Patents

Literature

43results about How to "Physical performance balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leather retanning method

InactiveCN102517409AHigh fullnessImprove firmnessTanning treatmentPre-tanning chemical treatmentIndustrial waste waterElectrical energy consumption

The invention relates to a leather retanning method. The method comprises the following steps of: water washing, rewetting to soften, retanning with chrome, neutralization, dyeing to fill, adding grease, dyeing in set and the like; and finally, drying, finishing and coating to obtain the finished product, i.e. leather. In the invention, the process of retanning with chrome is adjusted and a proper environment-friendly tanning agent is adopted, so the content of chrome in chrome liquid can be reduced, the fullness and the toughness of the leather is effectively improved, dyed color is uniform,the heat and humidity resistant stability of the leather can be improved, the physical performances of the leather are uniform, and the finished leather is soft and bend-resistant and is high in tensile strength; the amount of used water in the processing process is small, and the generated industrial waste water is little, so environment protection is facilitated; and the process period is relatively short, so the electric energy consumption is low, the cost is low, and the method has a better economic benefit.

Owner:郑州科信化工有限公司

Three-layer coextruded polyethylene label film and preparation method thereof

ActiveCN109532177APhysical performance balanceDie-cut effect is goodStampsSynthetic resin layered productsCo extrusionMedium-density polyethylene

The invention relates to a printing and die-cutting three-layer film structure label material, in particular to a three-layer co-extruded polyethylene label film and a preparation method thereof. Thepolyethylene label film comprises an outer layer, an intermediate layer and an inner layer, the label film is prepared from the outer layer, the intermediate layer and the inner layer through a three-layer co-extrusion up-blowing forming process, and the blowup ratio is controlled to be 2-3.5. The outer layer is prepared from the following components in percentage by mass: 70-85% of high-density polyethylene, 10%-20% of metallocene catalyzed polyethylene and 5%-10% of low-density polyethylene, wherein the sum of the mass percentages of all the components is 100%. The intermediate layer is prepared from the following components in percentage by mass: 75-90% of high-density polyethylene and 10%-25% of metallocene catalyzed polyethylene. The inner layer is prepared from the following components in percentage by mass: 70%-90% of medium-density polyethylene and 10%-30% of low-density polyethylene. The label film provides sufficient stiffness and excellent die-cutting performance and has good vertical and horizontal balanced physical properties.

Owner:广东超维塑料薄膜有限公司

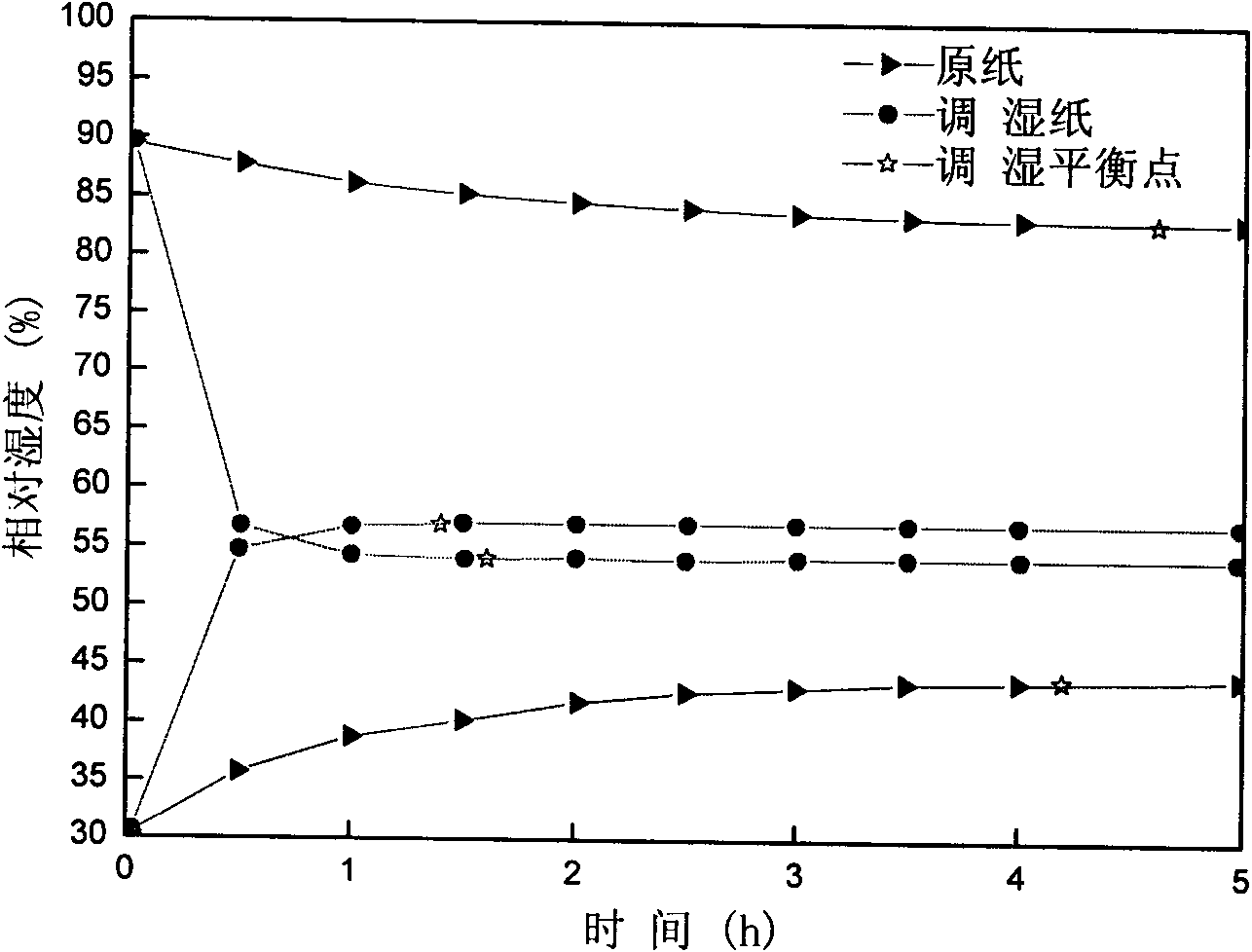

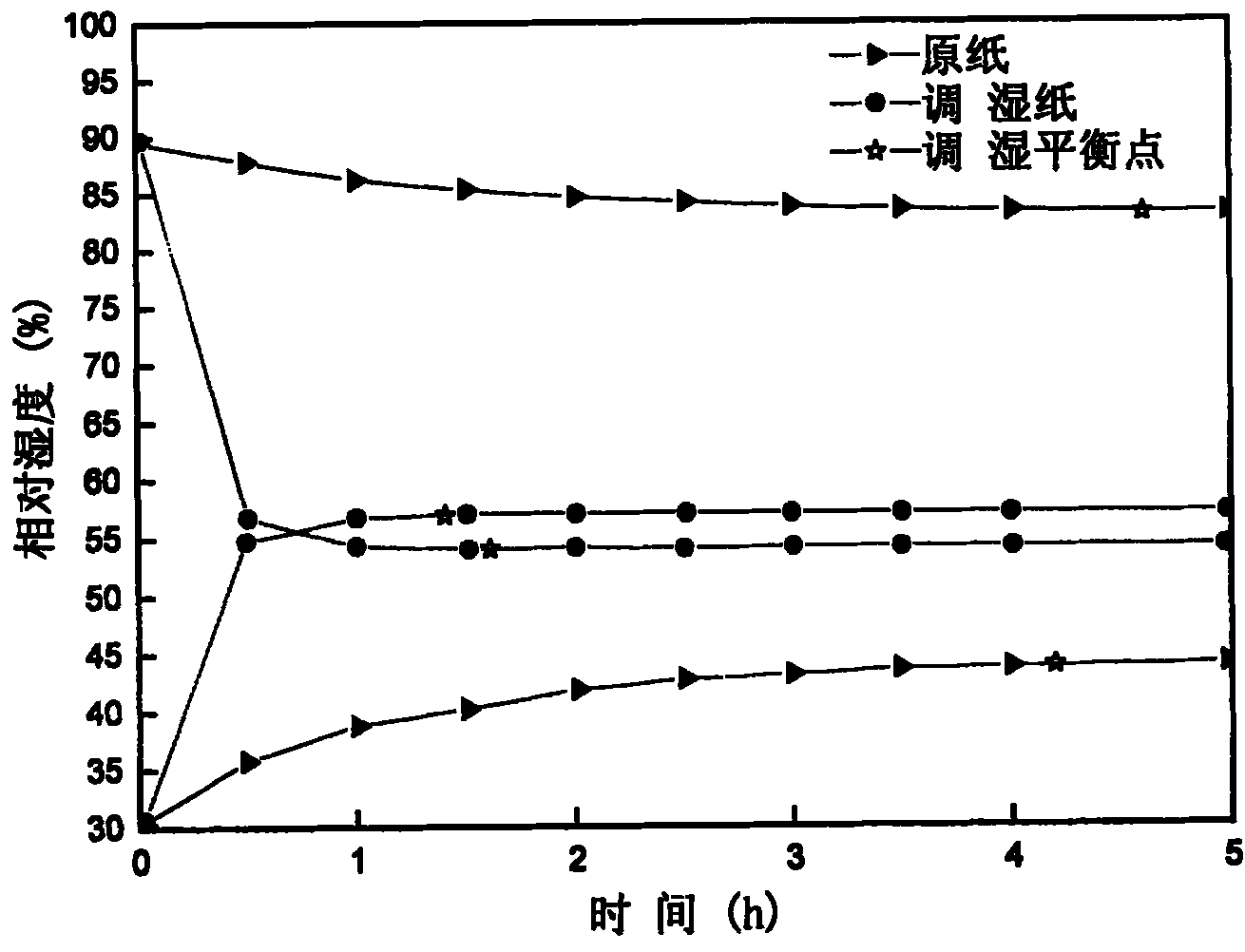

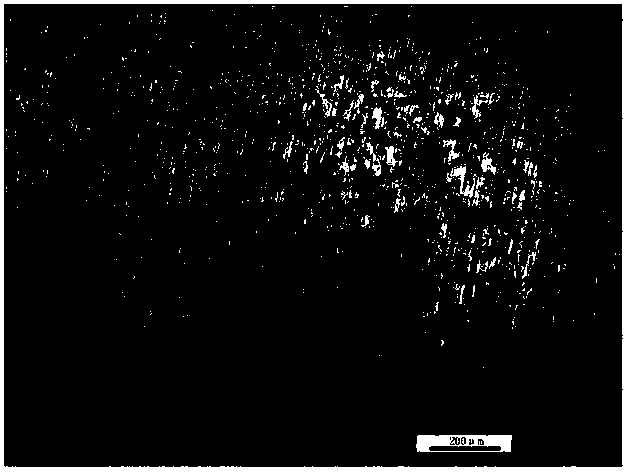

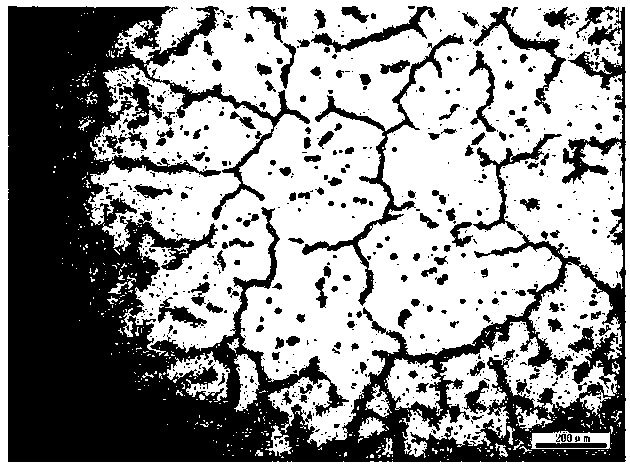

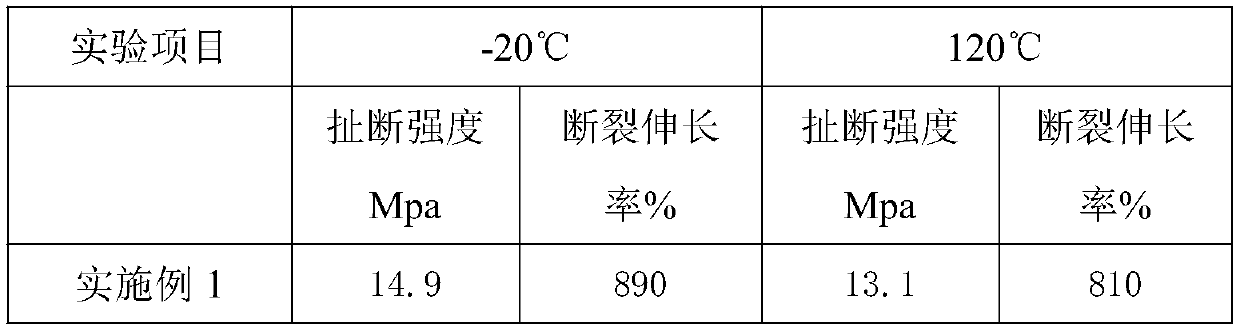

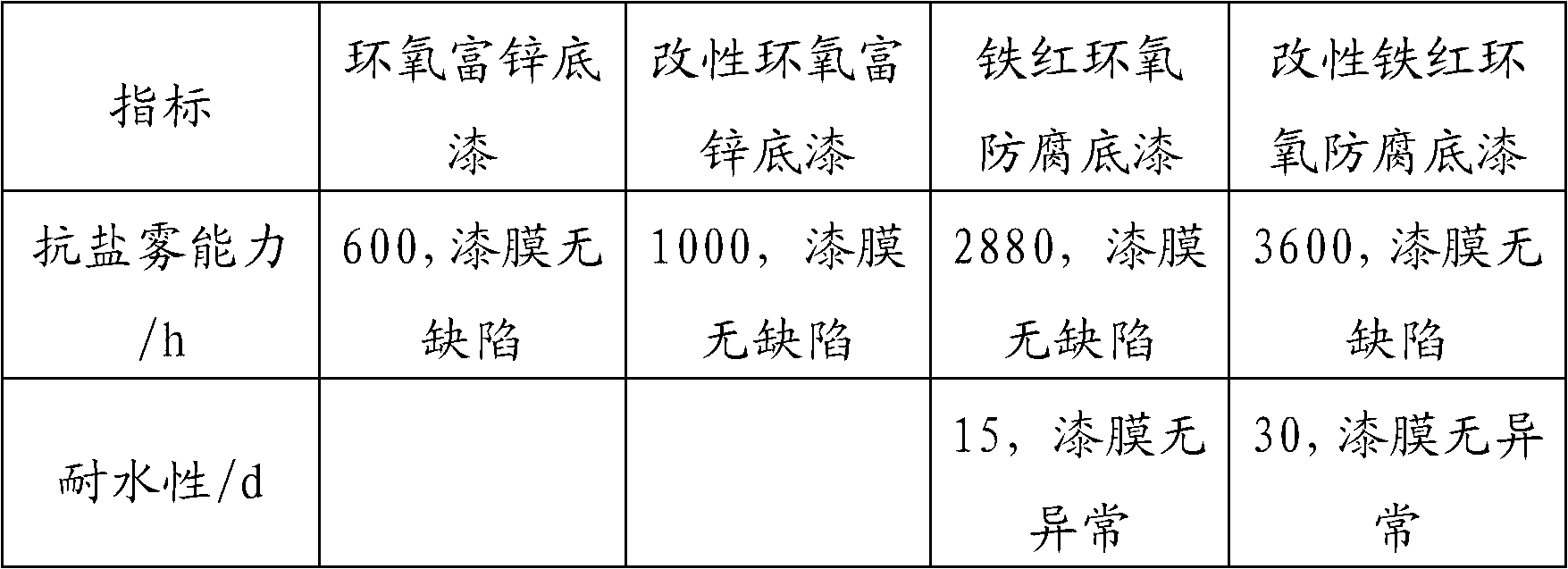

Method for preparing high-efficiency composite humidifying paper

InactiveCN101967775AImprove physical performancePhysical performance balanceNon-fibrous pulp additionSpecial paperBursting strengthPulp and paper industry

The patent refers to the field of 'special paper'. The invention relates to a method for preparing high-efficiency composite humidifying paper. The method is characterized in that: a copolymerization reaction of sodium polyacrylate, carboxymethylcellulose, sepiolite, acrylamide and paper pulp is performed so as to obtain composite paper pulp, and the composite paper pulp is subjected to papermaking to form paper. Compared with the prior art, the method has the advantages that 1) the moisture content of the humidifying paper is high, and the humidifying rate is quick; 2) the relative humidity of microenvironment can be regulated to be between 50 and 60 percent within short time, and is maintained within the humidity range for a long time; 3) the preparation method is simple, the cost is low, paper materials are light, and application modes are diversified; and 4) compared with that of raw paper, the bursting strength of the composite humidifying paper is increased by over 50 percent.

