Synthesis method and application of patterned silicon dioxide nanostructure

A silicon dioxide and nanostructure technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of limiting the complexity of the silicon dioxide nanostructure, limiting the accuracy of the silicon dioxide nanostructure, etc., to achieve accurate Positioned growth, broad application prospects, selective and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

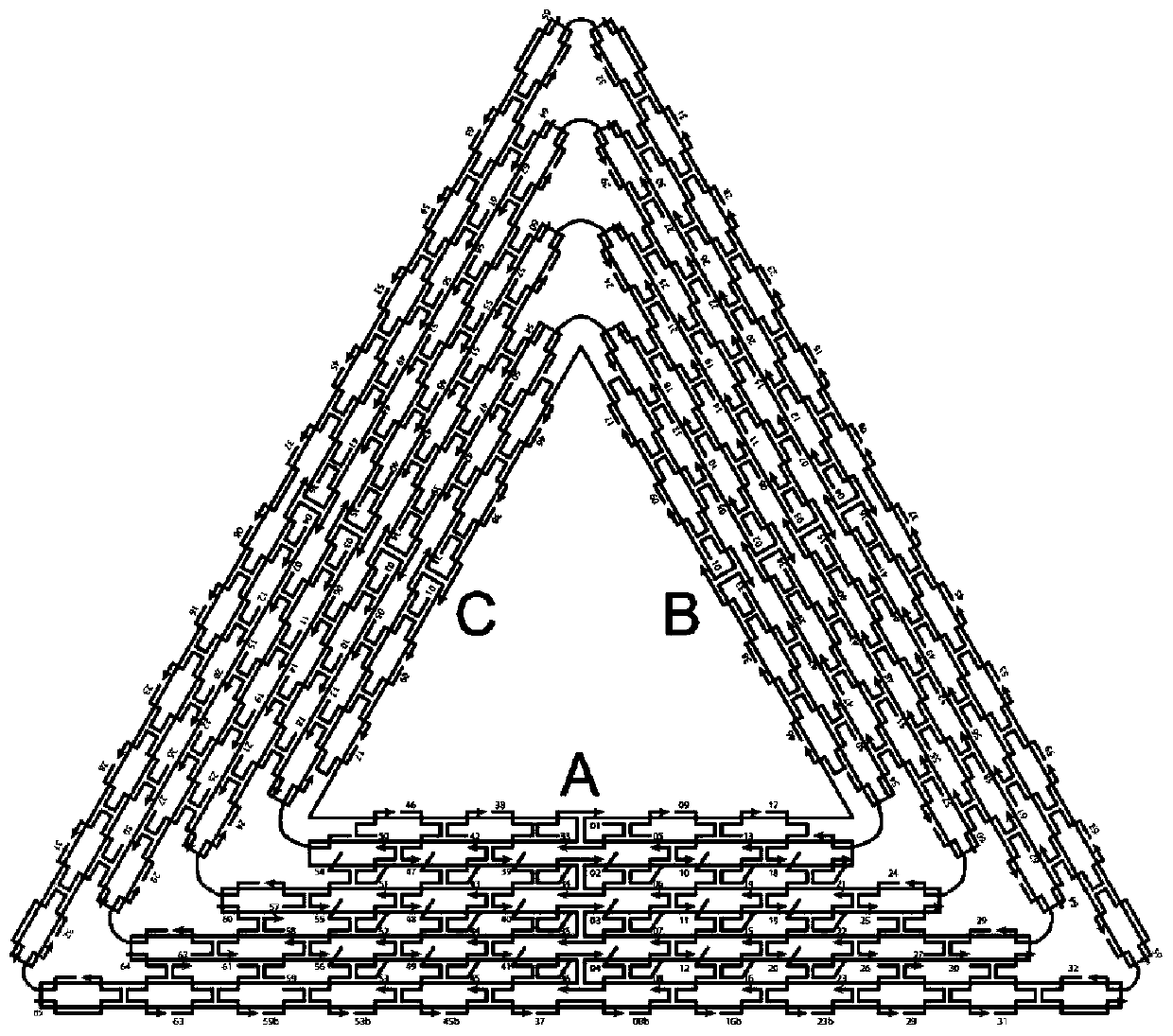

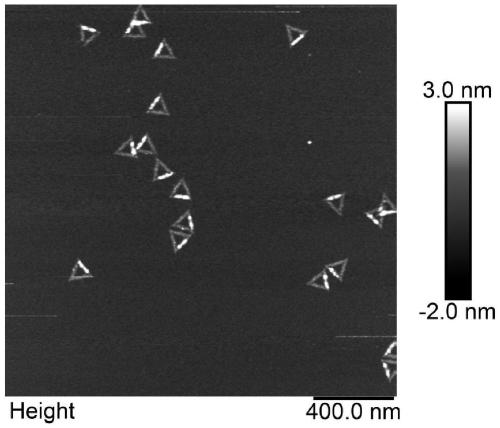

[0067] (1) Assembly of triangular DNA origami structures with extended strands

[0068] Mix DNA template strand, folding helper strand, and folding helper strand with extension strand at a molar ratio of 1:10:10 in 1×TAE / Mg 2+ Anneal in buffer (pH=8.0), the annealing condition is from 95°C to 25°C, every 5°C is a gradient, and each gradient stays for 5min;

[0069] After annealing is complete, add the DNA origami structure to a 100kDa spin column and add 1×TAE / Mg 2+ Buffer (pH=8.0), centrifuged to remove excess short-chain DNA;

[0070] (2) Hybridization of the complementary strand with the extended strand of the triangular DNA origami structure

[0071] The purified DNA origami structure was mixed with the complementary strand at a molar ratio of 1:360, and mixed in 1×TAE / Mg 2+ Annealing was carried out under buffer (pH=8.0) condition, the annealing condition was from 45°C to 25°C, every 5°C was a gradient, each gradient was kept for 5min, and 6 cycles were performed;

[...

