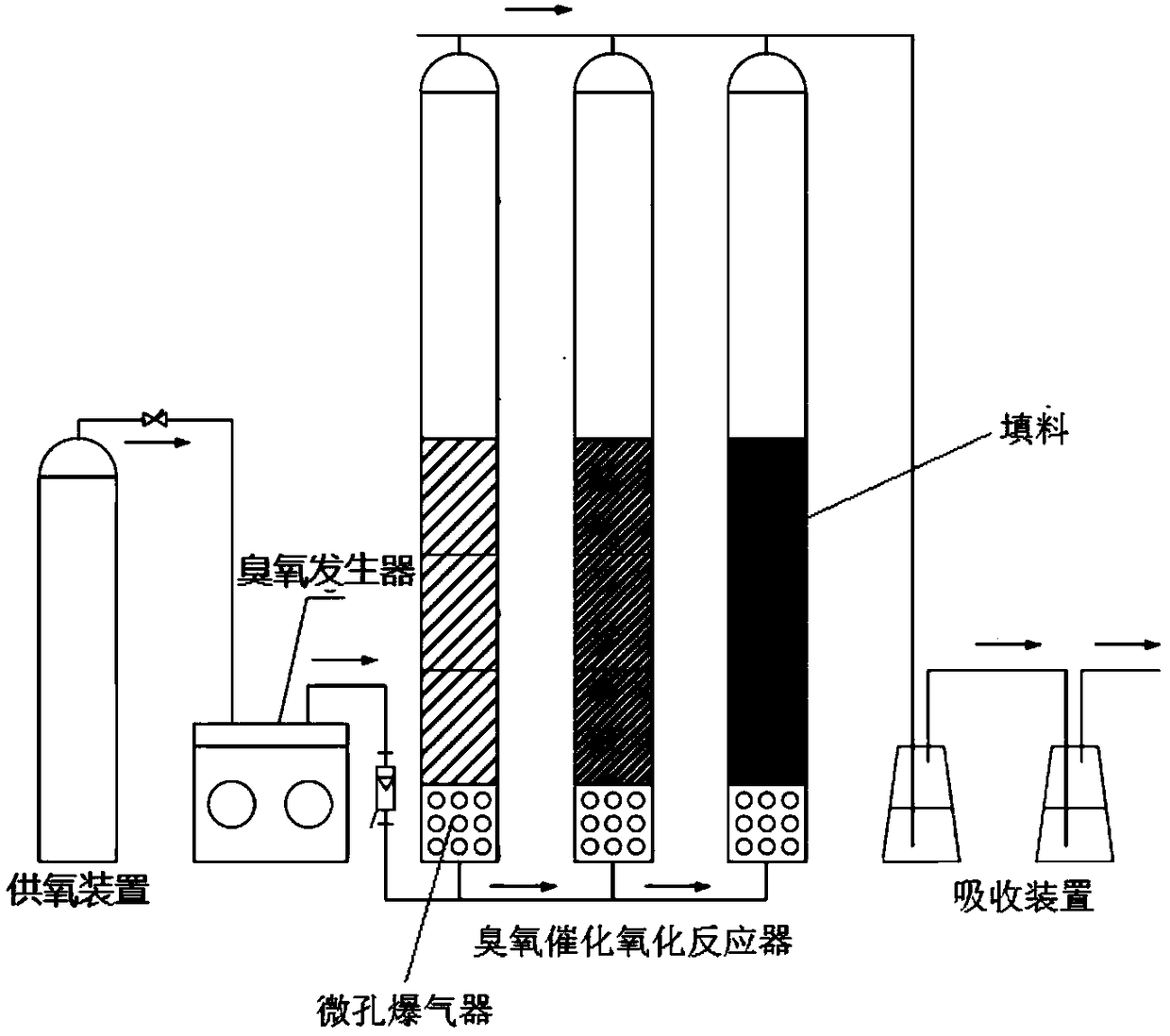

[0043] An ozone catalytic oxidation method, the ozone catalytic oxidation is carried out using an ozone catalytic oxidation device, the ozone catalytic oxidation device includes an oxygen supply device, an ozone generator, an ozone catalytic oxidation reactor and an absorption device connected in sequence through pipelines, wherein , the ozone catalytic oxidation reactor is a cylindrical pipe with an inner diameter of 100 mm and a height of 1000 ml, including a microporous detonator and a packing layer arranged from bottom to top, wherein the packing of the packing layer is activated gamma-alumina balls The loaded ferric oxide catalyst, and the loading percentage of the ferric oxide is 3%, the COD concentration of the effluent of the secondary settling tank is 92.8mg / L, and the filling capacity of the filler is 4L. The volume of the effluent from the settling tank is 5L.

Embodiment 2

[0045] The difference from Example 1 is that the catalyst loading is 2L, and the reaction time is 40min.

Embodiment 3

[0047]The difference from Example 1 is that the filler of the filler layer is a manganese dioxide catalyst supported by activated carbon, and the loading percentage of the manganese dioxide is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com