Owner:ZHEJIANG SCI-TECH UNIV

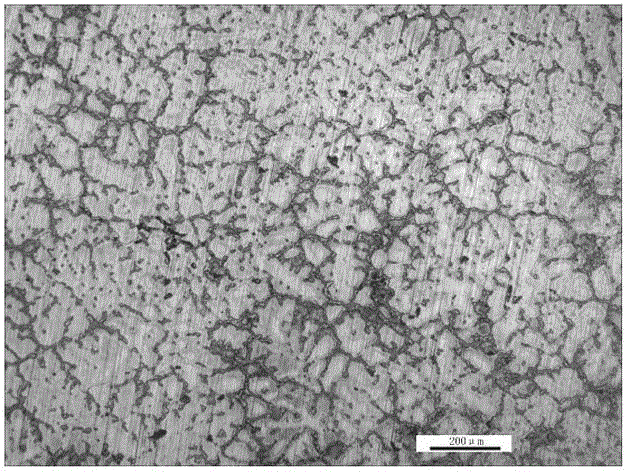

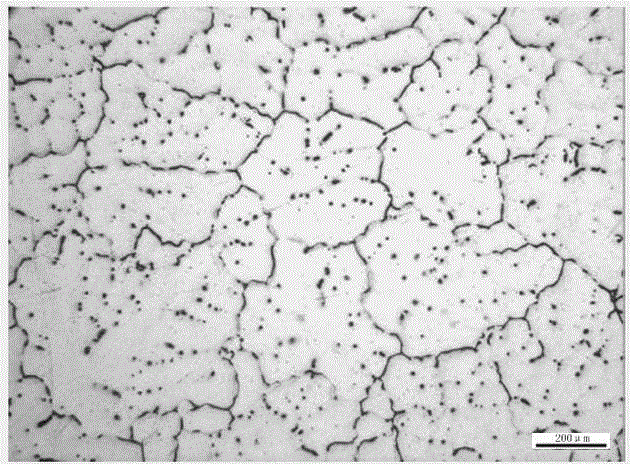

Manufacturing technology for rare earth-magnesium alloy

The invention belongs to the fields of metal materials and metallurgy, aims to solve the problems that impurities of alloy are hard to separate, ingredients are nonuniform, the utilization rate of rare earth element is low, precipitated rare earth phases are nonuniform, the segregation is more, and effects for the quality is great by adopting the manner that alloying, rare earth process, and casting are conducted in a pot during a conventional manufacturing technology process, and provides a manufacturing technology for rare earth-magnesium alloy. According to the manufacturing technology, conducting adding, refining, and degassing with hexachloroethane degassing agent of alloy element in a melting pot; and pouring into a second pot after standing for 30 min, adding rare earth, and standing and casing. A manufactured bar material has uniform and stable metallographic structure and clear crystal boundary; the product is without pore, shrinkage cavity and cold shut, and the surface is smooth and without rugosity; the purity, ingredients, and equilibrium of physical properties of the product are guaranteed, the grain size of the alloy is refined, very stable dispersed phase is precipitated, and the rigidity and the decay resistance of texture are improved; therefore, product performances are allowed to be superior to an ordinary alloy standard.

Owner:孝义市东义镁业有限公司 +1

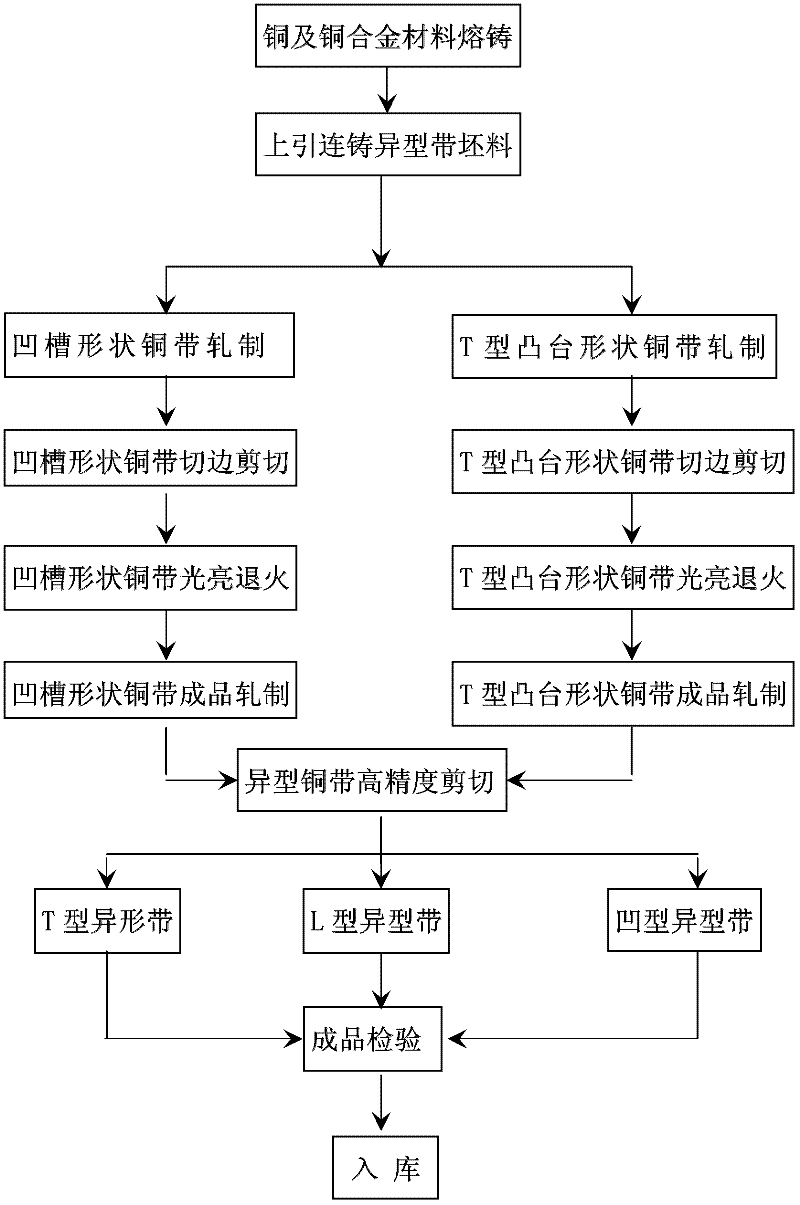

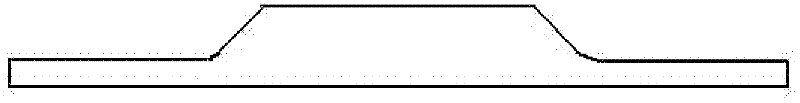

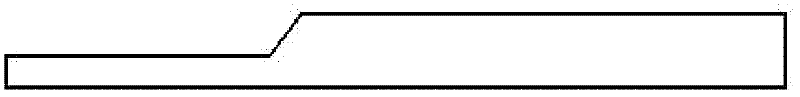

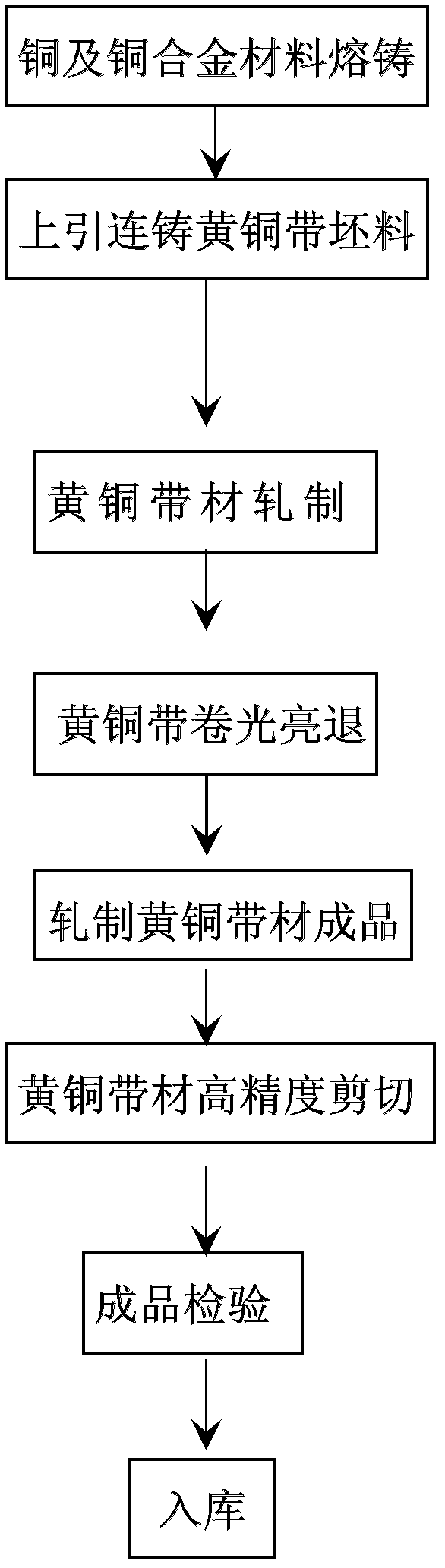

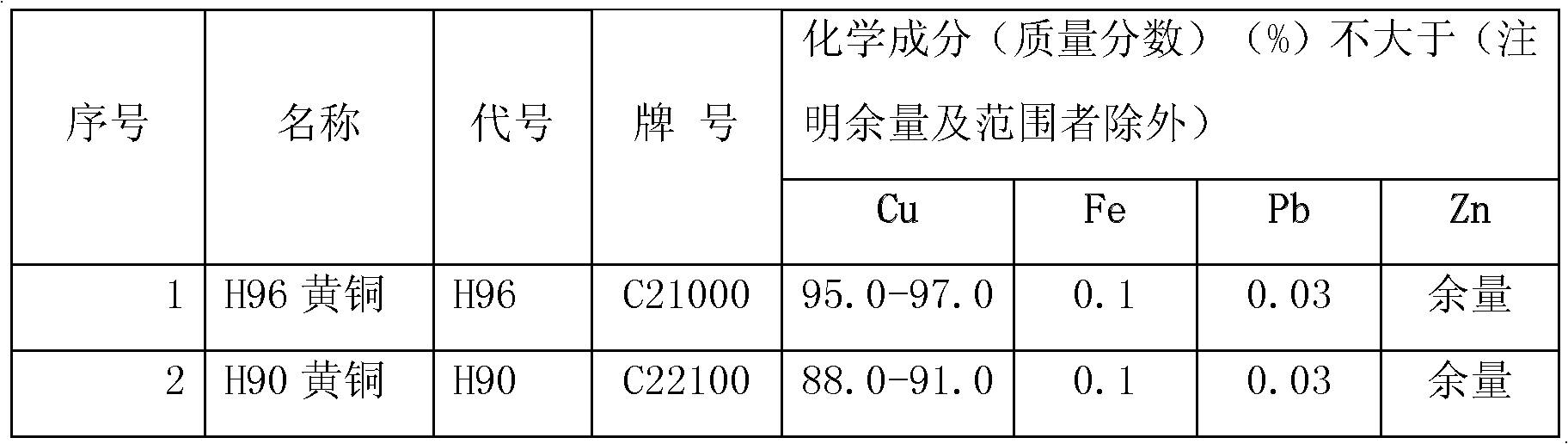

A processing technology for producing special-shaped cross-section brass strips

A processing technology for producing brass strips with special-shaped cross-sections, comprising the following steps: melting, casting, high-precision rolling, bright annealing, finished product rolling, and finished product shearing, characterized in that the casting adopts upward continuous casting to prepare billets , and the round crystallizer tooling equipped with graphite molds used for wire rod production by upward continuous casting was transformed into a design cross-section crystallizer tooling for strip production. Compared with the original processing method for producing brass strips with special-shaped cross-sections, it has the characteristics of low manufacturing cost and cheap tooling molds. The surface of the blank obtained by the invention is bright, the crystal texture is uniform, and the surface milling is not required in the subsequent processing. At the same time, the method has low energy consumption, and is a high-efficiency, low-cost method for producing brass strip blanks with special-shaped cross-sections.

