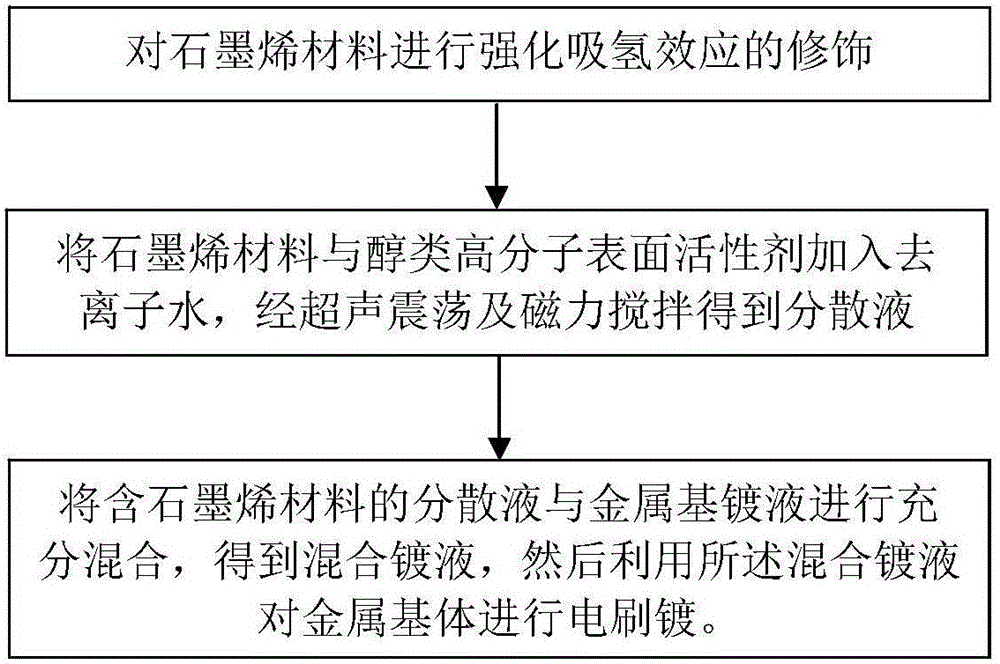

Graphene-containing metal-matrix composite plating solution capable of improving brushing electroplating coating quality by using hydrogen absorption effect

A metal-based composite and graphene technology, applied in coatings, electrolytic coatings, etc., to achieve the effects of reducing coating pores, improving quality, and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

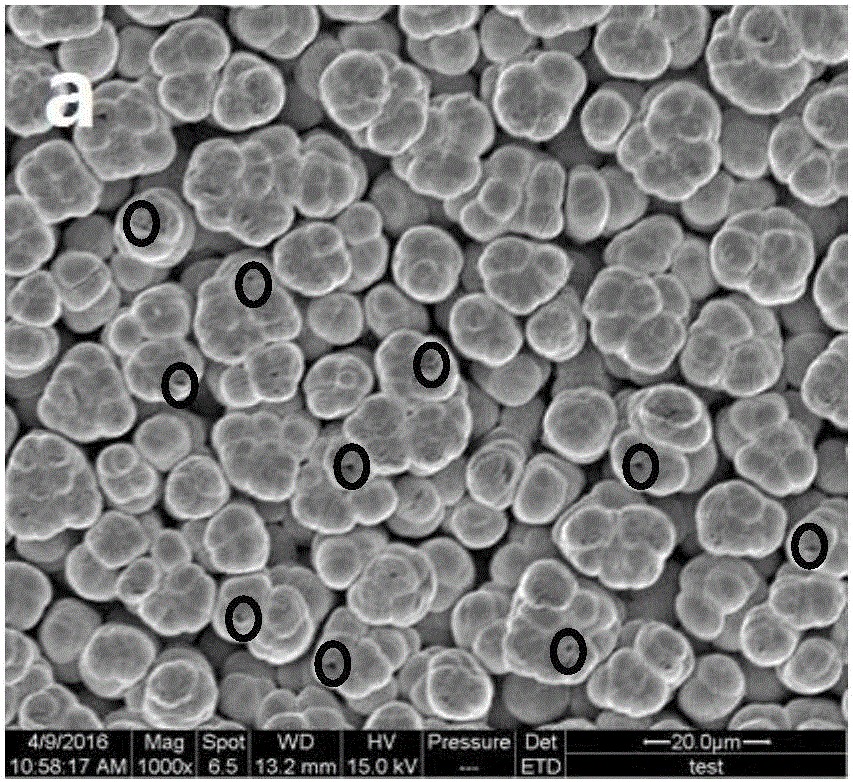

[0032] Embodiment 1: Brush plating technology prepares the nickel-based coating that contains graphene material

