Electrochemical deposition device

A deposition device and electrochemical technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of slow deposition rate, etc., and achieve the effects of uniform surface morphology, extended service life, uniform structure and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

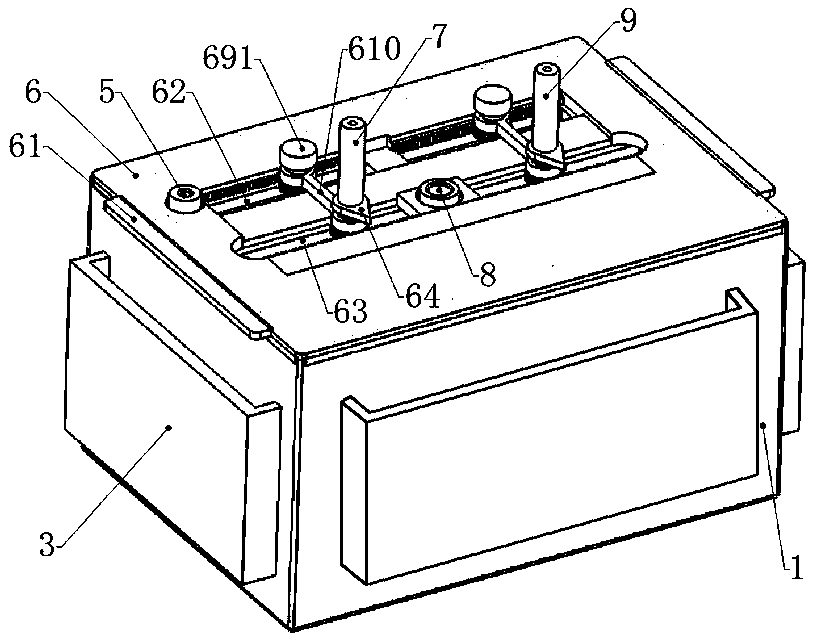

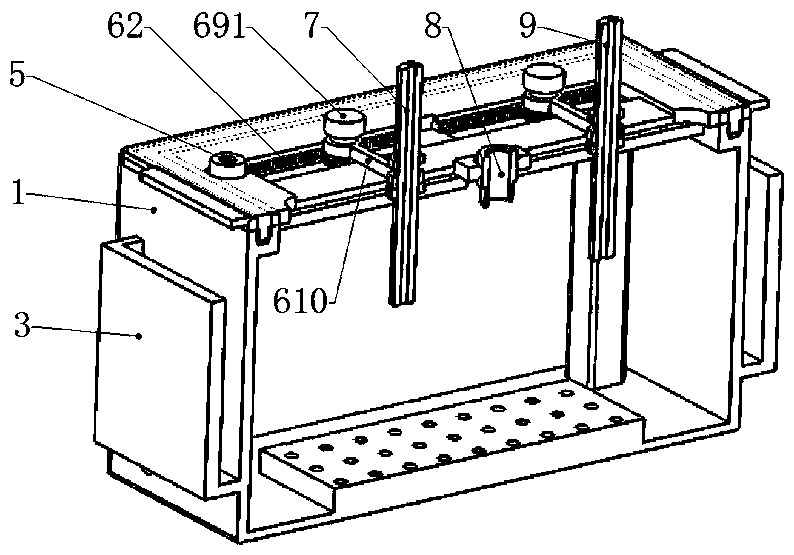

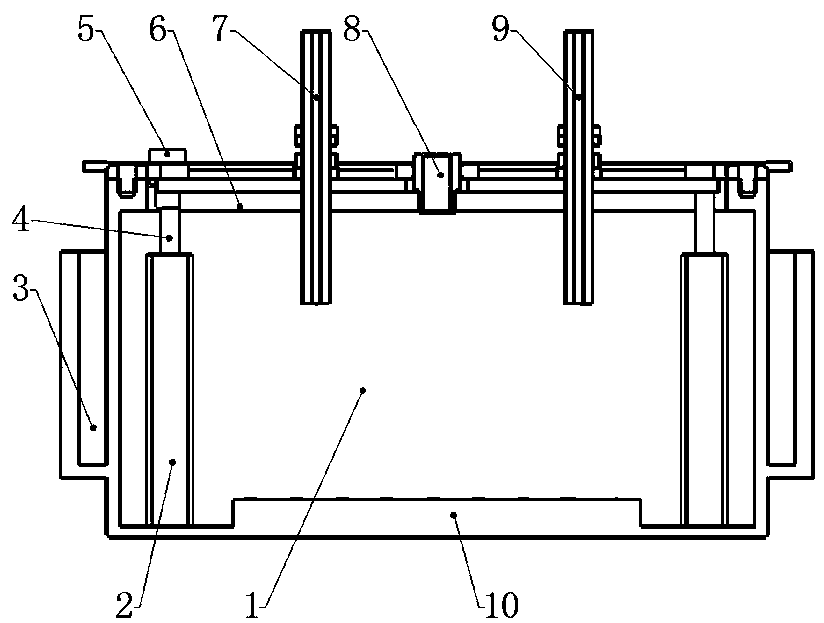

[0027] like Figure 1 to Figure 8 A kind of electrochemical deposition device shown, it comprises box body 1, covers the cover body 6 that is closed on box body 1 top and is used for the working electrode 7 of electrochemical deposition process, reference electrode 8 and counter electrode 9, wherein:

[0028] The outer side wall of the box body 1 is provided with a slot 3, and a permanent magnet block is detachably installed in the slot 3; The bottom of the side wall opposite to the liquid outlet and the liquid discharge port is also provided with an air guide tube under the slot 3; an air guide plate 10 is installed in the middle of the bottom surface of the box body 1, and the air guide plate 10 is a hollow shell body, the air guide pipe runs through the side wall of the box body and communicates with the hollow cavity inside the air guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com