Owner:赤峰京铜铜业有限公司 +1

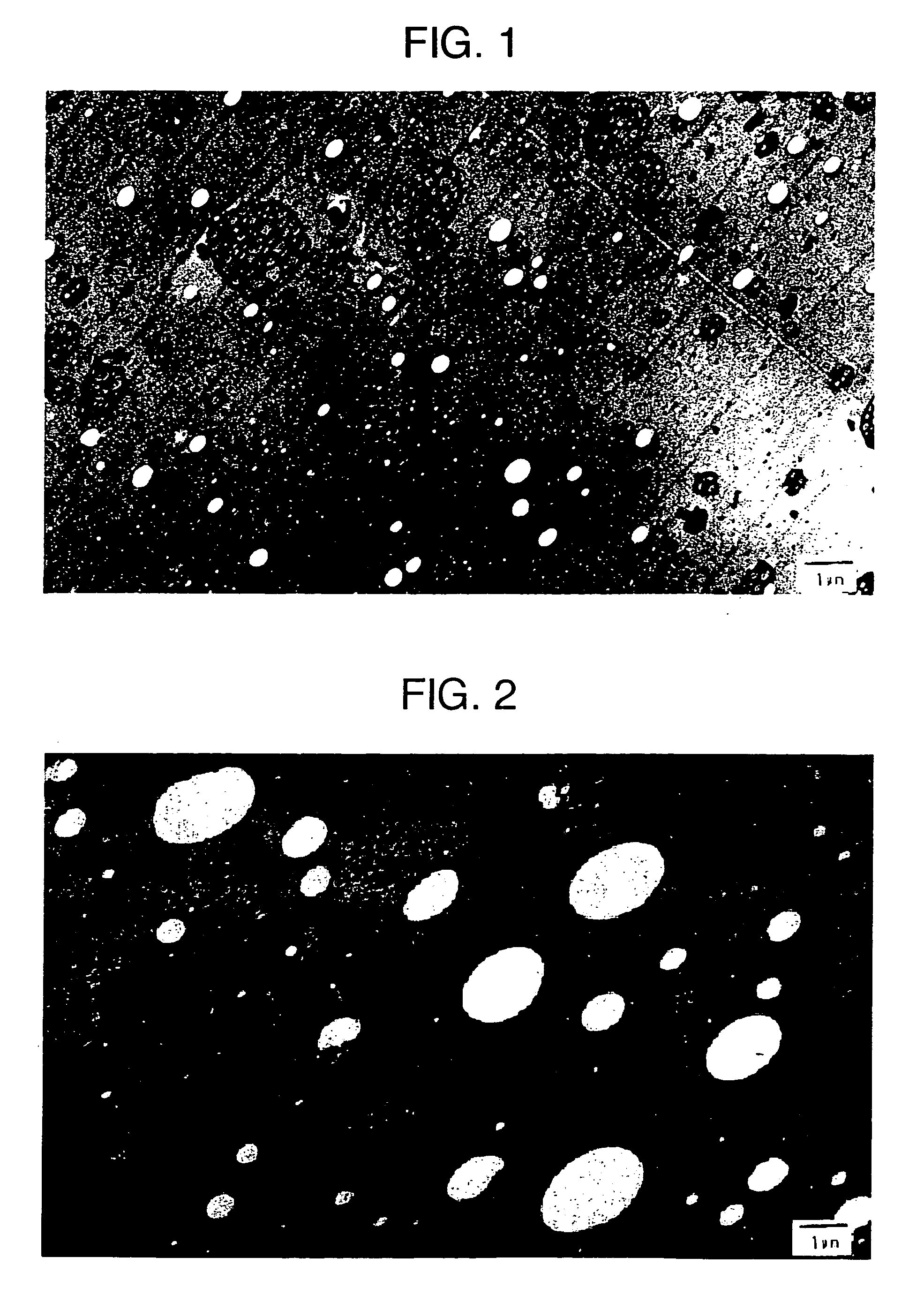

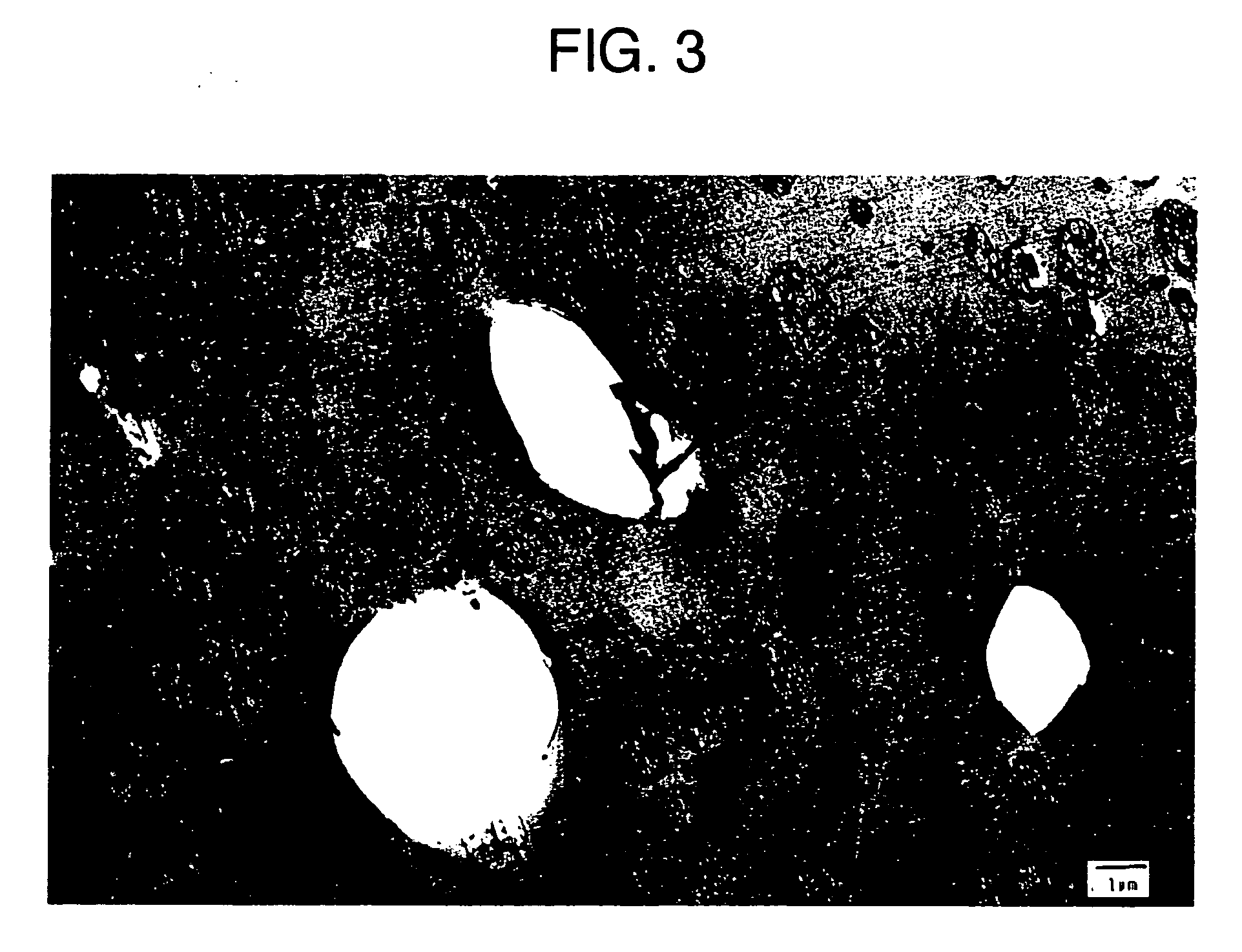

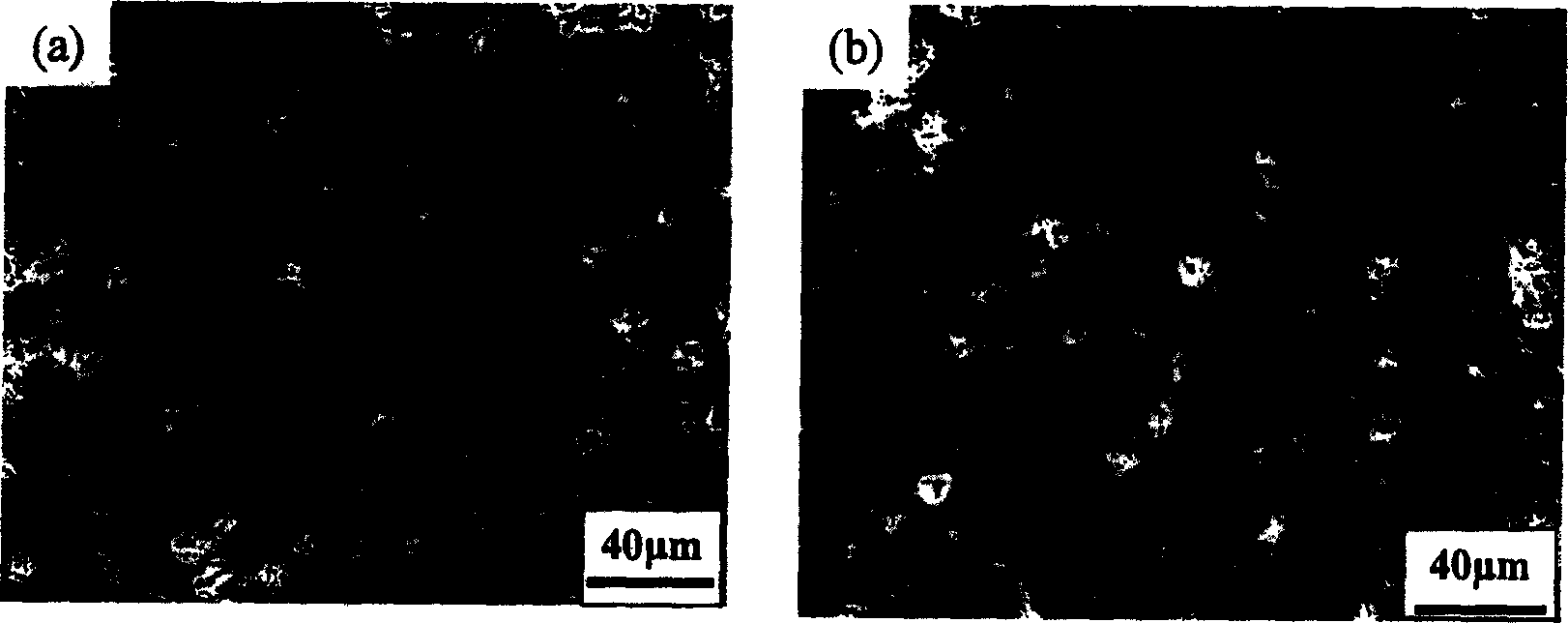

Flame-retardant styrenic resin composition

InactiveUS20060258816A1High capacityReduce heat resistanceGroup 5/15 element organic compoundsHalogenPolymer chemistry

The present invention provides a fire-retarding styrenic resin composition comprising (A) 100 parts by weight of a styrenic resin having a residue after thermal weight loss below 20% at 500° C., and (B) 0.5 to 50 parts by weight of a halogen compound-free fire retardant component, wherein the component (B) has a molecular weight of 200 to 2000, is dispersed in the form of circular or oval particles having an area-average particle size of 0.01 to 3 μm in the component (A), and has a residue after thermal weight loss of 20% or more at 500° C. and a melting point of 100 to 400° C.

