High-performance metal cutting fluid

A metal cutting fluid, high-performance technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of lubricity, corrosion resistance, hard water resistance, poor stability, etc., achieve good decontamination performance, improve cleaning, dissolution Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The high-performance metal cutting fluid of the present invention, its raw material comprises by weight: 3 parts of oleic acid amido-based nonionic surfactant, 5 parts of Tween 20, 7 parts of Tween 60, 10 parts of dodecylalanine , 10 parts of betaine type amphoteric surfactant, 10 parts of sodium alkylbenzene sulfonate, 10 parts of sophorolipid, 10 parts of glycerin, 18 parts of triethanolamine oleate, 5 parts of sodium borate, 1 part of benzotriazole, 20 parts of cyclohexyl phosphate, 8 parts of organic borate, 15 parts of molybdate, 8 parts of copper citrate, 3 parts of chelating agent, 3 parts of sodium citrate, 4 parts of citric acid, and 80 parts of water.

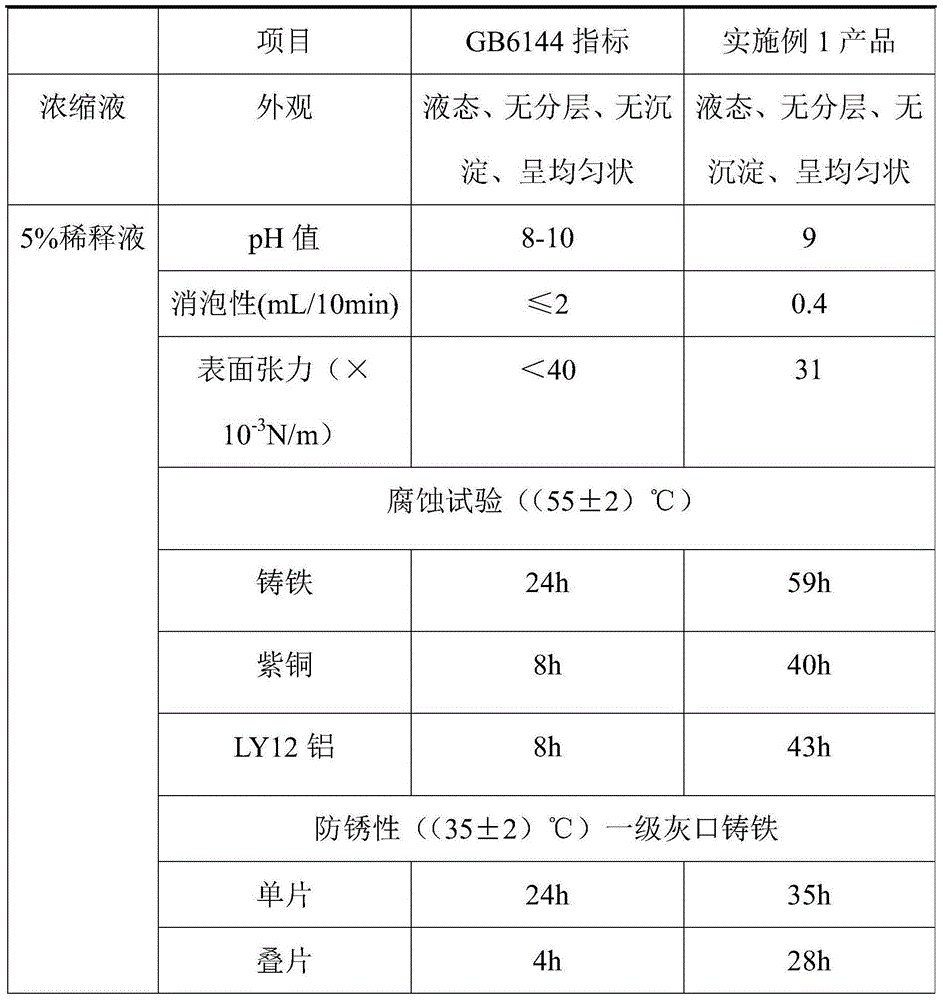

[0019] The performance index and GB6144 index of the high-performance metal cutting fluid described in this embodiment are shown in Table 1.

