Preparation method of homopolymerization polypropylene bidirection drawing film special material

A homopolypropylene, biaxially oriented technology, applied in the field of preparation of homopolypropylene biaxially oriented film special materials, can solve the problems of high film breaking rate, poor product quality, unapproved, etc., and achieve film breaking rate Low, excellent product quality, stable production line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

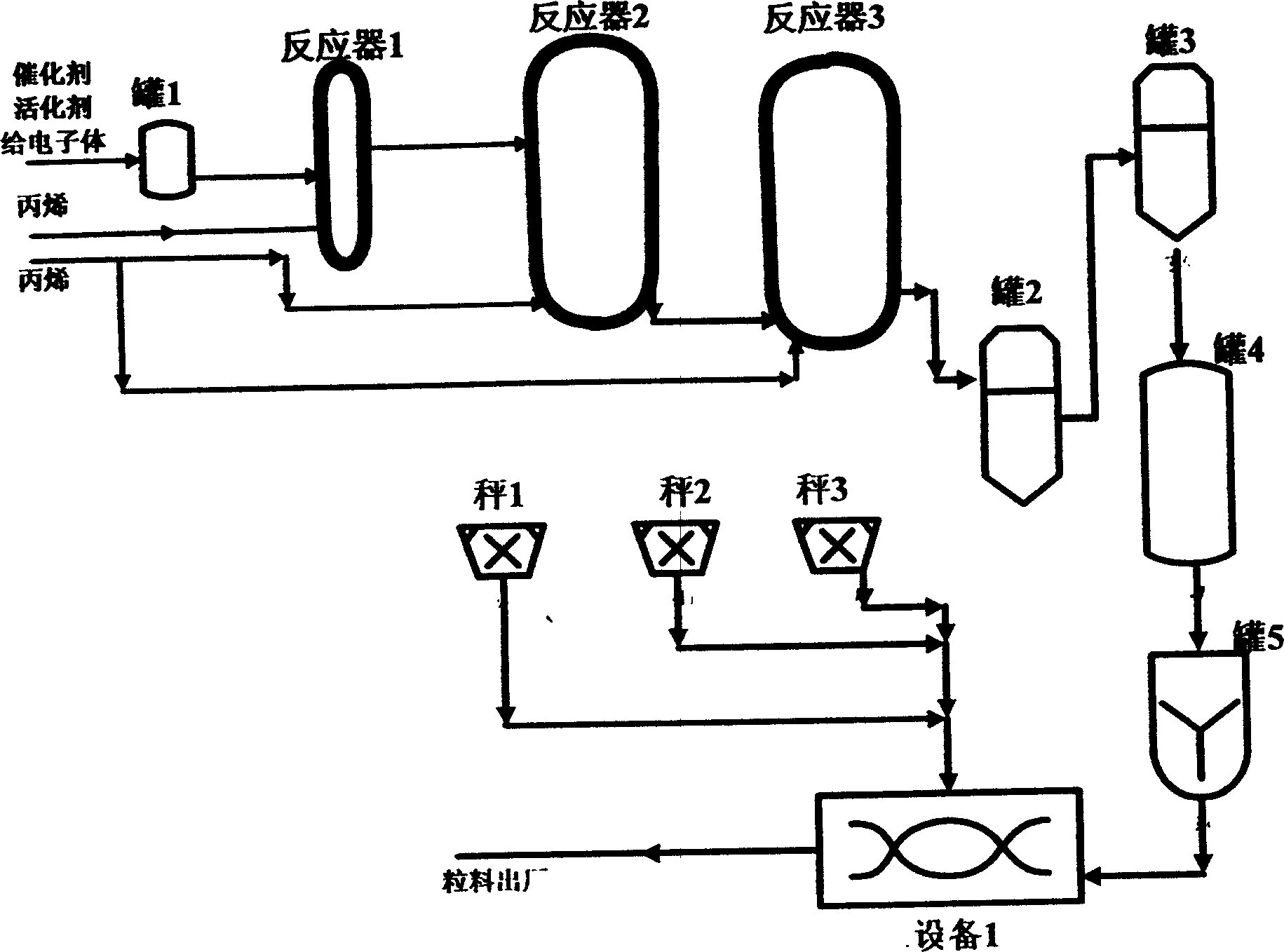

[0029] According to attached figure 1 In the process, the main catalyst, co-catalyst and electron donor (30% concentration) are sent into the tank 1 for full pre-contact. Propylene (reactor 1 propylene charge is set as 1000Kg / h) and catalyzer enters reactor 2 and 3 through reactor 1 (reactor 2 propylene charge is set as 7500Kg / h, reactor 3 propylene charge is set as 6000Kg / h), carry out the polymerization reaction.

[0030] The main catalyst adopts CS-2-B type high-efficiency catalyst, the addition amount is controlled between 0.2-0.23Kg / h, the device load is maintained at 7.5 tons / hour, the triethylaluminum / propylene is 180ppm; the electron donor / propylene is 5ppm , to ensure that the isotacticity of the product is between 94-96%. The amount of hydrogen added to reactor 2 is set to 350ppm, and the amount of hydrogen added to reactor 3 is set to 1350ppm, and the amount of hydrogen added to the reactor is fine-tuned according to the melt index of powder and pellets. The melt...

example 2

[0034] This example is an application example.

[0035] Use the homopolypropylene material produced by the present invention to sample in units such as Dezhou Qunli Plastic Co., Ltd., Qingdao Qingxin Plastic Co., Ltd., etc. Through the test, the manufacturers agree that the production line of our polypropylene raw material is stable during the film drawing process, the film breaking rate is low, the film thickness is evenly distributed, and the physical properties and appearance of the finished product are in line with the indicators specified in the national standard (see Table 6 and Table 1 for test data. 7-9), conducive to high output.

[0036] temperature, ℃

[0037] Element

[0038] Test based on

[0039]

[0040] Indicator name

[0041] Indicator name

[0042]

[0043] User units

[0044] User units

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com