Owner:PS JAPAN CORP

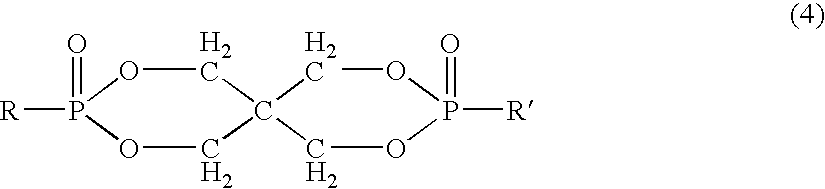

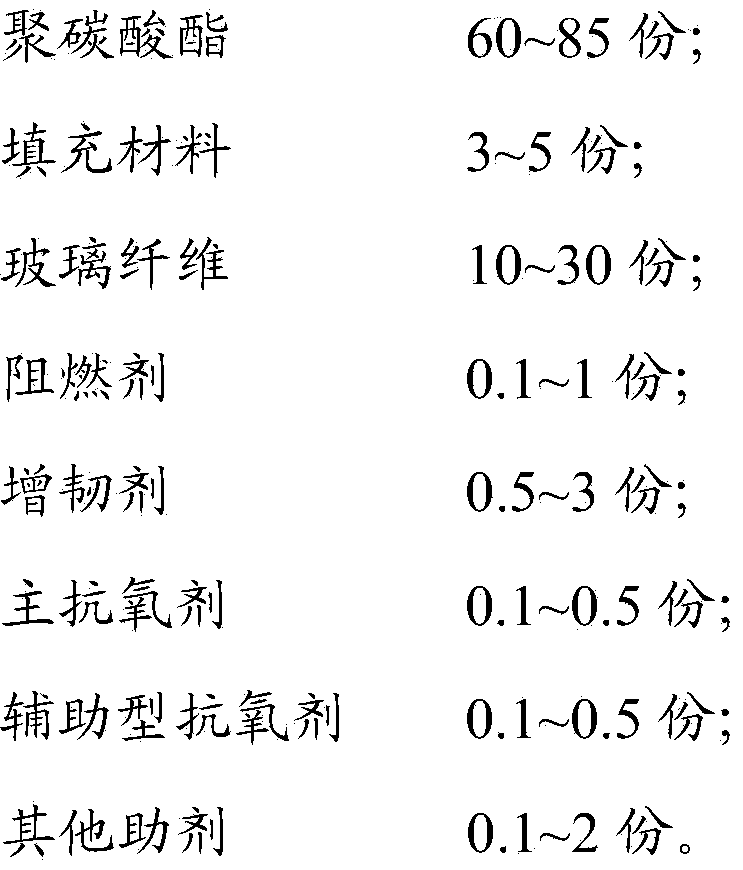

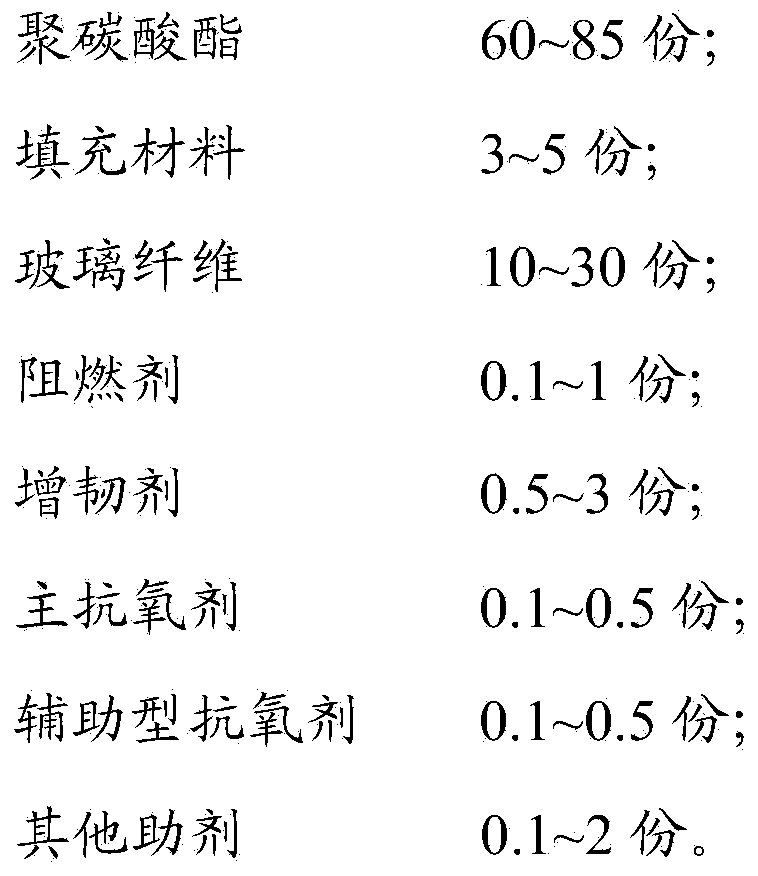

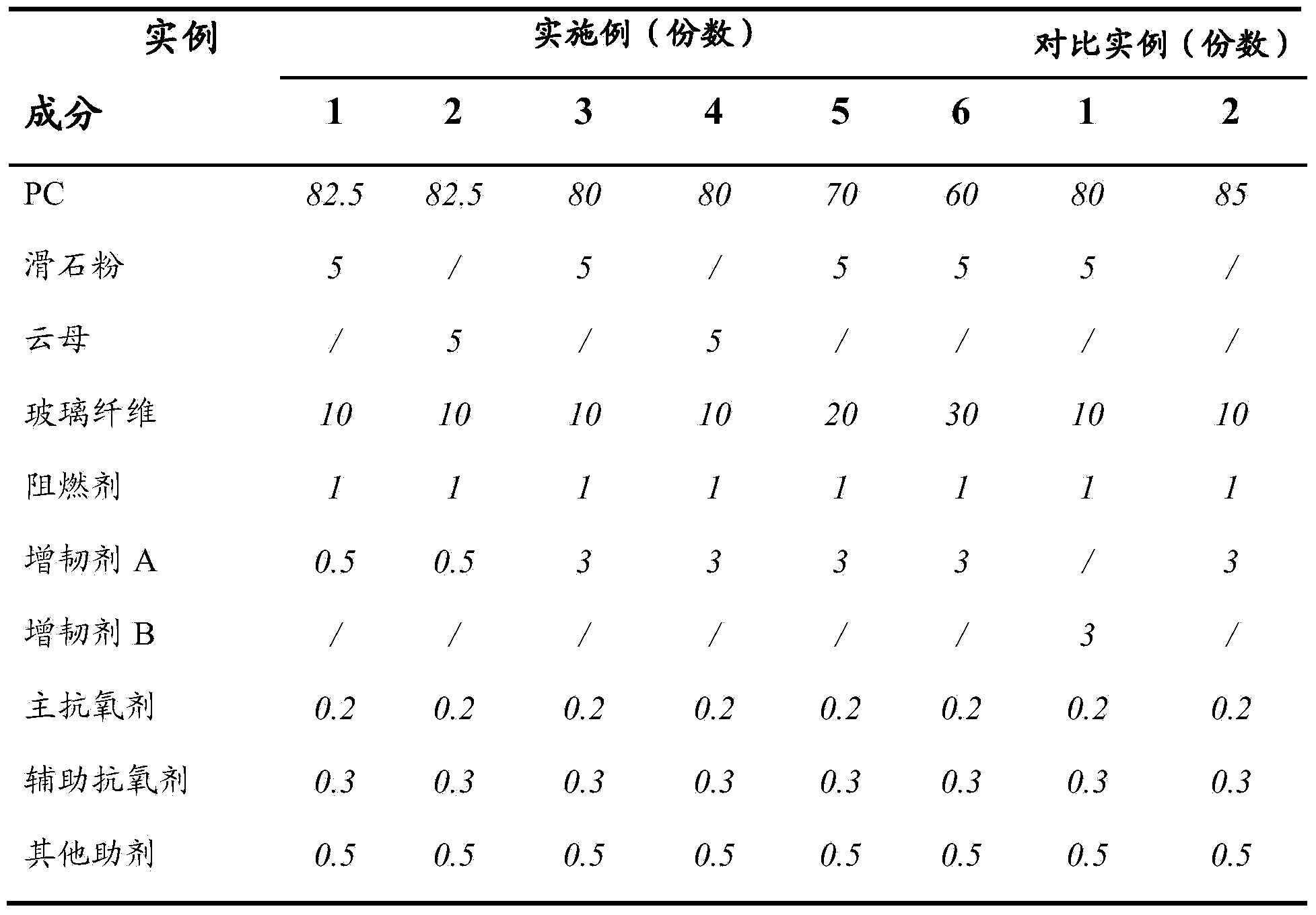

Polycarbonate composition and preparation method thereof

The invention discloses a polycarbonate composition and a preparation method thereof. The polycarbonate composition comprises the following components in parts by weight: 75-86 parts of polycarbonate, 3-5 parts of filling material, 10-15 parts of glass fibers, 0.1-1 part of flame retardant, 0.5-3 parts of toughening agent, 0.1-0.5 part of main antioxidant, 0.1-0.5 part of auxiliary antioxidant, and 0.1-2 parts of other agents. The polycarbonate is modified under the coordination of the reinforcing material, the toughening agent and the processing aid, so that the polycarbonate composition has the advantages of good stability, high strength, warping resistance, good surface glossiness and excellent high-speed puncture impact resistance and toughness. Meanwhile, the polycarbonate composition has a good flame-retardant performance.

Owner:惠州市沃特新材料有限公司

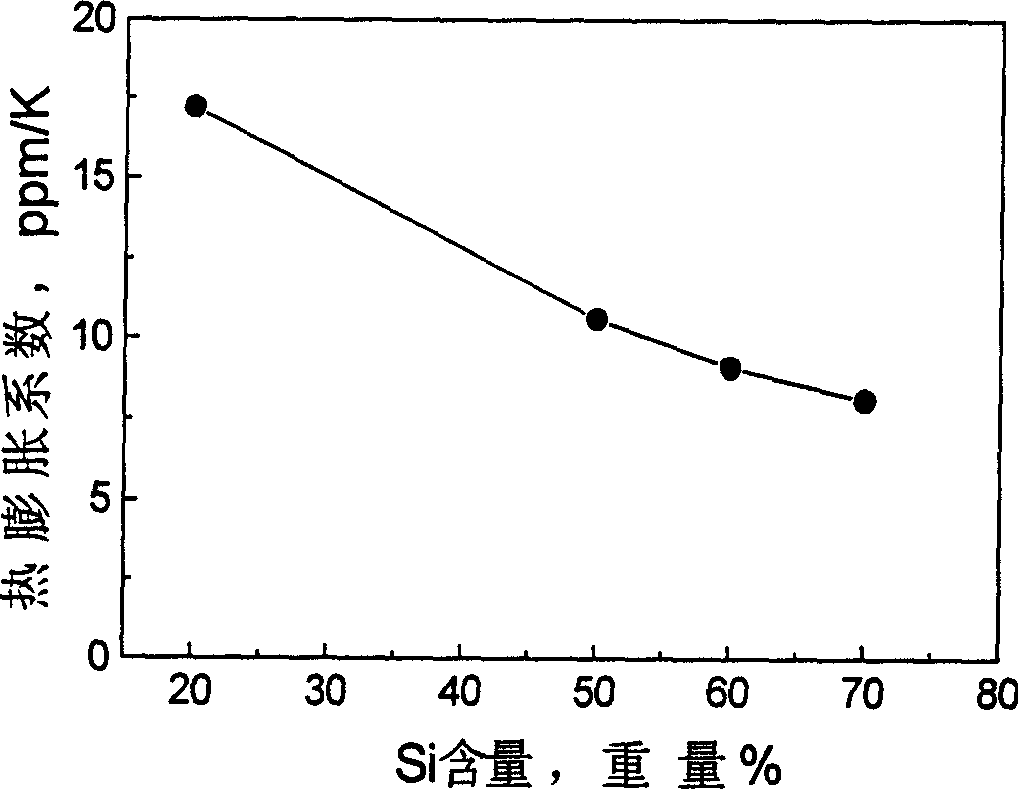

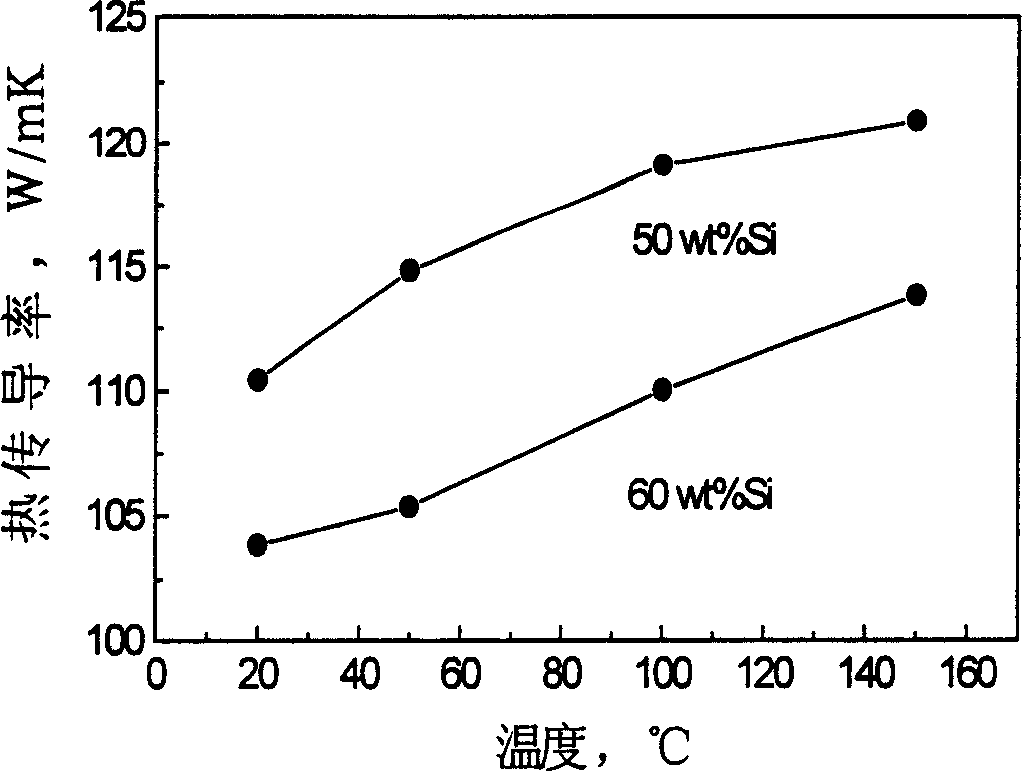

Method for preparing Si-Al alloy using spray deposition forming process

InactiveCN1557585APhysical performance balanceSmall coefficient of thermal expansionSemiconductor/solid-state device detailsSolid-state devicesNitrogen gasNitrogen

The present invention provides the preparation process of jetting and depositing molded Si-Al alloy, and features that intermediate 25-50 wt% Si-Al alloy ingot is first prepared and then jetted and deposited to prepare 50-70 wt% Si-Al alloy. The technological parameters of jetting and depositing process includes: nitrogen used as atomizing gas, atomizing pressure of 0.6-0.8 MPa, depositing distance of 400-600 mm and guide pipe diameter of 3.2-4.0 mm. The present invention has the advantages of adjustable expansion coefficient of the Si-Al alloy in (6-13)E(-6) / K, heat conductivity of 110-150 W / Mk, and density of 2.4-2.5 g / cu cm, and may be used widely as packing and heat dissipating material for electronic elements in telecomm, aeronautics, astronautics and other industry.