[0020] Table 1 Performance index of high-performance metal cutting fluid and GB6144 index in this embodiment

[0021]

Embodiment 2

[0023] The high-performance metal cutting fluid of the present invention, its raw material comprises by weight: 15 parts of oleic acid amido-based nonionic surfactants, 5 parts of Tween 80, 25 parts of dodecylaminopropionic acid, 25 parts of dodecyl diacetate 3 parts of methyl betaine, 2 parts of octadecyl dimethyl betaine, 20 parts of sodium alkylbenzene sulfonate, 1 part of sophorolipid, 10 parts of polyvinyl alcohol, 15 parts of caprylic acid, triethanolamine oleate 5 parts, 15 parts of sodium borate, 5 parts of benzotriazole, 5 parts of cyclohexyl phosphate, O-(N-succinimide)-1,1,3,3-tetramethylurea tetrafluoro 10 parts of borate, 15 parts of triethanolamide borate laurate, 5 parts of molybdate, 3 parts of copper citrate, 3 parts of salicylic acid, 7 parts of glycine, 10 parts of sodium citrate, 15 parts of citric acid, 150 parts of water.

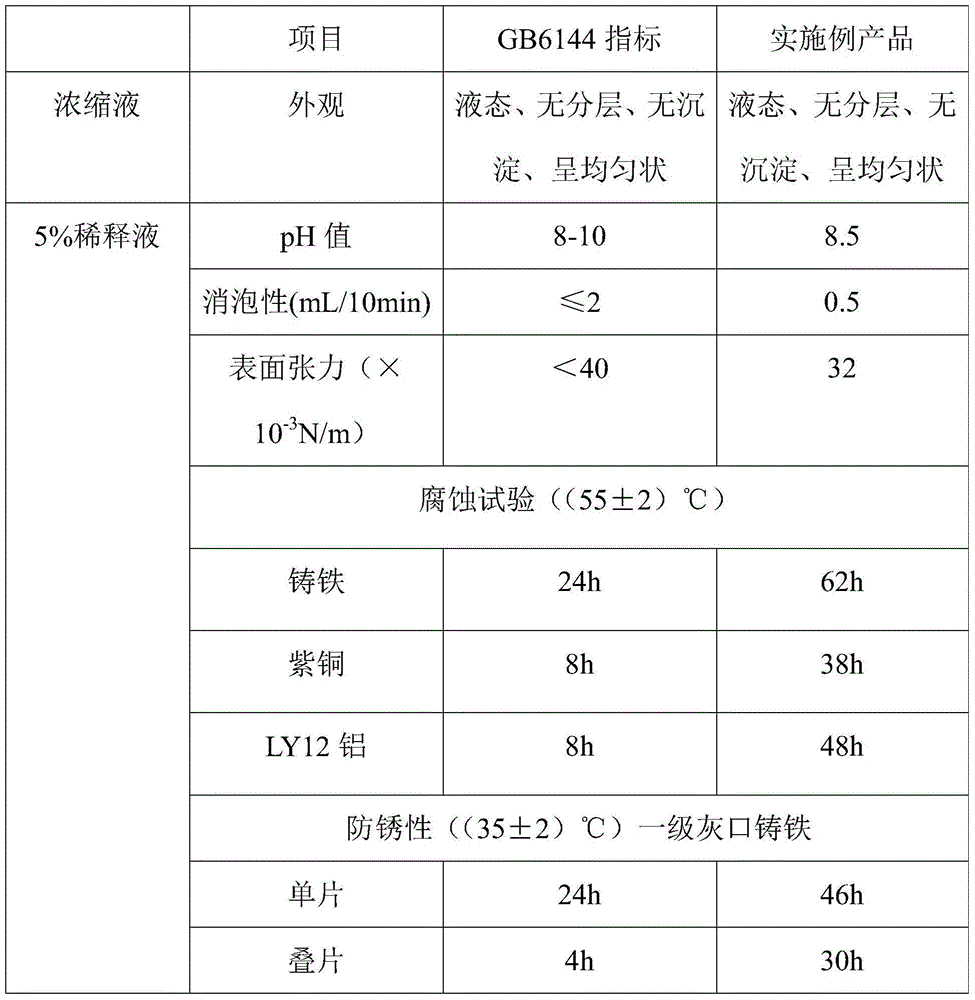

[0024] The performance index of the high-performance metal cutting fluid described in this embodiment and the index of GB6144 are sh...