Embodiment 2

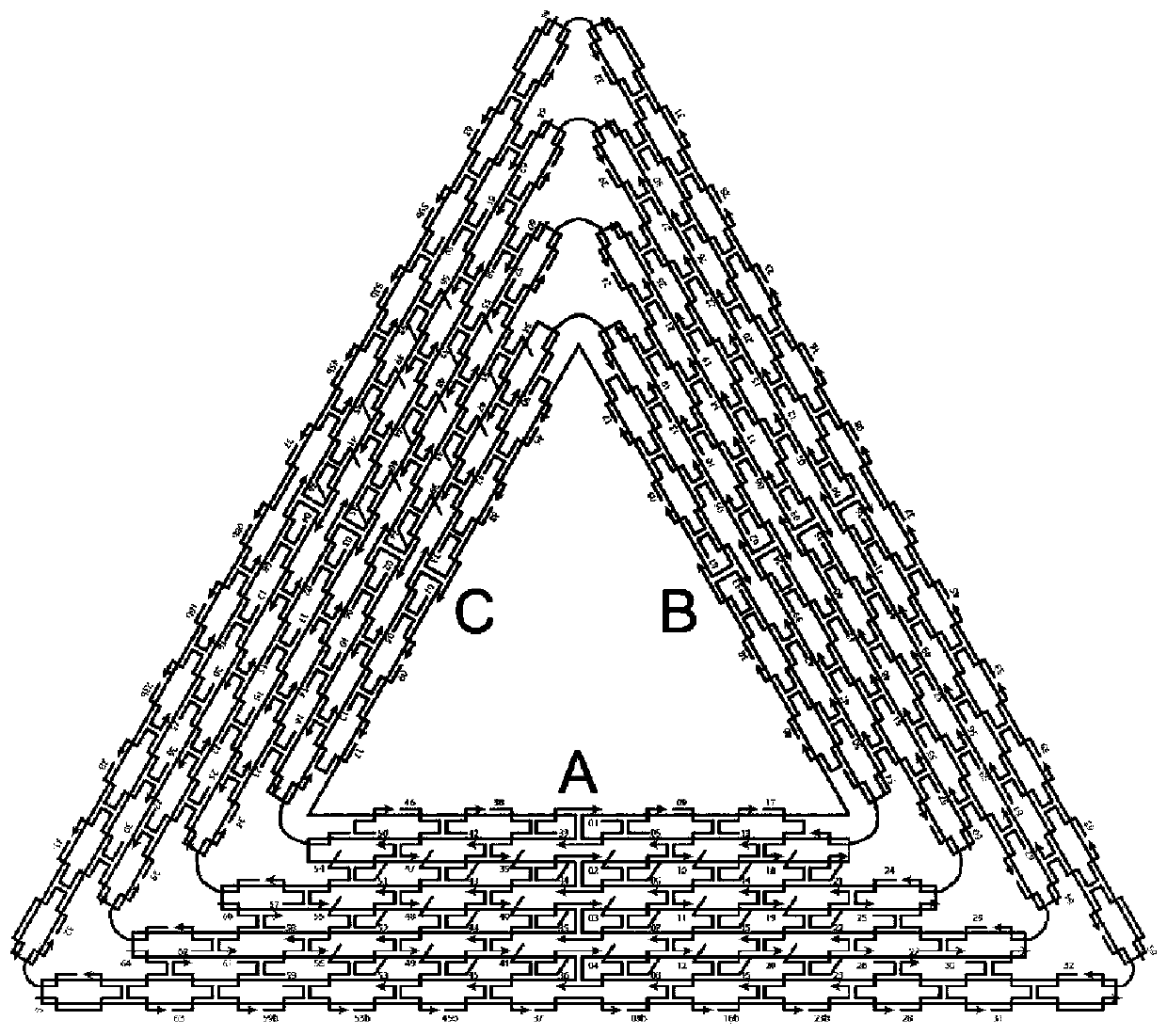

[0077] (1) Assembly of triangular DNA origami structures with extended strands

[0078]The DNA template strand, the auxiliary folding strand and the auxiliary folding strand with the extension strand were mixed in a molar ratio of 1:10:10 in 1×TAE / Mg 2+ Annealing in buffer (pH=8.0), the annealing conditions are from 95°C to 25°C, each 5°C is a gradient, and each gradient stays for 5 minutes;

[0079] After annealing, the DNA origami structure was added to a 100kDa spin column with 1×TAE / Mg 2+ Buffer (pH=8.0), centrifuged to remove excess short-stranded DNA;

[0080] (2) Hybridization of complementary strands and extended strands of triangular DNA origami structures

[0081] The purified DNA origami structure was mixed with complementary strands at a molar ratio of 1:540 and mixed in 1×TAE / Mg 2+ Annealing was carried out under the condition of buffer solution (pH=8.0), the annealing conditions were from 45°C to 25°C, each 5°C was a gradient, and each gradient was held for 5 ...

Embodiment 3

[0087] (1) Assembly of a triangular DNA origami structure with extended strands

[0088] The DNA template strand, the auxiliary folding strand and the auxiliary folding strand with the extension strand were mixed in a molar ratio of 1:10:10 in 1×TAE / Mg 2+ Annealing in buffer (pH=8.0), the annealing conditions are from 95°C to 25°C, each 5°C is a gradient, and each gradient stays for 5 minutes;

[0089] After annealing, the DNA origami structure was added to a 100kDa spin column with 1×TAE / Mg 2+ Buffer (pH=8.0), centrifuged to remove excess short-stranded DNA;

[0090] (2) Hybridization of complementary strands and extended strands of triangular DNA origami structures

[0091] The purified DNA origami structure was mixed with complementary strands at a molar ratio of 1:720 and mixed in 1×TAE / Mg 2+ Annealing was carried out under the condition of buffer solution (pH=8.0), the annealing conditions were from 45°C to 25°C, each 5°C was a gradient, and each gradient was held for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com