Owner:UNIV OF SCI & TECH BEIJING

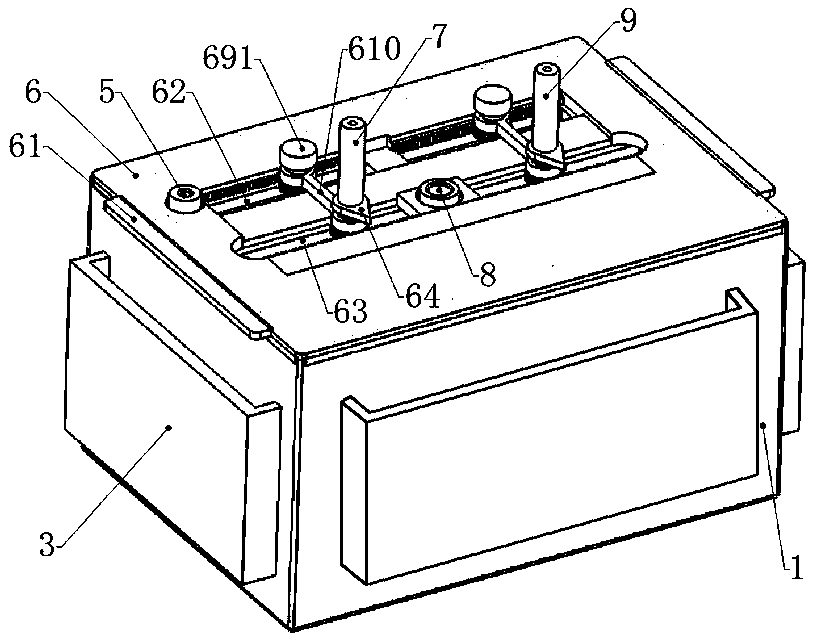

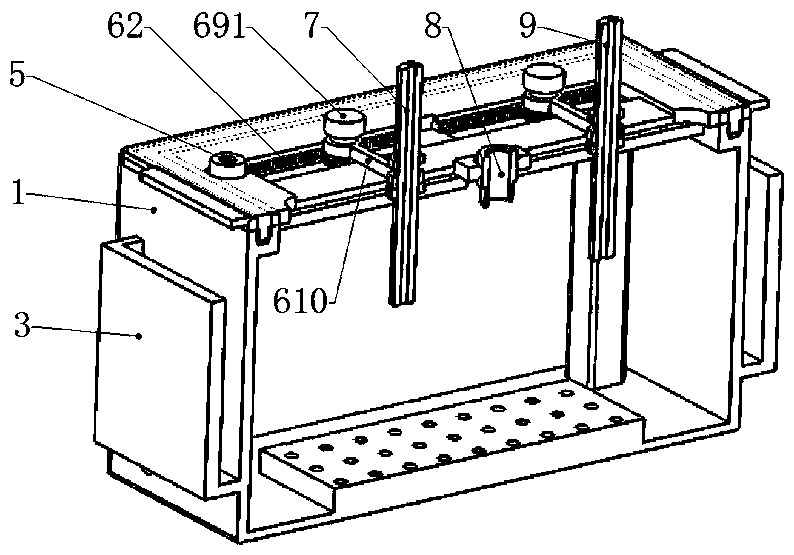

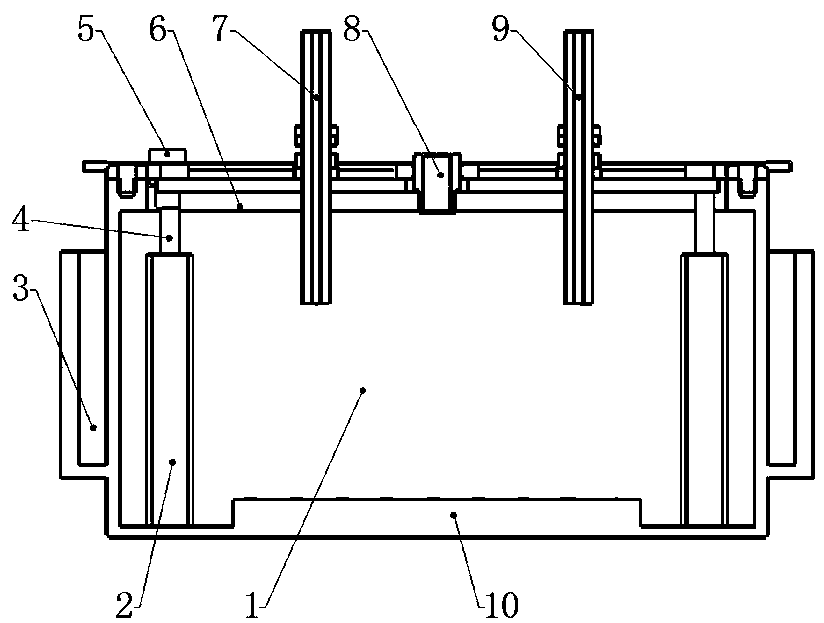

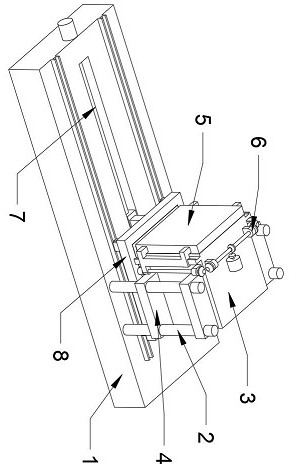

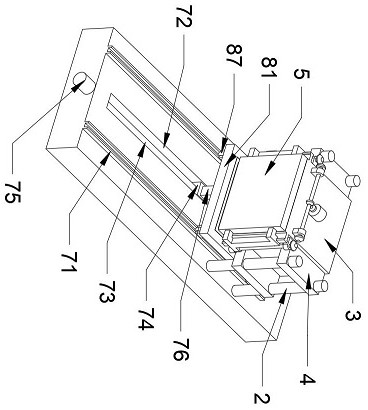

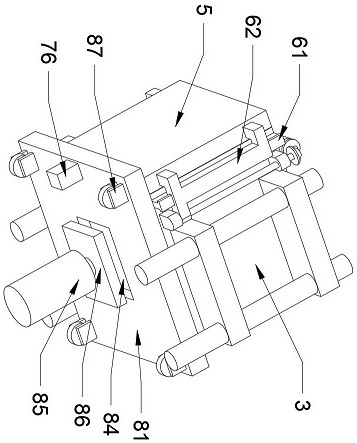

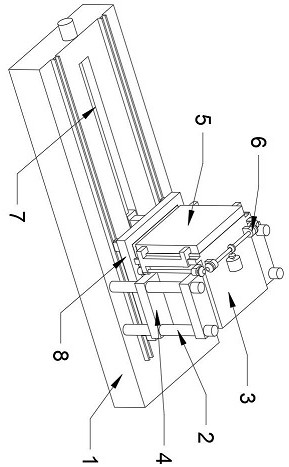

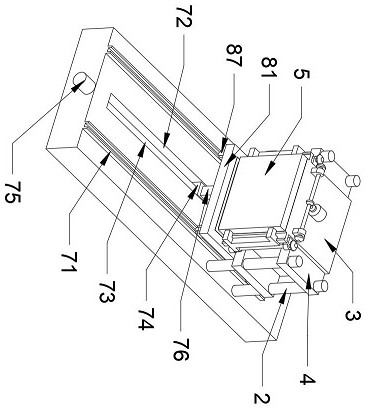

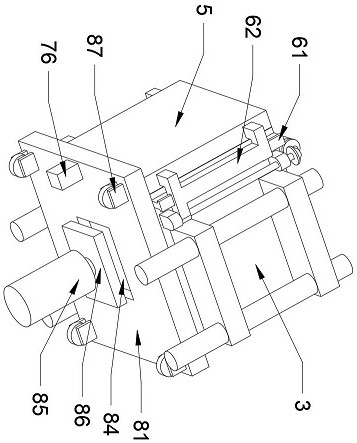

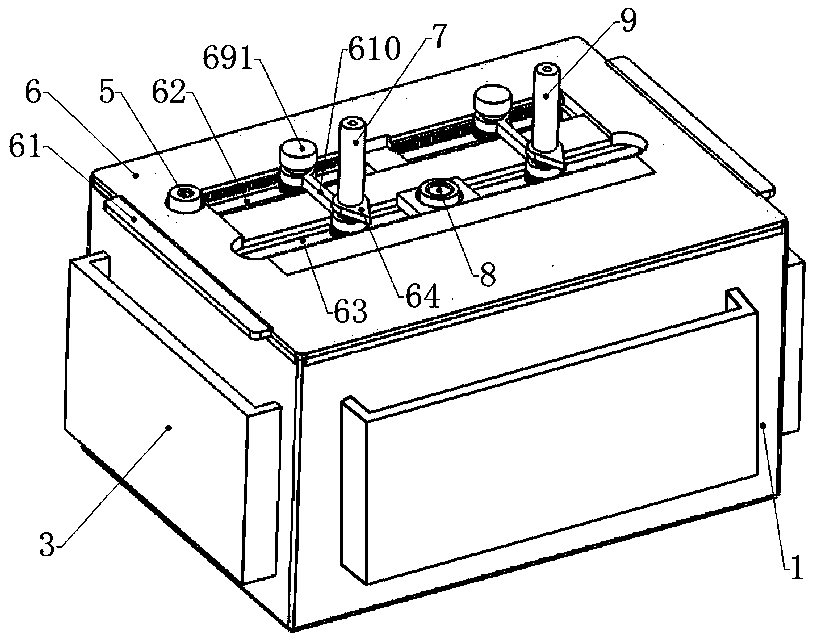

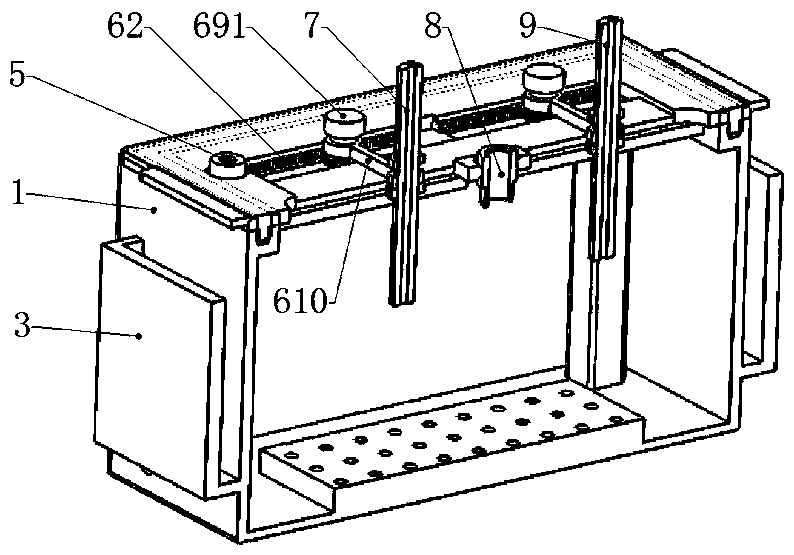

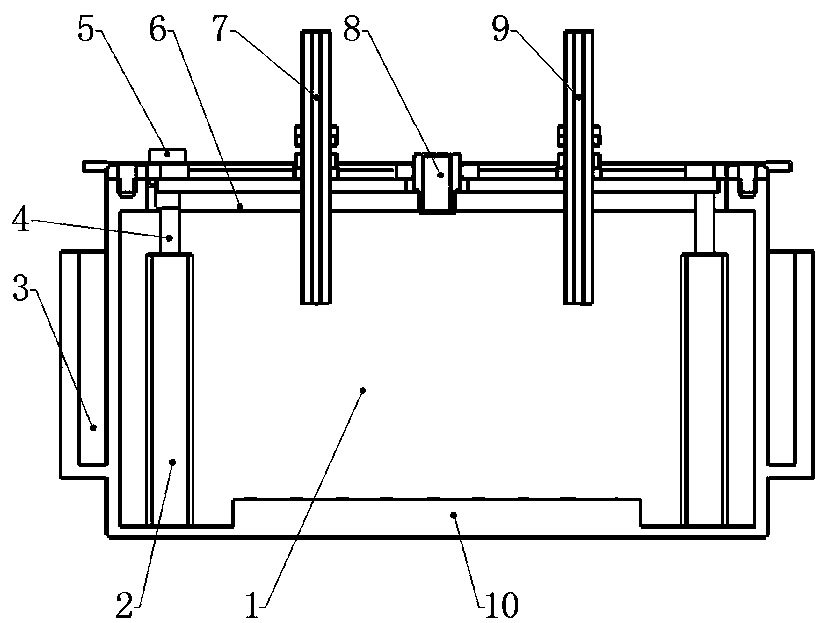

Electrochemical deposition device

ActiveCN109239168APrecise relative distance controlUniform and smooth surface topographyMaterial electrochemical variablesElectrochemical responseEngineering

The invention relates to an electrochemical deposition device, belongs to the technical field of electrochemical reaction devices for laboratories, and solves the technical problem that the depositionrate is low in an electrochemical deposition process. The device comprises a box body, a cover body and electrodes; slots are formed in the outer side walls of the box body respectively; permanent magnet blocks are installed in the slots; a gas guide plate is installed in the middle of the bottom surface of the box body; a liquid outlet and a gas guide pipe are formed / arranged in / on the side walls of the box body respectively; guide rails are vertically and upwards arranged at the four corners of the inner wall of the box body respectively; push rods are arranged in the guide rails; electrodesliding grooves for installing the working electrode, the reference electrode and the counter electrode are formed in the middle of the cover body; and the cover body is further provided with electrode positioning sliding grooves used for accurately controlling the relative positions of the electrodes. According to the device, the positions of the electrodes can be manually adjusted, and the working electrode and the counter electrode can be synchronously adjusted to move oppositely or backwards, so that the accurate control of the relative distance between the electrodes is realized, the electrochemical deposition rate is accelerated, and the surface quality and the physical property of a coating are ensured.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

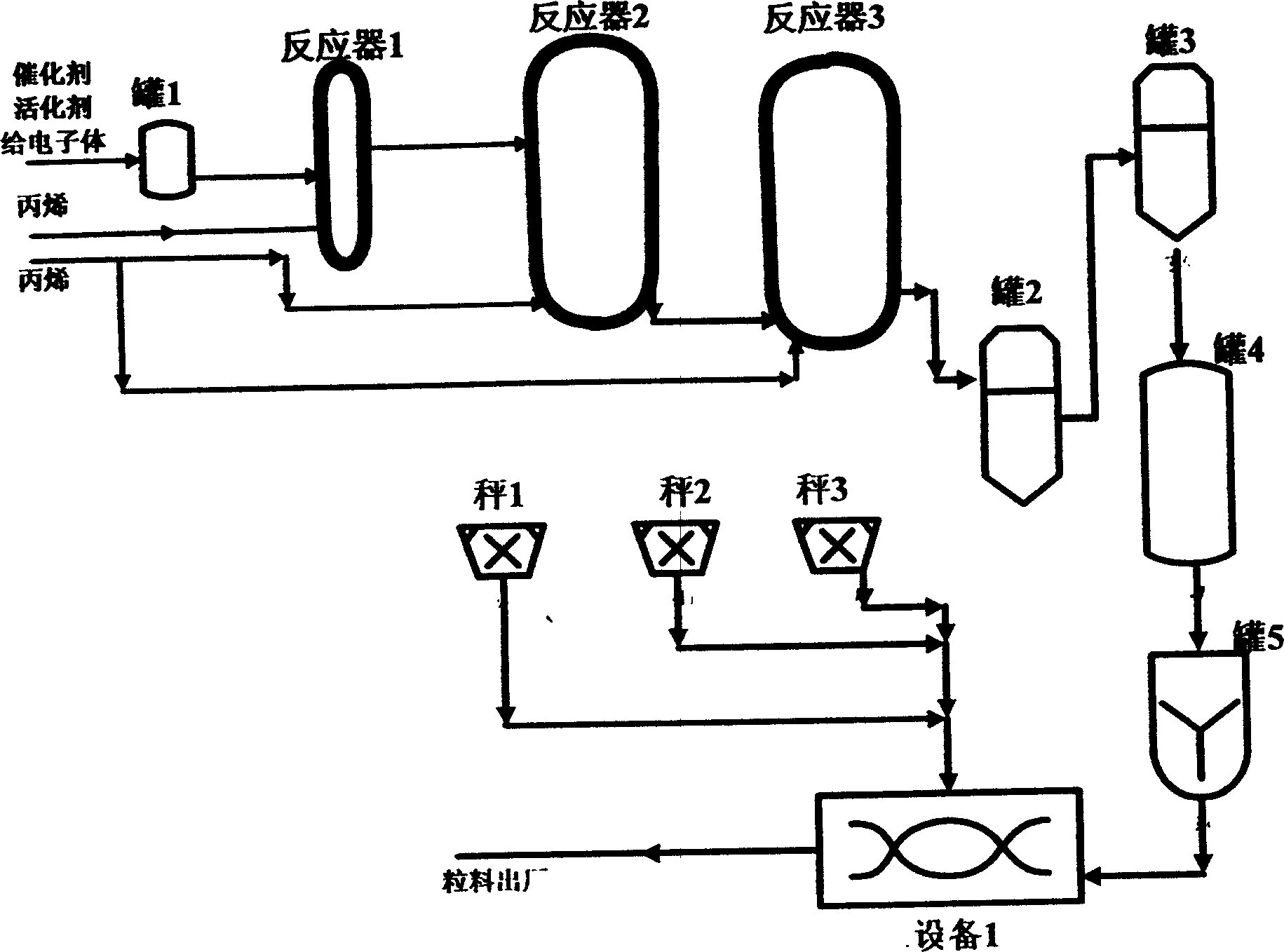

Preparation method of homopolymerization polypropylene bidirection drawing film special material

A process for preparing the homopolypropene used for bidirectional stretch film includes such steps as mixing propene, main catalyst, cocatalyst and electronic doner, prepolymerizing, polymerizing in serially connected two reactors, flash vaporizing deactivating, drying and granulating. It features that said main catalyst contains Ti and Mg and the antioxidizing agent, lubricant and stabilizer are used in said granulating step.

Owner:白跃华

Steel ingot heat treatment method and device

ActiveCN112143859AReduce hardnessHigh hardnessFurnace typesHeat treatment furnacesIngotHeat conservation

The invention discloses a steel ingot heat treatment method and device. The steel ingot heat treatment method comprises the following steps that 1, first heating: a steel ingot is conveyed into a heattreatment furnace to be heated to 727-800 DEG C; and 2, first annealing: the heated steel ingot is subjected to heat preservation for 2 h and subjected to furnace cooling to reach 500-600 DEG C, andthen the steel ingot is discharged out of the furnace and subjected to air cooling. According to the steel ingot heat treatment method and device, the steel ingot is sequentially subjected to annealing treatment after being cast, stress in the steel ingot can be eliminated, surface cracking of the steel ingot is prevented, certain hardness is reduced, grains in the steel ingot are refined throughnormalizing treatment, and the hardness and toughness of the steel ingot are improved; then through secondary annealing, elements in the steel ingot are subjected to solid diffusion, so that non-uniformity of chemical components is relieved, the non-uniformity of the chemical components in the grain size is mainly relieved, and the physical properties of all positions of the steel ingot are balanced; and by means of a heat treatment device, the steel ingot can be conveniently taken out of the furnace after being heated, and people can take and feed materials conveniently.

Owner:山东润金重工科技有限公司

Acrylic fluororesin and preparation method thereof

InactiveCN108467452AImprove vulcanization effectGood weather resistanceCoatingsChemistryDicumyl peroxide

The invention discloses acrylic fluororesin and a preparation method thereof. The acrylic fluororesin comprises, by weight, 50-55 parts of methyl methacrylate, 11-14 parts of butyl acrylate, 2-5 partsof acrylic acid, 11-14 parts of hydroxyethyl acrylate, 1.2-1.8 parts of tricarboxymethylpropane, 1-1.5 parts of dicumyl peroxide, 2-5 parts of chain transfer agent, 3-7 parts of rutile titanium dioxide, 3-7 parts of anti-settling agent, 3-7 parts of antifoaming agent, 3-7 parts of leveling agent, 3-7 parts of initiator, 60-80 parts of organic solvent and 2-6 parts of antioxidant. A mixed solutionB is placed in a reaction still, the temperature is controlled at 50-60 DEG C, a mixed monomer A is uniformly added dropwise within 2 hours, and heat preservation is conducted for 3 hours. The designis ingenious, and the formed resin has balanced physical and chemical properties, can adapt to different environments, has high adaptability and is suitable for popularization.