Embodiment 3

[0028] The high-performance metal cutting fluid of the present invention, its raw material comprises by weight: 10.5 parts of oleic acid amido-based nonionic surfactant, 9 parts of Tween 80, 16.8 parts of dodecylaminopropionic acid, 16.8 parts of dodecyl diaminopropionic acid, 8.3 parts of methyl betaine, 15 parts of sodium alkylbenzene sulfonate, 6.8 parts of sophorolipid, 7 parts of glycerin, 13 parts of polyvinyl alcohol, 13 parts of triethanolamine oleate, 10 parts of sodium borate, 3.3 parts of benzotriazole Parts, 13 parts of cyclohexyl phosphate, 16 parts of triethanolamide borate laurate, 10 parts of molybdate, 5 parts of copper citrate, 6 parts of diethyltriaminepentaacetic acid, 6 parts of sodium citrate, 9.8 parts of citric acid, 126 parts of water.

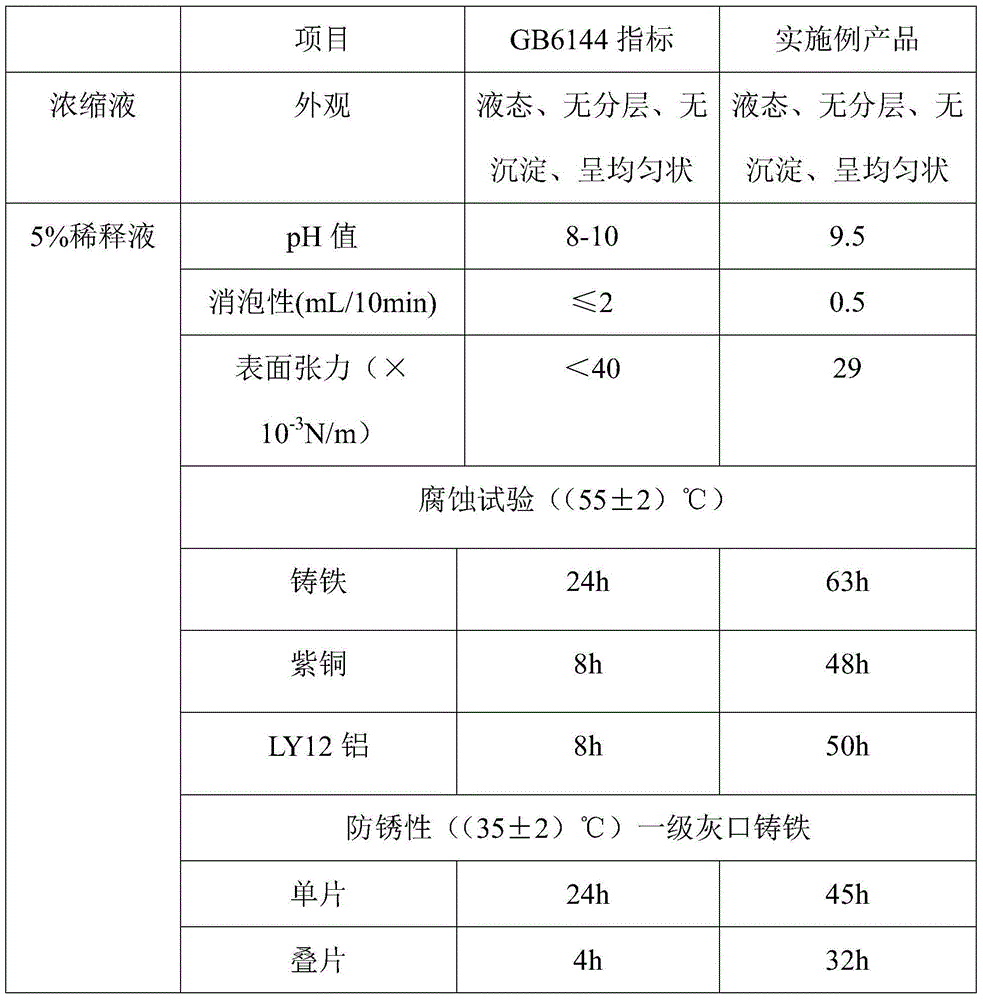

[0029] The performance index of the high-performance metal cutting fluid described in this embodiment and the index of GB6144 are shown in Table 3.

[0030] Table 3 The high-performance metal cutting fluid performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com