[0033] Graphene is heat-treated and purified at 400°C; 300mg of graphene is placed in a petri dish, placed in a plasma chamber, and reacted for 30min under the conditions of a chamber pressure of 0.1mbar and a power supply of 130W to prepare N-containing graphene. , and then compare it with quantitative PdCl 2 The reaction is prepared to obtain graphene containing Pd and N; then the modified graphene is mixed at 2-5g / L, the dispersant is at 200-500mg / L and deionized water, and then at room temperature at a frequency of 60KHz Ultrasonic vibration for 30 minutes, followed by magnetic stirring for 60 minutes to obtain a uniformly dispersed dispersion, and the dispersion was mixed with a conventional rapid nickel brush plating solution at a ratio of 1:1 to obtain a mixed plating solution in which graphene was uniformly dispersed. Finally, the target coating is brush-p...

Embodiment 2

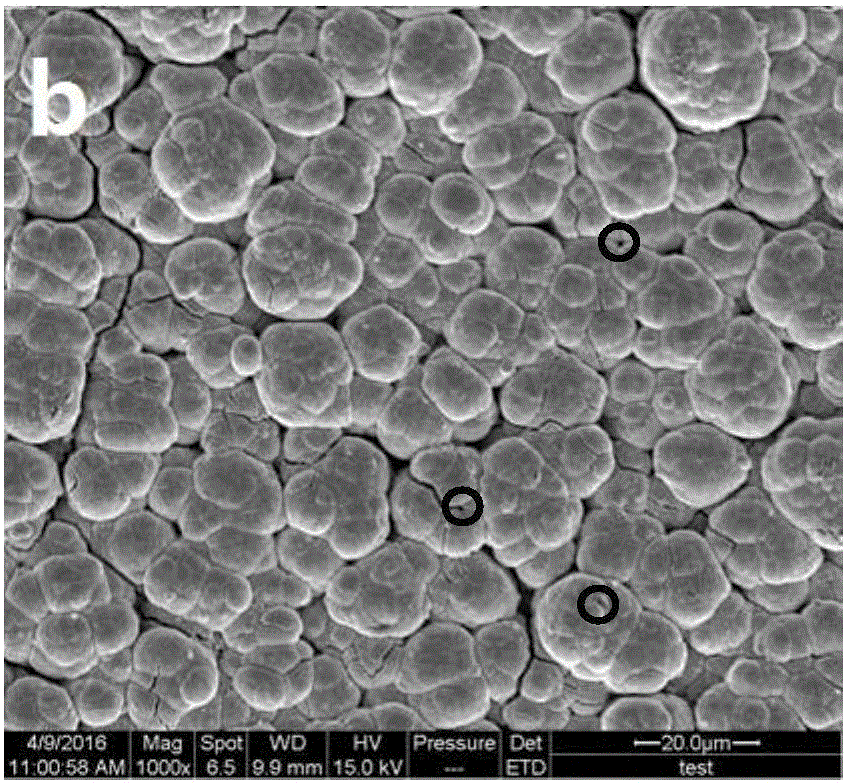

[0035] Embodiment 2: Brush plating technology prepares the iron-based coating that contains graphene material

[0036] Graphene samples were heat-treated and purified at 400°C; 300mg of graphene was placed in a petri dish, placed in a plasma chamber, and reacted for 30min under the conditions of a chamber pressure of 0.1mbar and a power supply of 130W to prepare N-containing graphite alkenes, which are then combined with quantitative PdCl 2The reaction is carried out to prepare graphene containing Pd and N; then the modified graphene is mixed at 5-10g / L, the dispersant is at 500-800mg / L and deionized water, and then at room temperature at a frequency of 60KHz Ultrasonic vibration for 50 minutes, followed by magnetic stirring for 80 minutes to obtain a uniformly dispersed dispersion, and the dispersion was mixed with a conventional iron-based solution at a ratio of 1:1 to obtain a mixed plating solution in which graphene was uniformly dispersed. Finally, the target composite c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com