Owner:宁波安工电子有限公司

White film and a method of manufacturing opaque white film

ActiveCN102030971APrevent the phenomenon of adhesive peeling offReduce contentFlat articlesIntrinsic viscosityHeat treated

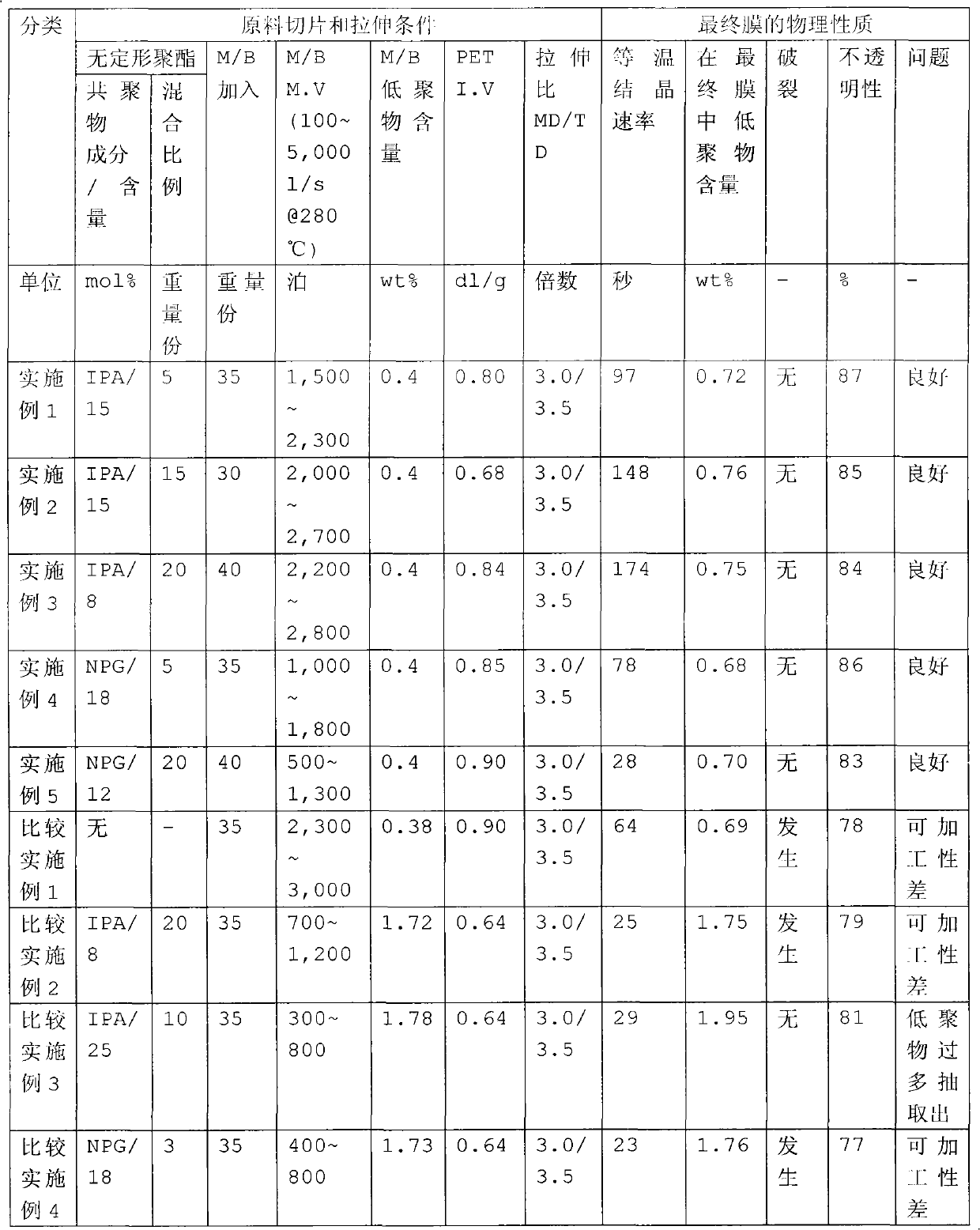

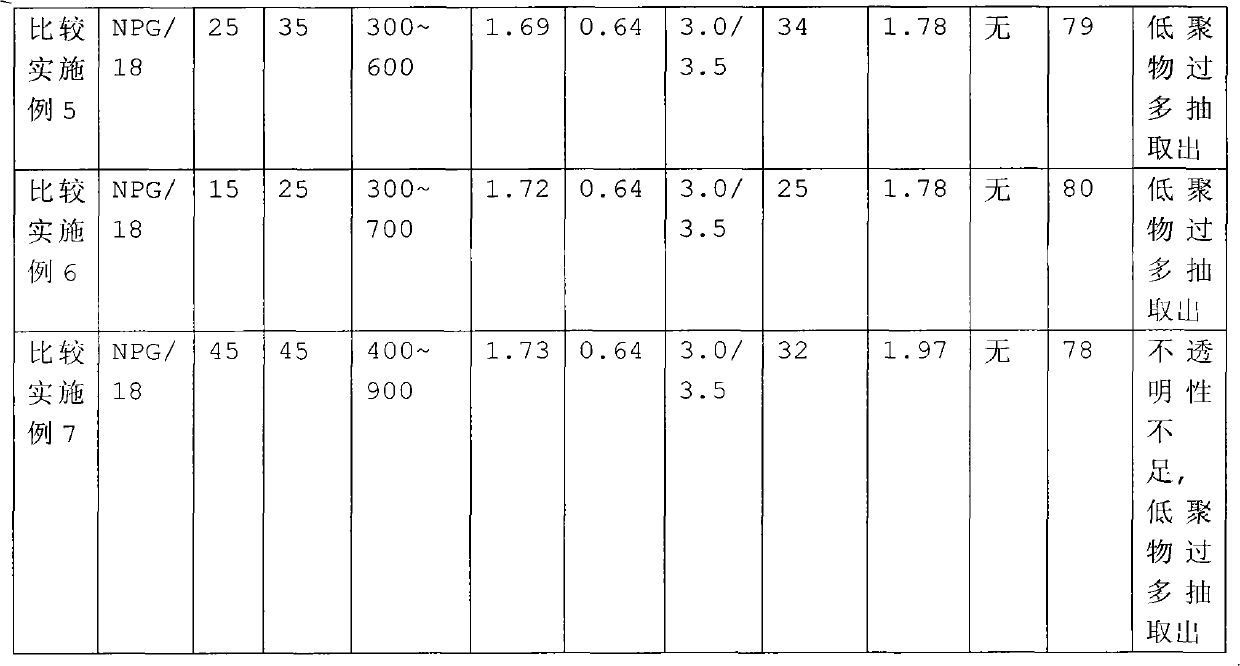

Disclosed is a white film having low content of oligomer within the film and a method of manufacturing the opaque white film. The method comprises: solid-phase polymerizing a polyester resin to prepare the polyester resin having the intrinsic viscosity of 0.65-0.90 and the oligomer content of less than 0.5%; preparing masterbatch including 5-25 parts by weight of amorphous polyester resin and 50-150 parts by weight of barium sulfate, based on 100 parts by weight of polyester resin, and then solid-phase polymerizing the masterbatch to prepare the masterbatch having less than of 0.5% of oligomer content within polyester resin, 500-3,000 Poise of melt viscosity in the full range of Shear rate 100-5,000 l / s after melting at 280[deg.] C. for 5 minutes; mixing the polyester resin in the solid-phase polymerizing of the polyester resin with the masterbatch in the preparing and solid-phase polymerizing of the masterbatch, and then extruding it after melt-mixing to prepare a sheet; uniaxially drawing or biaxially drawing the prepared sheet; heat-treating the drawn film; and heat-setting the heat-treated film. The white film has excellent blare and whiteness and opaqueness and low content of extracted oligomer and not breakdown.

Owner:KOLON IND INC

Functional masterbatch of polyolefin plastic woven product and preparation and application thereof

InactiveCN106957481APhysical performance balanceUniform colorMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchPolyolefin

The invention discloses a functional masterbatch of a polyolefin plastic woven product and a preparation and application thereof. The functional masterbatch of the polyolefin plastic woven product is prepared from the following components in parts by weight: 60-80 parts of polyolefin, 12-28 parts of an assistant and 3-5 parts of stearate, wherein the assistant contains an antioxidant and a light stabilizer; the mass ratio of the antioxidant to the light stabilizer is 1:(3-6); the stearate contains calcium stearate and zinc stearate; and the polyolefin is polyethylene or polypropylene. The functional masterbatch of the polyolefin plastic woven product is convenient to operate when the woven product is prepared, dust pollution and manpower and material losses can be avoided, and the functional masterbatch of the polyolefin plastic woven product has good light aging resistance.

Owner:BEIJING ADDITIVES INST

Polyurethane sponge and preparation method thereof

The invention discloses polyurethane sponge and a preparation method thereof, and belongs to the technical field of foam sponges. The polyurethane sponge comprises microcrystalline cellulose, soybeanoil, diethylene glycol, potassium hydroxide, polyether polyol, a foaming agent, a foam stabilizer, toluene diisocyanate, distilled water, silver-loaded zirconium phosphate, an aluminate coupling agent, cerium oxide, a silicone-acrylic emulsion, an EVA emulsion, polylactic acid fibers, oleic acid and fumed silica. The preparation method of the polyurethane sponge comprises mixing, catalyst preparation, crosslinking, foaming, etc. The rebound rate and tear strength of the polyurethane sponge are improved by polylactic acid fibers, fumed silica and oleic acid as reinforcing systems.

Owner:长沙浩然医疗科技有限公司

A processing method for producing brass strip

A processing method for producing brass strips, comprising the following steps: smelting, casting, high-precision rolling, bright annealing, finished product rolling, and finished product shearing, characterized in that the casting adopts upward continuous casting to prepare billets, and The circular crystallizer tooling equipped with graphite moulds, which was used for wire rod production by upward continuous casting, was transformed into a designed cross-section crystallizer tooling for strip production. Compared with the original brass strip processing method, it has the characteristics of low manufacturing cost and cheap tooling and molds. The surface of the blank obtained by the invention is bright, the crystal texture is uniform, and the surface milling is not required in the subsequent processing. At the same time, the method has low energy consumption, and is a high-efficiency, low-cost brass strip blank production method.

Owner:赤峰京铜铜业有限公司 +1

Biomass new energy fuel and preparation method thereof

InactiveCN109810742AIncrease the calorific value of combustionImprove physical performanceBiofuelsSolid fuelsChemistrySOYBEAN SEED OIL

The invention discloses biomass new energy fuel and a preparation method thereof, and belongs to the technical field of biomass fuel. The biomass new energy fuel is prepared from the following raw materials: straw, wood dust, fruit shell and peel, a dehydrating agent, calcium oxide, stigmasterol, hydroxyl silicone oil and epoxidized soybean oil. The preparation method comprises the following steps: mixing, squeezing and the like. According to the biomass new energy fuel disclosed by the invention, by adopting the stigmasterol, the hydroxyl silicone oil and the epoxidized soybean oil as reinforcers, the combustion heat value and the physical performance of the biomass new energy fuel are increased.

Owner:长沙而道新能源科技有限公司

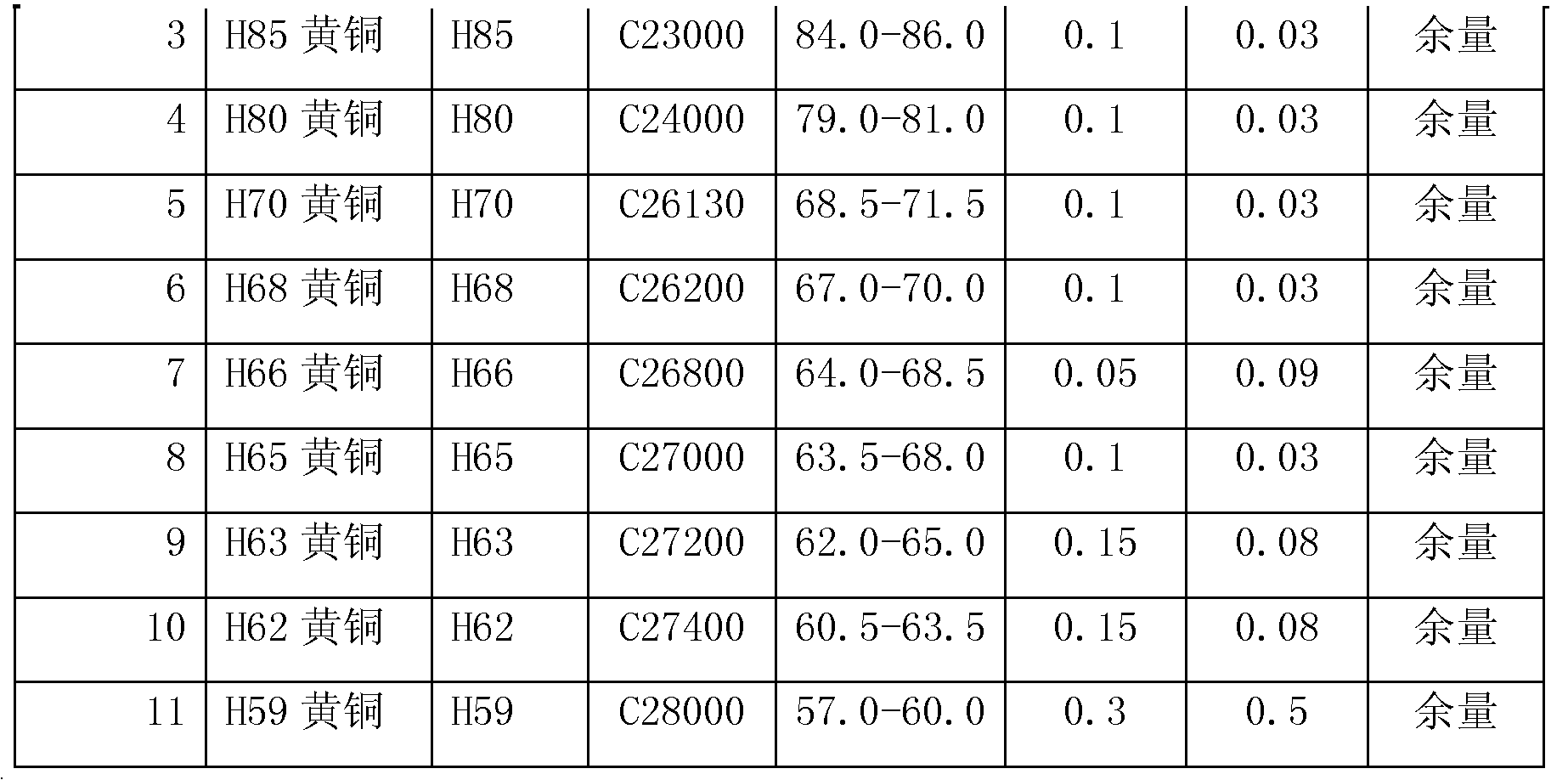

Isocyanate adhesive and method for preparing multilayer polyurethane structural composite by using same

ActiveCN106675488AImprove adaptabilityLow costPolyureas/polyurethane adhesivesSynthetic resin layered productsSimple Organic CompoundsAdhesive

The invention discloses an isocyanate adhesive. The adhesive comprises: A, an isocyanate component; B, a composite catalyst aqueous solution. The composite catalyst comprises an amine-containing organic compound and an aminocarboxylate stabilizer; aminocarboxylate is added, so that insoluble substances generated by an amine catalyst in water can be inhibited; water spraying equipment is not blocked in the application process; the curing speed of the isocyanate adhesive can be properly adjusted by changing the concentration of the catalyst; the operation is convenient. The invention also discloses a method for preparing a multilayer polyurethane structural composite by using the isocyanate adhesive. The prepared multilayer polyurethane structural composite can be applied to interior components and can be particularly applied to automobile ceiling roof components.

