A kind of printed circuit board osp micro-etching pretreatment liquid and micro-etching method

A technology for printed circuit boards and pretreatment liquids, which is applied in printed circuits, printed circuit manufacturing, and removal of conductive materials by chemical/electrolytic methods. The effect of stable etching solution, improving utilization rate and accelerating copper bite rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Chemical micro-etching solutions include: H 2 O 2 (6)+H 2 SO 4 (10g / L), N-methylbenzylamine 5g / L, butanediol 2g / L, alkenoic acid methylene amide ester 0.5g / L, corrosion inhibitor is benzotriazole 0.2g / L, three Ethanolamine 3ml / L.

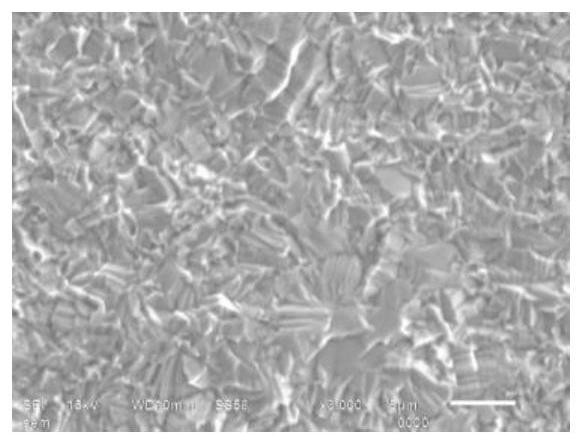

[0061] The copper sheets obtained above are measured by parameters including appearance brightness, copper surface bite uniformity, maximum copper ion concentration that can be accommodated in the bath, bite corrosion rate and final rate decrease rate, and fingerprint print degreasing function, etc. The appearance brightness is 5 (5 means excellent, 4 means good, 3 means poor, 2 means poor, 1 means very poor); bite uniformity 5 (5 means excellent uniformity, 4 means good uniformity, 3 means poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability); the maximum copper ion concentration that the bath can accommodate is 40g / L, and the immersion bite rate from the beginning to the maximum accommodated copper ion con...

Embodiment 2

[0063] H 2 O 2 (18g / L)+H 2 SO 4 (10g / L), N-methylbenzylamine 15g / L, butanediol 2g / L, alkenoic acid methylene amide ester 0.5g / L, corrosion inhibitor is benzotriazole 0.2g / L, triazole Ethanolamine 3mL / L.

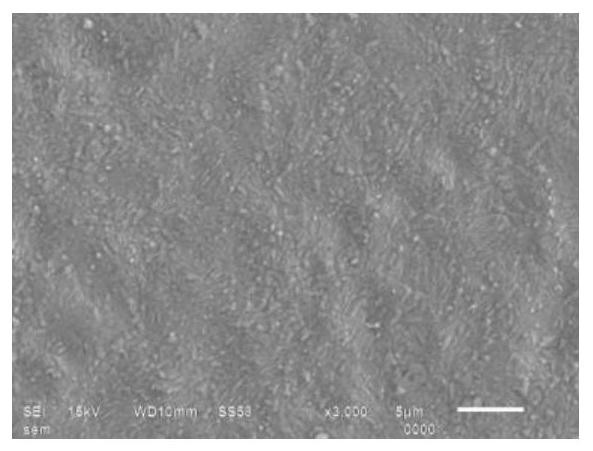

[0064] The copper sheets obtained above are measured by parameters including appearance brightness, copper surface bite uniformity, maximum copper ion concentration that can be accommodated in the bath, bite corrosion rate and final rate decrease rate, and fingerprint print degreasing function, etc. The appearance brightness is 5 (5 means excellent, 4 means good, 3 means poor, 2 means poor, 1 means very poor); bite uniformity 5 (5 means excellent uniformity, 4 means good uniformity, 3 means poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability; the maximum copper ion concentration that the bath can accommodate is 40g / L, and the immersion bite rate from the beginning to the maximum accommodated copper ion concentration ranges from 0.8 to 1.2 μ...

Embodiment 3

[0066] H 2 O 2 (6g / L)+H 2 SO 4 (10g / L), N-methylbenzylamine 5g / L, butanediol 8g / L, alkenoic acid methylene amide ester 1.5g / L, corrosion inhibitor is benzotriazole 0.55g / L, triazole Ethanolamine 3mL / L.

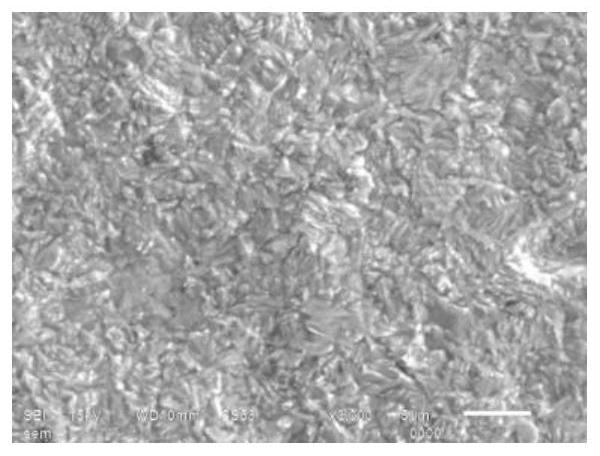

[0067] The copper sheets obtained above are measured by parameters including appearance brightness, copper surface bite uniformity, maximum copper ion concentration that the bath can accommodate, bite rate and final rate decline rate, and fingerprint print degreasing function, etc. The appearance brightness is 5 (5 means excellent, 4 means good, 3 means poor, 2 means poor, 1 means very poor); bite uniformity 5 (5 means excellent uniformity, 4 means good uniformity, 3 means poor uniformity, 2 Represents poor uniformity, 1 represents very poor solderability); the maximum copper ion concentration that the bath can accommodate is 40g / L, and the immersion bite rate from the beginning to the maximum accommodated copper ion concentration ranges from 0.8 to 1.2 μm / min; fingerprint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com