Owner:WANHUA CHEM BEIJING +1

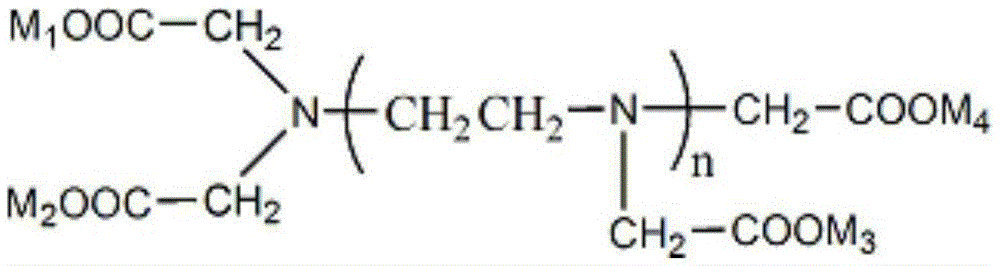

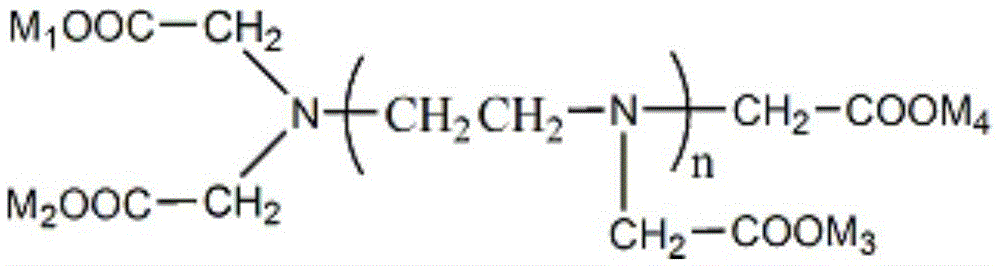

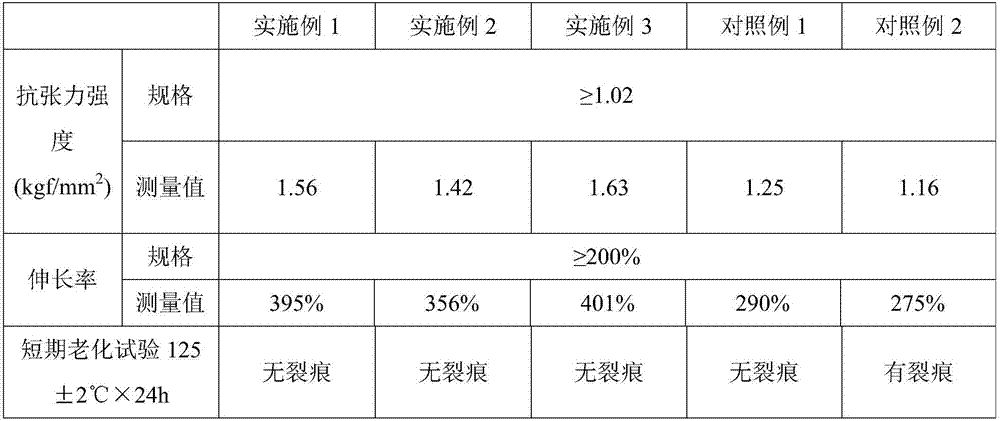

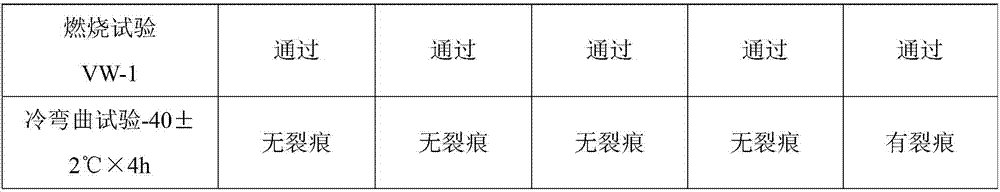

Antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material and preparation method thereof

ActiveCN107474433AGood flame retardant performancePhysical performance balancePlastic/resin/waxes insulatorsAmmonium polyphosphateChemistry

The invention discloses an antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material and a preparation method thereof. The antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material is prepared from the following materials in parts by weight: 100 to 150 parts of PVC (polyvinyl chloride) resin, 40 to 50 parts of polyester plasticizer, 4 to 8 parts of compound calcium-zinc stabilizer, 0.5 to 1 part of chemical lubricant, 25 to 40 parts of filler and 3 to 5 parts of components of a formula A. The formula A is prepared from the following materials in parts by weight: 0.6 to 1 part of zinc stannate, 1 to 2 parts of aluminium hydroxide, 0.8 to 1.2 parts of organic phosphorus flame retardant, 0.8 to 1.5 parts of nitrogen series flame retardant, 1 to 1.5 parts of ammonium polyphosphate, 1 to 2 parts of magnesium hydroxide, 0.1 to 0.3 parts of pentaerythritol and 0.1 to 0.3 parts of chemical lubricant. Besides flame-retardant property, the cable material disclosed by the invention also has excellent physical and chemical properties.

Owner:江西省安安科技有限公司

A kind of production technology of rare earth magnesium alloy

The invention belongs to the fields of metal materials and metallurgy, aims to solve the problems that impurities of alloy are hard to separate, ingredients are nonuniform, the utilization rate of rare earth element is low, precipitated rare earth phases are nonuniform, the segregation is more, and effects for the quality is great by adopting the manner that alloying, rare earth process, and casting are conducted in a pot during a conventional manufacturing technology process, and provides a manufacturing technology for rare earth-magnesium alloy. According to the manufacturing technology, conducting adding, refining, and degassing with hexachloroethane degassing agent of alloy element in a melting pot; and pouring into a second pot after standing for 30 min, adding rare earth, and standing and casing. A manufactured bar material has uniform and stable metallographic structure and clear crystal boundary; the product is without pore, shrinkage cavity and cold shut, and the surface is smooth and without rugosity; the purity, ingredients, and equilibrium of physical properties of the product are guaranteed, the grain size of the alloy is refined, very stable dispersed phase is precipitated, and the rigidity and the decay resistance of texture are improved; therefore, product performances are allowed to be superior to an ordinary alloy standard.

Owner:孝义市东义镁业有限公司 +1

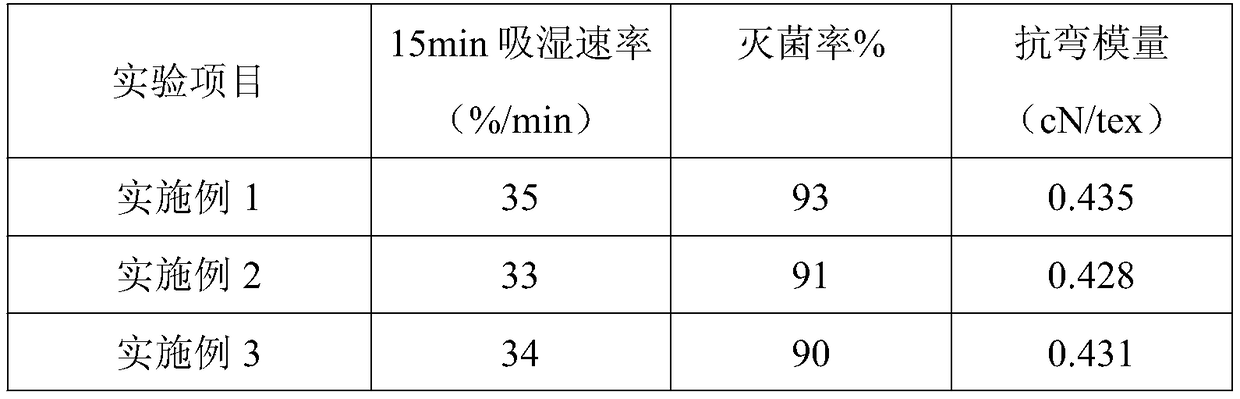

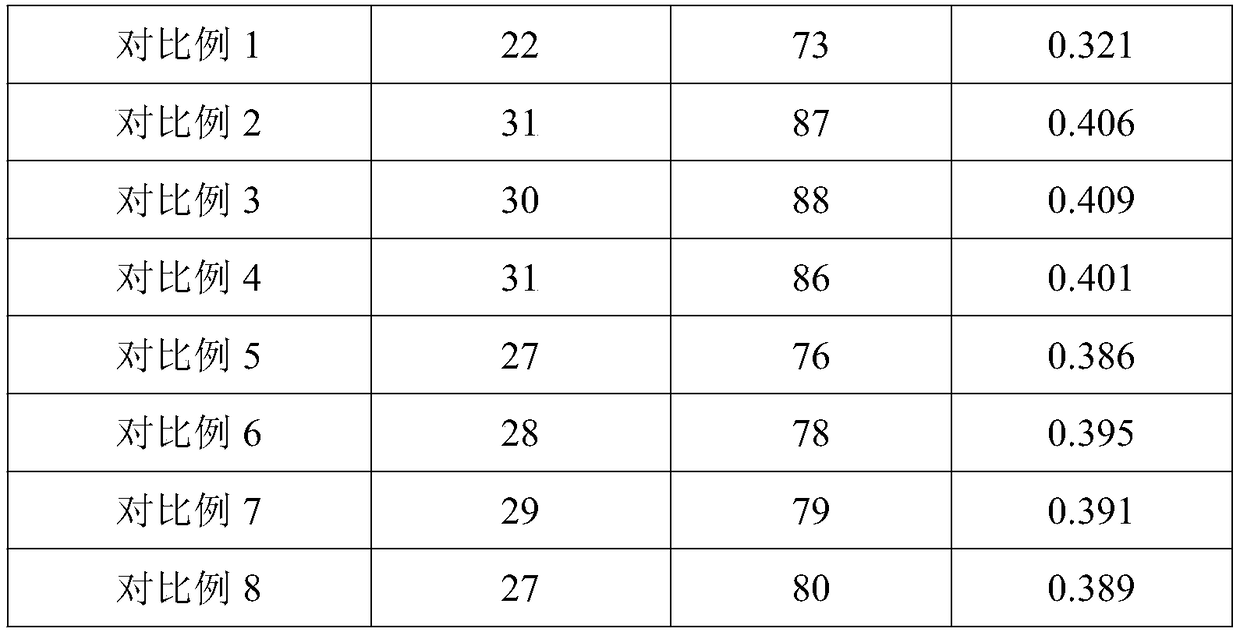

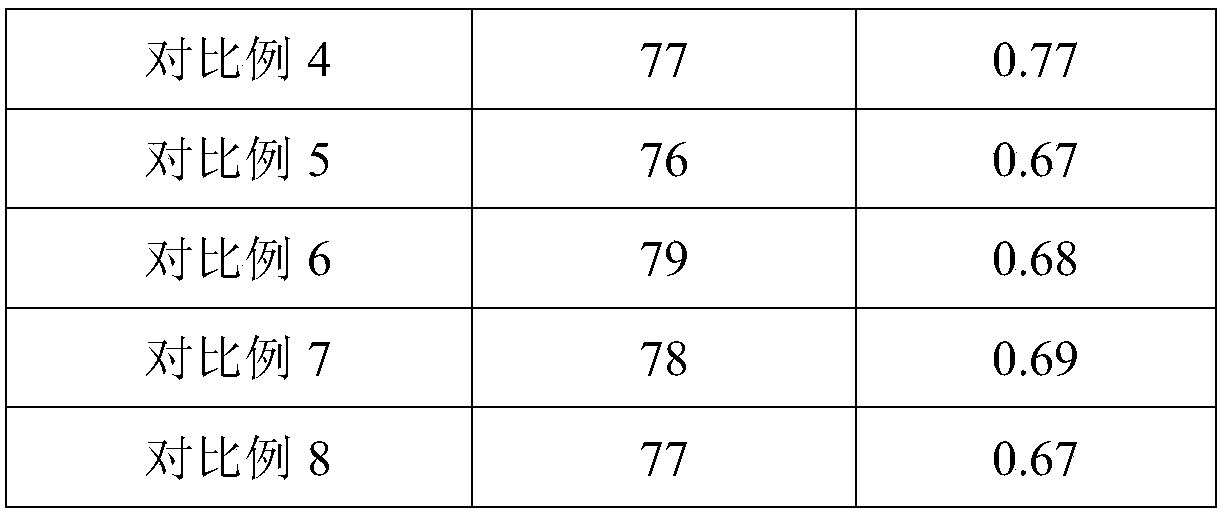

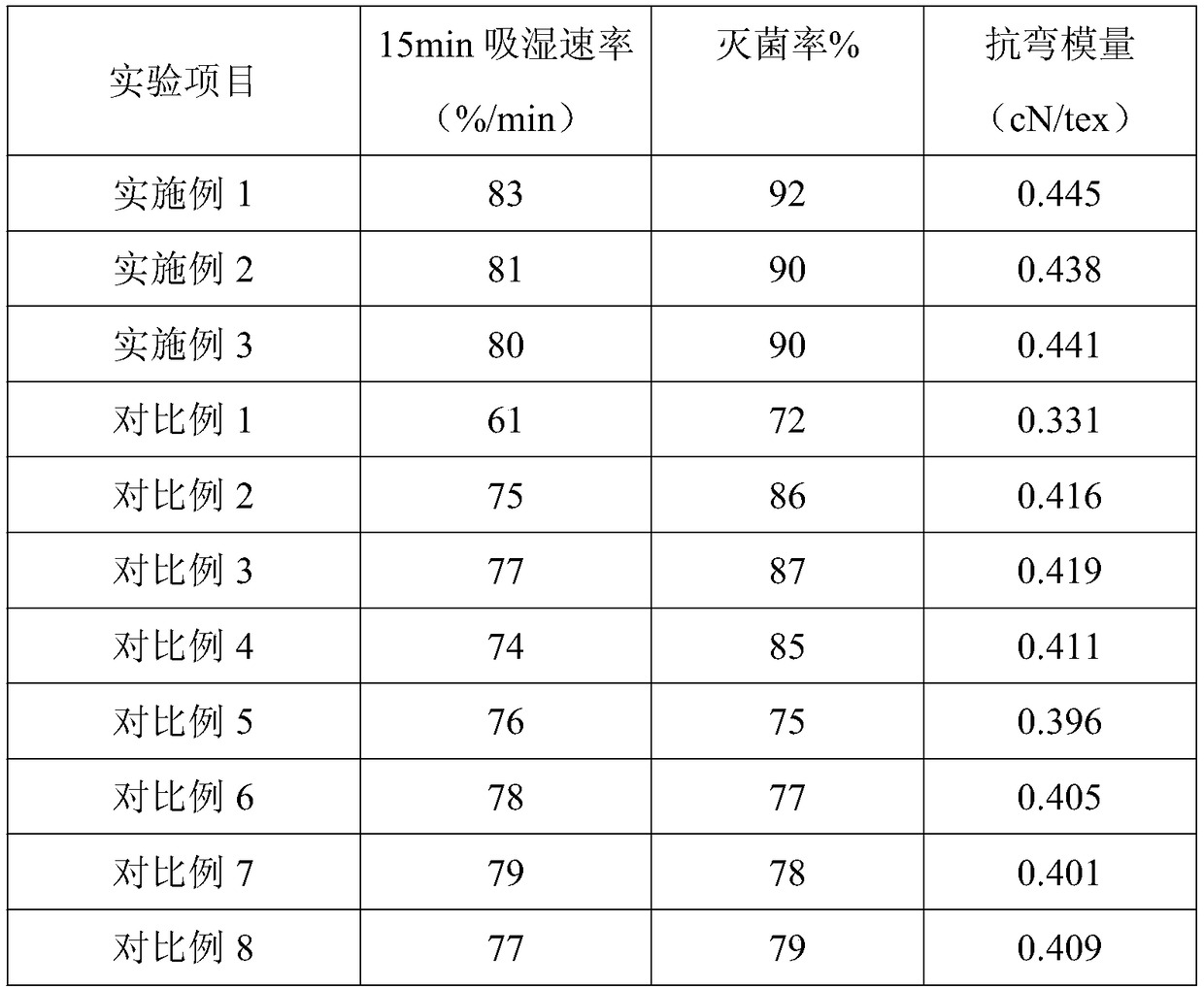

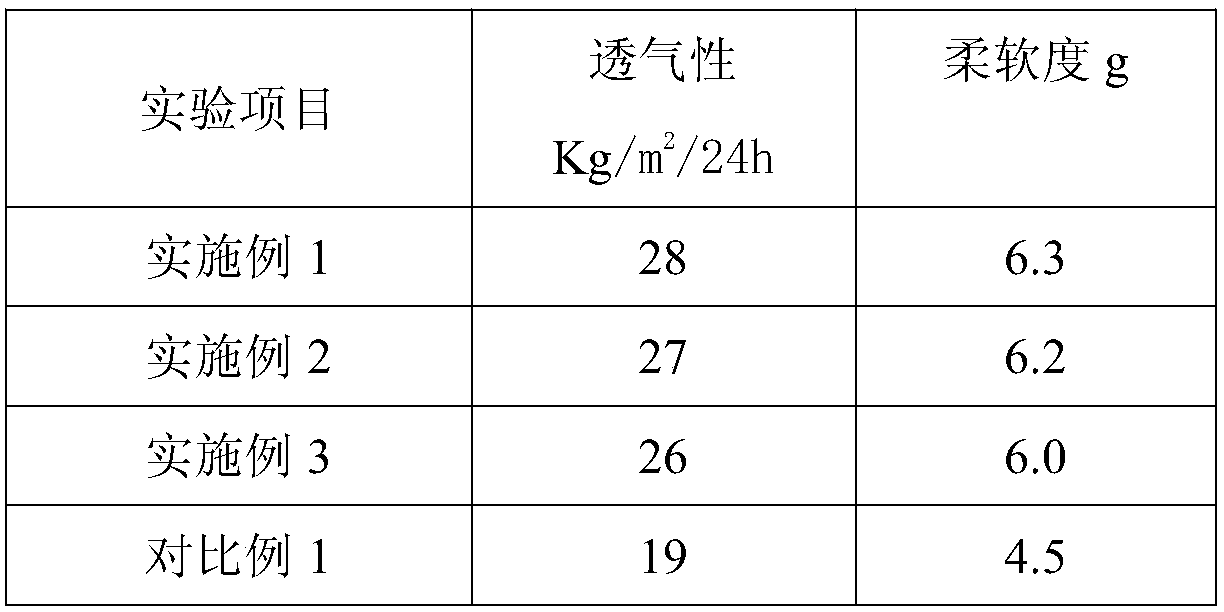

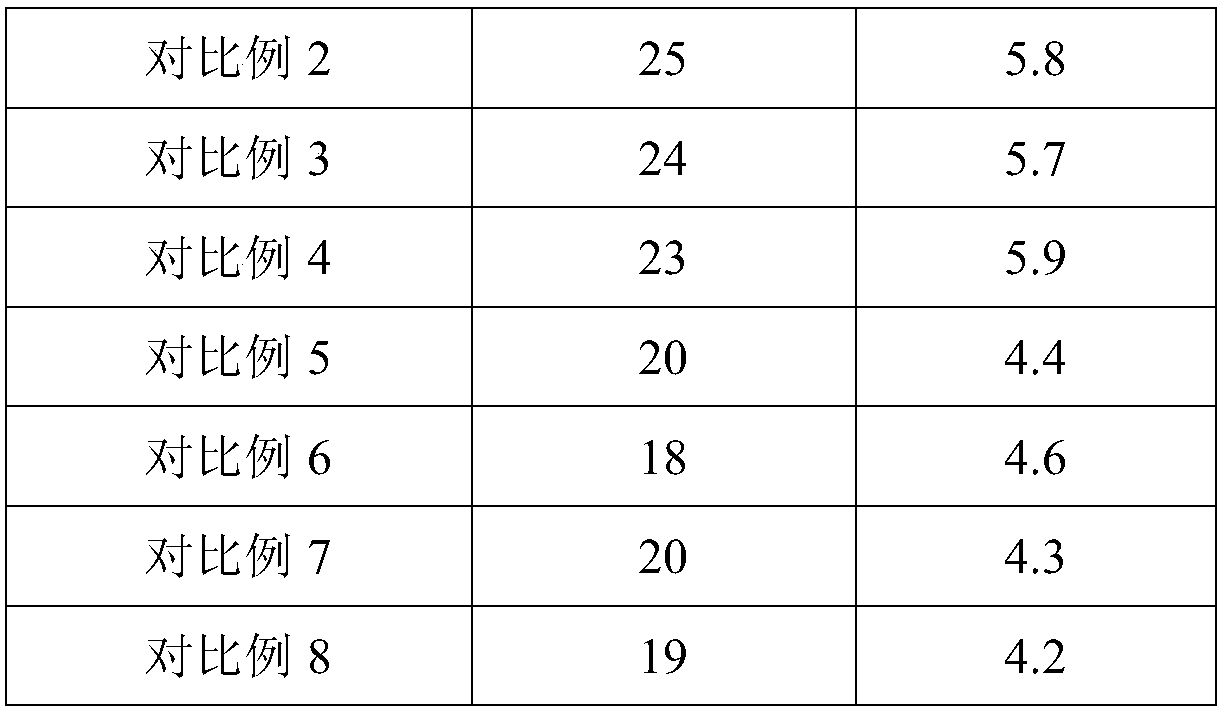

Baby clothes fabric and preparing method thereof

InactiveCN109371534AHigh moisture regainGood moisture absorption and releaseFilament/thread formingConjugated cellulose/protein artificial filamentsActivated carbonViscose fiber

The invention discloses a baby clothes fabric and a preparing method thereof, and belongs to the technical field of textile materials. The baby clothes fabric comprises silkworm chrysalis protein viscose fiber, soft silk fiber, ultrafine activated carbon fiber, soybean fiber, milk fiber and modified polylactic acid fiber. The modified polylactic acid fiber comprises polylactic acid fiber, castor oil, casein and calcium bentonite. The preparing method of the baby clothes fabric includes the steps of grinding, silk jetting, blending, weaving and the like. By using the castor oil, bentonite and casein as the enhancing systems, the breathability, mechanical performance and antibacterial property of the baby clothes fabric are improved.

Owner:长沙浩然医疗科技有限公司

High-strength sealing thermoplastic elastomer and preparation method thereof

InactiveCN109867901AGood high and low temperature resistanceImprove physical performanceElastomerPolymer science

The invention discloses a high-strength sealing thermoplastic elastomer and a preparation method thereof, and belongs to the technical field of polymer products. The high-strength sealing thermoplastic elastomer has raw material components including a hydrogenated styrene elastomer, white oil, polypropylene, an olefin elastomer, metallocene polyethylene, a polypropylene alloy modification substance, mineral powder, a stabilizer, natural rubber latex, hydroxy silicone oil and lignin sulfonic acid. The preparation method includes mixing, extrusion and other steps. According to the invention, the high- and low-temperature resistance and physical properties of the high-strength sealing thermoplastic elastomer are improved by using the natural rubber latex, hydroxy silicone oil and lignosulfonic acid for reinforcing.

Owner:奥世达弹性体(深圳)有限公司

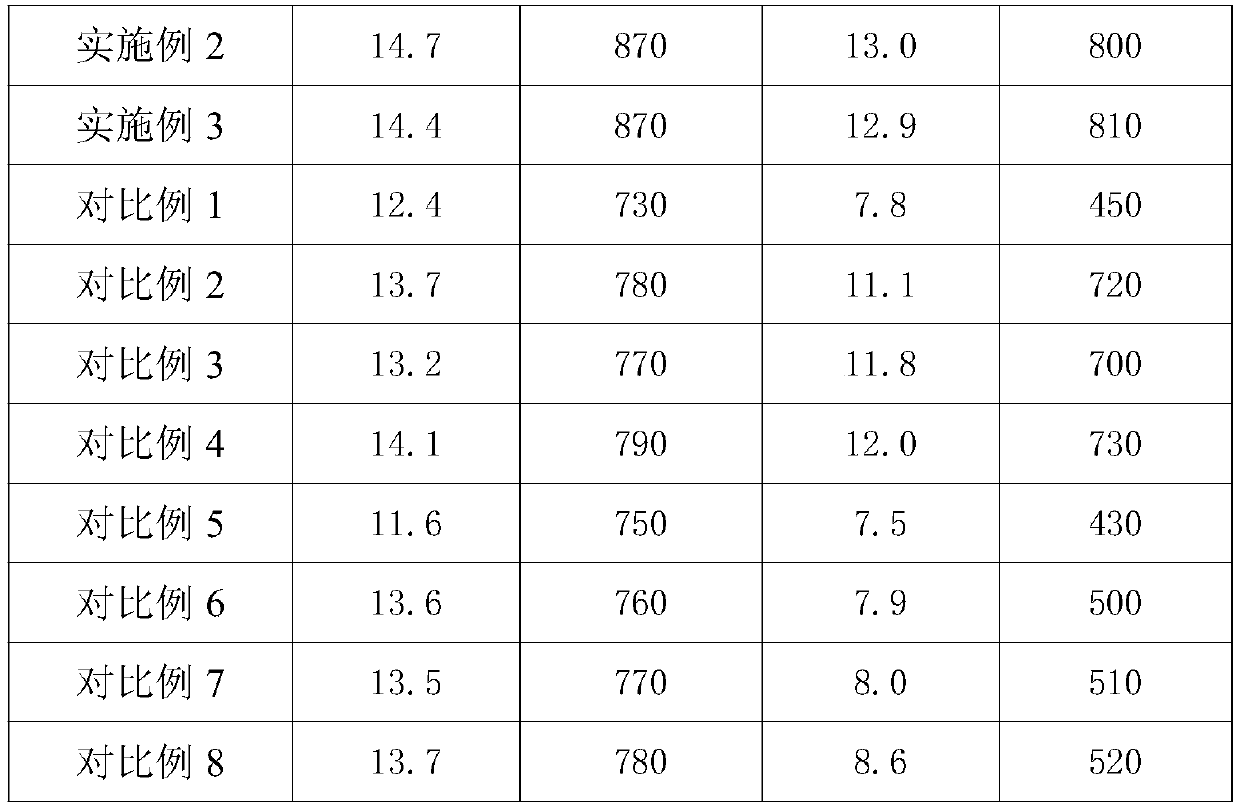

Nano modified epoxy antiseptic paint

InactiveCN102702927AImprove anti-corrosion performanceImprove permeabilityAnti-corrosive paintsEpoxy resin coatingsNano siliconEpoxy

Nano modified epoxy antiseptic paint is prepared by the following raw materials in weight parts: 25-35 parts of epoxy resin, 0.5-1 part of coupling agent, 20-22 parts of pigment, 20-23 parts of filler, 10-15 parts of nano silicon, and 8-12 parts of solution. As the raw materials are adopted by the nano modified epoxy antiseptic paint, during the film-forming process, the nano silicon can automatically enters generated cavities, as a result, the compactness and impermeability effects are achieved at last, the penetration resistance to water and other media is improved, and further, the antiseptic performance of the whole paint film is improved, and the extraordinary technical effect is achieved.

Owner:山东乐化漆业股份有限公司

Environment-friendly chest-protecting athletic undergarment having strong air permeability and high stability

InactiveCN109497634AImprove hydrophilicityHigh hydrophilic activityProtective garmentSpecial outerwear garmentsFiberEnvironmental resistance

The invention discloses an environment-friendly chest-protecting athletic undergarment having strong air permeability and high stability. The environment-friendly chest-protecting athletic undergarment comprises a back support, adjustable shoulder straps, a cover bellyband, a zipper and a sweat absorbing cushion, wherein the outer side of the back support is connected with the cover bellyband through the adjustable shoulder straps, the lower end of the cover bellyband is provided with the zipper, the sweat absorbing cushion is plug-connected in the cover bellyband and also comprises a modal fabric layer, a water-absorbing sponge layer and a cotton spun fabric layer, the modal fabric layer serves as an innermost side layer, the upper surface of the modal fabric layer is provided with the water-absorbing sponge layer, the upper surface of the water-absorbing sponge layer is provided with the cotton spun fabric layer, the water-absorbing sponge layer is prepared from polyether polysaccharide, toluene diisocyanate, dichloromethane, organic silicone oil, porous adsorption powder, dimethyl ethanolamine, stannous caprylate, cellulose, super absorbent resin, deionized water, high purity ammonium sulfate, soft long filament and chitin fiber. The air permeability and mechanical property of the environment-friendly chest-protecting athletic undergarment can be improved.

Owner:长沙浩然医疗科技有限公司

Paper diaper for infants

The invention discloses a paper diaper for infants. The paper diaper comprises a liquid permeable topsheet, a backsheet, an absorbent core between the topsheet and the backsheet, and an anti-leakage shield disposed on both sides of the longitudinal center plane of the absorbent article, each of the anti-leakage screens includes a substrate screen portion and a flat portion elastically telescopically contacting the human body in a surface contact manner connected to an upper end of the substrate screen portion, and in a state of use of the absorbent article, the top sheet and the anti-leakage screens on both sides surround a cavity for receiving human excreta; A surface of that liquid-permeable top sheet is provided with a hole through which the liquid-permeable top sheet can pass softly. The negative sheet is a humoral impermeable sheet. The absorbent core comprises the following raw materials: starch-acrylate graft copolymer, rose fiber, PVA, beeswax, ultrafine activated carbon. The invention adopts polyvinyl alcohol, beeswax and ultrafine activated carbon as reinforcing system to improve air permeability, mechanical property and antibacterial property of infant diapers.

Owner:长沙浩然医疗科技有限公司

Rubber nipple silica gel material and preparation method thereof

The invention discloses a rubber nipple silica gel material and a preparation method thereof, which belong to the technical field of a silica gel material. The rubber nipple silica gel material comprises the following raw materials: siloxane dimethicone, hydroxyl silicone oil, dimethoxydimethylsilane, gas-phase white carbon black, a platinum catalyst, polylactic acid fiber, casein, and ca bentonite. The preparation method comprises the steps of mixing, injection moulding, and sulfuration and the like. The method employs polylactic acid fiber, casein and ca bentonite as reinforcement, and the service life and physical properties of the rubber nipple silica gel material are increased.

Owner:长沙浩然医疗科技有限公司

Method for producing polyester microfibre and plolyester microfibre

InactiveCN1393581AIncrease percentageHigh strengthMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterMachinability

The invention relates to a method for producing polyester microfiber and the polyester microfiber therefor. The invention relates to a new method for producing 70 with fineness of 0.1-0.5 denier or microfiber composed by more monofilament, including melting spin polyester, regulating length of hot area to 20 mm or less when melting filature, and regulating distance between diffusing surface of quenching air and melting filature to 2-30 mm. The advantages of the invention is easy to obtain polyester microfiber with good percent of oust, machinability, coloring property and physics performance.

Owner:HYOSUNG CORP

Production technology of silk down feather

The invention discloses a production technology of silk down feather and belongs to the field of clothing materials. The production technology of the silk down feather comprises the following steps: firstly, washing, degreasing, purifying and drying the silk down feather and then treating the silk down feather with pre-treating liquid; secondly, feeding the down feather into a glutaraldehyde aqueous solution, and pouring silk micro powder, casein, bacterial cellulose and polylactic acid fibers after the reaction is finished; carrying out ultrasonic reaction and heat treatment on filtrate; thirdly, feeding a product obtained in the second step into post-treatment liquid, treating, washing and drying to obtain the silk down feather. According to the production technology disclosed by the invention, the air permeability and the softness of the silk down feather are improved by adopting the casein, the bacterial cellulose and the polylactic acid fiber as a reinforcement system.

Owner:长沙浩然医疗科技有限公司

Method and device for heat treatment of steel ingot

ActiveCN112143859BReduce hardnessHigh hardnessFurnace typesHeat treatment furnacesChemical compositionIngot

Owner:山东润金重工科技有限公司

An electrochemical deposition device

ActiveCN109239168BPrecise relative distance controlUniform and smooth surface topographyMaterial electrochemical variablesEngineeringElectroless deposition

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com